I-ASTM A53 ERWipayipi lensimbiUhlobo Eekucacisweni kwe-A53, ekhiqizwa inqubo yokushisela ukumelana, futhi itholakala kuwo womabili amabanga eBanga A neBanga B.

Ifanele kakhulu ukusetshenziswa kwemishini nengcindezi futhi ivame ukusetshenziswa njengenhloso evamile yokudlulisa isitimu, amanzi, igesi, nomoya.

Izinzuzo ERW steel pipe, ezifanaintengo ephansifuthiukukhiqiza okuphezulu, yenze ibe yinto yokuzikhethela ezinhlelweni eziningi zezimboni.

Insimbi ye-Botopingumkhiqizi wepayipi lensimbi elishiselwe phezulu elishiselwe kanye nomphakeli ovela eShayina, futhi iphinde ibe nesitoko sepayipi yensimbi engenamthungo, ikunikeza izixazululo eziningi zamapayipi ensimbi!

I-inventory yethu igcwele kahle futhi siyakwazi ukuhlangabezana nesidingo esisheshayo samakhasimende ethu sezinhlobonhlobo zamasayizi nenani.

I-ASTM A53/A53M ihlanganisa izinhlobo namabanga alandelayo:

Uhlobo E: I-Electric-resistance-welded, amabanga A no-B.

Uhlobo S: Ayinamthungo, amabanga A no-B.

Uhlobo F: I-Furnace-butt-welded, ashiselwe amabanga A no-B aqhubekayo.

Uhlobo EfuthiUhlobo Syizinhlobo ezimbili zamapayipi asetshenziswa kabanzi.Ngokungqubuzanayo,Uhlobo Fngokuvamile isetshenziselwa amashubhu amancane ububanzi.Ngenxa yokuthuthuka kwezobuchwepheshe bokushisela, le ndlela yokukhiqiza isetshenziswa kancane.

Ububanzi Okuzisholo: DN 6 - 650 [NPS 1/8 - 26];

Ububanzi bangaphandle: 10.3 - 660 mm [0.405 - 26 in.];

Ubukhulu bodonga namashadi esisindo sepayipi lensimbi:

Amashubhu ayisicaba angabukwa kuThebula X2.2;

Amashubhu anentambo nahlanganisiwe angabukwa kuThebula X2.3.

I-ASTM A53 iphinde ivumele ukufakwa kwepayipi ngobunye ubukhulu inqobo nje uma ipayipi lihlangabezana nazo zonke ezinye izidingo zalokhu kucaciswa.

ERWisetshenziswa kabanzi ukwenza amapayipi ensimbi ayindilinga, ayizikwele, nangamanxande kanye namapayipi ensimbi ayingxubevange ephansi.

Lokhu okulandelayo yinqubo yokukhiqiza yokukhiqizaround ERW ipayipi lensimbi:

a) Ukulungiselela impahla: Impahla yokuqala ivamise ukuba amakhoyili ensimbi agoqelwe ashisayo.Lawa makhoyili aqala enziwe isicaba futhi agundwe abe ububanzi obudingekayo.

b) Ukwakha: Kancane kancane, ngokusebenzisa uchungechunge lwemiqulu, i-strip ikhiwa ibe isakhiwo se-tubular esiyindilinga evulekile.Phakathi nale nqubo, imiphetho ye-strip isondelana kancane kancane kulungiselelwa ukushisela.

c) Ukushisela: Ngemva kokwenza isakhiwo se-tubular, emaphethelweni omugqa wensimbi ashiswa ukumelana nogesi endaweni ye-welding.I-high-frequency current idlula ezintweni, futhi ukushisa okukhiqizwa ukumelana kusetshenziselwa ukushisa imiphetho kuze kube yilapho incibilika, bese ihlanganiswa ndawonye ngokucindezela.

d) Ukukhipha imali: Ngemuva kokushisela, ama-weld burrs (insimbi eyeqile ekushiseni) akhishwa ngaphakathi nangaphandle kwepayipi ukuze kuqinisekiswe indawo ebushelelezi ngaphakathi kwepayipi.

e) Ukusetha usayizi nobude: Ngemva kokuphothulwa kwe-welding kanye nokukhishwa kwe-deburring, amashubhu adluliswa ngomshini wokulinganisa ukuze kulungiswe i-dimensional ukuze kuqinisekiswe ukuthi ahlangabezana nezidingo zobubanzi obuqondile kanye nendilinga.Amashubhu abe esesikwa abe ngobude obunqunywe kusengaphambili.

f) Ukuhlolwa nokuhlolwa: Ipayipi lensimbi lizohlolwa futhi lihlolwe ngokuqinile, okuhlanganisa ukuhlolwa kwe-ultrasonic, ukuhlolwa kwe-hydrostatic, njll., ukuze kuqinisekiswe ukuthi ikhwalithi yepayipi yensimbi ihlangabezana nezindinganiso kanye nokucaciswa.

g) Ukwelashwa kwendawo: Okokugcina, ipayipi lensimbi lingase libhekane nokwelashwa okwengeziwe okufana nokufaka i-hot dip galvanizing, ukupenda, noma okunye ukwelapha okungaphezulu ukuze kuhlinzekwe ukuvikela ukugqwala okwengeziwe kanye nobuhle.

Ishisela ngoHlobo E noma Uhlobo F Ibanga Bipayipi lizophathwa ngokushisa noma liphathwe ngenye indlela ngemva kokushiselwa ukuze i-martensite engagxiliwe ingabi khona.

Izinga lokushisa lokwelashwa kokushisa lizoba okungenani1000°F [540°C].

Uma ipayipi libandayo linwetshiwe, ukunwetshwa akufanele kudlule1.5%yobubanzi obushiwo bangaphandle bepayipi.

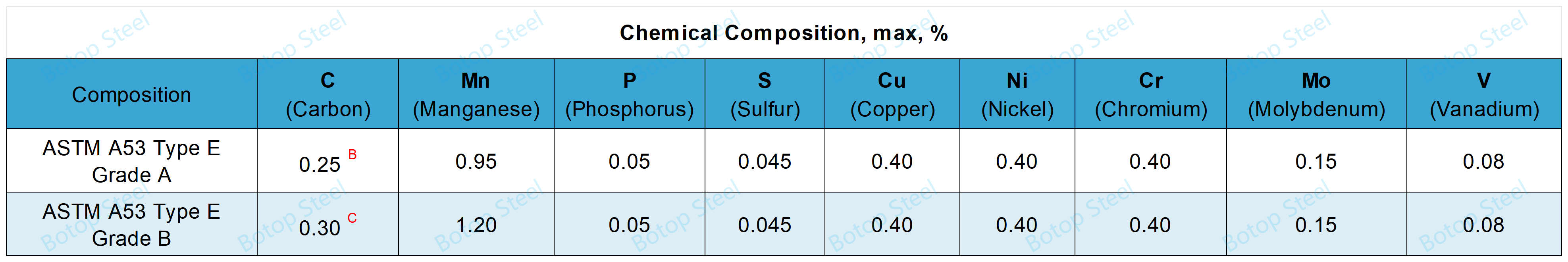

AIzakhi ezinhlanuCu, Ni, Cr, Mo, futhiVndawonye akumele kudlule u-1.00%.

BEkuncishisweni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06 % wemanganese ngaphezu kwesilinganiso esibekiwe kuzovunyelwa kuze kufike ku-1.35%.

CEkunciphiseni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06 % wemanganese ngaphezu komkhawulo oshiwo kuzovunyelwa kuze kufike ku-1.65%.

I-Tensile Property

| Uhlu | Ukwahlukanisa | Ibanga A | Ibanga B |

| Amandla aqinile, imiz | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla okukhiqiza, imiz | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ubude ngo-50 mm [2 in.] | Qaphela | A,B | A,B |

Qaphela A: Ubude obuncane kokungu-2 ku-[50 mm] buzoba yileyo enqunywa isibalo esilandelayo:

e = 625,000 [1940] A0.2/U0.9

e = ubude obuncane kumaphesenti angu-2 noma angu-50 mm, okufinyezwa kumaphesenti aseduze

A = okungaphansi kuka-0.75 in2[500 mm2] kanye nendawo ephambanayo yesampula yokuhlolwa kwengcindezi, ibalwe kusetshenziswa ububanzi obushiwo bangaphandle bepayipi, noma ububanzi obuncane besampula yokuhlolwa kwengcindezi nobukhulu bodonga olushiwo lwepayipi, inani elibaliwe lifinyezwa ku-0.01 eseduze phakathi2 [1 mm2].

U=amandla e-tensile amancane acacisiwe, i-psi [MPa].

Qaphela B: Bheka Ithebula X4.1 noma Ithebula X4.2, kungakhathaliseki ukuthi ikuphi okusebenzayo, ngamavelu amancane okunweba adingekayo ezinhlanganisela ezihlukahlukene zosayizi wesifanekiso sokuhlolwa kokucindezeleka namandla ashiwo ubuncane obuncane bokunyakaza.

Bend Test

Kupayipi DN ≤ 50 [NPS ≤ 2], ubude obanele bepayipi buzokwazi ukugotshwa ukubanda kuye ku-90° kuzungeze i-cylindrical mandrel, ububanzi bayo obuphindwe kashumi nambili kunobubanzi obushiwo bangaphandle bepayipi, ngaphandle kokwenza imifantu noma iyiphi ingxenye futhi ngaphandle kokuvula i-weld.

Okuphindwe kabili-okunamandla(isigaba sesisindo:XXS) ipayipi elingaphezu kwe-DN 32 [NPS 1 1/4] akudingeki lihlolwe ukugoba.

Ukuhlola Ukucaba

Ukuhlolwa kokucaba kuzokwenziwa epayipini elishiselwe ngaphezulu kwe-DN 50 ngesisindo esinamandla (XS) noma esilula.

Ifanele Uhlobo E, Ibanga A kanye no-B;kanye namashubhu oHlobo F, eBanga B.

Amashubhu ensimbi angenamthungo akudingeki ahlolwe.

Isikhathi Sokuhlola

Kubo bonke osayizi Bohlobo S, Uhlobo E, kanye Nohlobo F lwepayipi leBanga B, ingcindezi yokuhlola izonakekelwa ubuncane obungu-5s.

Ukuhlolwa kwe-hydrostatic kuzosetshenziswa, ngaphandle kokuvuza ngomthungo we-weld noma umzimba wepayipi.

Izingcindezi Zokuhlola

Ipayipi elingenaluthoizohlolwa nge-hydrostatic kungcindezi esebenzayo enikezweIthebula X2.2,

Ipayipi elinentambo futhi elihlanganisiweizohlolwa nge-hydrostatic kungcindezi esebenzayo enikezweIthebula X2.3.

Ngamapayipi ensimbi ane-DN ≤ 80 [NPS ≤ 80], ukucindezela kokuhlola akufanele kudlule i-17.2MPa;

Emapayipini ensimbi ane-DN>80 [NPS>80], ingcindezi yokuhlola ngeke idlule ku-19.3MPa;

Izingcindezi zokuhlola eziphakeme zingakhethwa uma kunezidingo ezikhethekile zobunjiniyela, kodwa lokhu kudinga ukuxoxisana phakathi komkhiqizi nekhasimende.

Ukumaka

Uma ipayipi ihlolwe nge-hydrostatic, ukumaka kufanele kuboniseingcindezi yokuhlola.

Lezi zidingo ezilandelayo zisebenza ku-Type E kanye Nohlobo F Ipayipi Lebanga B.

Ipayipi elingenamthungo linezidingo ezengeziwe ezingaxoxwanga ngazo kulo mbhalo.

Izindlela Zokuhlola

Amapayipi akhiqizwa yimishini engashisi yokwandisa nokufinyeza: DN ≥ 50 [NPS ≥ 2], iamashiselaesigabeni ngasinye sepayipi kudingeka kudlule ukuhlolwa kukagesi okungabhubhi, futhi indlela yokuhlola idinga ukuhambisana neE213, E273, E309 noma E570ejwayelekile.

Amapayipi e-ERW akhiqizwa umshini we-diameter we-hot stretch-rencing: DN ≥ 50 [NPS ≥ 2]Isigaba ngasinyeipayipi liyohlolwa ngokugcwele lilonke ngokuhlolwa kukagesi okungacekeli phansi, okuyohambisanaE213, E309, nomaE570izindinganiso.

Qaphela: Umshini Wokunwebeka Wokunwebeka Okushisayo ungumshini owelula ngokuqhubekayo futhi ukhama amashubhu ensimbi ngama-roller emazingeni okushisa aphakeme ukuze ulungise ububanzi nobukhulu bodonga.

Ukumaka

Uma ithubhu iye yahlolwa ngokuhlolwa okungabhubhisi, kuyadingeka ukukhombisaNDEekumaka.

IMisa

±10%.

Ipayipi DN ≤ 100 [NPS ≤ 4], ikalwe njengeqoqo.

Amapayipi DN > 100 [NPS > 4], akalwe ngezingcezu ezizodwa.

Ububanzi

Ngepayipi DN ≤40 [NPS≤ 1 1/2], ukuhluka kwe-OD akufanele kudlule ±0.4 mm [1/64 in.].

Ngepayipi DN ≥50 [NPS>2], ukuhluka kwe-OD akumele kudlule ±1%.

Ubukhulu

Ubukhulu obuncane bodonga akumele bube ngaphansi87.5%yobukhulu bodonga olushiwo.

ilula kunesisindo esinamandla kakhulu (XS).:

a) ipayipi elingaphethe lutho: 3.66 - 4.88m [12 - 16 ft], Hhayi ngaphezu kuka-5% yenani eliphelele.

b) ubude obungahleliwe obukabili: ≥ 6.71 m [22 ft], Ubude obumaphakathi obuncane obungu-10.67m [35 ft].

c) ubude bokungahleliwe okukodwa: 4.88 -6.71m [16 - 22 ft], hhayi ngaphezulu kuka-5 % yenani eliphelele lobude obucushiwe obuhlinzekiwe bungamajoyinti (izingcezu ezimbili ezihlanganiswe ndawonye).

Isisindo esinamandla kakhulu (XS) noma esindayo: 3.66-6.71 m [12 - 22 ft], akukho ngaphezu kuka-5% ingqikithi yepayipi 1.83 - 3.66 m [6 - 12 ft].

Okokuqedwa kwepayipi lensimbi le-ASTM A53 kutholakala kumnyama noma kufakwe uthayela.

Mnyama: Amashubhu ensimbi ngaphandle kokwelashwa okungaphezulu, ngokuvamile athengiswa ngokuqondile ngemva kwenqubo yokukhiqiza, kulezo zinhlelo zokusebenza lapho kungekho ukumelana nokugqwala okwengeziwe okudingekayo.

Amapayipi anamathangi kufanele ahlangabezane nezidingo ezifanele.

Inqubo

I-zinc kufanele ihlanganiswe ngaphakathi nangaphandle ngenqubo ye-hot-dip.

Impahla eluhlaza

I-zinc esetshenziselwa ukumboza izoba yinoma yiliphi ibanga le-zinc elihambisana nezidingo ze-SpecificationI-ASTM B6.

Ukubukeka

Ipayipi elinothayela ngeke libe nezindawo ezingamboziwe, amabhamuza omoya, amadiphozithi agelezayo, kanye nokufakwa kwe-slag emahhadla.Izigaxa, amaqhuqhuva, ama-globules, noma inani elikhulu lediphozithi ye-zinc eliphazamisa ukusetshenziswa okuhlosiwe kwento akumele kuvunyelwe.

Galvanized Coating Weight

Izonqunywa ngokuhlolwa kwekhasi ngokwendlela yokuhlola i-ASTM A90.

Isisindo sokumboza akufanele sibe ngaphansi kuka-0.55 kg/m² [1.8 oz/ft²].

Ipayipi lensimbi le-ASTM A53 ERWngokuvamile isetshenziswa ezinsizeni zengcindezi ephansi kuya emaphakathi njengobunjiniyela bakamasipala, ukwakhiwa, kanye nepayipi lesakhiwo semishini.Izimo ezijwayelekile zokusetshenziswa zihlanganisa ukudlulisa amanzi, isitimu, umoya, nolunye uketshezi olunomfutho ophansi.

Ngokushisela okuhle, alungele ukwenza imisebenzi ehlanganisa ukugoqa, ukugoba, nokupheqa.