I-EN 10219 S275J0H kanye ne-S275J2HIzingxenye zesakhiwo ezishiselwe ngokubandayo ezenziwe ngensimbi engafakwanga ngokwe-EN 10219.

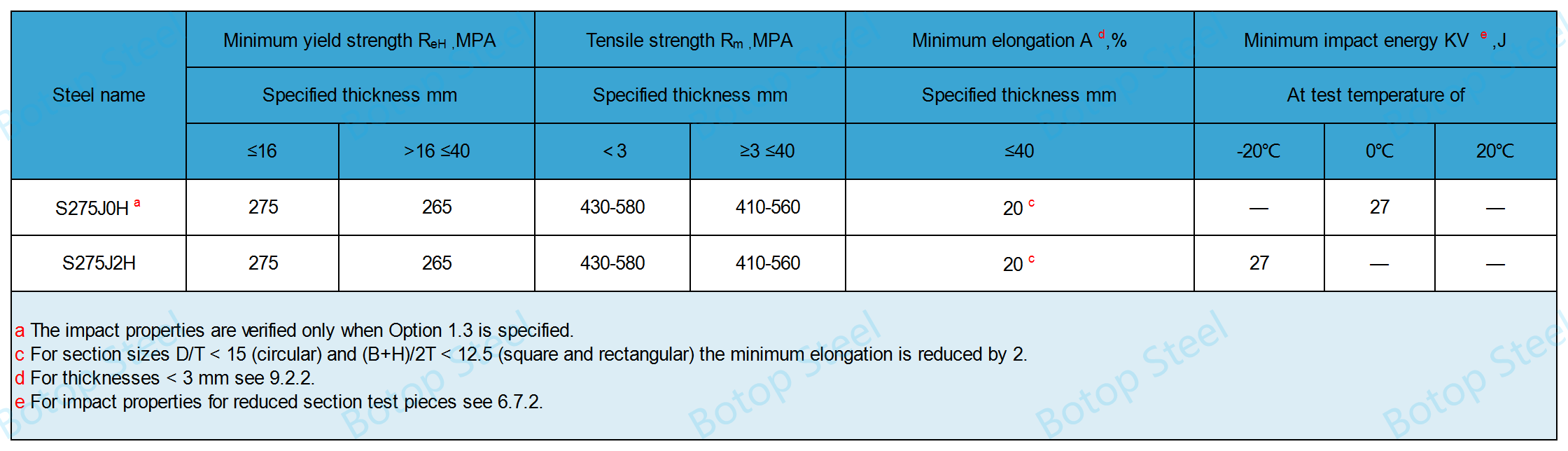

Zombili zinamandla amancane okukhiqiza angu-275MPa (ukujiya kodonga ≤16mm).Umehluko omkhulu usezicini ezithinta umthelela: I-S275J0H inamandla amancane omthelela angu-27 J ku-0°C, kuyilapho i-S275J2H inamandla omthelela amancane angu-27 J ku- -20°C.

Ifanele izicelo ezakhiweni nezakhiweni zobunjiniyela ezingaphansi kwemithwalo elula.

I-BS EN 10219 iyi-European Standard EN 10219 eyamukelwa yi-UK.

Ukujiya kodonga ≤40mm, Ububanzi bangaphandle ≤2500mm.

I-CFCHS isifinyezo se-Cold-Formed Circular Hollow Section.

Izinga le-EN 10219 limboza uhla olubanzi lomumo wensimbi wesakhiwo ongenalutho, okuhlanganisa inyingo, isikwele, unxande, kanye ne-oval, ukuze ivumelane nezidingo zokusetshenziswa ezihlukene.

Insimbi ye-Botopigxile ekuhlinzekeni amashubhu ensimbi ayindilinga angenalutho ngobukhulu obuhlukahlukene kanye nezinqubo ukuze ivumelane nezinhlelo eziningi zokusebenza zemboni, iqinisekisa ukuthi izidingo ezithile zamakhasimende ethu zingahlangatshezwana nazo.

Kusukela yasungulwa ngo-2014,Insimbi ye-Botopisibe ngumphakeli ohamba phambili wepayipi lensimbi ye-carbon eNyakatho yeChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezixazululo ezibanzi.

Le nkampani inikeza amapayipi ensimbi ahlukahlukene kanye nemikhiqizo ehlobene, kuhlanganiseI-SMLS, ERW, I-LSAW, futhiI-SSAWipayipi lensimbi, kanye nokuhlelwa okuphelele kokufakwa kwamapayipi nama-flanges.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Sibheke ngabomvu ukusungula ubudlelwano bokubambisana nawe nokudala ikusasa lokuwina-wina ndawonye.

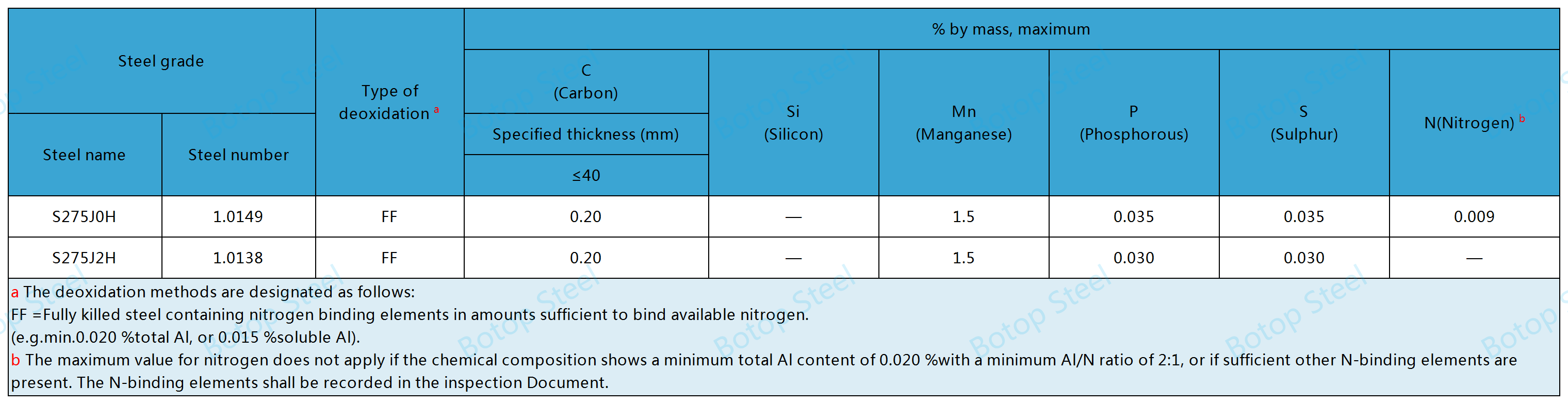

Insimbi engaphekiwe yokwakhiwa kwezingxenye ezingenalutho ezakhiwe ngendlela ebandayo ikhishwa yi-oxidized futhi kufanele ihlangabezane nezimo ezithile zokulethwa.

Izidingo ezifanele ze-S275J0H ne-S275J2H ziyiFF(Insimbi ebulawe ngokuphelele equkethe izakhi zokubopha i-nitrogen ngamanani anele ukuhlanganisa i-nitrogen etholakalayo (isb. min.0,020 % isiyonke i-Al noma i-0,015 % e-soluble Al)).

Isimo sokuletha: Okugoqiwe noma okujwayelekile/okujwayelekile okugoqiwe (N) kwezinsimbi ze-JR, J0, J2, ne-K2.

Amapayipi ensimbi aya ku-EN 10219 angakhiqizwa yiwo womabiliERW( electro resistance welding ) kanyeSAW(i-submerged arc welding) izinqubo zokukhiqiza.

Ukukhiqizwa kweERW amashubhuinenzuzo yokushesha futhi ethengekayo futhi ivame ukukhethwa kumaphrojekthi adinga ukukhiqizwa kwenani elikhulu kanye nezindleko eziphezulu.

ERWamashubhu ngokuvamile asetshenziselwa ukukhiqiza amadayamitha amancane futhi mncane odongeni ukushuba, kuyilaphoSAWamashubhu afaneleka kakhulu kuma-diameter amakhulu kanye nezindonga ezinkulu.Sicela ukhethe uhlobo olufanele lwepayipi lensimbi lephrojekthi yakho.

Amapayipi e-ERW akhiqizwa ngokwe-EN 10219 awavamisile ukudinga ukusikwa kwe-weld yangaphakathi.

Lokhu kungenxa yokuthi amashubhu e-EN 10219 asetshenziswa kakhulu ezinhlelweni zesakhiwo, njengokwakha nobunjiniyela bemishini, lapho izidingo zokubukeka kwe-weld ngokuvamile ziqinile kunemikhumbi yomfutho noma amapayipi anomfutho ophezulu.Ngakho-ke, inqobo nje uma amandla nobuqotho be-weld buhlangabezana nezidingo zezinga, ama-welds angaphakathi angasetshenziswa ngaphandle kokusikwa okwengeziwe.

Akukho ukwelashwa okulandelanayo kokushisa okwenziwayo, ngaphandle kokuthi i-weld ingase ibe sesimweni esishiselwe noma esiphathwe ngokushisa.

Ukuhlaziywa kwe-Cast (Ukwakheka Kwekhemikhali Kwezinto Ezingavuthiwe)

Kokubili i-S275J0H ne-S275J2H inenani eliphezulu elilingana nekhabhoni (CEV) elingu-0.40%.

I-S725J0H ne-S275J2H ene-CEV ephezulu engu-0.4% ibonisa ukushisela okungcono ngengozi encane yokuqina nokuqhekeka ngesikhathi sokushisela.

Ingase futhi ibalwe kusetshenziswa ifomula elandelayo:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

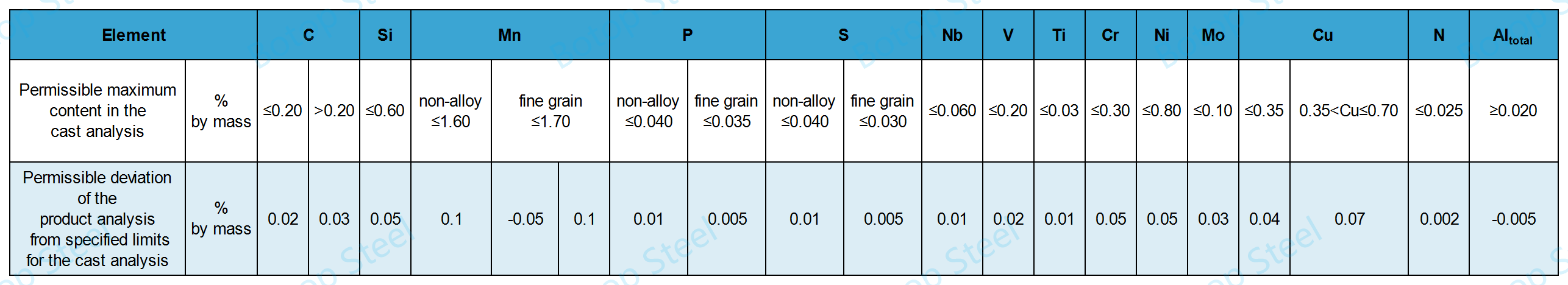

Ukuhlaziywa Komkhiqizo (Ukwakheka Kwekhemikhali Kwemikhiqizo Eqediwe)

Ngesikhathi sokukhiqizwa kwensimbi, ukwakheka kwamakhemikhali kungashintsha ngenxa yezizathu eziningi, futhi lezi zinguquko zingathinta izakhiwo kanye nekhwalithi yensimbi.

Ukwakhiwa kwamakhemikhali kwepayipi lensimbi lokugcina eliqediwe kufanele kuhambisane nokwakheka kwamakhemikhali kokusakazwa kanye nokuchezuka kwayo okuvumelekile.

Amapharamitha wezakhiwo zikamshini afaka amandla esivuno, amandla aqinile, ubude, namandla omthelela.

Ukunciphisa ingcindezi ngaphezu kuka-580 ℃ noma isikhathi esingaphezu kwehora elilodwa kungase kuholele ekuwohlokeni kwezakhiwo zemishini.

Amanothi:

Ukuhlolwa komthelela akudingekile uma ubukhulu obucacisiwe bungu-<6mm.

Izici zomthelela zamashubhu ekhwalithi ye-JR ne-J0 aziqinisekiswa ngaphandle uma kucacisiwe.

I-EN 10219 Welds kumapayipi ensimbi e-ERW angahlolwa ngokukhetha okukodwa kokulandelayo.

I-TS EN 10246-3 kuya kuzinga lokwamukela i-E4, ngaphandle kokuthi ishubhu elizungezayo/indlela yekhoyili ye-pancake ngeke ivunyelwe;

I-EN 10246-5 ezingeni lokwamukelwa F5;

I-EN 10246-8 kuya kuzinga lokwamukelwa kwe-U5.

Ukubalwa kwesisindo sethiyori samashubhu we-EN 10219 singasuselwa ku-tube density engu-7.85 kg/dm³.

M=(DT)×T×0.02466

M yisisindo ngobude beyunithi ngayinye;

D wububanzi obushiwo bangaphandle, amayunithi ngo-mm;

U-T uwugqinsi olucacisiwe lodonga, amayunithi ngo-mm.

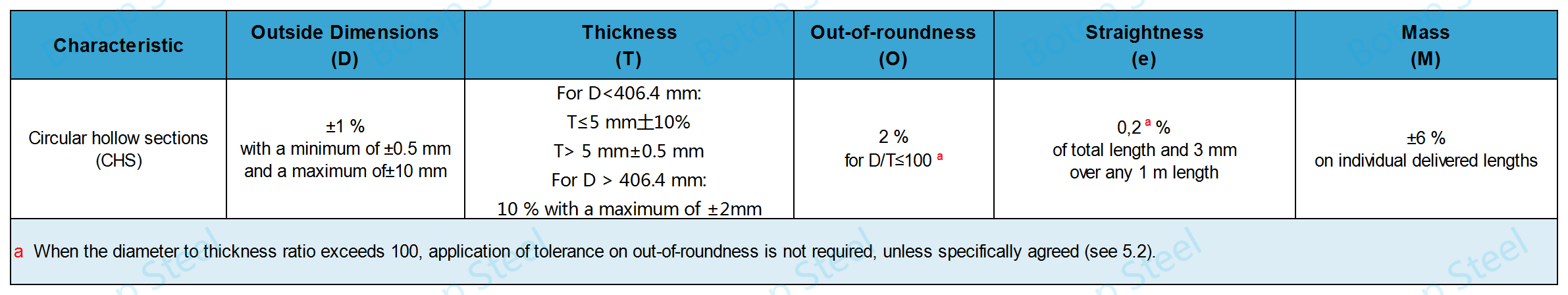

Ukubekezelela Isimo, UkuQopha kanye NeMisa

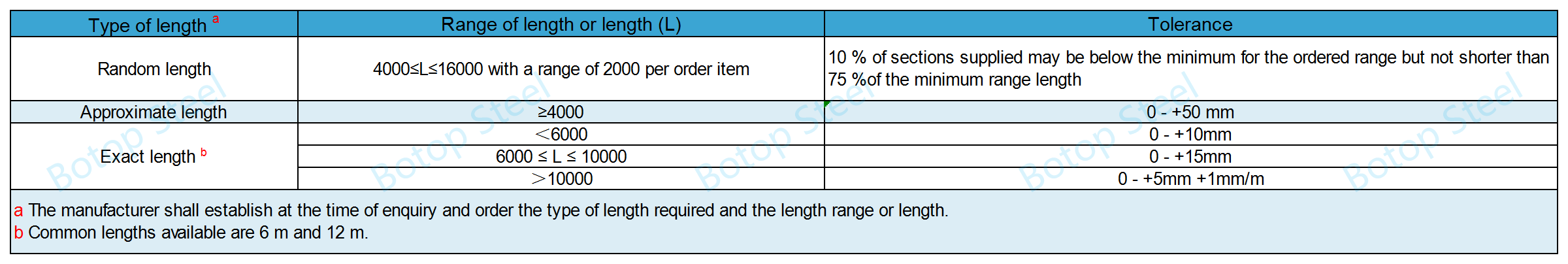

Ukubekezelela Ubude

Amashubhu esigaba esingenalutho enziwe ngokuya nge-EN 10219 ayashiseleka.

Lapho kushiselwa, ukuqhekeka okubandayo endaweni yokushisela kuyingozi enkulu njengoba ukushuba, izinga lamandla, kanye ne-CEV yomkhiqizo kukhuphuka.Ukuqhekeka okubandayo kubangelwa inhlanganisela yezinto ezimbalwa:

amazinga aphezulu e-hydrogen e-diffusable ensimbi yokushisela;

isakhiwo esinama-brittle endaweni ethinteke ukushisa;

ukugxila okubalulekile kokucindezeleka okuqinile endaweni ehlanganisiwe eshiselwe.

Ingaphezulu lepayipi lensimbi kufanele libe bushelelezi futhi lingabi nasici esingathinta ukusebenza komkhiqizo, njengokuqhekeka, imigodi, ukuklwebheka, noma ukugqwala.

Amaqhubu, ama-grooves, noma ama-longitudinal grooves angajulile adalwe inqubo yokukhiqiza ayamukeleka inqobo nje uma ukuqina kodonga olusele kungaphakathi kokubekezelelana, isici singasuswa ngokugaya, futhi ukujiya kodonga olulungisiwe kuhlangabezana nezidingo zokujiya ezincane.

Insimbi ye-Botopayinikezi kuphela amashubhu ensimbi ekhwalithi ephezulu ngokuhambisana ne-EN 10219, futhi ihlinzeka ngezinketho eziningi zokumbozwa ngaphezulu kwamashubhu ensimbi ukuze ivumelane nezidingo ezithile zamakhasimende ayo kumaphrojekthi wobunjiniyela ahlukene.Lezi zingubo zenzelwe ukuthuthukisa ukumelana nokugqwala kwamashubhu futhi zengeze ukuvikeleka okwengeziwe, ngaleyo ndlela andise impilo yazo yesevisi.

I-Hot-dip Galvanizing

I-3LPE (HDPE) Coating

I-FBE Coating

I-Varnish Coating

I-Paint Coating

I-Cement Weight Coating

Izingxenye zebhuloho: Izakhiwo ezingathwali umthwalo eziyinhloko ezisetshenziswa kumabhuloho, njengezinsimbi namapharaphethi.

Izinsika Zokwakha: amakholomu okusekela kanye nemishayo esetshenziswa ekwakheni kanye nobunjiniyela bomphakathi.

Amapayipi amapayipi: amapayipi okuthutha uketshezi namagesi, ikakhulukazi ezinhlelweni ezidinga izinga lokuguquguquka kanye nokumelana nokugqwala.

Izakhiwo zesikhashana: Izisekelo zesikhashana namafreyimu afanele izindawo zokwakha nezobunjiniyela.

Lezi zinhlelo zokusebenza zisebenzisa izici ezinhle kakhulu zemishini kanye nokushisela kwe-S275J0H ne-S275J2H ukuze kuhlangatshezwane nezidingo zezakhiwo ezingasindi kodwa ezizinzile.

I-ASTM A500:Ukucaciswa Okujwayelekile Kweshubhu Yensimbi Eyakheke Ngokubandayo Eyakheke Kakhulu futhi Engenamthungo KumaRound and Shapes.

I-ASTM A501: Ukucaciswa Okujwayelekile Kweshubhu Lesakhiwo Sensimbi Esakhiwe Ngokushisayo Esakheke Ngokushisayo.

I-EN 10210: Izingxenye ezingenalutho zesakhiwo eziqediwe ezishisayo zama-non-alloy nezinsimbi zokusanhlamvu ezinhle.

I-EN 10219: Izingxenye ezinezimbobo zesakhiwo ezishiselwe eziqinile ezingezona ingxubevange nezinsimbi zokusanhlamvu ezinhle.

I-JIS G 3466: Isikwele se-Carbon steel kanye namashubhu angama-rectangular wesakhiwo esijwayelekile.

AS/NZS 1163: Izingxenye ezingenalutho zensimbi ezakhiwe ngendlela ebandayo.

Lawa mazinga asetshenziswa kabanzi emhlabeni jikelele, futhi asiza ukuqinisekisa ukuthi amashubhu ensimbi esakhiwo ahlangabezana nenqubo elindelekile yokusebenza ezinhlelweni ezihlukene zobunjiniyela.Uma ukhetha izinga lepayipi lensimbi, kubalulekile ukucabangela izidingo zayo ezithile zohlelo lokusebenza, imithetho yesifunda, kanye nezidingo zokusebenza.

I-ASTM A252 GR.3 Structural LSAW(JCOE) Ipayipi Lensimbi Yekhabhoni

I-BS EN10210 S275J0H LSAW(JCOE) Ipayipi Lensimbi

I-ASTM A671/A671M LSAW Ipayipi Lensimbi

I-ASTM A672 B60/B70/C60/C65/C70 LSAW Ipayipi Lensimbi Lekhabhoni

I-API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Grade X70 LSAW Steel Pipe

I-EN10219 S355J0H Structural LSAW(JCOE) Ipayipi Lensimbi