Ipayipi lamanzi lensimbi i-AWWA C213iyinamathela ye-FBE esetshenziswa endaweni yangaphakathi nangaphandle yepayipi lensimbi ukuze isetshenziswe kumasistimu amapayipi amanzi ensimbi angaphansi komhlaba noma angaphansi kwamanzi.

Lokhu kunamathela kuhlinzeka ngokuvikeleka ekugqwaleni futhi kuqinisekisa ukusebenza okuthembekile kohlelo lwamapayipi isikhathi eside endaweni engaphansi komhlaba noma ngaphansi kwamanzi.

Iphayiphi ububanzi bangaphandle ≥ 660mm [24in].I-epoxy resin lining enokufinyelela epayipini ukuze lihlolwe futhi lilungiswe.

Ububanzi bepayipi lensimbi <660mm [24in] nabo bangase bafaneleke, inqobo nje uma kukhona indlela efanelekile yokuhlola ubuqotho bento enamathelayo yangaphakathi.

I-Fusion Bonded Epoxy (FBE)iyi-powder eyomile enengxenye eyodwa ye-thermosetting epoxy resin ethi, uma icushwe ukushisa, idale ukusabela kwamakhemikhali ebusweni bepayipi lensimbi ngenkathi igcina izakhiwo zayo.

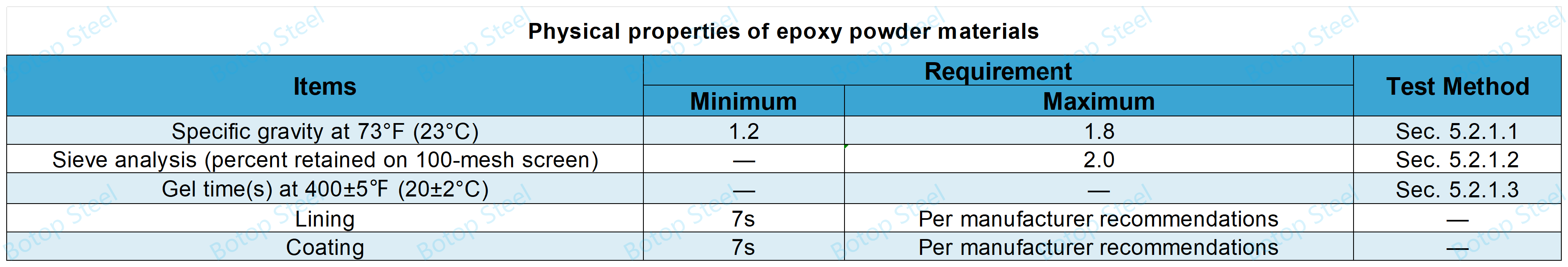

I-epoxy powder izoqukatha into eyodwa ehlanganisiwe eyinhlanganisela ehlanganisa i-epoxy resin, i-ejenti elaphayo, i-catalyst, i-filler, i-colorant, i-ejenti yokulawula ukugeleza, ne-UV inhibitor.

Izimpahla zizohambisana nezidingo ze-Umthetho Wamanzi Okuphuza Aphephile.

Uma kudingeka ukuthobela i-NSF, izinto ezithintana namanzi aphuzwayo zizogunyazwa ku-NSF/ANSI/CAN Standard 61.

Ngokuvamile, izinga lokushisa eliphezulu lesicelo sezingubo zokugqoka cishe65°C (150°F).Ngaphezu kwalokho, impilo yesevisi ye-coating iyancipha ngokugcina izinga lokushisa eliphezulu isikhathi eside.

Uma isetshenziswa kuma-athikili ashisiwe ngaphambilini ngokufafazwa kwe-electrostatic, umbhede omanzi noma isifutho somoya bese selashwa, impushana ye-epoxy ikhiqiza ukunamathela okufanayo kokuvikela.

Imisebenzi ethize imi kanje:

Ukuhlolwa Kwepayipi Nokwelashwa Kwangaphambili

Indawo engaphezulu ngeke ingabi nasici esithinta umkhiqizo wokugcina, njengama-burrs, ama-gouges, nama-weld spatters, angasuswa ngokufakwa kwesihlabathi.

futhi indawo engaphezulu ngeke ingabi nodaka, upende wokugaya, ingcina, itiyela lamalahle, itiyela, uwoyela, ugrisi, ama-chloride, nanoma iyiphi enye into yangaphandle noma ukungcola okuvuthayo okungase kuthungele emazingeni okushisa okusebenza e-epoxy ahlanganisiwe.Susa amachashaza abonakalayo amafutha kanye namafutha ngokusula nge-solvent engashiyi nsalela.

Ukulungiswa kwendawo

Sebenzisa i-sandblasting eyomile ukuze uhlanze ukugqwala okungaphezulu epayipini lensimbi.

Izidingo Zendawo Eqhumayo: Uma izinga lokushisa lepayipi lensimbi liku-3°C (5℉) ngaphezu kwezinga lokushisa lendawo yamazolo.

Ukuhlanzeka Komhlaba: Ingaphezulu lepayipi lensimbi elehlisiwe kufanele lihambisane ne-SSPC-SP10/NACE No. 2.

Ukuqina Kobuso: Ukujula okusanhlamvu okusetshenzwa kulengwa kububanzi obungu-51-102 μm (2.0-4.0 mil) kukalwa ngokuvumelana ne-ASTM D4417.Lokhu kungakalwa ngenhla kwephethini yehange noma imitha yephethini yehange.

Ubulukhuni bobuso obujule kakhulu noma obungashoni kakhulu buzophazamisa ukusebenza koqweqwe lokugcina lwe-FBE.

Qaphela: Sicela uqaphele isikhawu sesikhathi phakathi kokuphothulwa kokwehlisa kanye nenqubo yokumboza ukuze ugweme ukugqwala kwe-flash.

Ukuhlanza umoya

Umoya ocindezelwe ongangcolisi uzosetshenziswa ukufutha uthuli, insila, noma enye into yangaphandle evela engxenyeni engaphansi elungisiwe yepayipi ngendlela engathinti indawo ehlanzekile, elinye ipayipi elihlanziwe, noma ipayipi elizombozwa noma elifakwe ulayini.

Ukushisisa kwamapayipi

Ipayipi lensimbi yokushisa kusetshenziswa umthombo wokushisa okungafanele konakalise indawo engaphezulu yepayipi, kodwa akumele idlule ku-274°C (525°F).

Amazinga okushisa aphakeme angase aguqule izici ezibonakalayo nezici zokuqina zensimbi.

Izinga lokushisa elingaphezulu kwepayipi lensimbi lingalinganiswa kusetshenziswa ipeni le-thermometer noma ithemometha ye-optical calibrated.

Uma kuba nombala oluhlaza okwesibhakabhaka, ipayipi kufanele lipholiswe kumazinga okushisa asendaweni bese liqhunyiswa kabusha.

Inqubo yokumboza

Impushana ye-FBE isetshenziswa ngendlela efanayo phezu kwepayipi lensimbi elishisayo ngombhede oncibilikayo, isifutho se-electrostatic, noma ngokufafaza komoya.

Ama-grooves, ama-beveled, noma izindawo ezimpande akumele zimbozwe nge-FBE.

Lapho kusetshenziswa amajoyinti ane-raber-gasketed noma ama-couplings emishini, i-epoxy kufanele inwebeke kuze kube sekugcineni kwepayipi ngaphandle uma kuchazwe ngenye indlela umthengi.

Ukupholisa

Ukupholisa kungenziwa ngomoya noma ngamanzi.

I-PQT: Thenga i-AWWA C213 Water Transmission Pipe ngamanani amancane okuhlola ngaphambi kokuthenga amanani amakhulu.Ukufaneleka noma ukuhlolwa kwenziwa ukuze kuqinisekiswe ukuthi umkhiqizo noma isistimu ihlangabezana nemibandela ethile yekhwalithi nokusebenza.

Lokhu kuhlanganisa ukuhlolwa kwelabhorethri, ukuhlolwa kokusebenza, nezinye izinqubo.

Ukubukeka

I-epoxy ngokuvamile kufanele ibe bushelelezi.

I-epoxy akufanele ibe namabhamuza, imifantu, amabhamuza, i-delamination, noma okunye ukonakala okubonakalayo.

Ukungapheleli kwezimonyo, okufana nama-sags, i-dimpling, scuffing, ikhethini, isifutho esingaphezulu, kanye/noma i-orange-peel, ngeke kubhekwe njengesizathu sokunqatshelwa noma sokulungisa.

Ukuhlolwa kukagesi kokuqhubeka (ukuhlolwa kweholide le-voltage ephansi)

Ukuqhubeka kokumboza kufanele kuhlolwe ngokuhambisana ne-NACE SPO490.

Okwemigqaenogqinsi oluyi-20 mils (508 um) noma ngaphansi, umtshina weholide we-voltage ephansi obekwe ku-75 V umkhawulo uzosetshenziswa ngokuhambisana ne-NACE SPO188.

Uma inani lamaholide lidlula inombolo engezansi i-coating izodinga ukususwa futhi yenziwe kabusha.

Ububanzi bangaphandle (OD) <14in (360 mm), iholide elingu-1/imitha (3 ft).

Ububanzi bangaphandle (OD) ≥ 14in (360 mm), iholide elingu-1/25 ft² (2.3 mm²).

Thatha amaholide ahloliwe, walungise, futhi uphinde uwahlole.

Ukunamathela

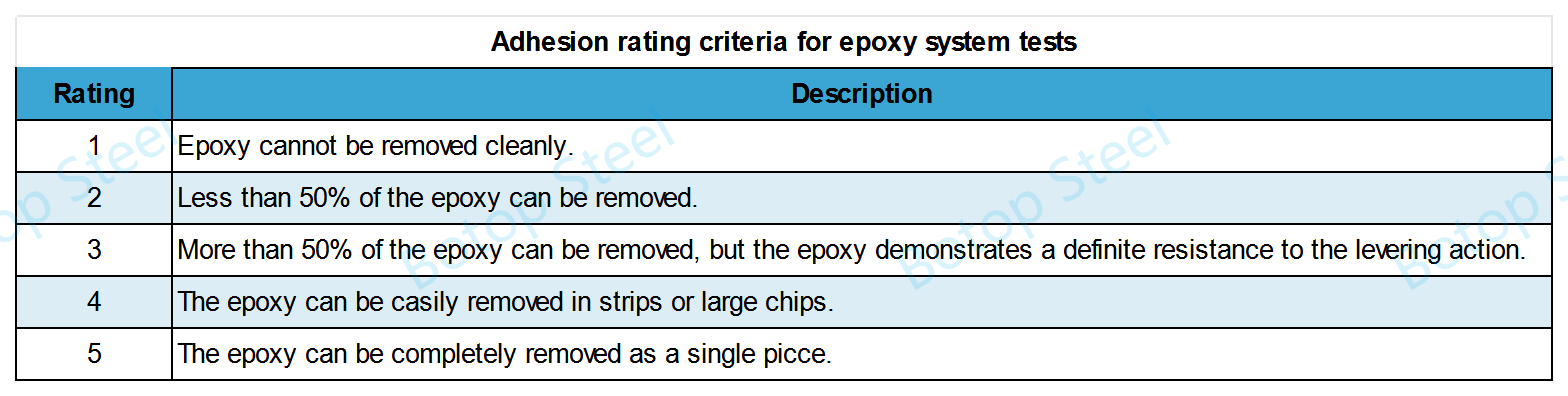

Ukunamathela kwe-epoxy ephulukisiwe ebusweni bepayipi kungafinyelelwa ngokucindezela i-blade ebukhali ngokusebenzisa i-epoxy ebusweni bepayipi nokusebenzisa ukunyakaza kokulima ngomzamo wokukhipha i-epoxy ebusweni bepayipi.

I-epoxy kufanele ibambelele ngokugcwele epayipini elisepayipini imelana ngokuqinile nesenzo sokulima futhi ingabi nemfucumfucu ephukile futhi ihlanganeisilinganiso sokunamathela se-1-3.

Ubukhulu

Ugqinsi lwefilimu yokugqoka eselashiwe akufanele lube ngaphansi kuka-305um (12mil), kufaka phakathi ama-weld seams.

Enguqulweni endala ye-AWWA C213, bekunomkhawulo we-406 um (16 mils) ubukhulu bokujiya obuphezulu, obususwe enguqulweni yakamuva ngenxa yobunzima bokufeza le mfuneko phakathi nenqubo yokukhiqiza yangempela.

Izivivinyo Ezengeziwe

Ukuhlola okwengeziwe kungashiwo ukuze kunqunywe ukusebenza kwe-epoxy.

1. I-cross-section porosity.

2. I-interface porosity.

3. Ukuhlaziywa kwe-Thermal (DSC).

4. Ukucindezeleka okungapheli (ukugoba).

5. Gcoba amanzi.

6. Umthelela.

7. Ukuhlolwa kwe-Cathodic disbondment.

Izophawulwa ngokucacile ngegama lomkhiqizi, uhlobo lwempahla, inombolo yenqwaba noma indawo, usuku lokukhiqiza, kanye nezimo zokugcinwa.

Ikakhulukazi amapayipi okuhambisa amanzi

Izembatho zangaphandle zivame ukusetshenziselwa ukuvikela amapayipi ekugqwaleni kwemvelo, kuyilapho ukumbozwa kwangaphakathi kusetshenziselwa ukuvimbela ukungcoliswa kwamanzi, ukunciphisa ukumelana nokungqubuzana, nokwelula ukuphila kwamapayipi.Lezi zembatho zisiza ukuqinisekisa ukwethembeka nokuqina kwezinhlelo zamapayipi, ukuthobela izindinganiso zokuhlanzeka, nokunciphisa isidingo sokunakekelwa.

ANSI/AWWA C203: Izingubo Zokuvikela Zamalahle Nethayela Lepayipi Lamanzi Lensimbi.

ANSI/AWWA C209: Tape Coatings for Steel Water Pipe kanye nokufakwa.

ANSI/AWWA C210: I-Liquid-Epoxy Coatings kanye namaLinings for Steel Water Pipe and Fittings.

I-Botop Steel iyi-Welded yekhwalithi ephezuluIpayipi Lensimbi Yekhabhoniumkhiqizi kanye nomphakeli ovela e-China, futhi isitokwe sepayipi lensimbi engenamthungo.

I-Botop Steel izinikele ngokuqinile kwikhwalithi futhi isebenzisa izilawuli eziqinile nokuhlolaqinisekisa ukwethembeka komkhiqizo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.Sibheke ngabomvu ukusebenza nawe.