Isinyathelo 370iyibanga lezinga elijwayelekile laseJapane i-JIS G 3456 lamapayipi ensimbi ye-carbon, esetshenziselwa amapayipi okucindezela ezindaweni ezinamazinga okushisa angaphezu kuka-350°C.Kungaba amapayipi angenamthungo noma ashiselwe kusetshenziswa inqubo yokushisela ukumelana nogesi (ERW).Izakhiwo zemishini zezinto ze-STPT 370 zingamandla amancane okubamba ama-MPa angama-370 kanye namandla amancane okukhiqiza angama-215 MPa.

Uma ufuna umkhiqizi kanye nomphakeli wamapayipi ensimbi ahlangabezana nezinga le-JIS G 3456, khona-ke singazakwethu omfunayo.Xhumana nathi namuhla futhi sizokujabulela ukukusiza!

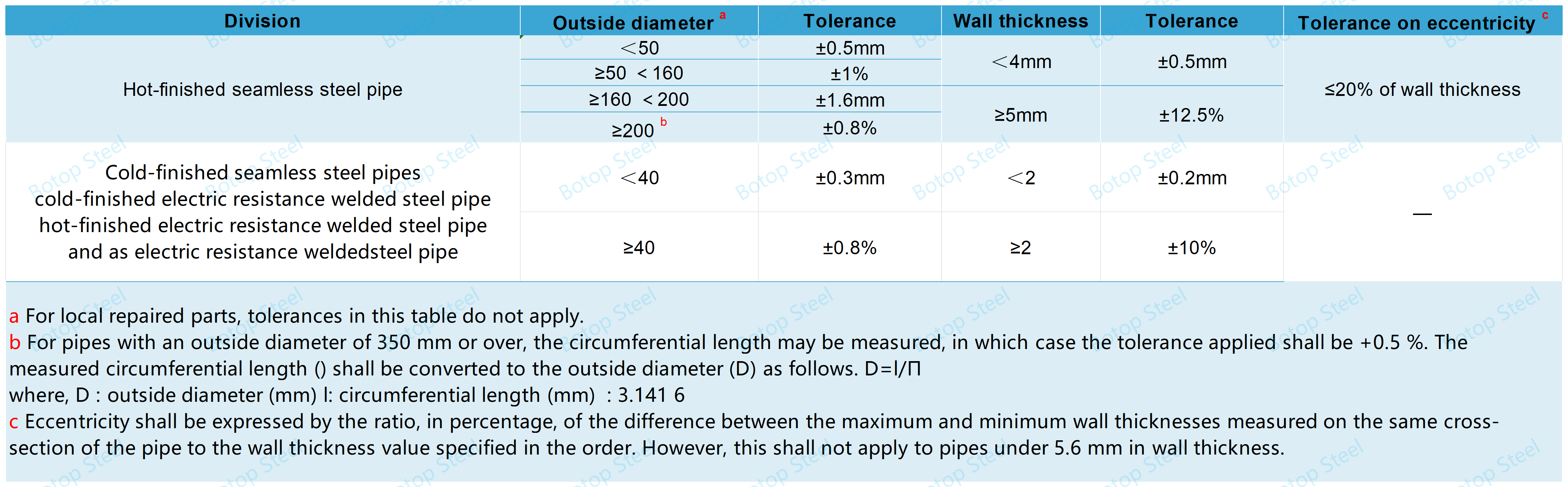

Ifanele ububanzi bangaphandle 10.5 mm - 660.4 mm (6A - 650A) (1/8B - 26B).

U-A no-B kuyizindlela ezimbili zokuveza ububanzi obujwayelekile ngokwendinganiso yesiJapane.Ngokuqondile, u-A uhambisana ne-DN, kuyilapho u-B ehambisana ne-NPS.

I-JIS G 3456 STPT 370 ingakhiqizwa kusetshenziswa iengenamthungoinqubo yokukhiqiza noma iukushisela ukumelana nogesi(ERW) inqubo.

Inqubo yokukhiqiza iphinde ihambisane nezindlela ezihlukene zokuqeda ukubhekana nezimo ezihlukene zokusetshenziswa.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | |

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | |

| I-JIS G 3456 STPT370 | I-Seamless: S | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C |

| Ukumelana nogesi okushiselwe: E I-Butt eshiselwe: B | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C Njengoba ukumelana kukagesi kushiselwe: G | |

I-STPT 370 kufanele iphathwe ngokushisa.

1. Ipayipi lensimbi elingenamthungo eliqediwe ngokushisa: Njengoba lakhiwe I-annealing enezinga lokushisa eliphansi noma elijwayelekile lingasetshenziswa njengoba kudingekile;

2. Ipayipi lensimbi elingenamthungo eliqedwe ngokubanda: I-annealing enezinga lokushisa eliphansi noma ukujwayelekile;

3. Ukumelana nogesi okuphothuliwe okushisa okushiselwe ipayipi lensimbi elishiselwe: Njengoba lakhiwe I-annealing yezinga lokushisa eliphansi noma evamile ingasetshenziswa njengoba kudingekile;

4. Ukumelana nogesi okuqediwe okubandayo okushiselwe futhi Njengokumelana nogesi okushiselwe ipayipi lensimbi: Ukushisa okuphansi kwe-annealing noma ukujwayelekile.

| Uphawu lwebanga | C | Si | Mn | P | S |

| I-JIS G 3456 STPT370 | 0.25% ubuningi | 0.10 - 0.35% | 0.30 - 0.90% | 0.035% ubuningi | 0.035% ubuningi |

Uma kunesidingo, izakhi ezengeziwe zingangezwa.

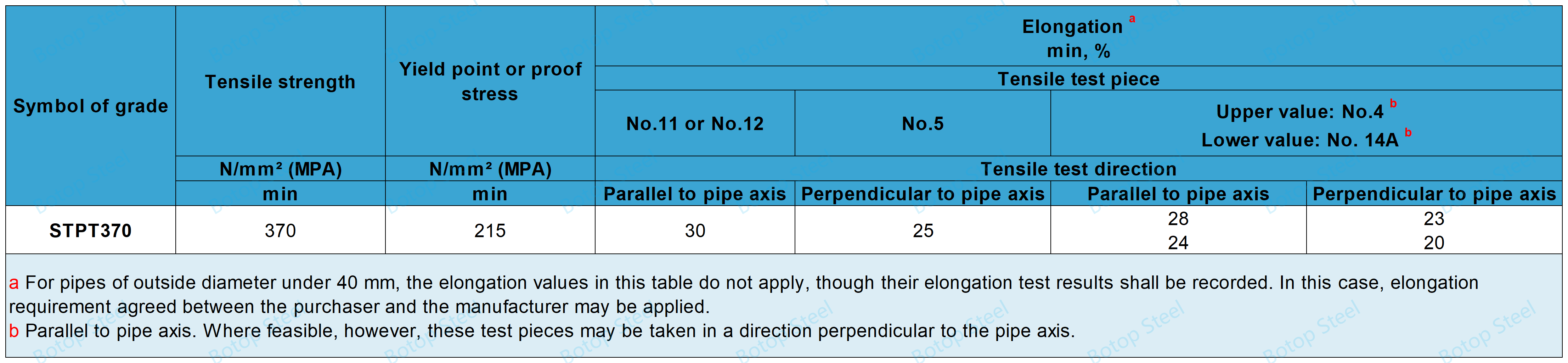

Amandla Aqinile, Iphuzu Lokuvuza noma Ingcindezi Yobufakazi, Nokwelula

Impahla Ephansi

Ifanele amapayipi ububanzi obungaphandle obungaphezu kuka-60.5 mm.

Isifanekiso sibekwe phakathi kwamapulatifomu amabili futhi sicaba.Lapho ibanga eliphakathi kwamapuleti amabili lifinyelelaH, akukho mifantu ebusweni besampula yepayipi lensimbi.

H = 1.08t/(0.08+ t/D)

н: ibanga phakathi kwamapuleti (mm);

t: ukujiya kodonga lwepayipi (mm);

D: ububanzi obungaphandle bepayipi (mm);

Ukugoba

Ifanele amapayipi ensimbi ane-diameter yangaphandle engu-60.5 mm noma ngaphansi.

Lapho isampula igobile izungeze i-mandrel ibe yi-radius yangaphakathi izikhathi ezingu-6 ububanzi obungaphandle bepayipi, isampula iyahlolwa futhi akukho mifantu etholakalayo.

| Ukujiya kodonga okuzisholo | Inombolo yeshejuli : Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Lapho ububanzi obungaphandle nokuqina kodonga lwepayipi lensimbi kungewona osayizi abajwayelekile, izindlela ezilandelayo zingasetshenziswa ukucacisa ibanga elifanele lokucaciswa:

Okokuqala, khetha ibanga elijwayelekile leshejuli eliseduze nosayizi ongajwayelekile;okwesibili, nquma ibanga elicacisiwe ngokubala inani elingu-P.

Kuzo zombili izindlela, inani elincane kufanele likhethwe njengebanga lokugcina lokucaciswa.

P = 2st/D

P: ingcindezi yokuhlola (MPa);

t: ukujiya kodonga lwepayipi (mm);

D: ububanzi obungaphandle bepayipi (mm);

s: 60% yenani elincane elishiwo lephoyinti lesivuno noma ingcindezi yobufakazi;

Izindlela ezijwayelekile zokuhlola ezingabhubhisi zifaka ukuhlolwa kwe-ultrasonic (UT) kanye nokuhlolwa kwamanje kwe-eddy (ET).

Lapho wenza ukuhlola kwe-ultrasonic, ireferensi kufanele yenziwe ku-JIS G 0582, futhi lapho umphumela wokuhlola ulingana noma udlula indinganiso yereferensi yekilasi le-UD, kuthathwa njengokuhluleka.

Lapho wenza ukuhlola kwamanje kwe-eddy, ireferensi kufanele yenziwe ku-JIS G 0583. Uma umphumela wokuhlola ulingana noma weqa izinga eliyireferensi lesigaba se-EY, kuthathwa njengokungafaneleki.

Ubukhulu obujwayelekile nobukhulu bodonga kububanzi obungu-10.5 mm kuya ku-660.4 mm bubhalwe ku-JIS G 3456, okuyi-steel ipayipi isisindo ithebula kanye nohlelo oluhambisanayo No.

Isheduli 10,Isheduli 20,Isheduli 30,Isheduli 40,Isheduli 60,Isheduli 80,Isheduli 100,Isheduli 120,Isheduli 140,Isheduli 160.

Kusukela yasungulwa ngo-2014,Insimbi ye-Botopisibe ngumphakeli ohamba phambili wepayipi lensimbi ye-carbon eNyakatho yeChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezixazululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Sicela uzizwe ukhululekile ukusithinta futhi sizokujabulela ukuphendula imibuzo yakho.