I-JIS G 3452iyindinganiso yaseJapane ecacisa ipayipi lensimbi elishiselwe ukuthutha isitimu, amanzi, uwoyela, igesi, umoya, njll. ngezingcindezi zokusebenza eziphansi uma kuqhathaniswa.I-JIS G 3452 iqukethe ibanga elilodwa kuphela, i-SGP, engenziwa nge-resistance welding (RW) noma i-butt welding.

Amapayipi ensimbi e-JIS G 3452 azokwenziwa kusetshenziswa inhlanganisela efanelekile yezindlela zokukhiqiza amapayipi nezindlela zokuqeda.

| Uphawu yebanga | Uphawu lwenqubo yokukhiqiza | Ukuhlukaniswa kwe-zinc-coating | |

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | ||

| I-SGP | Ukumelana nogesi okushiselwe: E I-Butt eshiselwe: B | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C Njengoba ukumelana kukagesi kushiselwe: G | Amapayipi amnyama: amapayipi anganikezwanga i-zinc-coating Amapayipi amhlophe: amapayipi anikezwe i-zinc-coating |

Amapayipi ngokuvamile azolethwa njengoba ekhiqiziwe.Amapayipi aqedwe ngokubanda azokhishwa ngemuva kokukhiqizwa.

Uma ipayipi lenziwa yi-ERW, amashisela angaphakathi nangaphandle kwepayipi azosuswa ukuze kutholwe i-weld ebushelelezi eduze kwe-contour yepayipi.

Uma kunqunyelwe ngenxa yobubanzi bepayipi noma okokusebenza, njll., i-weld endaweni engaphakathi ingase ingasuswa.

Ukulungiselela: Ngaphambi kokwenza i-hot-dip galvanizing, ingaphezulu lepayipi lensimbi kufanele lihlanzwe kahle nge-sandblasting, pickling, njll.

Ubukhulu: Ngokuhlanganisa i-zinc, ingot ye-zinc ehlutshiwe ye-Class 1 ecaciswe ku-JIS H 2107 noma i-zinc enekhwalithi okungenani elingana nalokhu izosetshenziswa.

Okunye: Ezinye izimfuneko ezijwayelekile zokugalela izinsimbi zihambisana ne-JIS H 8641.

Ukuhlolwa: Ukulinganisa ukufana kokunamathela kukathayela ngokwe-JIS H 0401 Isigaba sesi-6.

Ngaphezu kwezakhi ezinikeziwe, ezinye izakhi ze-alloying zingangezwa njengoba kudingeka.

| Uphawu lwebanga | I-P (Phosphorus) | S (Sulfur) |

| I-SGP | ubuningi 0.040% | ubuningi 0.040% |

I-JIS G 3452 inemikhawulo embalwa ekwakhiweni kwamakhemikhali ngoba i-JIS G 3452 isetshenziselwa ikakhulukazi izinhlelo zokusebenza ezijwayelekile ezifana nokuthuthwa kwesitimu, amanzi, uwoyela, negesi yemvelo.Ukwakhiwa kwamakhemikhali wezinto ezibonakalayo akuyona into ebaluleke kakhulu, kodwa kunalokho izakhiwo zemishini yepayipi ukumelana nokucindezela kokusebenza.

I-Tensile Properties

| Uphawu lwebanga | Amandla aqinile | Ubude, iminithi, % | ||||||

| Isiqephu sokuhlola | Hlola isiqondiso | Ubukhulu bodonga, mm | ||||||

| N/mm² (MPA) | >3 ≤ 4 | >4 ≤ 5 | >5 ≤ 6 | >6 ≤7 | >7 | |||

| I-SGP | 290 imiz | No.11 | Ngokuhambisana ne-axis yepayipi | 30 | 30 | 30 | 30 | 30 |

| No.12 | Ngokuhambisana ne-axis yepayipi | 24 | 26 | 27 | 28 | 30 | ||

| No.5 | I-Perpendicular to pipe axis | 19 | 20 | 22 | 24 | 25 | ||

Emapayipini anobubanzi obungu-32A noma ngaphansi, amanani obude kuleli thebula awasebenzi, nakuba imiphumela yawo yokuhlolwa yobude izorekhodwa.Kulesi simo, imfuneko yobude okuvunyelenwe ngayo phakathi komthengi nomkhiqizi ingasetshenziswa.

Impahla Ephansi

Ububanzi: Kumashubhu anobubanzi obuncane obungaphezu kuka-50A (2B).

Ayikho imifantu lapho ithubhu lenziwe isicaba libe ngu-2/3 wobubanzi obungaphandle beshubhu.

Ukugoba

Ububanzi: Kumashubhu ensimbi anobubanzi obungajwayelekile ≤ 50A (2B).

Gobisa isifanekiso sibe ngu-90° ngeradiyasi yangaphakathi ephindwe kasithupha ububanzi bepayipi ngaphandle kokukhiqiza noma yikuphi ukuqhekeka.

Ipayipi ngalinye lensimbi kufanele libe nokuhlolwa kwengcindezi ye-hydrostatic noma ukuhlolwa okungabhubhisi.

Ukuhlolwa kwe-Hydrostatic

Ingcindezi: 2.5 MPa;

Isikhathi: Bamba okungenani imizuzwana emi-5;

Ukwahlulela: ipayipi lensimbi ngaphansi kwengcindezi ngaphandle kokuvuza.

Ukuhlolwa Okungonakali

Ukuhlolwa kwe-ultrasonic okucaciswe ku-JIS G 0582 kuzosebenza.Izinga lokuhlola lingase libe nzima kakhulu kuneSigaba se-UE.

Ukuhlolwa kwamanje kwe-eddy okucaciswe ku-JIS G 0583 kuzosebenza.Izinga lokuhlola lingase libe nzima kakhulu kuneSigaba EZ.

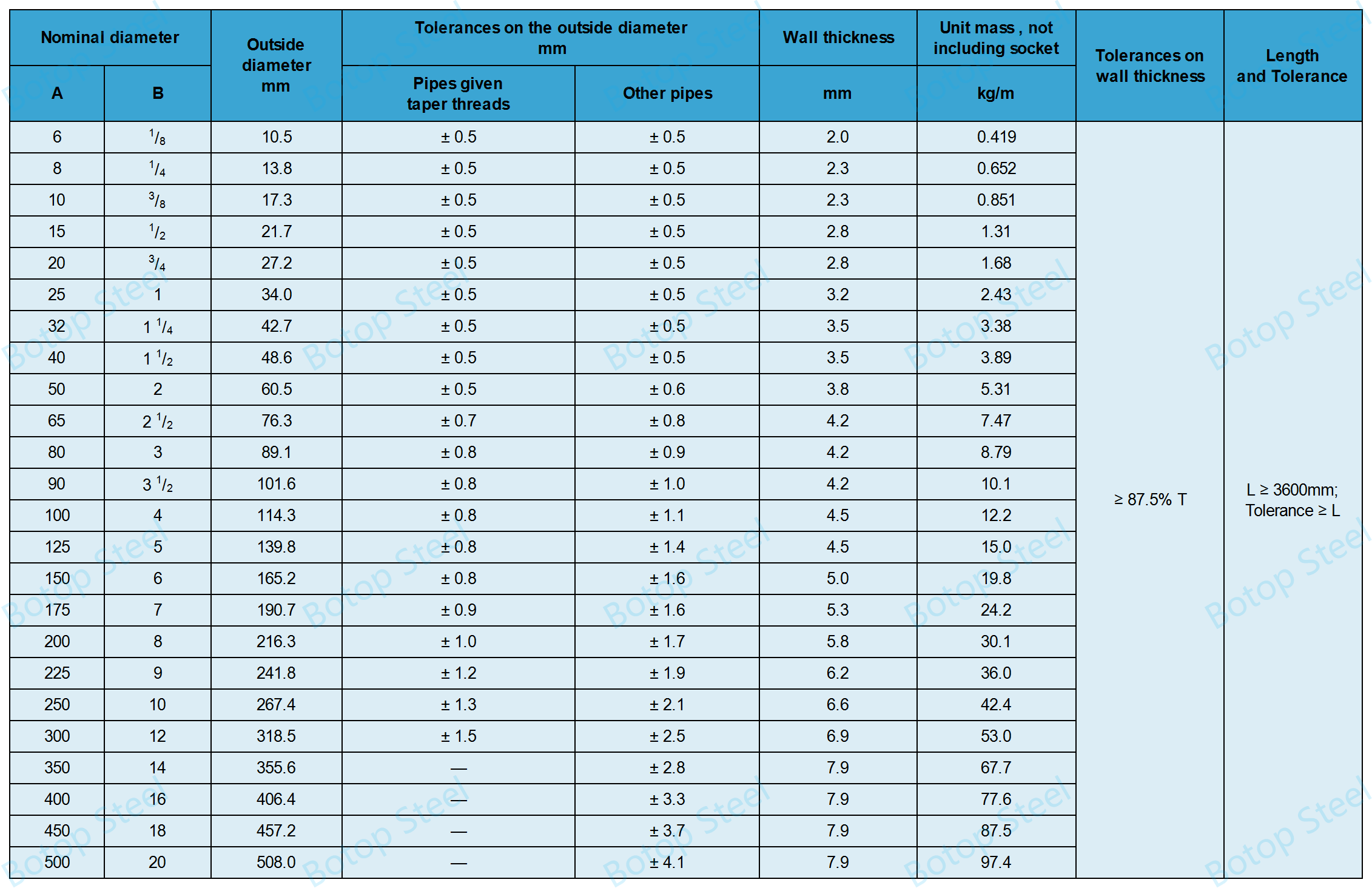

Kumapayipi anamadamitha okuzisholo ≥ 350A (14B), bala ububanzi ngokulinganisa umjikelezo, lapho ukubekezelelana kungu-± 0.5%.

Uhlobo lwesiphetho sepayipi le-DN≤300A/12B: intambo noma isiphetho esiyisicaba.

Uhlobo lokuphela kwepayipi le-DN≤350A/14B: isiphetho esiyisicaba.

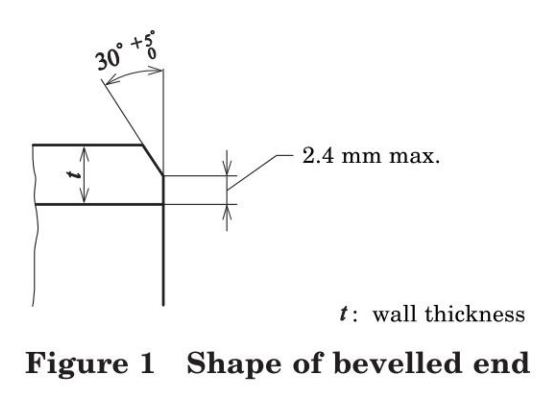

Uma umthengi edinga ukuphela kwe-beveled, i-engeli ye-bevel ingu-30-35 °, ububanzi be-bevel bonqenqema lwepayipi lensimbi: max 2.4mm.

I-JIS G 3452 inokulingana kuI-ASTM A53futhiI-GB/T 3091, futhi izinto zamapayipi ezichazwe kulawa mazinga zingabhekwa njengezilingana nomunye nomunye ngokusebenza nokusebenza.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Xhumana nathi, ithimba lochwepheshe likulungele ukukunikeza izinsizakalo ezisezingeni eliphezulu nezisombululo, libheke phambili ekufinyeleleni ukubambisana okujabulisayo nawe, futhi ngokuhlanganyela livule isahluko esisha sempumelelo.