I-JIS G3454 carbon ERW ipayipi lensimbi,

,

| Isitayela | Ezobuchwepheshe | Okubalulekile | Okujwayelekile | Ibanga | Ukusetshenziswa |

| Ukumelana Kagesi Okushiselwe (ERW) ipayipi lensimbi | Imvamisa ephezulu | Insimbi Yekhabhoni | I-API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70, njll | Ukuthuthwa kwamafutha negesi |

| I-ASTM A53 | G.A ,GR.B | Okwesakhiwo (I-Piling) | |||

| I-ASTM A252 | GR.1, GR.2,GR.3 | ||||

| I-BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H, njll. | ||||

| I-BS EN10219 | S275JRH,S275J0H,S355J0H,S355J2H, njll. | ||||

| I-JIS G3452 | I-SGP, njll | Ukuthuthwa koketshezi olunomfutho ophansi | |||

| I-JIS G3454 | STPG370,STPG410, njll | Ukuthuthwa kwe-High-pressure fluid | |||

| I-JIS G3456 | STPG370,STPG410,STPG480, njll | izinga lokushisa eliphezulu amapayipi ensimbi |

Ipayipi eli-odwe ngaphansi kwalokhu kucaciswa elesevisi yengcindezi ezingeni lokushisa elilinganiselwa ku-350℃.

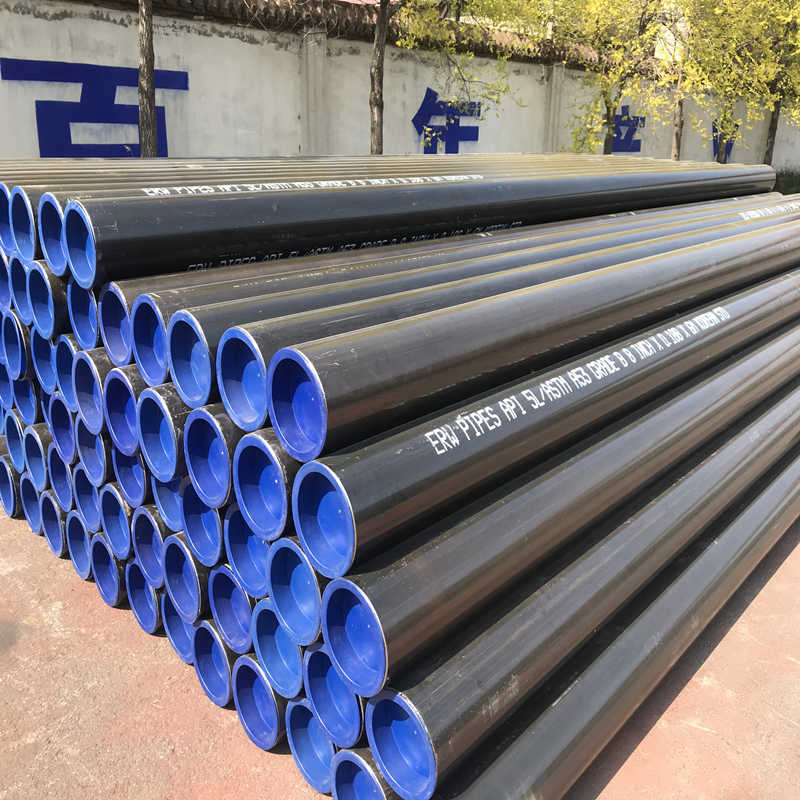

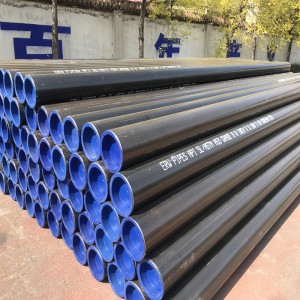

Ipayipi elingenalutho, i-coat emnyama noma i-dip eshisayo efakwe nge-zinc (eyenziwe ngokwezifiso);

Ezinyandeni ezinezihlilingi ezimbili zikakotini;

Zombili ziphela ngabavikeli bokugcina;

Isiphetho esingenalutho, isiphetho se-bevel (Lapho kudingwa umthengi kanye ne-S≤22mm, ukuphela kwepayipi kufanele kubhobhodwe, idigri: 30 ° (+5 ° ~0 °), futhi ukushuba kodonga lwempande akwehliswa ngo-<2.4mm.);

Ukumaka.

Ibanga Nokubunjwa Kwekhemikhali (%)

| Ibanga | C≤ | Si≤ | Mn | P≤ | S≤ |

| I-STPG370 | 0.25 | 0.35 | 0.30~0.90 | 0.040 | 0.040 |

| I-STPG410 | 0.30 | 0.35 | 0.30~1.00 | 0.040 | 0.040 |

|

|

|

|

|

|

|

| Izakhiwo Zemishini | ||||||

| Ibanga | Amandla aqinile | Amandla esivuno | Elongation % | |||

| N/ m㎡ | N/ m㎡ | Izingcezu zokuhlola ze-No.11 noma No.12 | Izingcezu zokuhlola eziyi-5 | Inombolo yokuhlola engu-4 | ||

|

|

| I-Longitudinal | Phenduka | I-Longitudinal | Phenduka | |

| I-STPG370 | 370 imiz | 215 imiz | 30 imiz | 25 imiz | 28 imiz | 23 imiz |

| I-STPG410 | 410 imiz | 245 imiz | 25 imiz | 20 imiz | 24 imiz | 19 imiz |

Ukubekezelela i-OD ne-WT

| Ukwehlukana | Ukubekezelela ku-OD | Ukubekezelelana ku-WT | ||

| Ipayipi Lensimbi Le-ERW eliphelile elibandayo | 24A noma ngaphansi | +/-0.3mm | Ngaphansi kuka-3mm

3mm noma ngaphezulu | +/-0.3mm

+/-10% |

| 32A noma ngaphezulu | +/-0.8% |

|

| |

| Kumapayipi anosayizi omncane ongu-350A noma ngaphezulu, ukubekezelela ku-OD kungase kunqunywe ubude bomjikelezo. Kulokhu, ukubekezelelana kuzoba +/-0.5% | ||||

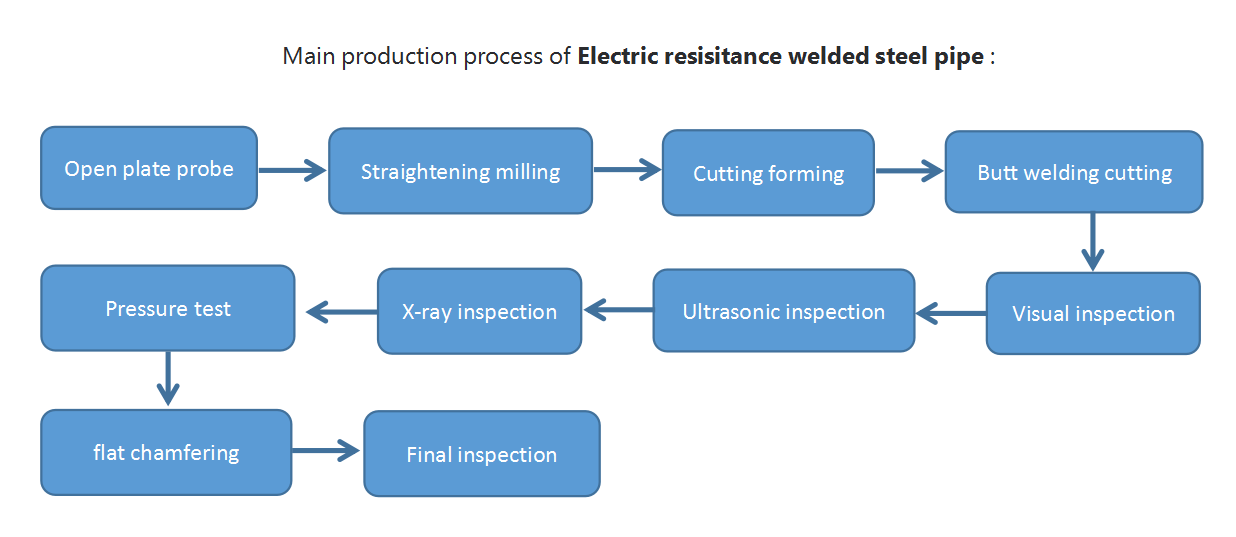

I-JIS G3454 ERW isevisi yokunyathela ipayipi lensimbi iyisici esibalulekile sokwenziwa nokukhiqizwa kwamapayipi ensimbi e-ERW. I-JIS G3454 iyi-Japanese Industrial Standard ecacisa amapayipi ensimbi ye-carbon yesevisi yokucindezela kwezinga lokushisa eliphezulu. I-ERW (i-electric resistance welded) ipayipi yensimbi yenziwa ngenqubo lapho imiphetho yamashidi ensimbi noma imicu ishiswa futhi ihlanganiswe ndawonye ngaphansi kwengcindezi, okwenza ipayipi elingenamthungo neliqinile. Izinsizakalo zokugxiviza ezihilelekile ekukhiqizweni kwe-JIS G3454 ERW Steel Pipes zidlala indima ebalulekile ekuqinisekiseni ikhwalithi nokwethembeka kwala mapayipi. Izinsizakalo zokugxiviza zibandakanya ukusetshenziswa kwemishini enengcindezi ephezulu ukwenza amapayipi abe nobukhulu obufunwayo kanye nemininingwane. Le nqubo iqinisekisa ukuthi ipayipi ineziphetho ezibushelelezi nezinembile, kanye nokuqina kodonga olungaguquki kulo lonke ubude bayo. Enye yezinzuzo ezibalulekile ze-JIS G3454 ERW izinsiza zokunyathelisa ipayipi lensimbi yikhono lokukhiqiza amapayipi anemba elihle kakhulu elinobukhulu kanye nobuqotho be-weld. Izinsizakalo zokugxiviza zivumela ukulawula okuqinile phezu kwenqubo yokukhiqiza, ukuqinisekisa ukuthi ipayipi ihlangabezana nezindinganiso ezidingekayo kanye nezici. Ukwengeza, ukusetshenziswa kwemishini enengcindezi ephezulu ngesikhathi sezinsizakalo zokugxiviza kusiza ukukhiqiza amapayipi anamandla akhethekile nokuqina, okuwenza afanelekele ukusetshenziswa okuhlukahlukene ezimbonini ezinjengowoyela negesi, ezokwakha, nezezimoto. Ngaphezu kwalokho, i-JIS G3454 ERW izinsiza zokucindezela ipayipi lensimbi nazo zingakhiqiza amapayipi abushelelezi futhi amahle. Imishini esetshenziswa ezinsizeni zokugxiviza ingapholisha futhi icwengisise indawo engaphezulu yepayipi, okuholela kumkhiqizo obukeka kakhudlwana. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza lapho amapayipi avezwa khona noma abonakala njengoba kuthuthukisa ukubukeka kwawo wonke futhi kuqinisekisa ukuqedwa kwekhwalithi ephezulu. Sengiphetha, izinsizakalo zokucindezela ze-JIS G3454 ERW Steel Pipe ziyingxenye ebalulekile yenqubo yokukhiqiza, eqinisekisa ukukhiqizwa kwamapayipi asezingeni eliphezulu futhi anokwethenjelwa ezicelo zesevisi yengcindezi ehlukahlukene. Iqinisekisa ukunemba kobukhulu, ubuqotho be-weld, kanye nezindawo ezibushelelezi, okwenza lawa mapayipi afanelekele uhla olubanzi lwezimboni nokusetshenziswa.

复制