I-JIS G 3444: Amashubhu ensimbi ekhabhoni esakhiwo esijwayelekile.

Icacisa izimfuneko zamapayipi ensimbi ekhabhoni asetshenziswa kubunjiniyela bomphakathi kanye nokwakhiwa, njengemibhoshongo yensimbi, isikafula, izinqwaba zesisekelo, izinqwaba zesisekelo, nezinqwaba zokunqanda ukushelela.

I-STK 400ipayipi lensimbi ingelinye lamabanga ajwayeleke kakhulu, elinezici zemishini ze-aubuncane be-tensile amandla angama-400 MPakanye aamandla amancane esivuno angama-235 MPa. Amandla ayo esakhiwo esihle nokuqinayenze ilungele izinhlelo zokusebenza eziningi ezahlukene.

Ngokusho kwamandla amancane wepayipi lensimbi ihlukaniswe ngamakilasi ama-5, okuyilawa:

I-STK 290, STK 400, STK 490, STK 500, STK 540.

Inhloso evamile Ububanzi bangaphandle: 21.7-1016.0mm;

Izinqwaba zesisekelo nezinqwaba zokucindezelwa kokudilika komhlaba OD: ngaphansi kuka-318.5mm.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | |

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | |

| I-STK 290 | I-Seamless: S Ukumelana nogesi okushiselwe: E I-Butt eshiselwe: B I-arc eshiselwe okuzenzakalelayo: A | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C Njengoba ukumelana kukagesi kushiselwe: G |

| I-STK 400 | ||

| I-STK 490 | ||

| I-STK 500 | ||

| Idatha ye-STK540 | ||

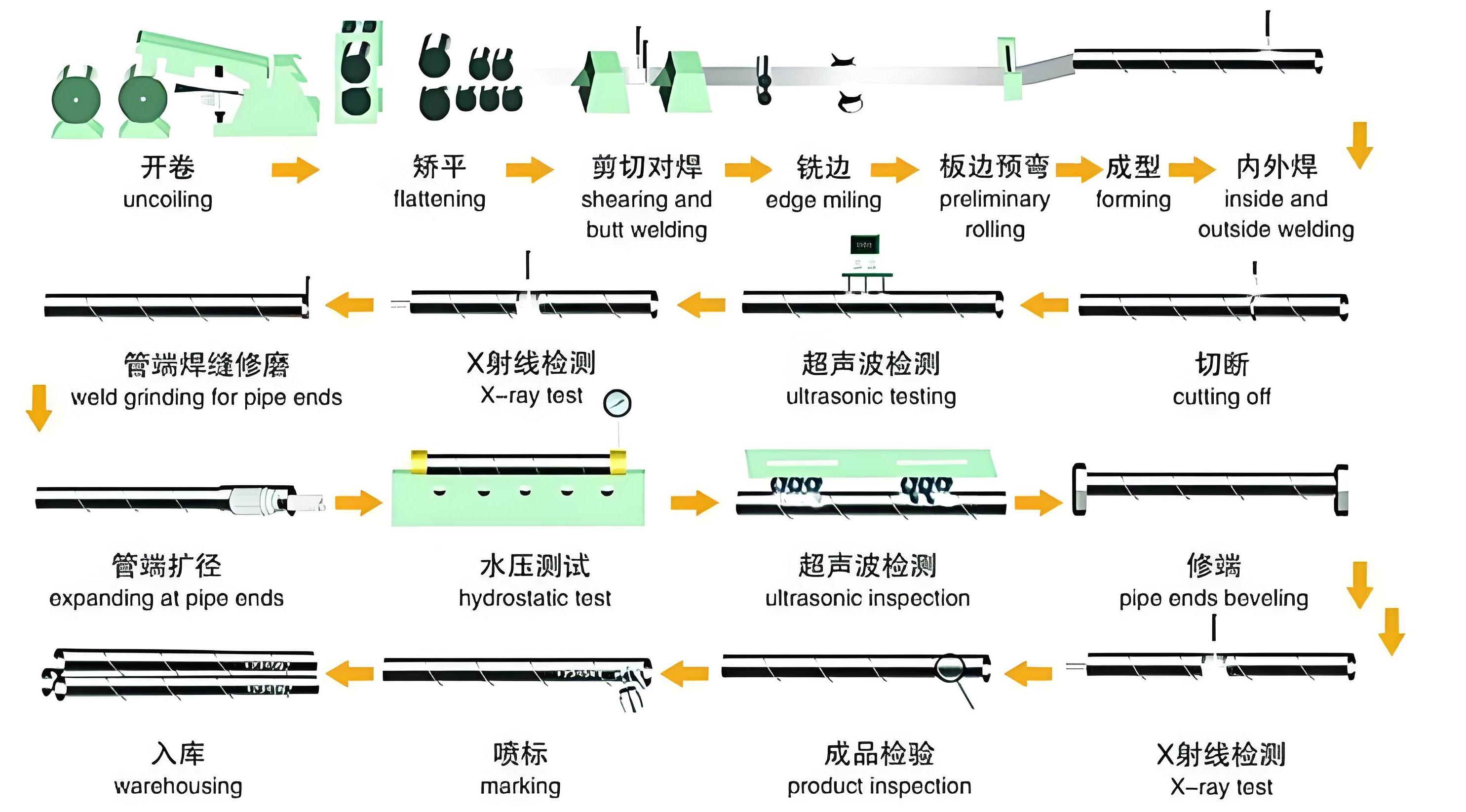

Amashubhu azokwenziwa ngenhlanganisela yendlela yokukhiqiza ishubhu kanye nendlela yokuqeda ekhonjisiwe.

Ngokuqondile, zingahlukaniswa ngezinhlobo eziyisikhombisa ezilandelayo, ngakho-ke khetha uhlobo olufanele ngokuya ngezidingo ezahlukahlukene:

1) Ishubhu yensimbi engenamthungo ephelile ngokushisa: -SH

2) Ishubhu yensimbi engenamthungo epholile eqediwe: -SC

3) Njengoba ukumelana kagesi ashiselwe steel tube: -EG

I-4) I-Hot-finished kagesi ukumelana ne-welded steel tube: -EH

5) Ukumelana kukagesi okuqediwe okuphothuliwe okushiselwe ishubhu lensimbi: -EC

6) Amashubhu ensimbi anezinqe: -B

7) Amashubhu ensimbi ashiselwe i-arc: -A

| Ukwakheka Kwamakhemikhalia% | |||||

| Uphawu lwebanga | C (Ikhabhoni) | I-Si (Silicon) | Mn (Manganese) | I-P (Phosphorus) | S (Sulfur) |

| ubuningi | ubuningi | ubuningi | ubuningi | ||

| I-STK 400 | 0.25 | - | - | 0.040 | 0.040 |

| aIzakhi zengxubevange ezingafakiwe kuleli thebula nezinto eziboniswe ngo-“—” zingase zengezwe ngokudingekayo. | |||||

I-STK 400iyinsimbi enekhabhoni ephansi futhi inokushisela okuhle nokusebenza kahle kwezinhlelo zokusebenza zesakhiwo ezidinga ukushiselwa.Iphosphorus nesibabule kulawulwa emazingeni aphansi ukusiza ukugcina ukuqina okuphelele nokusebenza kwempahla.Nakuba amanani athile e-silicon ne-manganese enganikezwanga, angase alungiswe ngaphakathi kwemikhawulo evumelekile ukuze kuthuthukiswe izakhiwo zensimbi.

Amandla Okuqina kanye Nephuzu Lokukhipha noma Ingcindezi Yobufakazi

Amandla aqinile we-weld asebenza kumashubhu ashiselwe nge-arc othomathikhi.Kuyinqubo ye-SAW welding.

| Uphawu lwebanga | Amandla aqinile | Iphuzu lesivuno noma ingcindezi yobufakazi | Amandla aqinile ku-weld |

| N/mm² (MPA) | N/mm² (MPA) | N/mm² (MPA) | |

| imiz | imiz | imiz | |

| I-STK 400 | 400 | 235 | 400 |

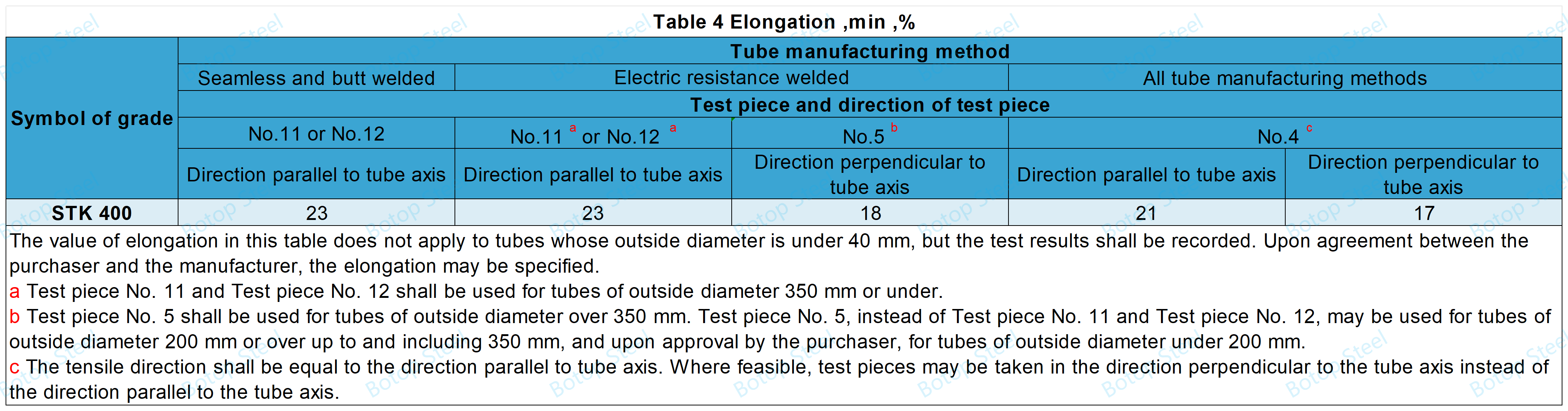

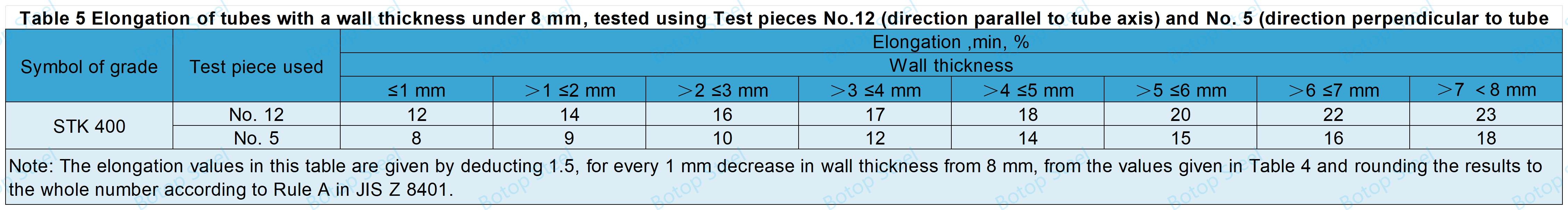

Ukwelulwa kwe-JIS G 3444

Ukwelulwa okuhambisana nendlela yokukhiqiza ishubhu kukhonjiswe kuThebula lesi-4.

Kodwa-ke, uma ukuhlolwa kwe-tensile kwenziwa ku-Test Piece No. 12 noma ku-Test Piece No.5 ethathwe eshubhuni elingaphansi kuka-8 mm ubukhulu bodonga, ubude kufanele buhambisane neThebula lesi-5.

Ezingeni lokushisa legumbi (5 °C kuya ku-35 °C), beka isifanekiso phakathi kwamapuleti amabili ayisicaba bese ucindezela ngokuqinile ukuze uwacabaze kuze kube ibanga elingu-H ≤ 2/3D phakathi kwamapuleti, bese uhlola ukuqhekeka kwesifanekiso.

Ezingeni lokushisa legumbi (5 °C ukuya ku-35 °C), goba isifanekiso sizungeze isilinda endaweni encane yokugoba engu-90° kanye nerediyasi yangaphakathi enkulu engekho ngaphezu kuka-6D bese uhlola isifanekiso ukuze uthole imifantu.

Ukuhlolwa kwe-Hydrostatic, ukuhlolwa okungangonakali kwamashisela, noma okunye ukuhlolwa kuzovunyelwana kusengaphambili ngezidingo ezifanele.

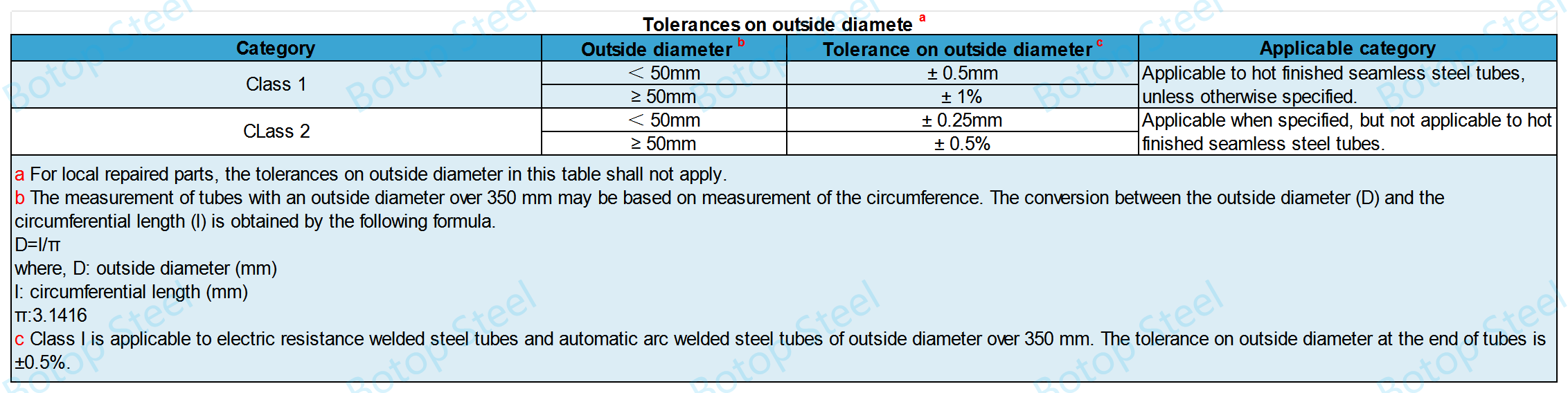

Ukubekezelelana Kwangaphandle Kobubanzi

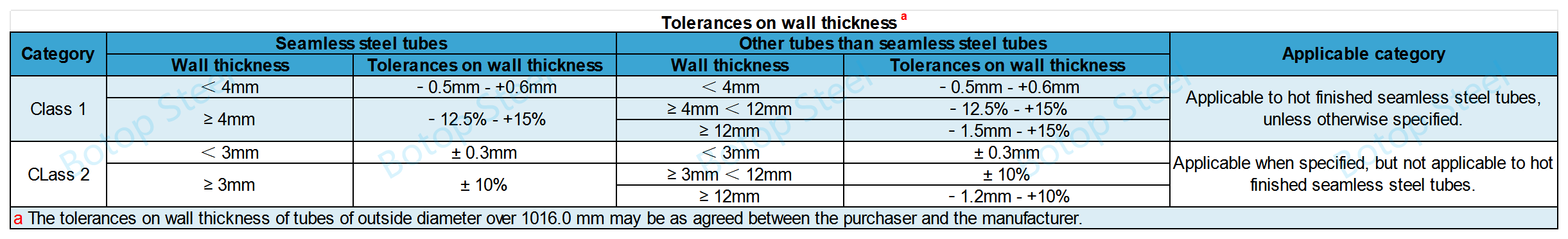

Ukubekezelela Ukuqina Kwezindonga

Ukubekezelela Ubude

Ubude ≥ ubude obushiwo

Indawo yangaphakathi nengaphandle yepayipi yensimbi izoba bushelelezi futhi ingabi namaphutha angalungile ekusebenziseni.

Ipayipi ngalinye lensimbi lizofakwa ilebula ngolwazi olulandelayo.

a)Uphawu lwebanga.

b)Uphawu lwendlela yokukhiqiza.

c)Ubukhulu.Ububanzi bangaphandle nokuqina kodonga kuzomakwa.

d)Igama lomkhiqizi noma isifinyezo.

Uma ukumaka eshubhuni kunzima ngenxa yokuthi ububanzi balo bangaphandle buncane noma uma umthengi ecelwe kanjalo, ukumaka kungase kunikezwe kunqwaba yamashubhu ngendlela efanelekile.

Izingubo zokunqanda ukugqwala ezifana ne-zinc-rich coatings, i-epoxy coatings, i-peint coatings, njll. ingasetshenziswa ezindaweni zangaphandle noma zangaphakathi.

I-STK 400 inikeza ibhalansi enhle yamandla nomnotho, iyenze ilungele amaphrojekthi amaningi wobunjiniyela nowokwakha.

Amashubhu ensimbi e-STK 400 avame ukusetshenziswa embonini yokwakha futhi afaneleka ngokukhethekile ukusetshenziswa njengezakhi zesakhiwo njengamakholomu, imishayo, noma amafreyimu ezakhiweni zezentengiselwano nezindawo zokuhlala.

Iphinde ifanele amabhuloho, izakhiwo zokusekela, namanye amaphrojekthi adinga amandla aphakathi nendawo nokuqina.

Ingase futhi isetshenziselwe ukwakha izinsimbi zokuqapha imigwaqo, izinhlaka zezimpawu zethrafikhi, nezinye izinsiza zomphakathi.

Ekwenziweni, i-STK 400 ingasetshenziselwa ukukhiqiza amafreyimu nezinhlaka zokusekela zemishini nemishini ngenxa yomthamo wayo omuhle wokuthwala nokusebenza.

Sicela uqaphele ukuthi nakuba lawa mazinga afana ekusetshenzisweni nasekusebenzeni, kungase kube nomehluko omncane ekwakhekeni kwamakhemikhali athile kanye namapharamitha athile ezakhiwo.

Lapho kufakwa izinto ezisetshenziswayo, izidingo ezithile zamazinga kufanele ziqhathaniswe ngokuningiliziwe ukuze kuqinisekiswe ukuthi izinto ezikhethiwe zizohlangabezana namazinga athile obuchwepheshe nezokuphepha ephrojekthi.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.