I-JIS G 3454iyindinganiso yezimboni yaseJapan yamapayipi ensimbi ye-carbon kumasistimu okucindezela anezinga lokushisa eliphakeme lokusebenza elingu-350°C. Izinga lihlanganisa amabanga amabili:I-STPG 370futhiI-STPG 410. Kusebenza kumapayipi angangeni kagesi ashiselwe (ERW) noma amapayipi angenamthungo anobubanzi obungu-10.5 mm kuya ku-660.4 mm (okungukuthi 6A kuya ku-650A, noma 1/8B kuya ku-26B).

I-JIS G 3454 Amapayipi ensimbi azokhiqizwa kusetshenziswa inhlanganisela efanele yezindlela zokukhiqiza amapayipi ensimbi nezindlela zokuqeda kuthebula elingezansi.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | ||

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | Ukuhlukaniswa kwe-zinc-coating | |

| I-STPG370 I-STPG410 | I-Seamless: S Ukumelana nogesi okushiselwe: E | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C Njengoba ukumelana kukagesi kushiselwe: G | Amapayipi amnyama: amapayipi anganikezwanga i-zinc-coating Amapayipi amhlophe: amapayipi anikezwe i-zinc-coating |

Ikakhulukazi, kunezindlela ezinhlanu zokukhiqiza:

SH: Ipayipi lensimbi engenamthungo elishisayo eliphelile;

SC: Ipayipi lensimbi engenamthungo elipholile eliqediwe;

EH: Ipayipi lensimbi elishisiwe elishisiwe elishisiwe;

EC: Ukuphikiswa kukagesi okuqediwe okubandayo okushiselwe ipayipi lensimbi;

EG: Ukumelana nogesi okushiselwe ipayipi lensimbi ngaphandle kwalawo aphelile ashisayo naqediwe abandayo.

Insimbi ye-Botopingumkhiqizi kanye nomphakeli wamapayipi ensimbi ensimbi ashiselwe esezingeni eliphezulu avela eChina, kanye nesitoko samapayipi ensimbi angenamthungo. Uma unezidingo, sicela ukhululeke ukuxhumana nathi futhi sizokunikeza ukwesekwa kwamahhala kochwepheshe.

| Uphawu lwebanga | C | Si | Mn | P | S |

| ubuningi | ubuningi | - | ubuningi | ubuningi | |

| I-STPG 370 | 0.25% | 0.35 % | 0.30-0.90% | 0.040 % | 0.040% |

| I-STPG 410 | 0.30% | 0.35 % | 0.30-1.00% | 0.040 % | 0.040% |

Ivumela ukungezwa kwezinye izakhi ze-alloying.

Amandla Aqinile, Iphuzu Lokuvuza noma Ingcindezi Yobufakazi, Nokwelula

| Uphawu yebanga | Amandla aqinile | Iphuzu lesivuno noma ingcindezi yobufakazi | Ukwelula iminithi, % | |||

| Isiqephu sokuhlola esiqinile | ||||||

| No.11 noma No.12 | No.5 | No.4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Isiqondiso sokuhlolwa kwe-tensile | ||||

| imiz | imiz | Ngokuhambisana ne-axis yepayipi | I-Perpendicular to pipe axis | Ngokuhambisana ne-axis yepayipi | I-Perpendicular to pipe axis | |

| I-STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| I-STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Ukuhlola Ukucaba

Lapho ibanga eliphakathi kwamapuleti amabili lifinyelela ebangeni elishiwo H, akumele kube namaphutha noma imifantu ebusweni bepayipi lensimbi.

Kumashubhu ensimbi angenamthungo: H = (1+e) t/(e + t/D);

Emapayipi ensimbi e-ERW: H = 1/3 D (ye-weld) noma i-H = 2/3 D (ngengxenye ngaphandle kokushisela);

H: ibanga phakathi kwamapuleti aphansi (mm);

е: kuchazwa njalo ngakunye ebangeni ngalinye lepayipi, 0.08 ye-STPG 370, 0.07 ye-STPG 410;

t: ukujiya kodonga lwepayipi (mm);

D: ububanzi obungaphandle bepayipi (mm);

Ukuhlolwa Kokwenza Isicaba sisebenza kumapayipi ensimbi anobubanzi obujwayelekile obungaphezu kuka-40A (48.6mm).

Ukugoba

I-Bendability isebenza kumapayipi anobubanzi obungu-40 A (48.6) noma obuncane.

Ipayipi kufanele igotshwe ngo-90 ° endaweni engaba izikhathi eziyisi-6 ububanzi bayo obungaphandle. Udonga lwamapayipi akumele lungabi nasici noma imifantu.

Ipayipi ngalinye lensimbi kufanele lihlolwe ingcindezi ye-hydrostatic noma ukuhlolwa okungabhubhisi.

Ukuhlolwa kwe-Hydrostatic

Gcina ingcindezi ethile okungenani imizuzwana emi-5 ngaphandle kokuvuza.

Inani lokucindezela lihlobene neshejuli No. yepayipi lensimbi.

| Ukujiya kodonga okuzisholo | Inombolo yeshejuli: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Ukuhlolwa Okungonakali

Uma kusetshenziswa ukuhlolwa kwe-ultrasonic, kufanele kusekelwe esimisweni esiqinile kunesiginali yekilasi le-UD ku-JIS G 0582.

Uma kusetshenziswa ukuhlolwa kwamanje kwe-eddy, kufanele kusekelwe ezingeni eliqine kakhulu kunesiginali yekilasi le-EY ku-JIS G 0583.

| Ububanzi bokuzisholo | Ububanzi bangaphandle | Ukujiya kodonga | I-unit mass | Inombolo yeshejuli (Sch No.) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

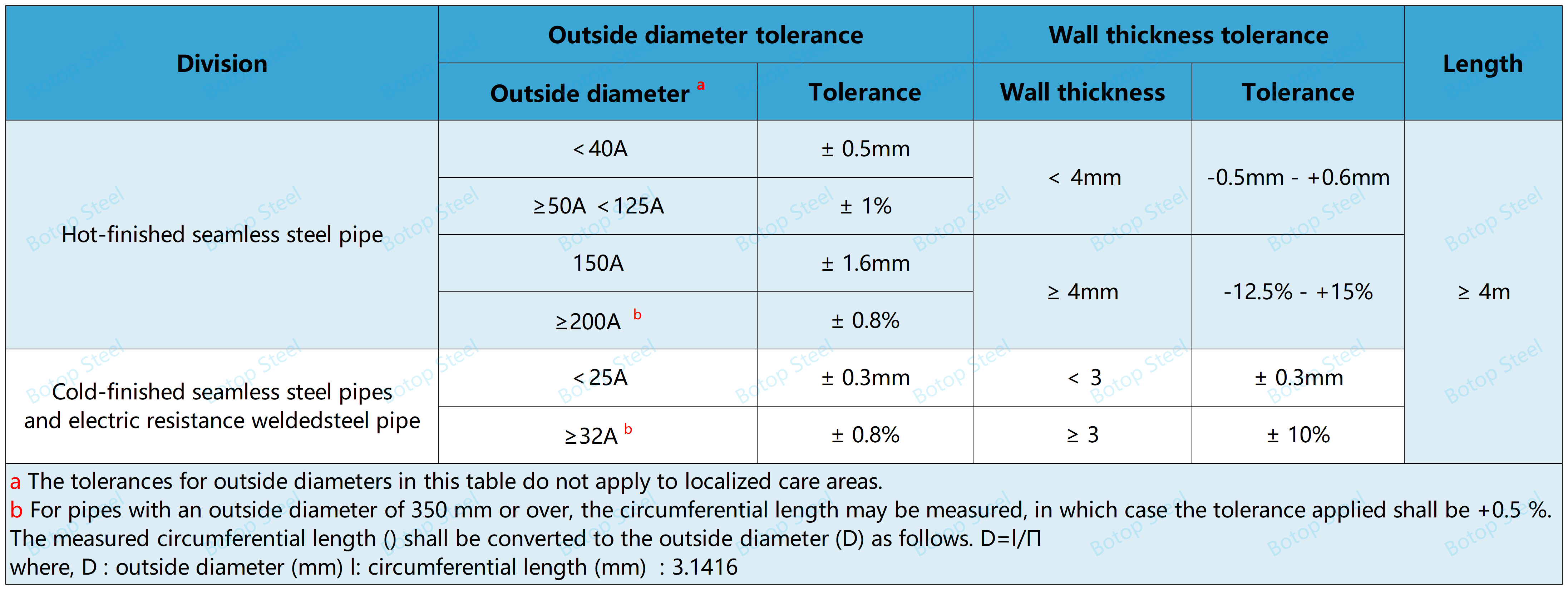

I-JIS G 3454 Ukubekezelela ububanzi bangaphandle, ukujiya kodonga, ukugqama, nobude kuzohlangabezana nezidingo ezilandelayo.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Sicela usithinte, sizokunikeza izinga eliphezulu, amapayipi ensimbi ajwayelekile anenkonzo yobungcweti nephumelelayo. UBotop ubheke ngabomvu ukukusiza.