I-ASTM A519amashubhu azokwenziwa ngenqubo engenamthungo futhi azoqedwa ngokushisa noma abandayo njengoba kucacisiwe.

Kumashubhu ayindilinga anobubanzi obungaphandle obungeqi ku-12 3/4 in (325 mm).

Amashubhu ensimbi nawo angenziwa ngesikwele, unxande, noma ezinye izimo njengoba kudingekile.

I-ASTM A519 ingahlukaniswa ngokwezinto zensimbi:Insimbi Yekhabhonikanye ne-Alloy Steel.

Insimbi ye-carbonihlukaniswe yabaIkhabhoni ephansi MT(I-Mechanical Tubing),Insimbi Ephakeme YekhabhonifuthiI-Desulfurized noma i-Rephosphorized, noma kokubiliInsimbi Yekhabhoni, ukuze ivumelane nezidingo zezimboni ezahlukene kanye nezimo zohlelo lokusebenza.

Uma lingekho ibanga elishiwo, abakhiqizi banenketho yokunikelaMT1015 noma MTX1020amabanga.

Ububanzi bangaphandle: 13.7 - 325 mm;

Ubukhulu bodonga: 2-100mm.

Insimbi ingenziwa nganoma iyiphi inqubo.

Insimbi ingaphonswa ngama-ingots noma i-strand cast.

Amashubhu azokwenziwa ngu-ainqubo Seamlessfuthi izoqedwa ngokushisa noma ngokubanda, njengoba kucacisiwe.

Amashubhu ensimbi angenamthungo angamashubhu angenawo ama-seam ashiselwe kuwo wonke.

Amashubhu aphelile abandayozinconywa ngezidingo eziphezulu zokunemba kwe-dimensional kanye nekhwalithi ephezulu.

Okukhathaza kakhulu ukonga izindleko kanye nokuqina kwempahla,ipayipi lensimbi eliphelile elishisayokungaba ukukhetha okufaneleka kakhudlwana.

Okulandelayo inqubo yokukhiqiza ipayipi lensimbi elingenamthungo eligoqelwe ngokushisayo.

Umkhiqizi wensimbi uzohlaziya ukushisa kwensimbi ngayinye ukuze anqume iphesenti lezinto ezishiwo.

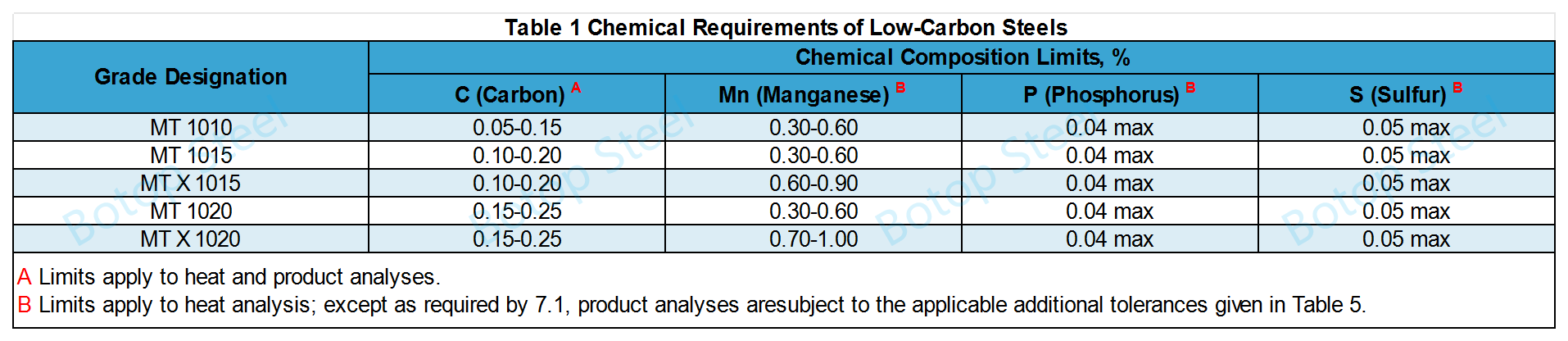

Ithebula 1 Izidingo Zekhemikhali Zezinsimbi Zekhabhoni Ephansi

Insimbi ethambile iyinsimbi enekhabhoni evamise ukungeqi ku-0.25%.Ngenxa yokuqukethwe kwayo kwekhabhoni ephansi, le nsimbi inokudubeka okungcono nokungabi lula futhi ayiqinile futhi iqinile uma iqhathaniswa nensimbi enekhabhoni ephezulu.

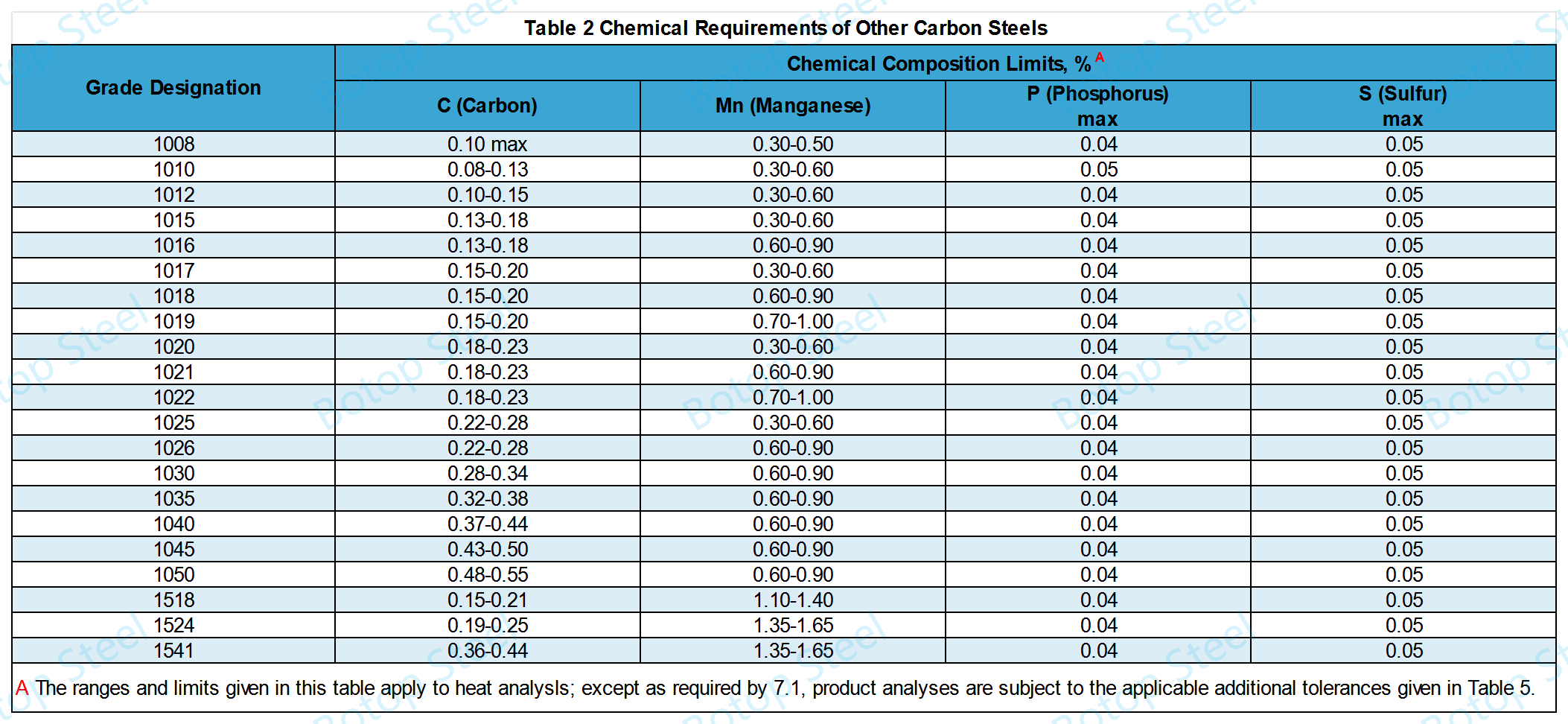

Ithebula 2 Izidingo Zamakhemikhali Zezinye Izinsimbi Zekhabhoni

Izinsimbi ze-carbon ezimaphakathi: Iqukethe phakathi kuka-0.25% no-0.60% wekhabhoni, ihlinzeka ngobulukhuni obuphakeme namandla futhi idinga ukwelashwa okushisa ukuze kuthuthukiswe izakhiwo.

High carbon steel: Iqukethe phakathi kuka-0.60% no-1.0% noma ngaphezulu ikhabhoni, futhi inikeza ubulukhuni obuphezulu kakhulu namandla, kodwa ukuqina okuphansi.

Ithebula 3 Izidingo Zamakhemikhali Ezinsimbi Zengxubevange

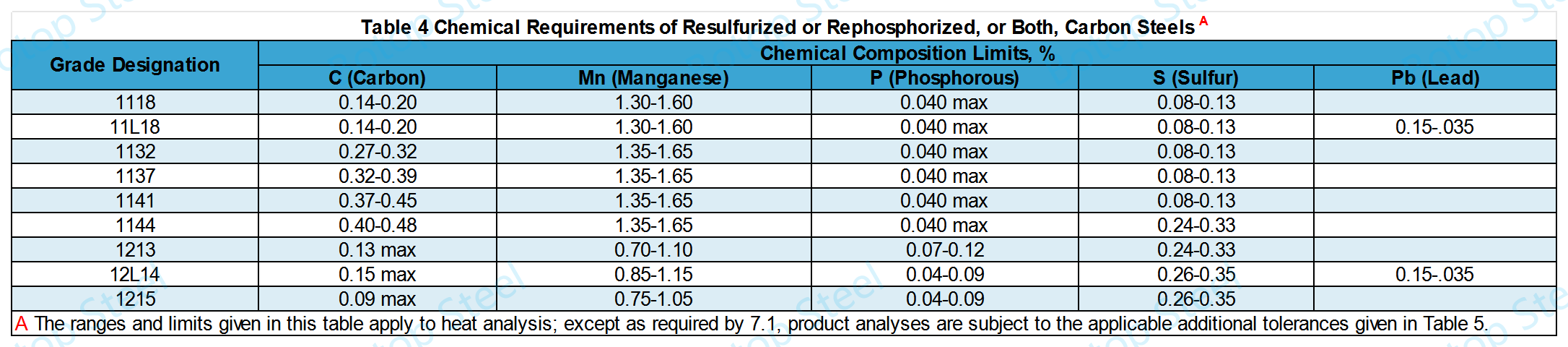

Ithebula 4 Izidingo Zekhemikhali Zokuphinda zenziwe kabusha noma ezenziwe kabusha, noma Zombili, Izinsimbi Zekhabhoni

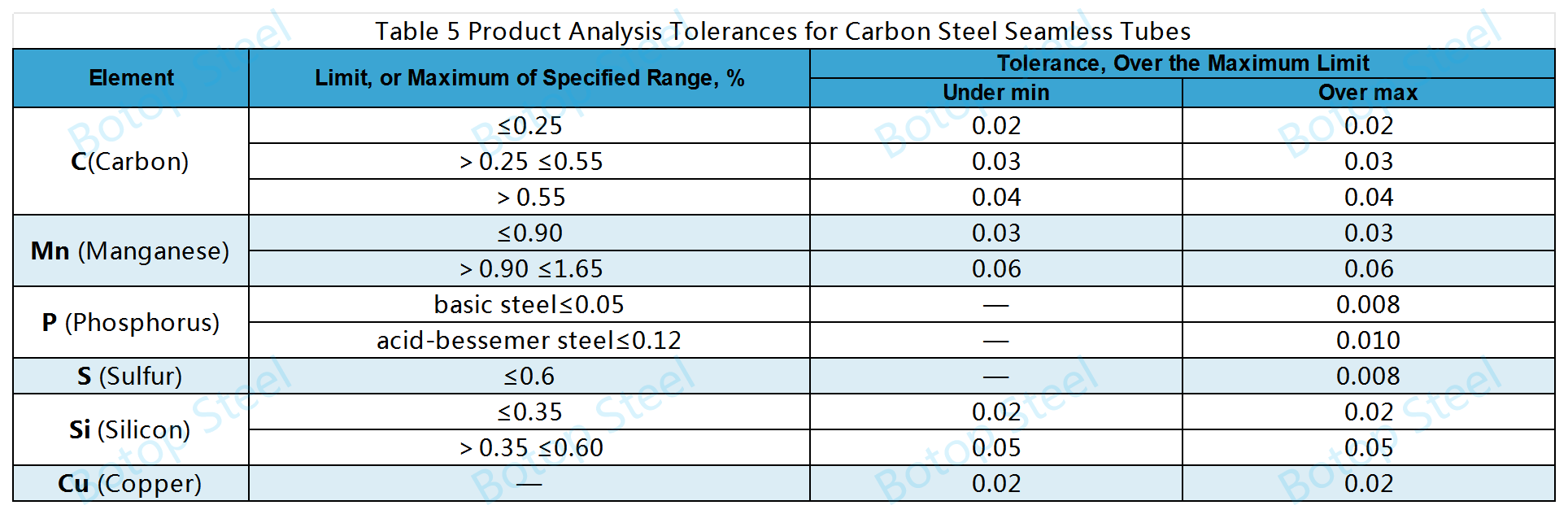

ITHEBULA 5 Ukuhlaziywa Komkhiqizo Ukubekezelela Ngaphezulu Noma Ngaphansi Kwebanga Elicacisiwe noma Umkhawulo

Umkhiqizi kufanele acelwe kuphela ukuthi ahlaziye umkhiqizo uma udingwa nge-oda.

I-ASTM A519 ihlanganisa izinto zokuhlola ezilandelayo:

Ukuhlolwa kokuqina;Izivivinyo Zokushuba;Ukuhlolwa Okungonakali;Ukuhlolwa kwe-Flaring;Ukuhlanzeka Kwensimbi Nokuqina.

| Ukuqokwa Kwebanga | Uhlobo Lwepayipi | Isimo | Amandla Asetshenziswayo | Isivuno Amandla | Ubude ku-2in.[50mm],% | Rockwell, Ubulukhuni B Isikali | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Insimbi Yekhabhoni | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Insimbi Yekhabhoni | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Insimbi Yekhabhoni | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Insimbi Yekhabhoni | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Insimbi Yekhabhoni | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | I-Resulfurized noma i-Rephosphorized, noma kokubili, Izinsimbi Zekhabhoni | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | I-Resulfurized noma i-Rephosphorized, noma kokubili, Izinsimbi Zekhabhoni | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | I-alloy Steels | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | I-alloy Steels | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

I-HR-Hot Rolled, i-CW-Cold Worked, i-SR-Stress Relieved, i-A-Annealed ne-N-Normalized.

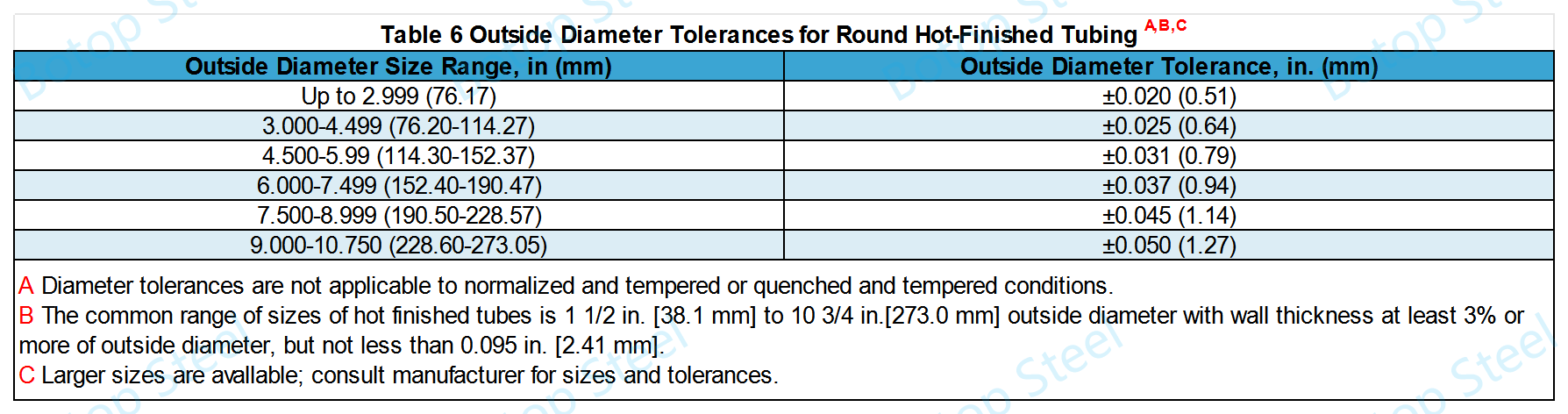

Ukubekezelelana Kwangaphandle Kobubanzi

Ithebula 6 Ukubekezelela Kobubanzi Bangaphandleye-Round Hot-Finished Tubing

Ithebula 12 Ukubekezelela Kobubanzi Bangaphandle kweI-Ground Seamless Tubing

| Usayizi Ongaphandle Kobubanzi, phakathi.[mm] | Ukubekezelelwa Kwangaphandle Kobubanzi Kosayizi Nobude Okunikeziwe, ngaphakathi. [mm] | |||

| Kuphelile | Ngaphansi | Kuphelile | Ngaphansi | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] lapho L≤16ft[4.9m] | 0.000 | 0.004 [0.10] lapho L>16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] lapho L≤16ft[4.9m] | 0.000 | 0.006 [0.15] lapho L>16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] lapho L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lapho L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] lapho L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lapho L≤16ft[4.9m] | 0.000 |

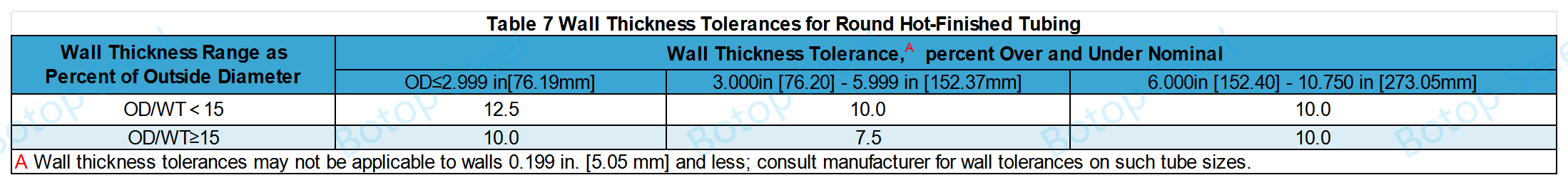

Ukubekezelela Ukuqina Kwezindonga

Ithebula 7 Ukubekezelela Ukuqina Kwezindongaye-Round Hot-Finished Tubing

Ithebula 10 Ukubekezelela Ukuqina Kwezindongaye-Round Cold-Working Tubing

| Ukuqina Kwezindonga Kuhluka njenge Iphesenti Lobubanzi Bangaphandle | Ukubekezelela Ukuqina Kodonga Ngaphezulu Nangaphansi Kwegama,% | |

| OD≤1.499in[38.07mm] | OD≥1.500 kokuthi [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

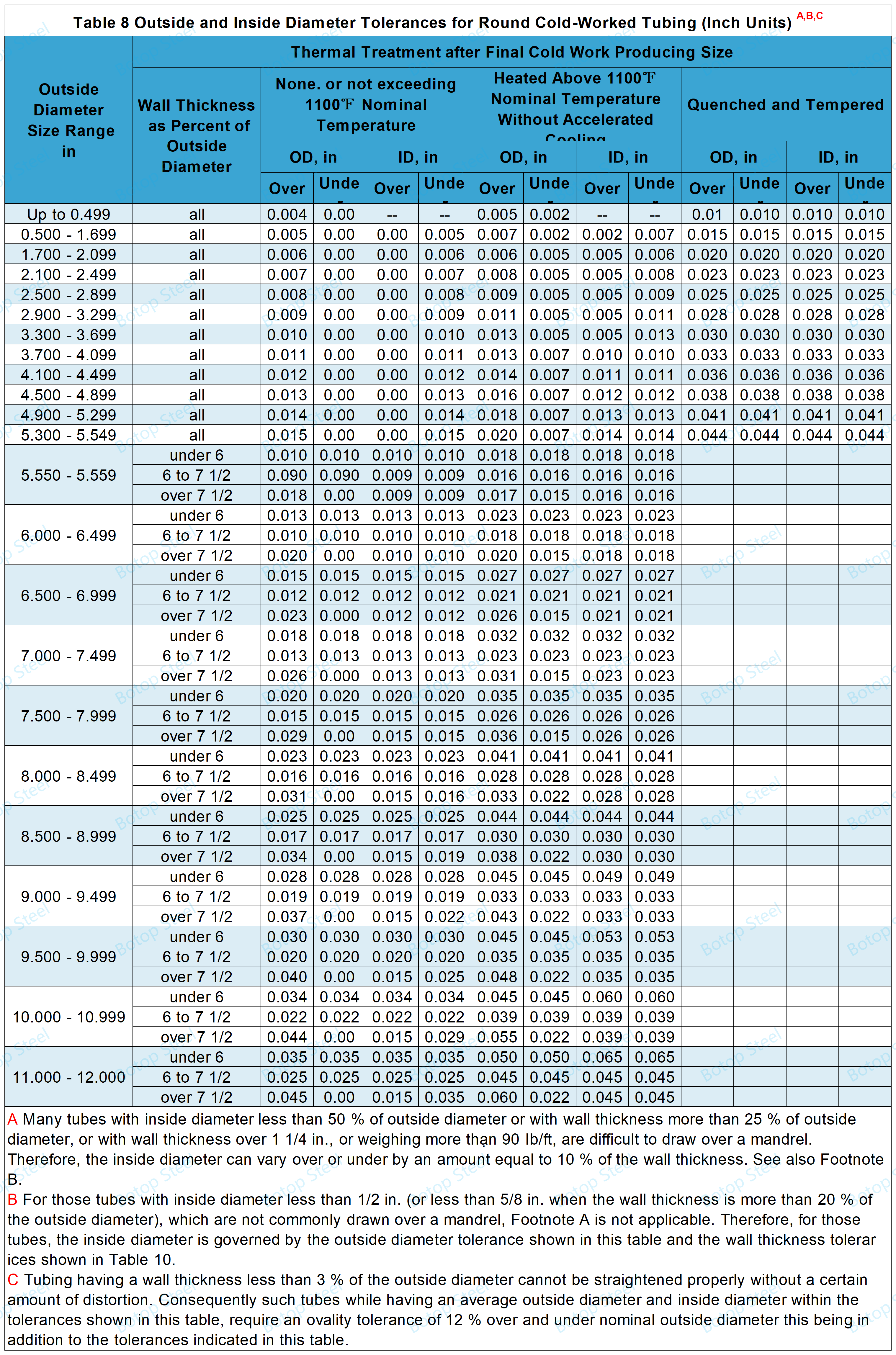

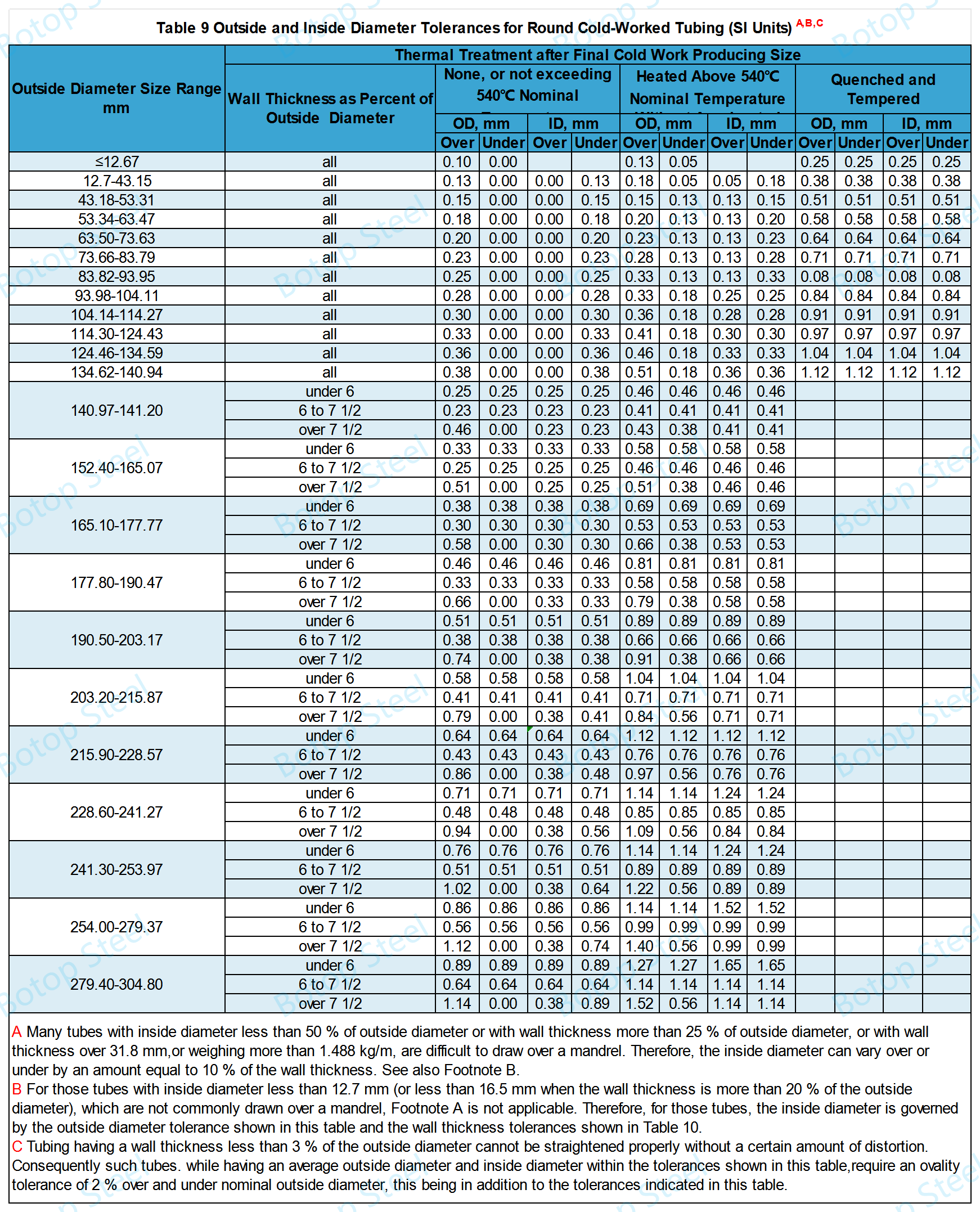

Ukubekezelelana Kwangaphandle Nangaphakathi Kwe-Diameter

Ithebula 8 Ukubekezelela Ngaphandle Nangaphakathi Kwe-Diameter forIshubhu Eyindilinga Esebenza Ngokubandayo (Amayunithi Amayintshi)

Ithebula 9 Ukubekezelela Ngaphandle Nangaphakathi Kwe-Diameterye-Round Cold-Worked Tubing (Amayunithi e-SI)

Ukubekezelela Ububanzi Bangaphandle Nokuqina Kodonga

Ithebula 11 Ububanzi Bangaphandle kanye Nokubekezelelwa Kwezindongaye-Rough-Turned Steel Tubing engenamthungo

| Usayizi Ocacisiwe Wangaphandle Ububanzi, phakathi. [mm] | Ngaphandle Ububanzi, phakathi. [mm] | Ukuqina Kwezindonga, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Ukubekezelela Ubude

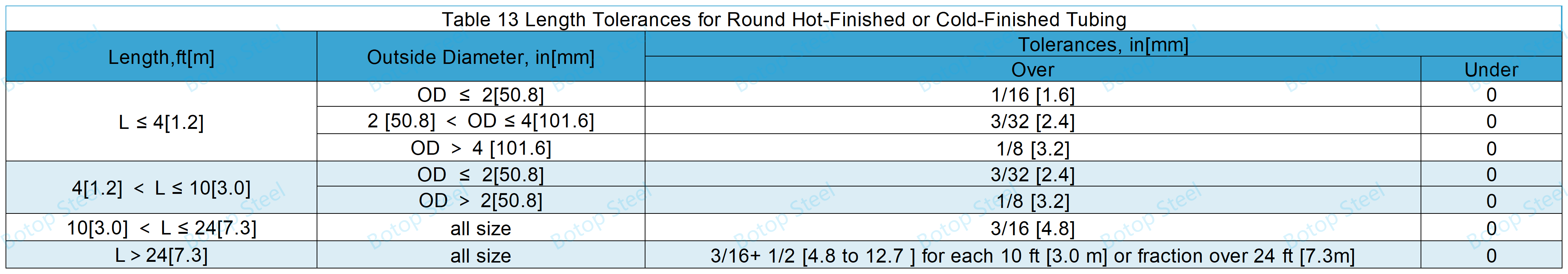

Ithebula 13 Ukubekezelela UbudeyeRound Hot-Finished noma Cold-Finished Tubing

Ukubekezelelana Okuqondile

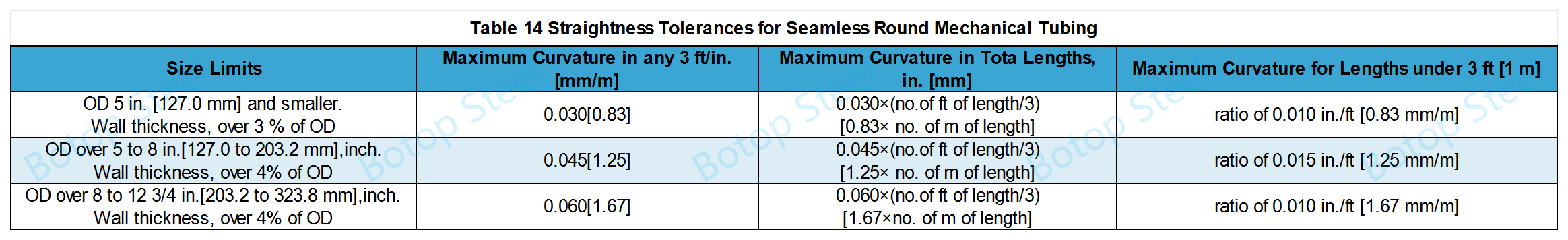

Ithebula 14 Ukubekezelelana Kokuqondileye-Seamless Round Mechanical Tubing

Ipayipi kufanele limbozwe ngefilimu yamafutha ngaphambi kokubunjwa ukuvimbela ukugqwala.

Amafutha okuvimbela ukugqwala angasetshenziswa nasezindaweni zangaphakathi nezangaphandle zepayipi.

Indiza kanye ne-aerospace: ukukhiqizwa kwezingxenye ezibalulekile njengezinjini zezindiza nezinhlelo zokusekela imikhumbi-mkhathi.

Imboni yamandla: imishini yokumba kanye nokukhiqizwa kwamapayipi amabhoyili anengcindezi ephezulu.

Ukukhiqizwa kwemishini nemishini: Izingxenye ezibalulekile ezakha uhla olubanzi lwemishini yezimboni nemishini.

Imishini yezemidlalo: Ukwenziwa kwamafreyimu amabhayisikili asebenza kahle kakhulu nezinye izinsiza zemidlalo.

Ukwakha nokwakha: Izakhi zokusekela zezakhiwo zezakhiwo nezinhlelo zokusebenza ezindaweni ezinengcindezi ephezulu.

1. I-EN 10297-1: E355, 25CrMo4, 42CrMo4, njll. Lezi zinto zingathathwa njengezilingana nezinye izinsimbi ze-carbon ne-alloy ku-ASTM A519.

2. I-DIN 1629: I-St52, i-St37.4, njll. Ivamise ukusetshenziselwa izinjongo zemishini nesakhiwo, lezi zifana namabanga ensimbi athambile ku-ASTM A519.

3. I-JIS G3445: I-STKM13A, i-STKM13B, njll. Lawa amashubhu e-carbon steel asetshenziselwa izinjongo zemishini nezakhiwo.

4. BS 6323:CFS 3, CFS 4, CFS 8, njll. Lawa amashubhu ensimbi angenamthungo futhi ashiselwe ezinjongo zezimoto, zemishini, nezobunjiniyela obujwayelekile.

5. GB/T 8162:20 #, 45 #, 40Cr, 20CrMo, njll. Amashubhu ensimbi angenamthungo namapayipi esakhiwo esijwayelekile kanye nesakhiwo somshini.

6. I-ISO 683-17:100Cr6, njll., evame ukusetshenziswa ekukhiqizeni okuthwele, ingathola futhi isicelo kubunjiniyela bemishini futhi inezinhlelo zokusebenza ezifanayo kwezinye izinsimbi ze-ASTM A519.

Lapho ukhetha into efanayo, kubalulekile ukubhekisela ekubunjweni kwamakhemikhali okuningiliziwe kanye nokucaciswa kwempahla yemishini ukuze kuqinisekiswe ukuthi okokusebenza okukhethiwe kuzohlangabezana nezidingo zokusebenza zohlelo oluthile.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.