Ipayipi lensimbi le-ASTM A556 lisetshenziswa kakhulu njengepayipi lensimbi elidonswa ngokubanda elingenamthungo kumahitha amanzi okuphakelayo.

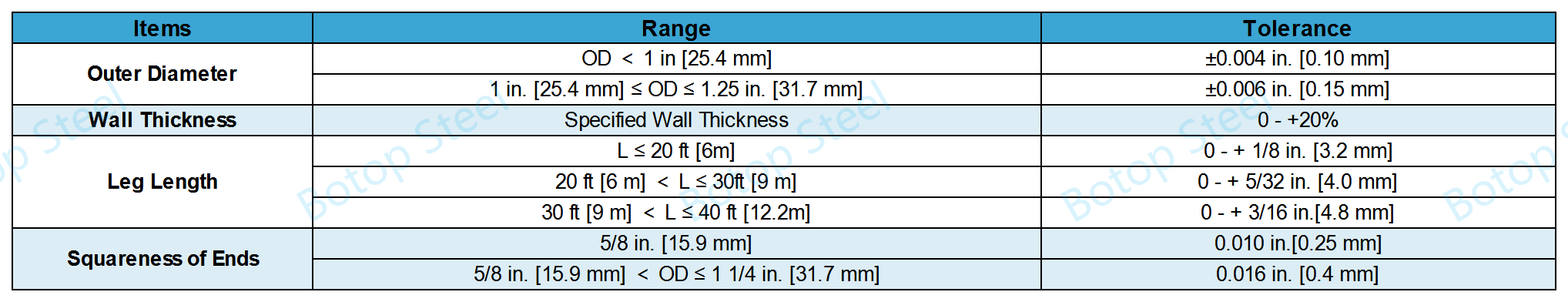

Ububanzi bayo bokusebenza ipayipi lensimbi elingenamthungo elinobukhulu obungaphandle bobubanzi obuphakathi kuka-15.9-31.8mm nogqinsi olungekho ngaphansi kuka-1.1mm.

Lesi sihloko sigxile epayipini lensimbi futhi asibandakanyi ama-U-tubes ashiwo esilinganisweni.

Ububanzi bangaphandle: 5/8 - 1 1/4 in. [15.9 -31.8 mm].

Ukujiya kodonga: ≥ 0.045 in [1.1 mm].

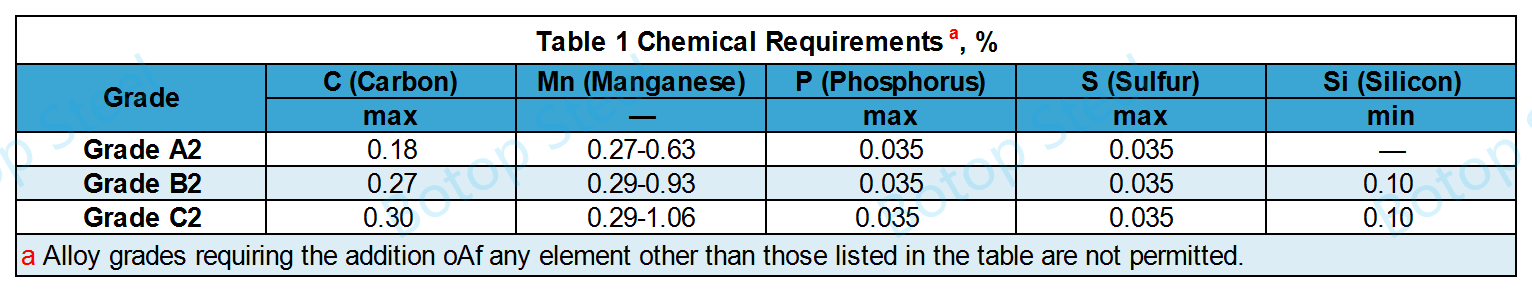

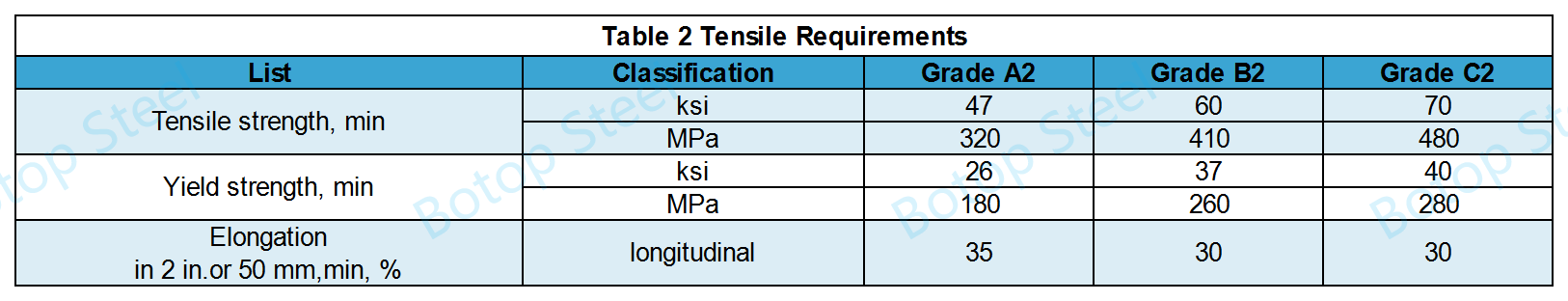

I-ASTM A556 ihlukanisa amabanga amathathu,Ibanga A2, Ibanga B2, futhiIbanga C2.

Amashubhu ensimbi azokhiqizwa ngu-aengenamthungoinqubo futhi izodonswa kubanda.

Amashubhu ensimbi engenamthungo adonswa ngokubanda anikeza ukunemba kobukhulu obuphezulu kanye nokuqedwa okuhle kwendawo kuyilapho ecwenga ukwakheka kwe-microstructure futhi ethuthukisa izici zayo zomshini ezifana namandla nobulukhuni.Isakhiwo esingenamthungo senza amashubhu azinze futhi aphephe lapho engaphansi kwezingcindezi eziphezulu namazinga okushisa, okuwenza afanelekele izinhlelo zokusebenza zezimboni ezidinga ukunemba okuphezulu nokusebenza.

Kodwa-ke, amashubhu ensimbi adonswa ngokubanda angenamthungo abiza kakhulu ukukhiqiza ngoba inqubo yawo yokukhiqiza iyinkimbinkimbi futhi idinga imisebenzi eyinkimbinkimbi nemishini.Ukwengeza, ukusebenza kahle kwazo kokukhiqiza okuphansi, ikakhulukazi ekukhiqizeni kwevolumu ephezulu, akukona ukonga njengenqubo yokugoqa okushisayo, futhi kwezinye izimo kungase kube nokulahlekelwa kwezinto ezibonakalayo, okukhawulela ukusetshenziswa kwazo kwezinye izinhlelo zokusebenza.

Amashubhu adonswa ngokubanda kufanele aphathwe ngokushisa ngemva kokudlula kokugcina okubandayo ezingeni lokushisa elingu-1200°F [640°C] noma ngaphezulu ukuze kuqinisekwe ukuthi i-ductility iyanelisa ukugingqika emashidini amashubhu futhi ihlangabezane nezakhiwo eziwumshini njengoba kucacisiwe.

Uma ukuhlaziywa komkhiqizo kwenziwa, bheka ku-ASTM A751 ukuthola izindlela zokuhlola.

1. Impahla Eqinile

Indlela yokuhlola: I-ASTM A450 Isigaba 7.

Kumaqoqo angafika kwangu-50, ishubhu elilodwa lizokhethwa ukuze lihlolwe.

Kumaqoqo amashubhu angaphezu kuka-50, amashubhu ama-2 azokhethwa ukuze ahlolwe.

2. Ubulukhuni

Indlela yokuhlola: I-ASTM A450 Isigaba 23.

Izibonelo ezivela kumashubhu okuhlola amabili asuka endaweni ngayinye zizohlolelwa ukuqina kwe-Brinell noma i-Rockwell.

Ukuqina kwepayipi le-Rockwell akumele kudlule lokho okuboniswe kuthebula.

| Ibanga | Ukuqina |

| Ibanga A2 | 72 HRBW |

| Ibanga B2 | 79 HRBW |

| Ibanga C2 | 89 HRBW |

3. Ukuhlolwa Kokucaba

Indlela yokuhlola: I-ASTM A450 Isigaba 19.

Ukuhlolwa kokucaba kuzokwenziwa esibonelweni esisodwa kusukela ekugcineni kweshubhu lensimbi eliqediwe kusukela ekukhethweni kwamashubhu angaphezu kuka-125 endaweni ngayinye.

4. Ukuhlolwa kwe-Flaring

Indlela yokuhlola: I-ASTM A450 Isigaba 21.

Ukuhlolwa kokuvutha kuzokwenziwa esibonelweni esisodwa kusukela ekugcineni kweshubhu eliqediwe, kungabi namashubhu angaphezu kuka-125 akhethiwe kubhetshi ngayinye.

Akukho ukuhlolwa kwe-hydrostatic okuphoqelekile kwamapayipi ensimbi.

Kodwa-ke, wonke amapayipi e-U kufanele ahlolwe nge-hydrostatically ngoketshezi olungagqwali.

Ishubhu ngalinye lizohlolwa ithuluzi lokuhlola elingonakali elikwazi ukubona amaphutha kuyo yonke ingxenye yeshubhu ngemva kokwelashwa kokushisa okungaphezulu ngemva kokudweba kokugcina okubandayo.

Izindlela zokuhlola ezingalimazi zokucaciswaE213, UkucaciswaE309(yezinto ze-ferromagnetic), UkucaciswaE426(okwezinto ezingezona kazibuthe), noma UkucaciswaE570ingase ikhethelwe ukuhlolwa.

Ukubekezelelana okulandelayo akusebenzi engxenyeni egobile ye-U-tube.

Ipayipi eliqediwe kufanele lingabi nesikali kodwa libe nefilimu ye-oxide engaphezulu.

Amashubhu aqediwe kufanele aqonde ngokufanelekile futhi abe neziphetho ezibushelelezi ezingenazo ama-burrs.Amashubhu azoba nokuqedwa okufana nomsebenzi futhi ngeke abe nokungapheleli okungaphezulu okungeke kususwe ngaphakathi kokubekezelela udonga okuvunyelwe.

Ukususwa kokungapheleli okungaphezulu okufana nezimpawu zokubamba, izimpawu zokuqondisa, i-mandrel ekhanyayo nama-die marks, imigodi engashoni, namaphethini esikali ngeke kudingeke inqobo nje uma kungaphakathi kokubekezelela odongeni okuvunyelwe.

Ububanzi bangaphakathi nangaphandle bepayipi eliqediwe kufanele buboshwe ukuze kuvinjelwe ukugqwala ngesikhathi sokuthutha.

Izingubo ezivamile ziyiamafutha okuvimbela ukugqwala, ama-varnish, nomaamapende.

Ukukhethwa kwezinto zokugqoka ngokuvamile kuncike ezidingweni ezithile zohlelo lokusebenza lwepayipi lensimbi, indawo yokusetshenziswa okuhlosiwe, kanye nobude besikhathi sokuvikela.

Ama-heaters amanzi okuphakelayo: Lesi ngesinye sezicelo ezivame kakhulu zeshubhu yensimbi ye-ASTM A556.

Embonini yamandla, izifudumezi zamanzi eziphakelayo zisetshenziselwa ukushisa kuqala amanzi e-boiler, ngokuvamile ngokukhipha isitimu.Ukusetshenziswa kwalolu hlobo lweshubhu yensimbi kuvumela ukudluliswa okuphumelelayo kwamandla ashisayo, ukuthuthukisa ukusebenza kahle kwamandla kanye nokusebenza kwesistimu.

Izishintshi zokushisa kanye nama-condenser: Ngenxa yezindawo zayo ezinhle kakhulu zokudlulisa ukushisa nokumelana nokugqwala, ishubhu yensimbi ye-ASTM A556 nayo ifaneleka ukusetshenziswa kwezinye izinhlobo zokushintshisana kokushisa nama-condenser, asetshenziswa ezinhlobonhlobo zamakhemikhali, i-petrochemical, nezinye izinqubo zezimboni.

Amasistimu we-steam anengcindezi ephezulu: Ukumelana nezinga lokushisa eliphezulu kanye nokucindezela okuphezulu kweshubhu ye-ASTM A556 kuyenza ifanelekele ukusetshenziswa ezinhlelweni zesitimu esinomfutho ophezulu kanye nezinye izinhlelo zokusebenza ezidinga ukucindezela okukhulu kakhulu nokumelana nezinga lokushisa.

I-ASTM A179/A179M- Lena indinganiso yezishintshi zokushisa ze-carbon steel ezingenamthungo ezidonswa ngokubanda kanye namashubhu e-condenser wesevisi ye-cryogenic.

I-ASTM A192/A192M- Icacisa izidingo zobuchwepheshe zamashubhu ebhayela ensimbi yensimbi engenamthungo kumabhayela asetshenziswa kusevisi yokucindezela okukhulu.

I-ASTM A210/A210M- Izinga lamashubhu kabhoyela ensimbi angenamthungo ekhabhoni emaphakathi kanye ne-carbon-manganese yensimbi yamabhoyili nama-superheaters.

I-ASTM A213/A213M- Ihlinzeka ngezindinganiso ze-boiler yensimbi engenamthungo ne-austenitic alloy, i-superheater, namashubhu okushintsha ukushisa.

I-ASTM A249/A249M- Okujwayelekile kusebenza kubhayela wensimbi oshiselwe i-austenitic, i-superheater, isishintshi sokushisa, namashubhu e-condenser.

I-ASTM A334/A334M- Izinga le-carbon engenamthungo neshiselwe kanye ne-alloy steel tubing yesevisi ye-cryogenic.

Ngayinye yalezi zindinganiso ihlanganisa amashubhu ensimbi asetshenziswa kuma-heaters, ama-boilers noma izinhlelo ezifanayo.Iliphi izinga elikhethiwe lincike ezidingweni ezithile zohlelo lokusebenza, njengezinga lokushisa lokusebenza, isilinganiso sokucindezela, nokumelana nokugqwala okulindelekile.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.