I-ASTM A53 ipayipi yensimbi engenamthungoihlukaniswa njenge-A53 Type S futhi iyipayipi lensimbi elingenamthungo.

Ihlukaniswe ngamabanga amabili, iBanga A kanye neBanga B, futhi ilungele ukusetshenziswa kwemishini nengcindezi, kanye nokusetshenziswa okuvamile umusi, amanzi, igesi, nomoya.Leli payipi lensimbi liyipayipi lensimbi ye-carbon elilungele ukushisela nokwenza imisebenzi ehlanganisa ukugoqa, ukugoba, nokuxhuma kwe-flange.

| Okujwayelekile | I-ASTM A53/A53M |

| Ububanzi Okuzisholo | I-DN 6- 650 [NPS 1/8 - 26] |

| I-Diameter Yangaphandle Ecacisiwe | 10.3 - 660 mm [0.405 - 26 in.] |

| Ikilasi lesisindo | I-STD (Ejwayelekile), i-XS (Inamandla Kakhudlwana), XXS (I-Double Extra Strong) |

| Ishejuli No. | Isheduli 10, iSheduli 20, iSheduli 30, iSheduli 40, iSheduli 60, iSheduli 80, iSheduli 100, iSheduli 120, 140, 160, |

Empeleni, iSheduli 40 kanye neSheduli 80 zingamabanga amabili ogqinsi lwamapayipi asetshenziswa kakhulu.Ukuze uthole ukwaziswa okwengeziwe, sicela ubhekeHlela i-PDF yebangaifayela esihlinzeka ngalo.

Kusukela yasungulwa ngo-2014,Insimbi ye-Botopisibe ngumphakeli ohamba phambili wepayipi lensimbi ye-carbon eNyakatho yeChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezixazululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Amapayipi ensimbi e-ASTM A53 angaba angenamthungo noma ashiselwe.

Indlela yokukhiqiza engenamthungo (Uhlobo S) wukusebenza okushisayo kwensimbi futhi, uma kunesidingo, ukuqedwa okubandayo komkhiqizo weshubhu owenziwe ngokushisayo ukuze kuzuzwe umumo odingekayo, ubukhulu, kanye nezakhiwo.

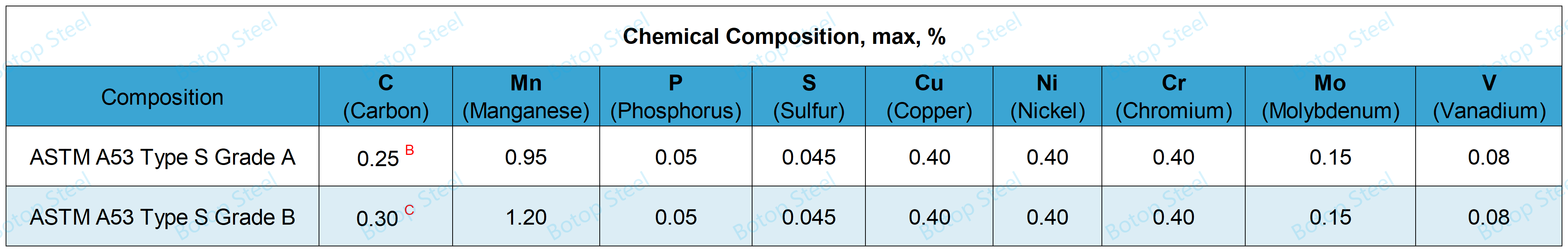

Ezingeni le-ASTM A53, izidingo zokwakheka kwamakhemikhali zohlobo S kanyeUhlobo Eamapayipi ensimbi ayafana, kuyilapho izidingo zokwakheka kwamakhemikhali zohlobo F zihlukile.

AIzakhi ezinhlanuCu,Ni,Cr,Mo, futhiVndawonye akumele kudlule u-1.00%.

BEkuncishisweni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06 % wemanganese ngaphezu kwesilinganiso esibekiwe kuzovunyelwa kuze kufike ku-1.35%.

CEkunciphiseni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06 % wemanganese ngaphezu komkhawulo oshiwo kuzovunyelwa kuze kufike ku-1.65%.

Ukusebenza Kwengcindezi

| Uhlu | Ukwahlukanisa | Ibanga A | Ibanga B |

| Amandla aqinile, imiz | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla esivuno, imiz | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ukwelulaku-50 mm [2 in.] | Qaphela | A, B | A, B |

Izidingo zeNothi A no-B zichazwe kabanzi kuUhlobo E, okungaboniswana uma unesithakazelo.

Ngaphezu kwalokho,I-API 5LfuthiI-ASTM A106banezidingo ezifanayo zefomula yokubala yokwelula.

Bend Test

Nge-DN ≤ 50 [NPS ≤ 2], ubude obanele bepayipi buzokwazi ukugotshwa ukubanda nge-90 ° kuzungeze i-cylindrical mandrel, ububanzi bayo obuphindwe kashumi nambili ububanzi obushiwo obungaphandle bepayipi, ngaphandle kokwenza imifantu kunoma iyiphi ingxenye.

Okuphindwe kabili-okunamandla(XXS) ipayipi elingaphezu kwe-DN 32 [NPS 1 1/4] akudingeki lihlolwe ukugoba.

Ukuhlola Ukucaba

Amashubhu ensimbi angenamthungo awadingi ukuhlolwa okucaba.

Uma kudingwa yinkontileka, ukuhlolwa kungenziwa ngokuya ngenqubo eku-S1.

Bonke osayizi bamapayipi ensimbi angenamthungo bazogcina inani elithile lokucindezela kwamanzi ngaphandle kokuvuza okungenani imizuzwana emi-5.

Ingcindezi yokuhlola yamapayipi ensimbi angenalutho ingatholakala kuThebula X2.2.

Izingcindezi zokuhlola zamapayipi ensimbi aluchungechunge nahlanganisiwe zingatholakala kuThebula X2.3.

Ingasetshenziswa njengenye indlela yokuhlolwa kwe-hydrostatic.

Ubude bonke bepayipi ngalinye elingenamthungo buzohlolwa ngogesi ongabhubhisi ngokuhambisanaE213, E309, nomaE570.

Lapho uthenga i-ASTM A53, ukubekezelela usayizi wepayipi lensimbi kufanele kuhlangabezane nezidingo ezilandelayo.

| Uhlu | Hlunga | Ukubekezelelana |

| ubuningi | Isisindo sethiyori | ±10% |

| Ububanzi | I-DN 40mm[NPS 1/2] noma encane | ±0.4mm |

| I-DN 50mm[NPS 2] noma ngaphezulu | ±1% | |

| Ubukhulu | ubuncane bodonga obukhulu kufanele buhambisane neThebula X2.4 | iminithi 87.5% |

| Ubude | ilula kunesisindo esinamandla kakhulu(XS). | 4.88m-6.71m (hhayi ngaphezu kuka-5 % yenani eliphelele lobude obufakwe imicu obuhlanganisiwe (izingcezu ezimbili ezihlanganiswe ndawonye)) |

| ilula kunesisindo esinamandla kakhulu(XS). (ipayipi elingenalutho) | 3.66m-4.88m (Ayidluli ku-5% yenani eliphelele) | |

| I-XS, XXS, noma ukujiya kodonga | 3.66m-6.71m (akukho ngaphezu kuka-5% isiyonke ipayipi 1.83m-3.66m) | |

| ilula kunesisindo esinamandla kakhulu(XS). (ubude obuphindwe kabili okungahleliwe) | ≥6.71m (Isilinganiso esimaphakathi sobude obungu-10.67m) |

Izinga le-ASTM A53 licacisa izidingo zesimo sepayipi elimnyama kanye nokufakwa kukathayela wediphu eshisayo yamapayipi ensimbi.

Ipayipi Elimnyama

Ipayipi elimnyama libhekisela esimweni sepayipi lensimbi ngaphandle kokwelashwa okungaphezulu.

Amapayipi amnyama avame ukusetshenziswa ezindaweni lapho isikhathi sokugcina sifushane, indawo ezungezile yomile futhi ayigqwali, futhi intengo ngokuvamile iphansi ngoba akukho ukunamathela.

I-Hot-dip Galvanized Coating

Amapayipi anamathani, aziwa nangokuthi amapayipi amhlophe, avame ukusetshenziswa ezindaweni ezinomswakama noma ezigqwalile.

I-zinc esembozweni ye-zinc ingaba yiliphi ibanga le-zinc ku-ASTM B6.

Ipayipi elinothayela ngeke libe nezindawo ezingamboziwe, amabhamuza, amadiphozithi agelezayo, kanye nokufaka i-gross dross.Izigaxa, ama-projections, ama-globules, noma amadiphozithi esindayo e-zinc azophazamisa ukusetshenziswa okuhlosiwe kwento ngeke kuvunyelwe.

Okuqukethwe kwe-Zinc okungengaphansi kuka-0.55 kg/m² [1.8 oz/ft²].

Amanye Ama-Coatings

Ngaphandle kwepayipi elimnyama kanye ne-galvanized coating, izinhlobo ezivamile zokugqoka zihlanganisaupende, I-3LPE, I-FBE, njll. Uhlobo olufanele lokugqoka lungakhethwa ngokuvumelana nezidingo ezithile zendawo yokusebenza.

Ukunikeza ulwazi olulandelayo kuzokwenza inqubo yakho yokuthenga isebenze kahle futhi inembe.

Igama elijwayelekile: ASTM A53/A53M;

Ubuningi: Isamba sobude noma inombolo ephelele;

IBanga: IBanga A noma iBanga B;

Uhlobo: S, E, noma F;

Ukwelashwa okungaphezulu: okumnyama noma okufakwe ama-galvanized;

Usayizi: Ububanzi bangaphandle, ukujiya kodonga, noma isheduli No. noma ibanga lesisindo;

Ubude: ubude obucacisiwe noma ubude obungahleliwe;

Ukuphela kwepayipi: indawo engenalutho, ukuphela kwe-beveled, noma ukuphela kwentambo;