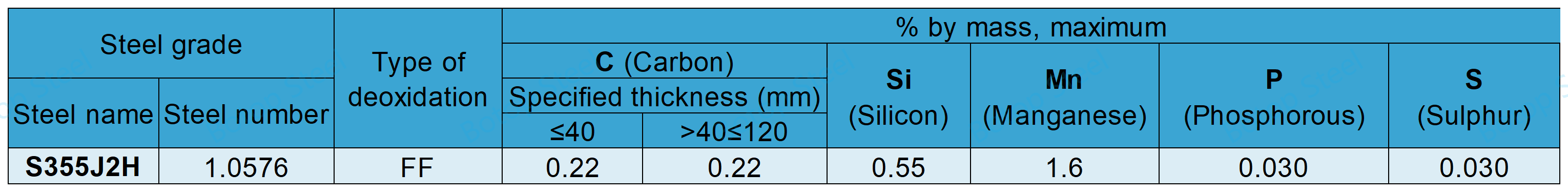

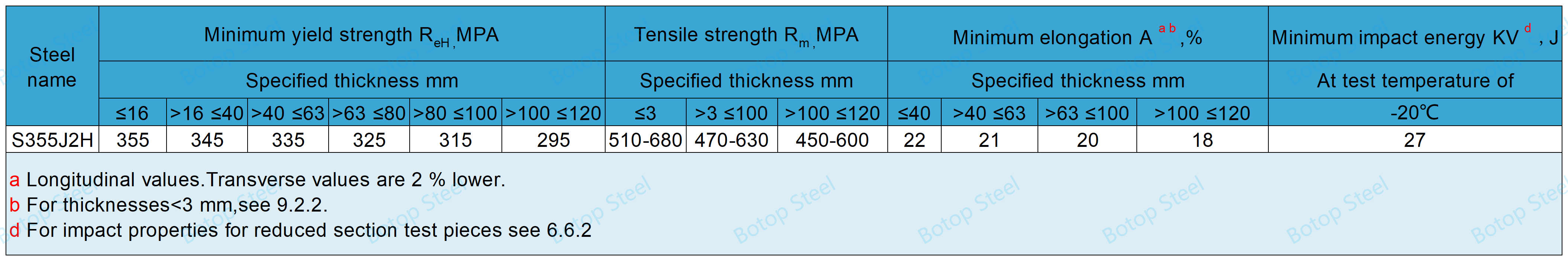

I-EN 10210 S355J2Hiyinsimbi yesigaba esingenalutho esiqediwe esishisayo ngokushoI-EN 10210ngamandla amancane okukhiqiza angu-355 MPa (obukhulu bodonga ≤ 16 mm) kanye nezakhiwo ezinomthelela omuhle emazingeni okushisa aphansi kuze kufike ku--20 ° C, okwenza kube kuhle ukusetshenziswa ezinhlobonhlobo zezakhiwo zokwakha nezobunjiniyela.

Yebo, i-EN 10210 =I-BS EN 10210.

I-BS EN 10210 kanye ne-EN 10210 ziyafana kokuqukethwe kobuchwepheshe futhi zombili zimelela izindinganiso zase-Europe zokuklama, ukukhiqiza, kanye nezidingo zezingxenye ezingenalutho zesakhiwo se-thermoformed.

I-BS EN 10210 inguqulo eyamukelwa e-UK, kanti i-EN 10210 iyindinganiso yaseYurophu yonke. Izindikimba kazwelonke ezihlukene zokumisa zingase ziqalise izinga ngezifinyezo zikazwelonke ezithile, kodwa okuqukethwe okuyinhloko kwezinga kuhlala kufana.

Izingxenye ezingenalutho zingahlukaniswa njengeziyingi, isikwele noma unxande, noma i-elliptical.

Futhi ngenxa yokuthi kuyinqubo eqediwe eshisayo ngokuhambisana ne-EN 10210, lesi sifinyezo esilandelayo singasetshenziswa.

HFCHS= izingxenye eziyizigodi eziyindilinga eziphelile ezishisayo;

HFRHS= isikwele esiphelile esishisayo noma izingxenye ezingenalutho eziwunxande;

HFEHS= izingxenye eziyizimbobo eziyiziyingi eziphelile ezishisayo.

Umjikelezo: Ububanzi bangaphandle bufika ku-2500 mm;

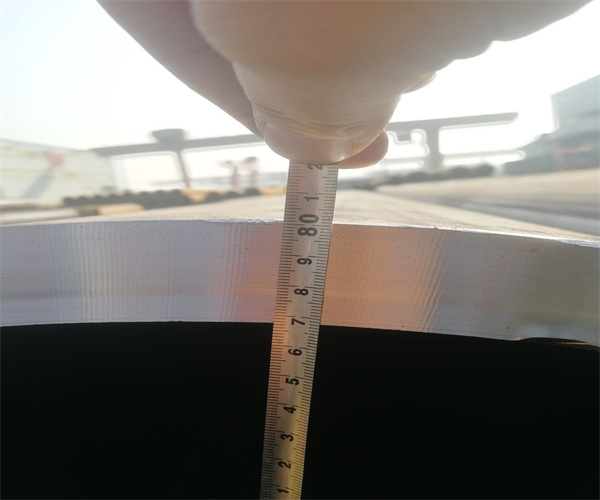

Ubukhulu bezindonga bufika ku-120 mm.

Yebo, ayikho indlela yokukhiqiza amashubhu alobu bukhulu nobukhulu bodonga uma kusetshenziswa inqubo ye-ERW yokushisela.

I-ERW ingakhiqiza amashubhu afinyelela ku-660mm anogqinsi oluyi-20mm.

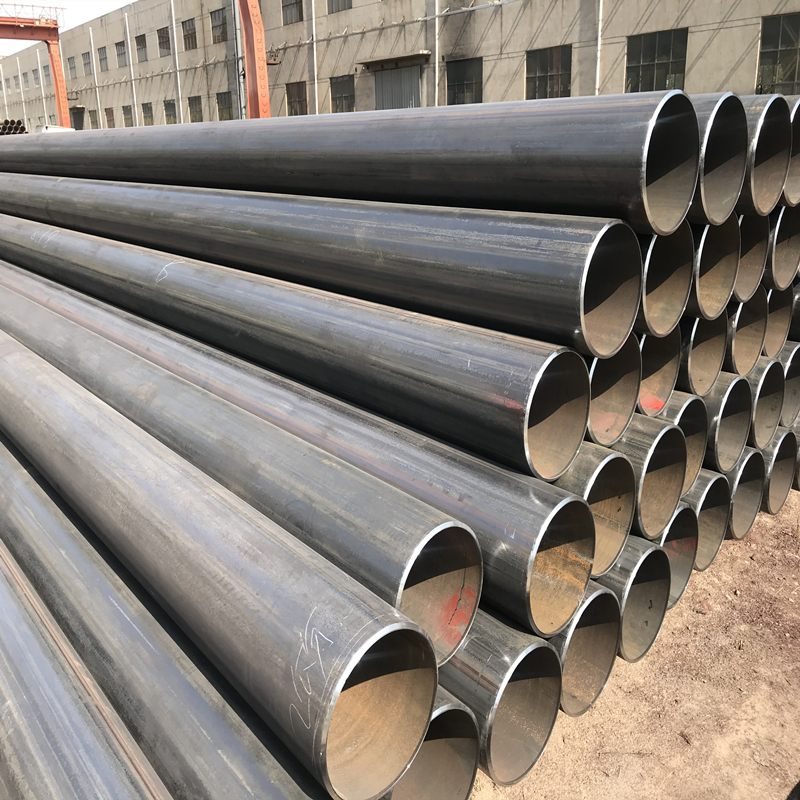

Insimbi ingakhiqizwa ngokusebenzisa aingenamthungo noma i-weldinginqubo.

Phakathi kweizinqubo zokushisela, izindlela ze-welding ezivamile zihlanganisaERW(ukushisela ukumelana nogesi) kanyeSAW(i-arc welding engaphansi kwamanzi).

Phakathi kokunye,ERWkuyindlela yokushisela ehlanganisa izingxenye zensimbi ngokushisa okuqinile nokucindezela. Le nqubo isetshenziswa ezinhlobonhlobo zezinto kanye nobukhulu futhi yenza inqubo yokushisela isebenze kahle.

SAW, ngakolunye uhlangothi, iyindlela yokushisela esebenzisa i-granular flux ukumboza i-arc, ehlinzeka ngokungena okujulile kanye nekhwalithi engcono yokushisela futhi ifaneleka ngokukhethekile ukushisela amapuleti awugqinsi.

Okulandelayo, inqubo ye-ERW, okuyindlela yokukhiqiza esebenza kahle kakhulu esetshenziswa kabanzi ukukhiqiza inqwaba yamashubhu ensimbi namaphrofayili.

Kumele kuqashelwe ukuthi ezigabeni ezingenalutho ezingenalutho kanye nezinhlamvu ezincane ezenziwe ngenqubo yokushisela, ukulungisa ama-welds akuvunyelwe ngaphandle kwe-arc welding engaphansi kwamanzi.

I-Quality JR, JO, J2 kanye ne-K2 - iphelile ukushisa,

Amandla amancane okukhiqiza wepayipi lensimbi le-S355J2H awalungisiwe, azoshintsha ngokuqina kodonga oluhlukile.

Ngokuqondile, amandla okukhiqiza we-S355J2H asethwe ngokwezinga lapho ubukhulu bodonga bungaphansi noma bulingana no-16mm, kodwa lapho ukushuba kodonga kukhula, amandla okukhiqiza azoncishiswa, ngakho-ke akuwona wonke amapayipi ensimbi we-S355J2H angafinyelela amandla amancane okukhiqiza angu-355MPa.

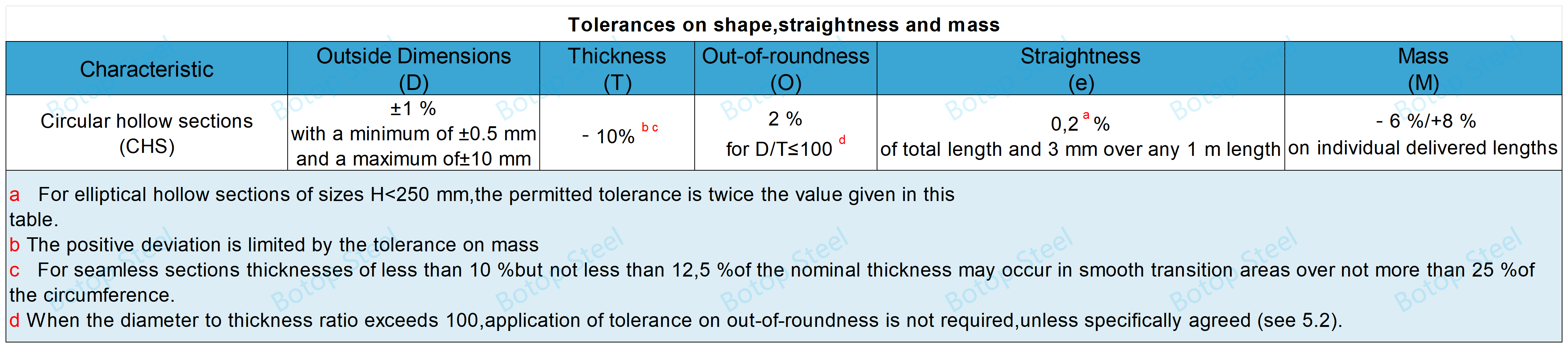

Ukubekezelela ukuma, ukuqondile kanye nesisindo

Ubude bokubekezelela

| Uhlobo lobudea | Ibanga lobude noma ubude L | Ukubekezelelana |

| Ubude obungahleliwe | 4000≤L≤16000 ngebanga elingu-2000 into ngayinye ye-oda | U-10 % wezigaba ezinikeziwe ungase ube ngaphansi kwenani eliphansi lebanga eli-odiwe kodwa ungabi mfushane kuno-75 % wobude obuncane bebanga |

| Ubude obulinganiselwe | 4000≤L≤16000 | ±500 mmb |

| Ubude obuqondile | 2000≤L≤6000 | 0 - +10mm |

| 6000c | 0 - +15mm | |

| aUmkhiqizi uzosungula ngesikhathi sophenyo futhi ahlele uhlobo lobude obudingekayo kanye nebanga lobude noma ubude. bU-Otion 21 ukubekezelela kubude be-annrevimata ngu-0 - +150mm cUbude obujwayelekile obukhona buyi-6 m no-12 m. | ||

Ipayipi lensimbi le-S355J2H liyipayipi lensimbi lesakhiwo esinamandla aphezulu elinokusebenza okuhle kokushisela kanye nokuqina komthelela wezinga lokushisa eliphansi, ngakho linokusetshenziswa okubanzi emikhakheni yezimboni eziningana.

1. Ukwakha: isetshenziswa kumabhuloho, emibhoshongweni, ezakhiweni zefreyimu, ezokuthutha zikaloliwe, imigwaqo engaphansi komhlaba, amafreyimu ophahla, amaphaneli odonga, nezinye izakhiwo.

2. Uhlelo lwamapayipi: Isetshenziswa njengamapayipi okuthutha uketshezi, ikakhulukazi ezikhathini lapho kudingeka amandla aphezulu kanye nokumelana nengcindezi.

3. Ubunjiniyela basolwandle nasogwini: isetshenziswa ezakhiweni zemikhumbi, izinkundla zasolwandle, nezinye izakhiwo zobunjiniyela basolwandle.

4. Imboni yamandla: esetshenziswa ezindaweni zamandla njengemibhoshongo yamandla omoya, izinkundla zokumba uwoyela, namapayipi.

5. Imikhumbi yokucindezela: isetshenziswa ekwenzeni imikhumbi yokucindezela ngokuhambisana nezidingo ezithile zokushisela kanye nokwelashwa kokushisa.

6. Imboni yezimayini: isetshenziselwa izingxenye zesakhiwo sezakhiwo ezisekela imayini, amasistimu okuthutha, kanye nemishini yokucubungula insimbi.

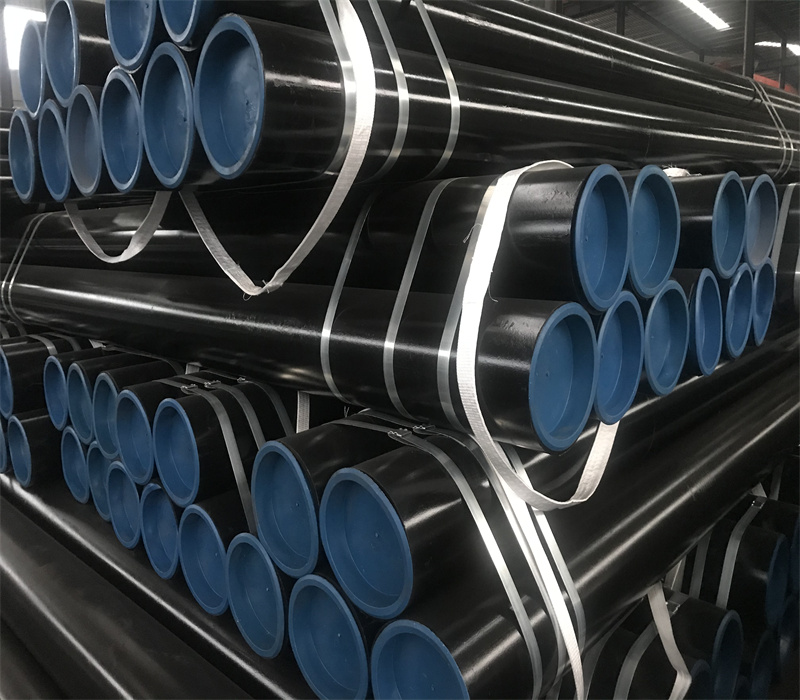

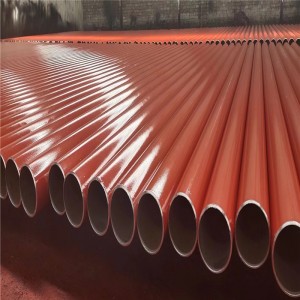

Ipayipi elingenalutho noma i-Black / Varnish enamathela (okwenziwe ngokwezifiso);

ngama-bundle noma ngokuxekethile;

Zombili ziphela ngabavikeli bokugcina;

Isiphetho esingenalutho, isiphetho se-bevel(2"nangaphezulu eneziphetho ze-bevel, idigri: 30~35°), intambo futhi ihlanganiswe;

Ukumaka.