I-JIS G 3461 ipayipi yensimbiiyipayipi lensimbi engenamthungo (i-SMLS) noma i-electric-resistance-welded (ERW), ikakhulukazi esetshenziswa kumabhayela nezishintshisi zokushisa izinhlelo zokusebenza ezifana nokubona ukushintshana kokushisa phakathi kwangaphakathi nangaphandle kweshubhu.

I-STB340iyizinga lepayipi lensimbi ye-carbon kuzinga le-JIS G 3461.Inamandla amancane okudonsa angu-340 MPa kanye namandla amancane okukhiqiza angu-175 MPa.

Iwumsebenzi okhethwayo wezinhlelo zokusebenza eziningi zezimboni ngenxa yamandla ayo aphezulu, ukuzinza okuhle kokushisa, ukuguquguquka, ukumelana nokugqwala okuhlobene, ukusebenza kahle kwezindleko, kanye nokucutshungulwa okuhle.

I-JIS G 3461inamabanga amathathu.STB340, STB410, STB510.

I-STB340: Amandla amancane okudonsa: 340 MPa;Amandla esivuno esincane: 175 MPa.

I-STB410: Amandla Okuqina Okuncane: 410 MPa;Amandla Okukhiqiza Ancane: 255 MPa.

STB510:Amandla Okuqina Okuncane: 510 MPa;Amandla Esivuno Esincane: 295 MPa.

Eqinisweni, akunzima ukuthola ukuthi ibanga le-JIS G 3461 lihlukaniswa ngokusho kwamandla amancane wepayipi lensimbi.

Njengoba izinga lezinto ezibonakalayo landa, amandla ayo okudonsa kanye nesivuno akhuphuka ngokufanele, okuvumela impahla ukuthi imelane nemithwalo ephakeme kanye nezingcindezi zezindawo zokusebenza ezinzima kakhulu.

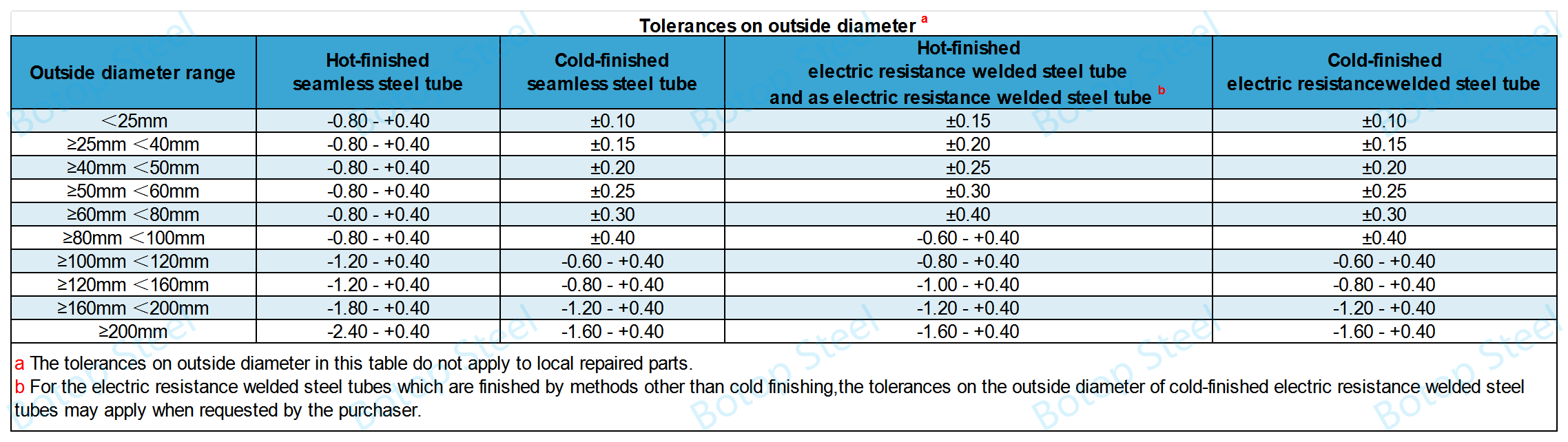

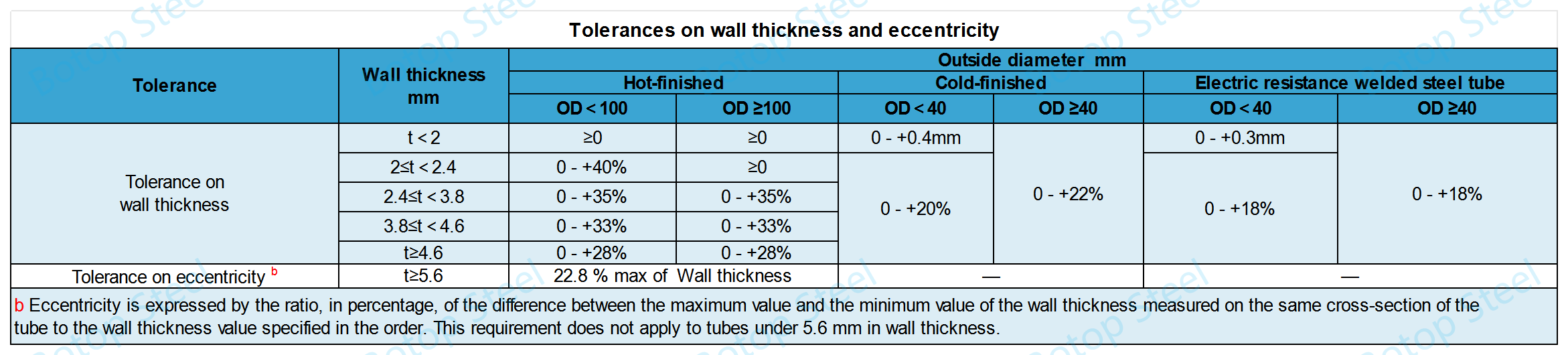

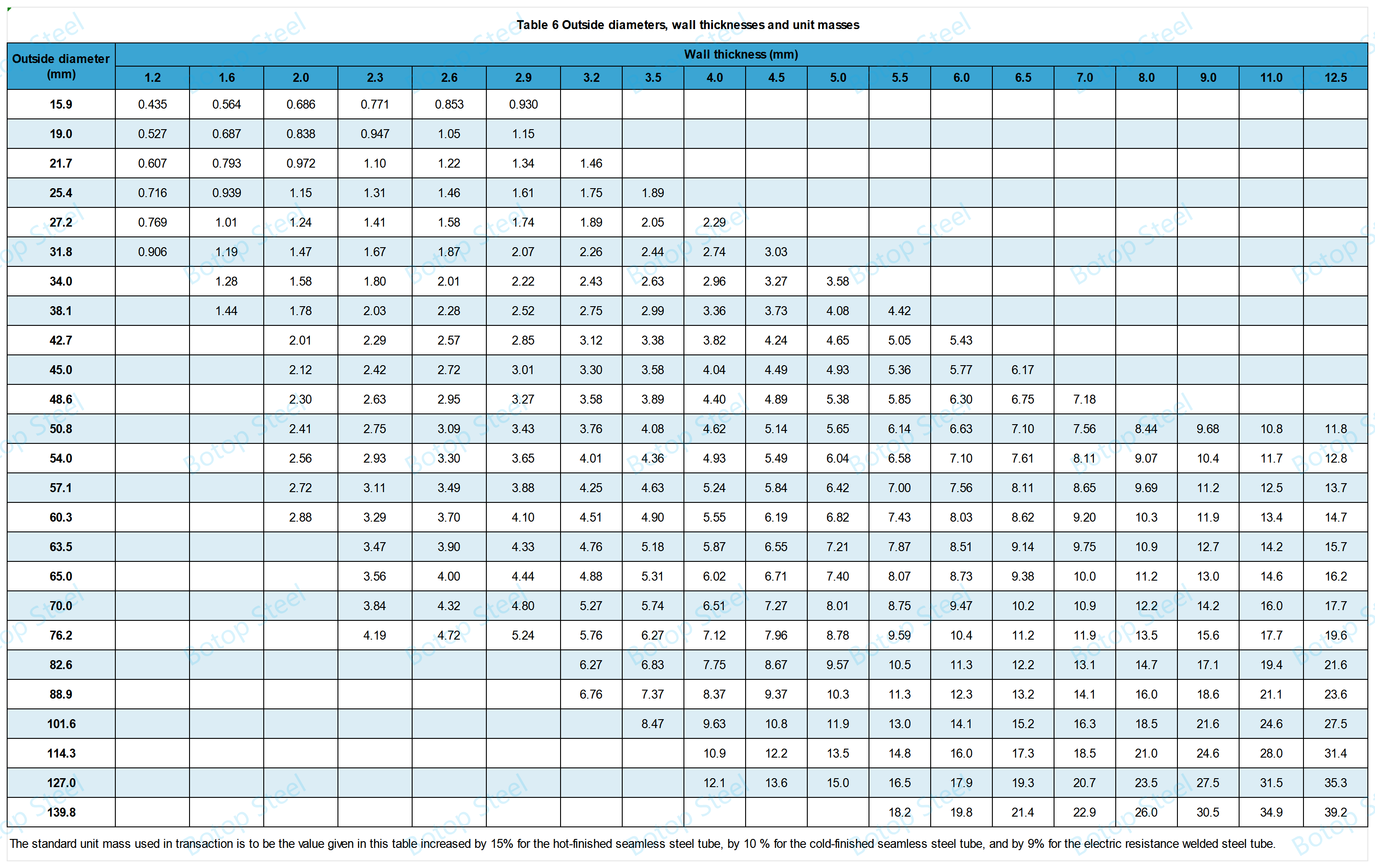

Ububanzi bangaphandle buyi-15.9-139.8mm.

Izicelo kuma-boilers kanye nezishintshisi zokushisa ngokuvamile azidingi ububanzi obukhulu kakhulu beshubhu.Amadayimitha amashubhu amancane akhulisa ukusebenza kahle kokushisa ngoba indawo engaphezulu nesilinganiso sevolumu yokudlulisa ukushisa iphezulu.Lokhu kusiza ukudlulisa amandla okushisa ngokushesha nangempumelelo kakhudlwana.

Amashubhu azokwenziwa kusuka ku-insimbi ebulewe.

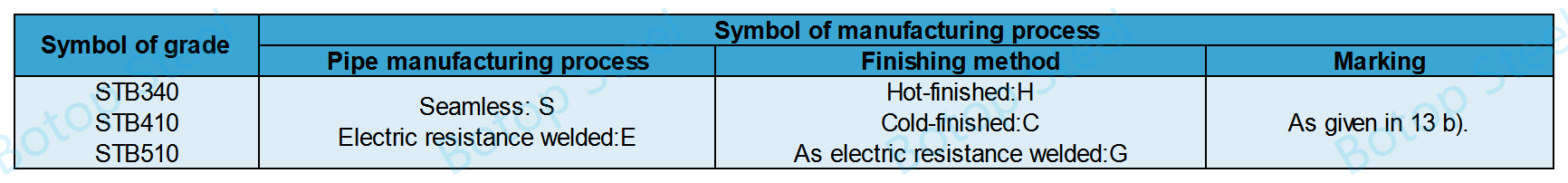

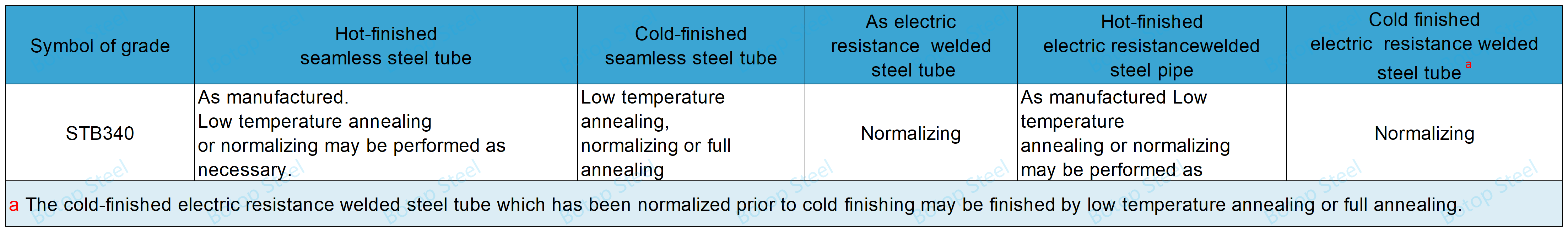

Inhlanganisela yezindlela zokukhiqiza amapayipi nezindlela zokuqeda.

Ngokuningiliziwe, zingahlukaniswa ngale ndlela elandelayo:

Ishubhu yensimbi engenamthungo eqedwe ukushisa: SH

Ishubhu yensimbi engenamthungo eqediwe ebandayo: SC

Njengoba ukumelana kagesi ashiselwe steel tube: EG

Ishubhu lensimbi elishiselwe okushisa kagesi eliqedwe ukushisa: EH

Ishubhu yensimbi eshiselwe ukuqina kagesi eqediwe ebandayo: EC

Nakhu ukugeleza kokukhiqiza kwe-Hot-finished seamless.

Ngenqubo yokukhiqiza engenamthungo, ingahlukaniswa cishe ibe amapayipi ensimbi angenamthungo anobubanzi bangaphandle obungaphezu kuka-30mm kusetshenziswa ukukhiqizwa kokugcina okushisayo, kanye no-30mm kusetshenziswa ukukhiqizwa kokuqeda okubandayo.

Izindlela zokuhlaziya ukushisa kufanele zihambisane namazinga aku-JIS G 0320.

Izakhi ze-alloying ngaphandle kwalezo zingase zengezwe ukuze kutholwe izakhiwo ezithile.

Lapho umkhiqizo uhlaziywa, amanani okuchezuka okwakheka kwamakhemikhali epayipi azohlangabezana nezidingo zeThebula 3 le-JIS G 0321 lamapayipi ensimbi angenamthungo kanye neThebula 2 le-JIS G 0321 lamapayipi ensimbi anensimbi eqinile.

| Uphawu lwebanga | C (Ikhabhoni) | I-Si (Silicon) | Mn (Manganese) | I-P (Phosphorus) | S (Sulfur) |

| ubuningi | ubuningi | ubuningi | ubuningi | ||

| I-STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Umthengi angase acacise inani le-Si elizoba ku-0.10 % kuya ku-0.35%. | |||||

Ukwakheka kwamakhemikhali kwe-STB340 kuklanyelwe ukuqinisekisa izakhiwo ezanele zemishini kanye nokusebenziseka kalula ngenkathi kwenziwa izinto ezisetshenziswayo zifanelekele ukushisela kanye nezinhlelo zokusebenza ezindaweni ezishisa kakhulu.

| Uphawu lwebanga | Amandla okuqina a | Iphuzu lesivuno noma ingcindezi yobufakazi | Elongation min, % | ||

| Ububanzi bangaphandle | |||||

| <10 mm | ≥10mm<20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Isiqephu sokuhlola | |||

| No.11 | No.11 | No.11/No.12 | |||

| imiz | imiz | Isiqondiso sokuhlolwa kwe-tensile | |||

| Ihambisana ne-axis yeshubhu | Ihambisana ne-axis yeshubhu | Ihambisana ne-axis yeshubhu | |||

| I-STB340 | 340 | 175 | 27 | 30 | 35 |

Qaphela: kuphela kumashubhu okushintsha ukushisa, umthengi angase, lapho kunesidingo, acacise inani eliphezulu lamandla aqinile.Kulesi simo, inani eliphezulu lamandla e-tensile lizoba inani elitholwe ngokwengeza u-120 N/mm² kunani elikuleli thebula.

Uma ukuhlolwa okuqinile kwenziwa esiqeshini sokuhlola No. 12 seshubhu elingaphansi kuka-8 mm ubukhulu bodonga.

| Uphawu lwebanga | Ucezu lokuhlola olusetshenzisiwe | Ukwelula iminithi, % | ||||||

| Ukujiya kodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7<8 mm | ||

| I-STB340 | No. 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Amanani obude kuleli thebula abalwa ngokukhipha u-1.5 % enanini lokwelula elinikezwe kuThebula 4 ngokuncipha ngakunye okungu-1 mm kogqinsi lwamashubhu ukusuka ku-8 mm, futhi ngokusondeza umphumela ube inombolo ephelele ngokoMthetho A we-JIS Z 8401.

Indlela yokuhlola izohambisana ne-JIS Z 2245. Ukuqina kocezu lokuhlola kufanele kukalwe endaweni yalo ephambanayo noma endaweni yangaphakathi ezindaweni ezintathu ngocezu ngalunye lokuhlola.

| Uphawu lwebanga | Ukuqina kwe-Rockwell (inani elisho inani lezikhundla ezintathu) I-HRBW |

| I-STB340 | 77 max. |

| I-STB410 | 79 max. |

| I-STB510 | 92 max. |

Lokhu kuhlolwa akufanele kwenziwe kumashubhu odongeni obukhulu obungu-2 mm noma ngaphansi.Ngokumelana nogesi amashubhu ensimbi ashiselwe, ukuhlolwa kuzokwenziwa engxenyeni ngaphandle kwe-weld noma izindawo ezithintekile ukushisa.

Ayisebenzi kumashubhu ensimbi angenamthungo.

Indlela Yokuhlola Beka isifanekiso emshinini bese usicaba kuze kube yilapho ibanga phakathi kwamapulatifomu amabili lifinyelela inani elishiwo H. Bese uhlola isifanekiso ukuze uthole imifantu.

Lapho kuhlolwa ukumelana okubalulekile okushiselwe ipayipi, umugqa phakathi kwe-weld kanye nendawo yepayipi i-perpendicular isiqondiso sokucindezela.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwamapuleti (mm)

t: ukuqina kodonga lweshubhu (mm)

D: ngaphandle kobubanzi beshubhu (mm)

е:njalo kuchazwe ebangeni ngalinye le-tube.I-STB340: 0.09;I-STB410: 0,08;I-STB510: 0.07.

Ayisebenzi kumashubhu ensimbi angenamthungo.

Uhlangothi olulodwa lwesifanekiso luvutha ekamelweni lokushisa (5°C kuya ku-35°C) ngethuluzi eliyindilinga nge-engeli engu-60° kuze kube yilapho ububanzi obungaphandle bukhuliswa isici esingu-1.2 futhi buhlolelwa imifantu.

Lesi sidingo sisebenza futhi kumashubhu anobubanzi obungaphandle obungaphezu kuka-101.6 mm.

Ukuhlolwa kokucaba okuphambene kungase kushiywe lapho kwenziwa ukuhlolwa kokuvuleka.

Sika ucezu lokuhlola oluyi-100 mm ukusuka kolunye uhlangothi lwepayipi bese usika ucezu lokuhlola lube uhhafu wama-90° ukusuka kumugqa wokushisela ezinhlangothini zombili zesiyingi, uthathe uhhafu oqukethe i-weld njengocezu lokuhlola.

Emazingeni okushisa asekamelweni (5 °C kuya ku-35 °C) yenza isifanekiso sibe sicaba epuleti elineshisela phezulu bese uhlola isifanekiso ukuze uthole imifantu endaweni yokushisela.

Wonke amapayipi ensimbi adinga ukuhlolwa nge-hydrostatic noma ngokungabhubhisiukuqinisekisa ikhwalithi nokuphepha kwepayipi kanye nokuhlangabezana nezindinganiso zokusetshenziswa.

Ukuhlolwa kweHydraulic

Bamba ingaphakathi lepayipi okungenani ingcindezi encane noma ephakeme engu-P (P max 10 MPa) okungenani imizuzwana engu-5, bese uhlola ukuthi ipayipi ingakwazi ukumelana nokucindezela ngaphandle kokuvuza.

P=2st/D

P: ingcindezi yokuhlola (MPa)

t: ukujiya kodonga lweshubhu (mm)

D: Ububanzi obungaphandle beshubhu (mm)

s: 60 % yenani elincane elishiwo lephoyinti lesivuno noma ingcindezi yobufakazi.

Ukuhlolwa Okungonakali

Ukuhlolwa okungabhubhisi kwamashubhu ensimbi kufanele kwenziwe nguukuhlolwa kwamanje kwe-ultrasonic noma eddy.

Ngobai-ultrasonicizici zokuhlola, isignali evela kusampula yereferensi equkethe izinga eliyisethenjwa lekilasi le-UD njengoba licaciswe kuI-JIS G 0582izobhekwa njengezinga le-alamu futhi izoba nesignali eyisisekelo elingana noma enkulu kuneleveli ye-alamu.

Ukuzwela okujwayelekile kokutholwa kwe-eddy currentukuhlolwa kuzoba yisigaba se-EU, i-EV, i-EW, noma i-EX ecaciswe kusoI-JIS G 0583, futhi akumele kube namasiginali alingana noma amakhulu kunamasiginali asuka kusampula yesithenjwa equkethe izinga eliyisethenjwa lesigaba esishiwo.

Ukuze uthole okwengeziweAmashadi Wesisindo Sombhobho kanye namashejuli wamapayipingaphakathi kwezinga, ungachofoza.

Thatha indlela efanele yokulebula ulwazi olulandelayo.

a) Uphawu lwebanga;

b) Uphawu lwendlela yokukhiqiza;

c) Ubukhulu: ububanzi obungaphandle nokuqina kodonga;

d) Igama lomkhiqizi noma uhlobo oluhlonzayo.

Lapho ukumaka eshubhuni ngalinye kunzima ngenxa yobukhulu balo obungaphandle obuncane noma lapho umthengi ecelwa kanjalo, ukumaka kungase kunikezwe kunqwaba yamashubhu ngendlela efanelekile.

I-STB340 ivame ukusetshenziswa ekwenzeni amapayipi amanzi kanye namapayipi ophayiphu kuma-boilers ahlukahlukene ezimboni, ikakhulukazi ezindaweni lapho kudingeka ukumelana nokushisa okuphezulu nezingcindezi.

Ngenxa yezakhiwo zayo ezinhle zokushisa ukushisa, kufanelekile futhi ekwenzeni amapayipi okushintshanisa ukushisa, okusiza ukudlulisa ukushisa ngokuphumelelayo phakathi kwemidiya ehlukene.

Ingase futhi isetshenziselwe ukuthutha izinga lokushisa eliphezulu noma uketshezi olunomfutho ophezulu, njengesitimu noma amanzi ashisayo, futhi isetshenziswa kakhulu kumakhemikhali, amandla kagesi, nezimboni zokukhiqiza imishini.

I-ASTM A106 Ibanga A

I-DIN 17175 St35.8

I-DIN 1629 St37.0

BS 3059-1 Ibanga 320

I-EN 10216-1 P235GH

GB 3087 20#

I-GB 5310 20G

Nakuba lezi zinto zingase zifane mayelana nokwakheka kwamakhemikhali kanye nezakhiwo eziyisisekelo, izinqubo ezithile zokwelashwa kokushisa kanye nomshini womshini zingathinta izakhiwo zomkhiqizo wokugcina.

Ngakho-ke, ukuqhathanisa okuningiliziwe nokuhlolwa okufanele kufanele kwenziwe lapho kukhethwa izinto ezilinganayo zezinhlelo zokusebenza ezingokoqobo.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.