I-JIS G 3455iyi-Japanese Industrial Standard (JIS) yesevisi yokucindezela okuphezulu emazingeni okushisa angu-350 °C noma aphansi, ikakhulukazi izingxenye zemishini.

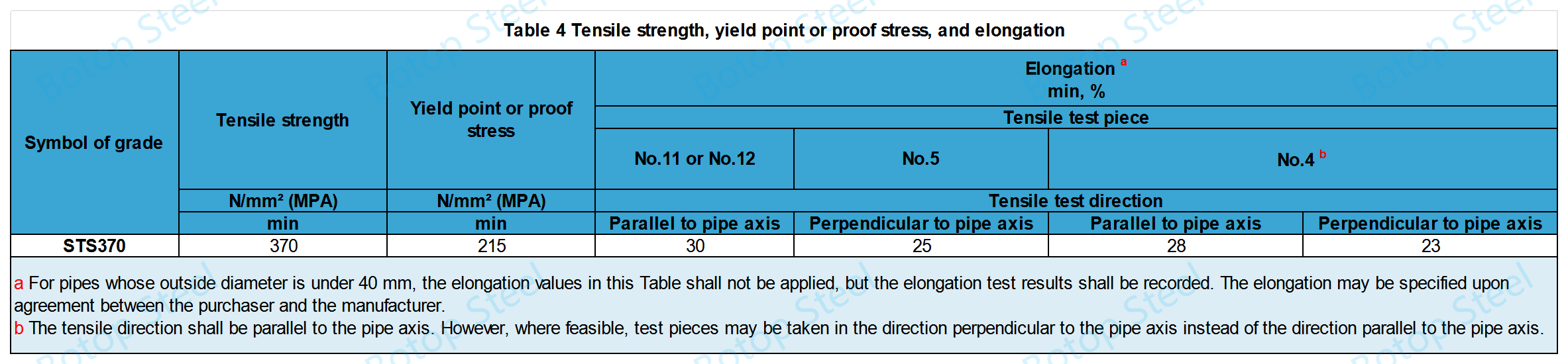

Ipayipi lensimbi le-STS370iyipayipi lensimbi elinamandla amancane okudonsa angu-370 MPa kanye namandla amancane okukhiqiza angu-215 MPa, okuqukethwe kwekhabhoni okungeqile ku-0.25% kanye nokuqukethwe kwe-silicon phakathi kuka-0.10% no-0.35%, futhi isetshenziswa kakhulu izicelo ezidinga ukuphakama. amandla kanye nokushisela okuhle, njengezakhiwo zokwakha, amabhuloho, imikhumbi yokucindezela, nezingxenye zemikhumbi.

I-JIS G 3455 inamabanga amathathu.STS370, STS410, STA480.

I-diameter yangaphandle engu-10.5-660.4mm (6-650A) (1/8-26B).

Amashubhu azokwenziwa kusuka ku-insimbi ebulewe.

Insimbi ebulewe insimbi eye yakhishwa ngokuphelele emzimbeni ngaphambi kokuba iphonswe kuma-ingots noma ezinye izinhlobo.Inqubo iqukethe ukungeza i-ejenti eyenza i-deoxidizing efana ne-silicon, i-aluminium, noma i-manganese ensimbi ngaphambi kokuthi iqine.Igama elithi "wabulawa" libonisa ukuthi akukho ukusabela komoya-mpilo okwenzeka ensimbi phakathi nenqubo yokuqinisa.

Ngokuqeda umoya-mpilo, insimbi ebulewe ivimbela ukwakheka kwamabhamuza omoya ensimbi encibilikisiwe, ngaleyo ndlela igwema i-porosity namabhamuza omoya emkhiqizweni wokugcina.Lokhu kubangela insimbi elinganayo futhi eminyene enezakhiwo ezisezingeni eliphakeme zemishini kanye nobuqotho besakhiwo.

Insimbi ebulewe ifaneleka ngokukhethekile izinhlelo zokusebenza ezidinga izinga eliphezulu nokuqina, njengemikhumbi yokucindezela, izakhiwo ezinkulu, namapayipi anezidingo zekhwalithi ephezulu.

Ngokusebenzisa insimbi ebulewe ukukhiqiza amashubhu, ungaqiniseka ngokusebenza okungcono nempilo ende yesevisi, ikakhulukazi ezindaweni ezingaphansi kwemithwalo esindayo nezingcindezi.

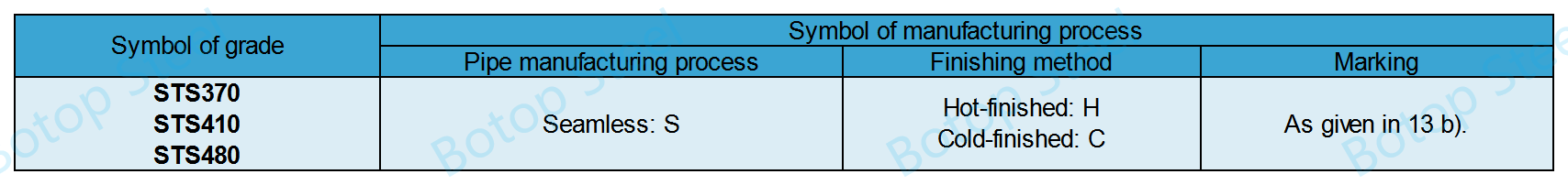

Ikhiqizwe kusetshenziswa inqubo yokukhiqiza engenamthungo ehlanganiswe nendlela yokuqeda.

Ipayipi lensimbi engenamthungo eliqedwe ukushisa: SH;

Ipayipi lensimbi elingenamthungo eliqedwe ngokubanda: SC.

Ngenqubo yokukhiqiza engenamthungo, ingahlukaniswa cishe ibe amapayipi ensimbi angenamthungo anobubanzi bangaphandle obungaphezu kuka-30mm kusetshenziswa ukukhiqizwa kokugcina okushisayo, kanye no-30mm kusetshenziswa ukukhiqizwa kokuqeda okubandayo.

Nakhu ukugeleza kokukhiqiza kwe-Hot-finished seamless.

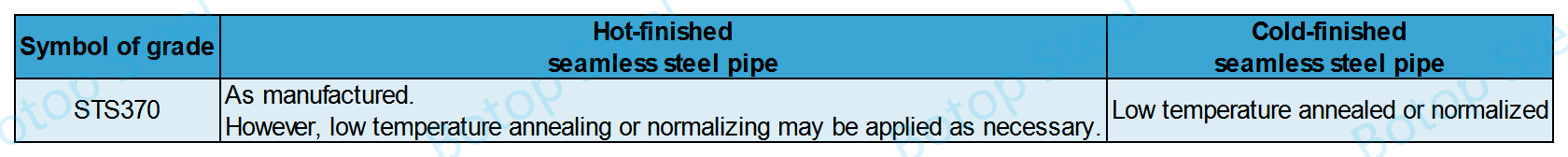

I-annealing yezinga lokushisa eliphansi isetshenziswa kakhulu ukuthuthukisa ukusebenza kahle kwezinto, ukunciphisa ubulukhuni, nokuthuthukisa ukuqina, futhi ifanele insimbi esebenza ngokubandayo.

I-normalizing isetshenziselwa ukuthuthukisa amandla nokuqina kwezinto, ukuze insimbi ifaneleke kakhulu ukumelana nokucindezeleka kwemishini nokukhathala, okuvame ukusetshenziselwa ukuthuthukisa ukusebenza kwensimbi ebandayo.

Ngalezi zinqubo zokwelashwa kokushisa, isakhiwo sangaphakathi sensimbi sithuthukisiwe futhi izakhiwo zayo ziyathuthukiswa, okwenza kube ngokufaneleka kakhulu ukusetshenziswa ekufuneni izicelo zezimboni.

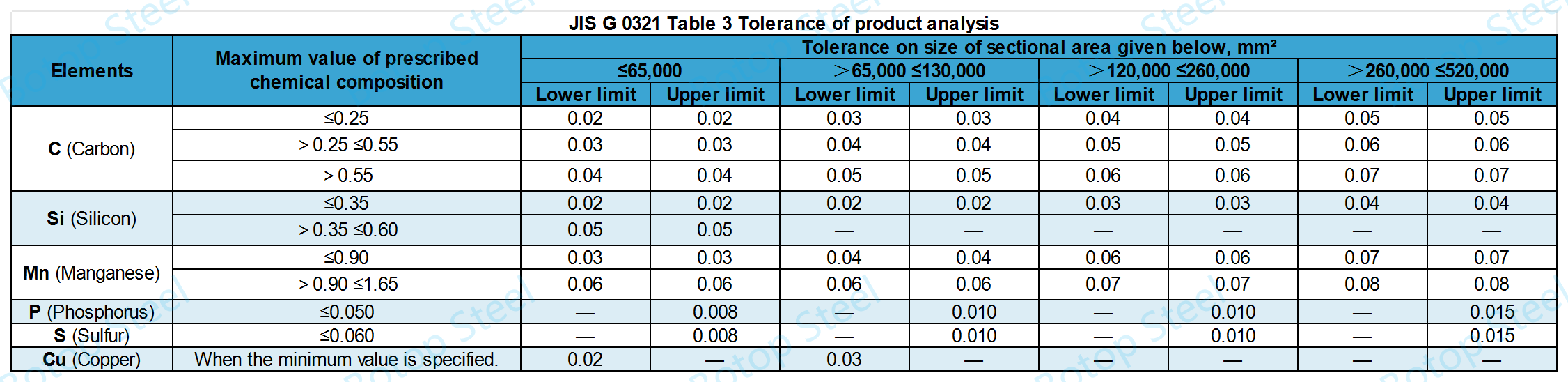

Ukuhlaziywa kokushisa kuzohambisana ne-JIS G 0320. Ukuhlaziywa komkhiqizo kuzohambisana ne-JIS G 0321.

| ibanga | C (Ikhabhoni) | I-Si (Silicon) | Mn (Manganese) | I-P (Phosphorus) | S (Sulfur) |

| STS370 | 0.25% ubuningi | 0.10-0.35% | 0.30-1.10% | 0.35% ubuningi | 0.35% ubuningi |

Ukuhlaziywa kokushisaihloselwe kakhulu ukuhlola ukwakheka kwamakhemikhali ezinto ezingavuthiwe.

Ngokuhlaziya ukwakheka kwamakhemikhali wezinto zokusetshenziswa, kungenzeka ukubikezela nokulungisa izinyathelo zokucubungula nezimo ezingase zidingeke enqubweni yokukhiqiza, njengamapharamitha wokwelapha ukushisa kanye nokwengezwa kwezakhi ze-alloying.

Ukuhlaziywa komkhiqizoihlaziya ukwakheka kwamakhemikhali emikhiqizo eqediwe ukuze kuqinisekiswe ukuhambisana nekhwalithi yomkhiqizo wokugcina.

Ukuhlaziywa komkhiqizo kuqinisekisa ukuthi zonke izinguquko, izengezo noma noma yikuphi ukungcola okungenzeka emkhiqizweni ngesikhathi senqubo yokukhiqiza kungaphansi kokulawulwa nokuthi umkhiqizo wokugcina uhlangabezana nokucaciswa kobuchwepheshe kanye nezidingo zohlelo lokusebenza.

I-JIS G 3455 amanani okuhlaziywa komkhiqizo ngeke athobele kuphela izimfuneko zezinto ezikuthebula elingenhla, kodwa futhi ububanzi bokubekezelela kufanele buhambisane nezimfuneko ze-JIS G 3021 Ithebula 3.

Amanani obude ocezu Lokuhlola No. 12 (elihambisana ne-axis yepayipi) kanye nesiqephu sokuhlola No. 5 (i-perpendicular to pipe axis) ethathwe emapayipini angaphansi kuka-8 mm ukujiya kodonga.

| Uphawu lwebanga | Ucezu lokuhlola olusetshenzisiwe | Ukwelula iminithi, % | ||||||

| Ukujiya kodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7<8 mm | ||

| STS370 | No. 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| No. 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Amanani obude kuleli thebula atholakala ngokukhipha u-1.5 % enanini lokwelula elinikezwe kuThebula 4 ngokuncipha ngakunye kodonga ngo-1 mm ukusuka ku-8 mm, nangokusondeza umphumela enambeni ephelele ngokoMthetho A we-JIS Z 8401. | ||||||||

Ukuhlolwa kokucaba kungase kukhishwe ngaphandle uma kucaciswe ngenye indlela umthengi.

Beka isifanekiso emshinini bese usicaba kuze kube yilapho ibanga phakathi kwamapulatifomu amabili lifinyelela inani elishiwo H. Bese uhlola isifanekiso ukuze uthole imifantu.

Lapho kuhlolwa ukumelana okubalulekile okushiselwe ipayipi, umugqa phakathi kwe-weld kanye nendawo yepayipi i-perpendicular isiqondiso sokucindezela.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwamapuleti (mm)

t: ukuqina kodonga lweshubhu (mm)

D: ngaphandle kobubanzi beshubhu (mm)

е:njalo kuchazwe ebangeni ngalinye le-tube.0.08 ye-STS370: 0.07 ye-STS410 kanye ne-STS480.

Ifanele amapayipi anobubanzi obungaphandle obungu-≤ 50 mm.

Isampula ngeke ibe nemifantu uma igotshwe ku-90° ngobubanzi bangaphakathi obuphindwe ka-6 kunobubanzi obungaphandle bepayipi.

I-engeli yokugoba izolinganiswa ekuqaleni kokugoba.

Wonke amapayipi ensimbi adinga ukuhlolwa nge-hydrostatic noma ngokungabhubhisiukuqinisekisa ikhwalithi nokuphepha kwepayipi kanye nokuhlangabezana nezindinganiso zokusetshenziswa.

Ukuhlolwa kweHydraulic

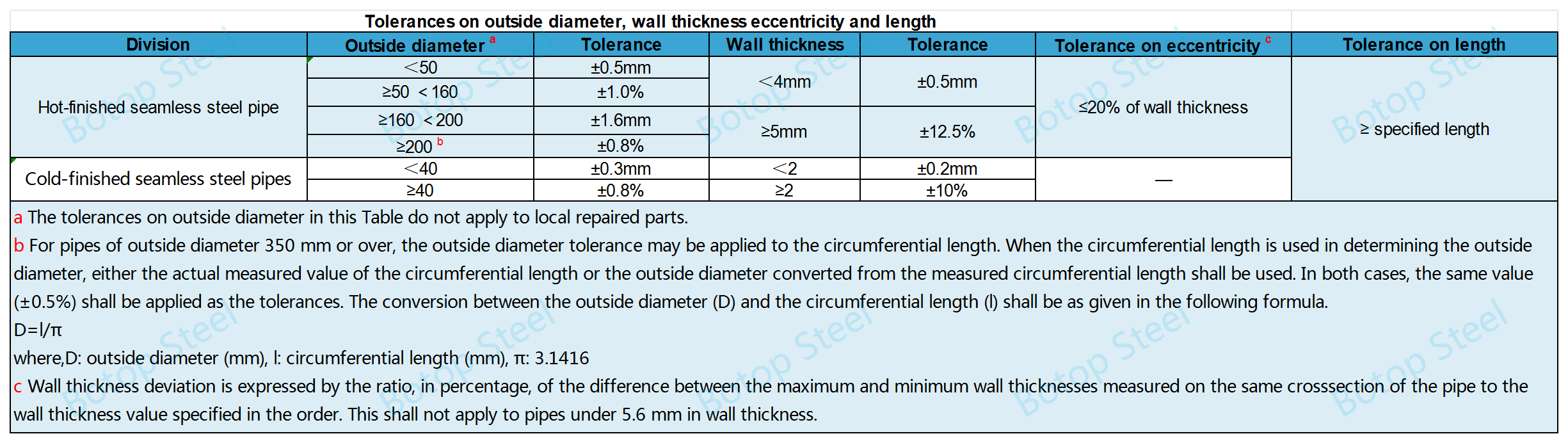

Uma kungekho ngcindezi yokuhlola eshiwo, ubuncane bengcindezi yokuhlolwa kwamanzi obumanzi buyonqunywa ngokuhambisana neSheduli Yepayipi.

| Ukujiya kodonga okuzisholo | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Lapho ubukhulu bodonga be-diameter yangaphandle yepayipi yensimbi akuyona inani elijwayelekile etafuleni lesisindo sepayipi yensimbi, kuyadingeka ukusebenzisa ifomula ukubala inani lokucindezela.

P=2st/D

P: ingcindezi yokuhlola (MPa)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

s: 60 % yenani elincane lephoyinti lesivuno noma ingcindezi yobufakazi enikeziwe.

Lapho ingcindezi encane yokuhlolwa kwe-hydrostatic yenombolo yohlelo olukhethiwe idlula ingcindezi yokuhlola engu-P etholwe ifomula, ingcindezi engu-P izosetshenziswa njengengcindezi yokuhlola ye-hydrostatic encane esikhundleni sokukhetha ukucindezela okuncane kwe-hydrostatic test kuthebula elingenhla.

Ukuhlolwa Okungonakali

Ukuhlolwa okungabhubhisi kwamashubhu ensimbi kufanele kwenziwe nguukuhlolwa kwamanje kwe-ultrasonic noma eddy.

Ngobai-ultrasonicizici zokuhlola, isignali evela kusampula yereferensi equkethe izinga eliyisethenjwa lekilasi le-UD njengoba licaciswe kuI-JIS G 0582izobhekwa njengezinga le-alamu futhi izoba nesignali eyisisekelo elingana noma enkulu kuneleveli ye-alamu.

Ukuzwela okujwayelekile kokutholwa kwe-eddy currentukuhlolwa kuzoba yisigaba se-EU, i-EV, i-EW, noma i-EX ecaciswe kusoI-JIS G 0583, futhi akumele kube namasiginali alingana noma amakhulu kunamasiginali asuka kusampula yesithenjwa equkethe izinga eliyisethenjwa lesigaba esishiwo.

Ukuze uthole okwengeziweAmashadi Wesisindo Sombhobho kanye namashejuli wamapayipingaphakathi kwezinga, ungachofoza.

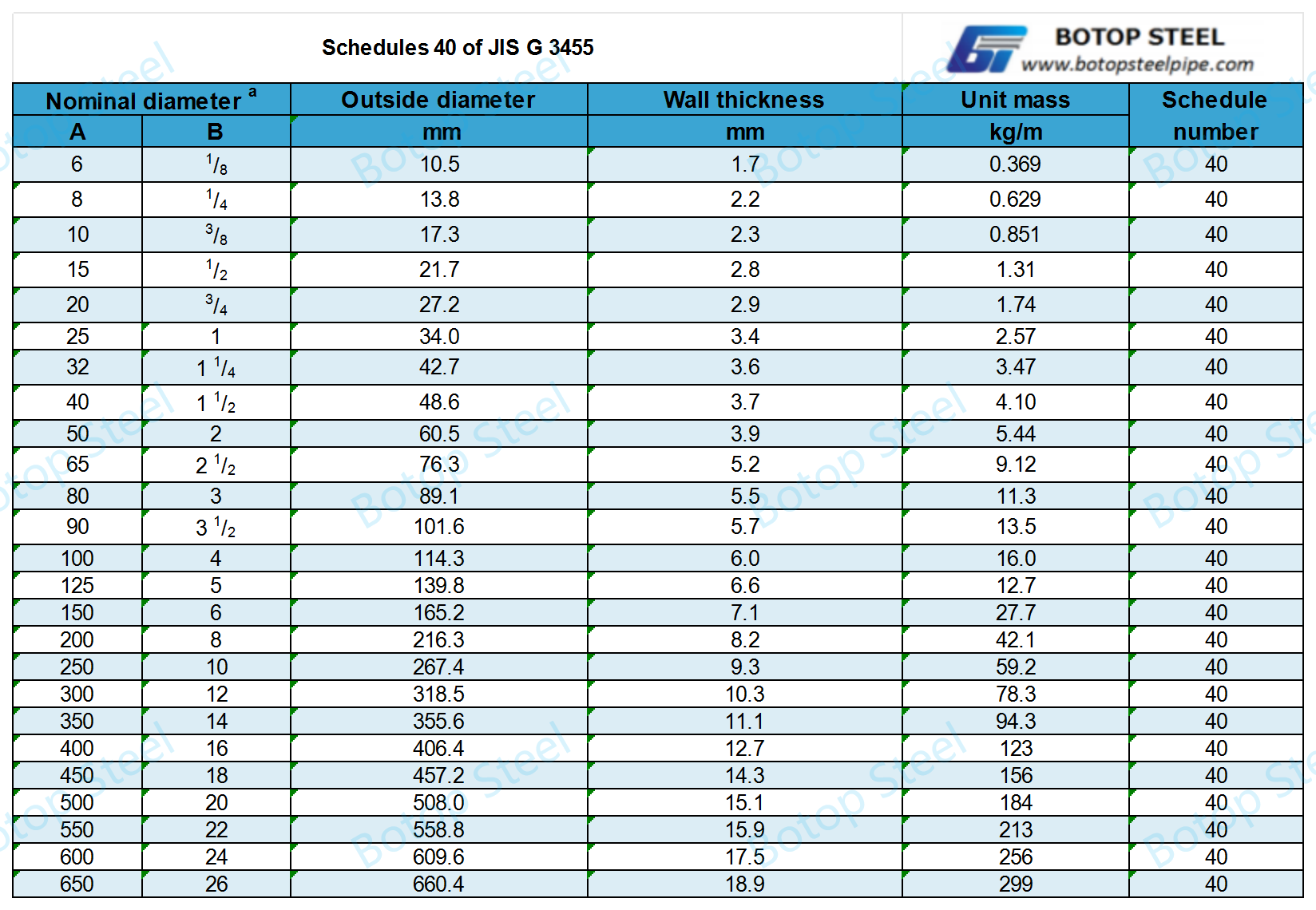

Ipayipi leSheduli 40 lifaneleka ngokufanelekile ezinhlelweni zokucindezela okuphansi kuya kokuphakathi ngoba linikeza ukujiya kodonga olumaphakathi olugwema isisindo esiningi kanye nezindleko kuyilapho kuqinisekiswa amandla anele.

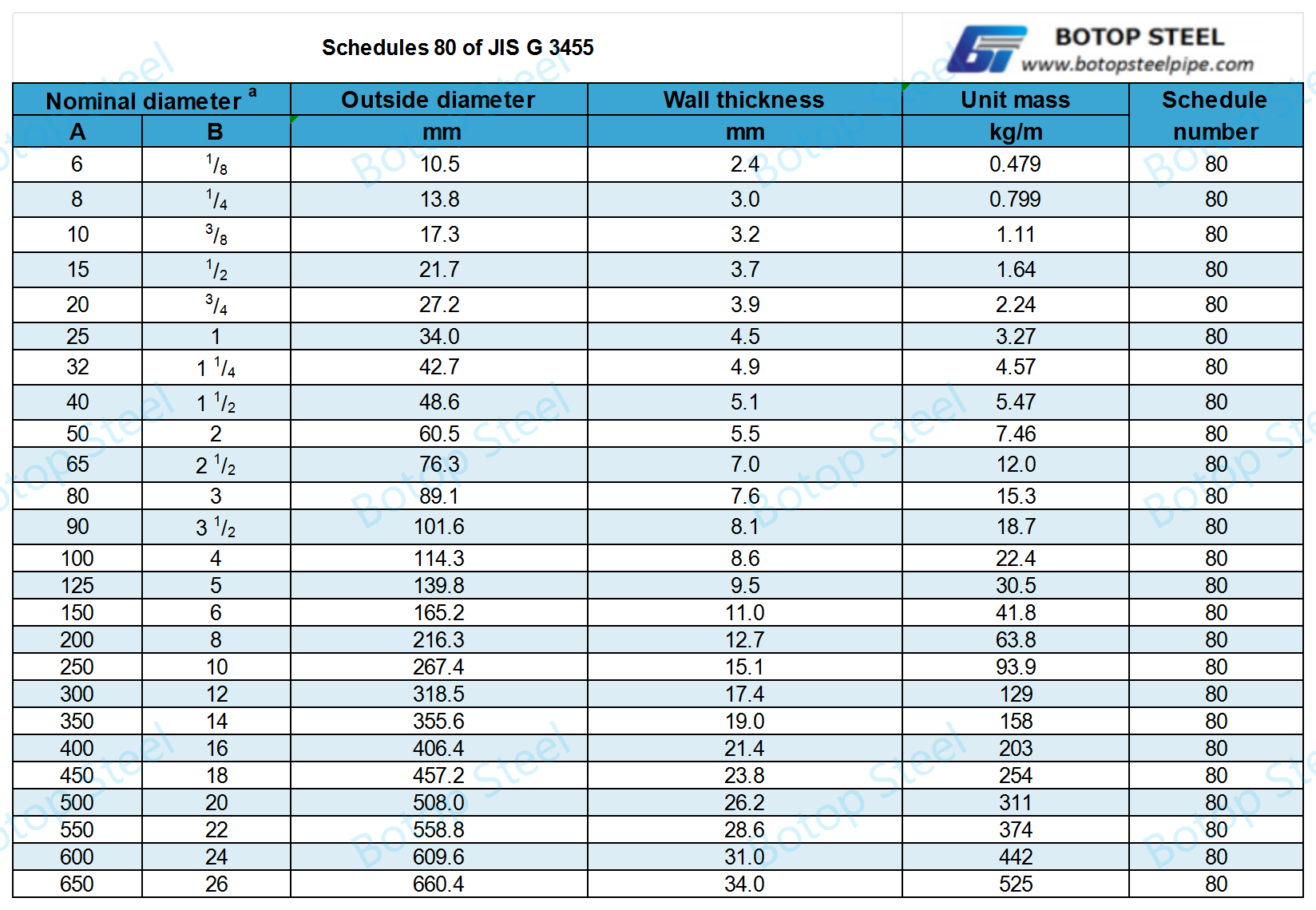

Amapayipi eSheduli 80 asetshenziswa kakhulu ezindaweni zezimboni ezidinga ukuphathwa kwengcindezi ephezulu, njengamasistimu okucubungula amakhemikhali kanye namapayipi okuhambisa uwoyela negesi, ngenxa yekhono lawo lokumelana nezingcindezi eziphakeme kanye nomthelela onamandla wemishini ngenxa yokuqina kodonga lwawo, okuhlinzeka ngokuphepha okwengeziwe. , ukuphepha, nokuqina.

Ishubhu ngalinye lizofakwa ilebula ngolwazi olulandelayo.

a)Uphawu lwebanga;

b)Uphawu lwendlela yokukhiqiza;

c)UbukhuluIsibonelo 50AxSch80 noma 60.5x5.5;

d)Igama lomkhiqizi noma uhlobo oluhlonzayo.

Lapho ububanzi bangaphandle beshubhu ngalinye buncane futhi kunzima ukumaka ishubhu ngalinye, noma lapho umthengi efuna ukuthi inyanda ngayinye yamashubhu imakwe, inyanda ngayinye ingase imakwe ngendlela efanele.

I-STS370 ifanele amasistimu okudlulisa uketshezi olunengcindezi ephansi kodwa esezingeni eliphezulu uma kuqhathaniswa.

Amasistimu okushisa: Ekushiseni kwedolobha noma izinhlelo zokushisa izakhiwo ezinkulu, i-STS370 ingasetshenziswa ukuthutha amanzi ashisayo noma isitimu ngoba ingakwazi ukumelana nokucindezela kanye noshintsho lokushisa ohlelweni.

Izitshalo zamandla: Ekukhiqizeni ugesi, inani elikhulu lamapayipi e-steam aphezulu liyadingeka, futhi i-STS370 iyinto efanelekile yokukhiqiza lawa mapayipi ngoba ingakwazi ukumelana nezinkathi ezinde zokushisa okuphezulu kanye nezindawo zokusebenza ezinomfutho ophezulu.

Amasistimu omoya acindezelwe: Emigqeni yokukhiqiza kanye nokukhiqiza okuzenzakalelayo, umoya ocindezelwe ungumthombo wamandla obalulekile, futhi ipayipi lensimbi le-STS370 lisetshenziselwa ukwakha amapayipi kulezi zinhlelo ukuze kuqinisekiswe ukulethwa komoya okuphephile nokusebenza kahle.

Ukusetshenziswa kwesakhiwo kanye nemishini ejwayelekile: Ngenxa yezakhiwo zayo ezinhle zemishini, i-STS370 ingasetshenziswa futhi ekwenzeni izingxenye ezihlukahlukene zesakhiwo nemishini, ikakhulukazi ezinhlelweni zokusebenza lapho kudingeka khona amandla athile okucindezela.

I-JIS G 3455 STS370 iyinsimbi yensimbi esetshenziswa kusevisi yokucindezela okukhulu.Izinto ezilandelayo zingathathwa njengezilingana noma zicishe zilingane:

1. I-ASTM A53 Ibanga B: Ifanele ukusetshenziswa okujwayelekile kwesakhiwo kanye nemishini kanye nokuthuthwa kwamanzi.

2. I-API 5L Ibanga B: Okwamapayipi okuthutha uwoyela negesi anengcindezi ephezulu.

3. I-DIN 1629 St37.0: Ngobunjiniyela bemishini kanye nokwakhiwa kwemikhumbi.

4. I-EN 10216-1 P235TR1: Ipayipi yensimbi engenamthungo yokushisa okuphezulu kanye nemvelo yokucindezela okukhulu.

5. I-ASTM A106 Ibanga B: Ipayipi le-carbon steel engenamthungo yesevisi yokushisa okuphezulu.

6.I-ASTM A179: Amashubhu ensimbi athambile adonswa ngokubanda angenamthungo wesevisi yezinga lokushisa eliphansi.

7. I-DIN 17175 St35.8: Izinto zeshubhu ezingenamthungo zama-boilers nemikhumbi yokucindezela.

8. I-EN 10216-2 P235GH: Amashubhu angenamthungo namapayipi wensimbi engeyona i-alloy ne-alloy yezindawo ezishisa kakhulu nezinomfutho ophezulu.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.