I-BS EN 10210 S355J0H, inombolo yensimbi 1.0547, iyingxenye yensimbi yesakhiwo esingenalutho esakhiwe ngendlela eshisayo futhi ingaba yipayipi lensimbi elingenamthungo noma elishiselwe, elisetshenziswa kakhulu ezakhiweni ezidinga amandla aphezulu kanye nokuqina okuhle, njengamafreyimu esakhiwo amakhulu namabhuloho.

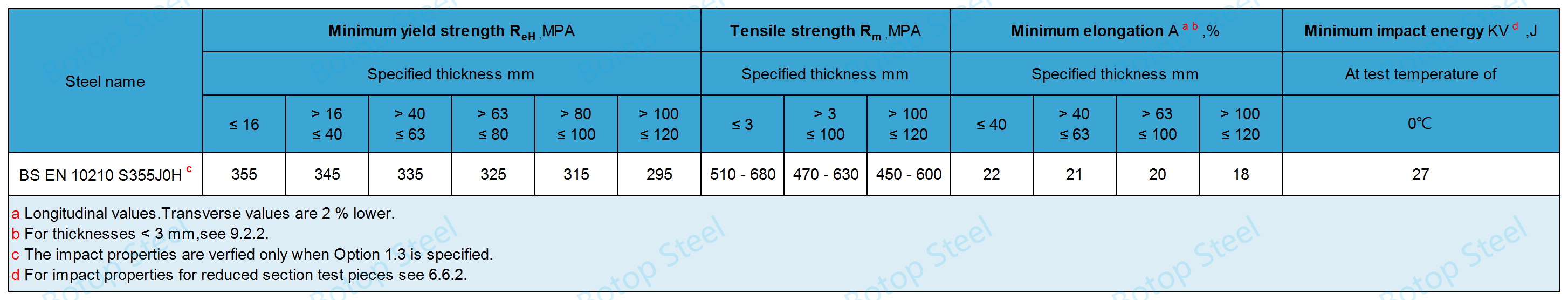

Impahla ye-S355J0H inezinto zokusebenzisa ukuthi amandla amancane esivuno angu-355MPa lapho ukujiya kodonga kungeqi ku-16 mm futhi kuhlangabezana namandla omthelela amancane angu-27J ku-0℃.

I-BS EN 10210 iqukethe izinhlobonhlobo zomumo wezingxenye eziphambanayo, njengesiyingi, isikwele, unxande, noma i-elliptical, i-Botop Steel igxile kakhulu kumashubhu ensimbi ayindilinga anosayizi abahlukahlukene, ikunikeza ngezinto ezisezingeni eliphezulu nezivumelana nezinga lensimbi ezithengiswa ngqo efekthri. kanye nentengo yokuncintisana.

Qaphela: Zonke izidingo ezikulo mbhalo ziyasebenza naku-EN 10210.

Ukujiya kodonga ≤120mm.

Isiyingi (HFCHS): Ububanzi bangaphandle bufika ku-2500 mm;

Isikwele (HFRHS): Ubukhulu bangaphandle bufika ku-800 mm x 800 mm;

Unxande (HFRHS): Ubukhulu bangaphandle bufika ku-750 mm x 500 mm;

I-Elliptical (HFEHS): Ubukhulu bangaphandle obufika ku-500 mm x 250 mm.

| Ibanga lensimbi | Uhlobo lwe i-deoxidationa | % ngesisindo, esiphezulu | |||||||

| C | Si | Mn | P | S | Nb,c | ||||

| Igama lensimbi | Inombolo yensimbi | Ugqinsi olucacisiwe (mm) | |||||||

| ≤40 | >40 ≤120 | ||||||||

| I-BS EN 10210 S355J0H | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

aFN = Insimbi yokugoqa ayivunyelwe;

bKuvunyelwe ukweqa amanani ashiwo inqobo nje uma ekukhuphukeni ngakunye ngo-0.001 % N the P, ubuningi.okuqukethwe nakho kwehliswe ngo-0.005 %.Okuqukethwe kwe-N kokuhlaziywa kwabalingisi, nokho, akumele kube ngaphezu kuka-0.012 %;

cInani eliphakeme kakhulu le-nitrogen alisebenzi uma ukwakheka kwamakhemikhali kubonisa inani elincane eliphelele lokuqukethwe kwe-Al elingu-0.020 % elinesilinganiso esincane se-Al/N esingu-2:1, noma uma kukhona ezinye izakhi ezanele zokubopha i-N.Izinto ezibophezela i-N zizorekhodwa kuMqulu Wokuhlola.

Ukuqokwa kwezinto ezibonakalayo ku-BS EN 10210 kusekelwe emandleni azo amancane esivuno ku-16mm ugqinsi lwezindonga kanye nezakhiwo ezinomthelela emazingeni okushisa athile.Amandla okukhiqiza, amandla aqinile, nobude be-BS EN 10210 S355J0H kuncipha njengoba ukushuba kodonga kukhula.

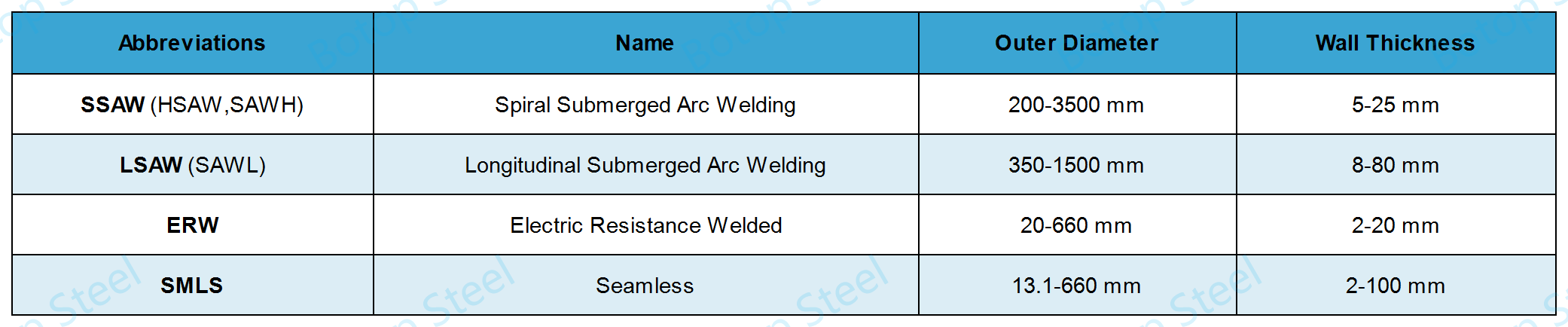

I-BS EN 10210 ivumela ukukhiqizwa kusetshenziswa izinqubo ezahlukahlukene zokukhiqiza, ezivame ukufaka izinqubo zokushisela ezingenamthungo, i-LSAW, SSAW, kanye ne-ERW.

Ngezansi ububanzi bosayizi bezinqubo zokukhiqiza ezivamile.

Kusukela kulesi siqhathaniso esingenhla, kungabonakala ukuthi ipayipi lensimbi elingenamthungo linenzuzo engokwemvelo ekukhiqizeni ipayipi lensimbi elinezindonga eziwugqinsi, ikakhulukazi ipayipi lensimbi eliwugqinsi elinobubanzi obuncane, kodwa ubukhulu bayo buzonqunyelwa.Uma udinga ukukhiqiza amapayipi ensimbi ububanzi obungaphezu kuka-660mm, kuzoba nzima kakhulu.

Ipayipi Elimnyama

Lokhu kubhekisela epayipini lensimbi ngaphandle kokwelashwa okungaphezulu.

I-Temporary Protective Coating

Ukuvimbela ukugqwala kwamapayipi ensimbi ngesikhathi sokugcina, ukuthutha, noma ukufakwa, indlela evamile ukugqoka ubuso bepayipi ngendwangu kapende noma i-varnish.

I-Anti-corrosion Coating

Kunezinhlobo eziningi ze-anti-corrosion coatings, kufaka phakathi upende, i-FBE,I-3LPE, futhi amagalani.Uhlobo ngalunye lokumboza lunezici ezihlukile kanye nezindawo ezisebenzayo.Ukugqwala nokugqwala kungavinjelwa ngempumelelo ngokufaka i-anti-corrosion coating efanelekile ezindaweni zensimbi.

I-TS EN 10210 I-Hot dip galvanized coatings ezindaweni zamapayipi ensimbi kufanele ihambisane nezidingo ezifanele ze-EN ISO 1461.

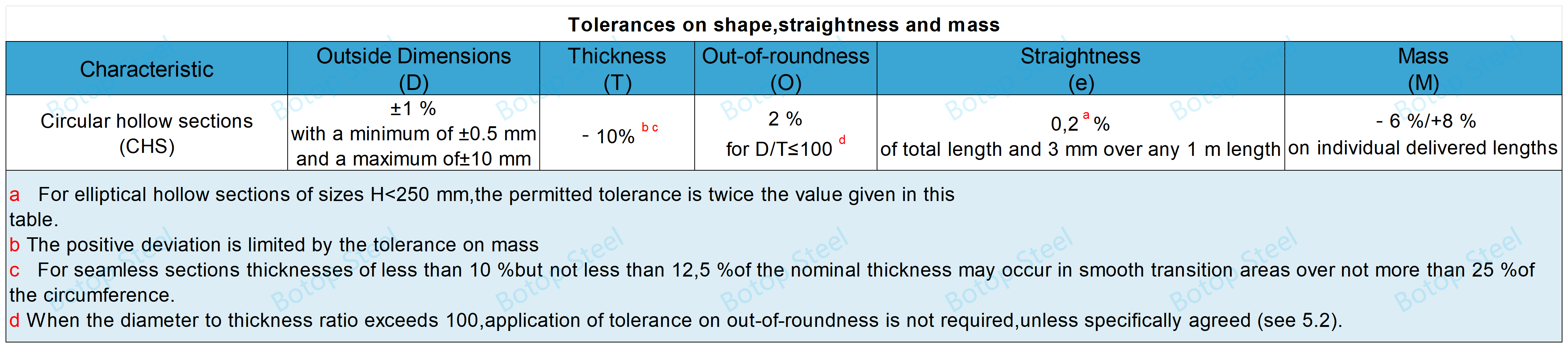

Ukubekezelela Isimo, UkuQopha kanye NeMisa

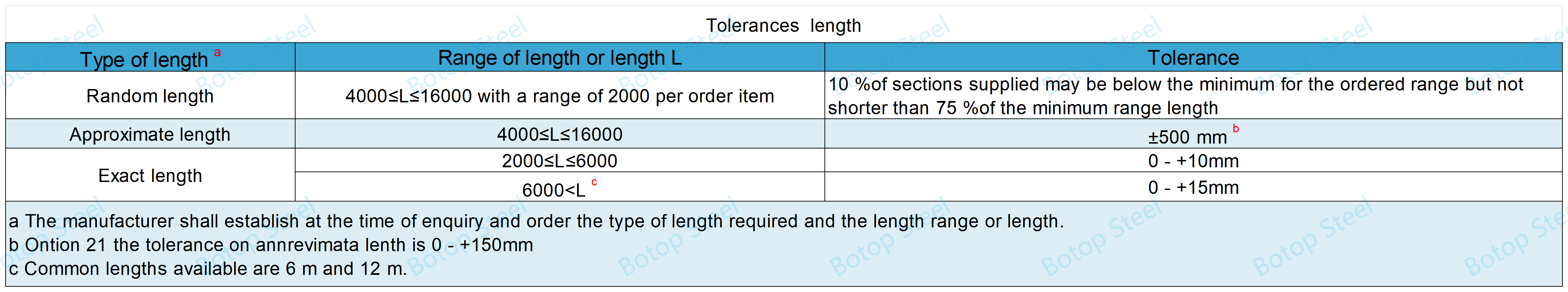

Ukubekezelela Ngobude

Ukuphakama Kwe-Seam ye-SAW Weld

| Ubukhulu, T | Ubukhulu bobude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Ukuphakama komthungo we-weld weld ngokuvamile akudluli ngaphezu kobuso bepayipi, futhi phakathi nenqubo yokukhiqiza, i-weld seam iphathwa ukuze ifakwe ebusweni bepayipi futhi ingabonakali ibonakala.

I-BS EN 10210 S355J0H isetshenziswa kabanzi ezakhiweni zokwakha, ukukhiqizwa kwemishini, amapayipi ezokuthutha, ukwakhiwa kwengqalasizinda, imikhumbi, nobunjiniyela basolwandle.Amandla ayo aphezulu kanye nokuqina kwawo okuhle kuyenza ibe yinhle kakhulu kumaphrojekthi anjengamabhuloho, izakhiwo eziphakeme kakhulu, izitshalo zezimboni, okhreni, amapayipi kawoyela negesi, nemibhoshongo yamandla omoya.

| I-GB/T | I-GOST | I-ASTM | I-JIS |

| I-GB/T 1591 Q345B | I-GOST 19281 09G2S | I-ASTM A501 Ibanga C | I-JIS G 3101 SS490 |

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Eminye imikhiqizo ehlobene:

Xhumana nathi ukuze uthole isilinganiso samahhala kanye nokubonisana ngephrojekthi yakho.