I-API (American Petroleum Institute Standard) 5L indinganiso yamazwe ngamazwe yamapayipi ensimbi asetshenziswa ezinhlelweni zokuthutha zamapayipi.

I-API 5L ihlanganisa ipayipi lensimbi lezinhlelo zokusebenza ezihlukahlukene zokuthutha igesi yemvelo, uwoyela, nolunye uketshezi.Idethi esebenza ngayo yohlelo lwama-46: iqala ukusebenza ngomhla ka-Novemba 1, 2018.

Uma ufuna nje ukuthola umbono ojwayelekile we-API 5L, sicela uchofozeUhlolojikelele lokucaciswa kwepayipi le-API 5L.

Izinkinobho Zokuzulazula

Yini Okubuyekeziwe ku-API 5L 46th

Umsuka we-API 5L PSL

Ukuhlukaniswa KwamaBanga Ensimbi kanye Namabanga Amapayipi

Amazwe Okulethwa Okuvumelekile

Izinto ezingavuthiwe zamapayipi ensimbi

Izinhlobo zepayipi lensimbi kanye neziphetho zeshubhu ezimbozwe yi-API 5L

Izinqubo Ezamukelekile Zokukhiqiza ze-PSL2 Steel Tubing

Ukuhlolwa kokubukeka kanye nokukhubazeka okuvamile kwe-API 5L

Ukuhlolwa kobukhulu (Ukuchezuka kobukhulu)

Izinto Zokuhlola ze-API 5L

Ukumakwa Kwepayipi kanye Nendawo

I-Equivalence Standard

Imikhiqizo Yethu Ehlobene

Yini Okubuyekeziwe ku-API 5L 46th

Izibuyekezo

Izidingo ezibuyekeziwe nezinwetshiwe zamajoyinti agayiwe;

Izidingo ezibuyekeziwe ze-perpendicularity yokuphela kwepayipi;

Izidingo ezibuyekeziwe zokuhlola ubulukhuni zamapayipi e-API 5LPSL 2 ezindaweni ezimuncu namapayipi e-API 5L PSL 2 ezindaweni ezisogwini;

Okusha

Ipayipi le-API 5L PSL 2 lezinhlelo zokusebenza ezidinga umthamo wepulasitiki we-longitudinal.

Umsuka we-API 5L PSL

I-PSL: Isifinyezo Sezinga Lokucaciswa Kwepayipi ;

Ihlukaniswe yaba: API 5L PSL 1 kanye ne-API 5L PSL 2.

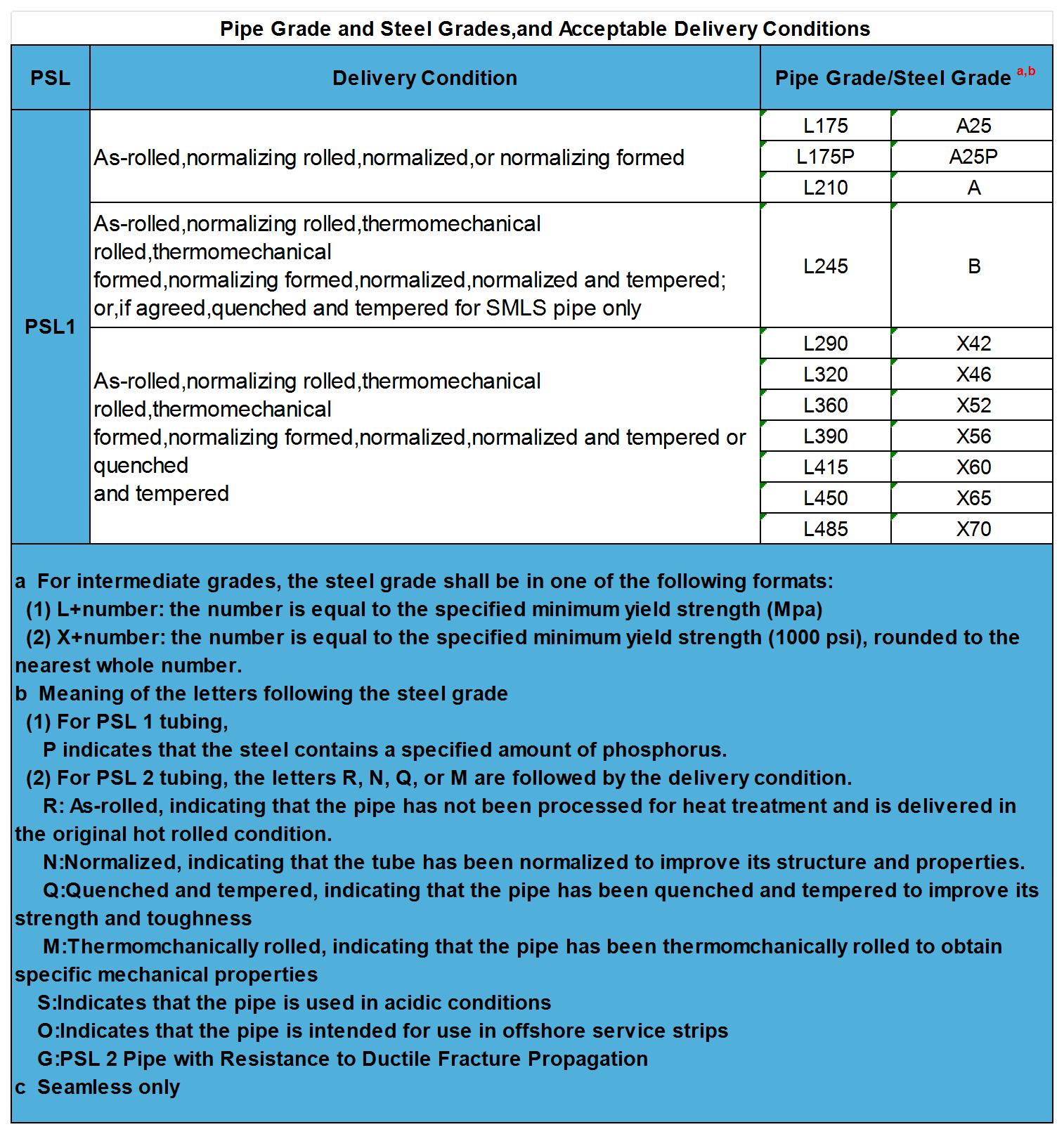

Ukuhlukaniswa KwamaBanga Ensimbi kanye Namabanga Amapayipi

L + inombolo(uhlamvu L lulandelwa amandla amancane ashiwo ku-MPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + inombolo(inombolo elandela uhlamvu X icacisa ubuncane bamandla okukhiqiza ngo-1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Futhi ibanga a kanye nebanga b.Ibanga A=L210 Ibanga B=L 2459

Izimo zokulethwa ezamukelekayo

Qaphela: I-L415/X60 noma amamaki aphezulu akufanele asetshenziswe esikhundleni sika-L360/X52 noma amamaki aphansi ngaphandle kwesivumelwano somthengi.

Izinto ezingavuthiwe zamapayipi ensimbi

Ingot, billet, billet, strip (coil) noma ipuleti.

Qaphela:

1. The impahla eluhlaza forI-API 5L PSL2ipayipi lensimbi kufanele libe yinsimbi encibilikisiwe okusanhlamvu.

2. Umugqa wensimbi (ikhoyili) noma ipuleti elisetshenziselwa ukwakhiwa kwepayipi lensimbi le-API 5L PSL2 ngeke libe nama-tack welds.

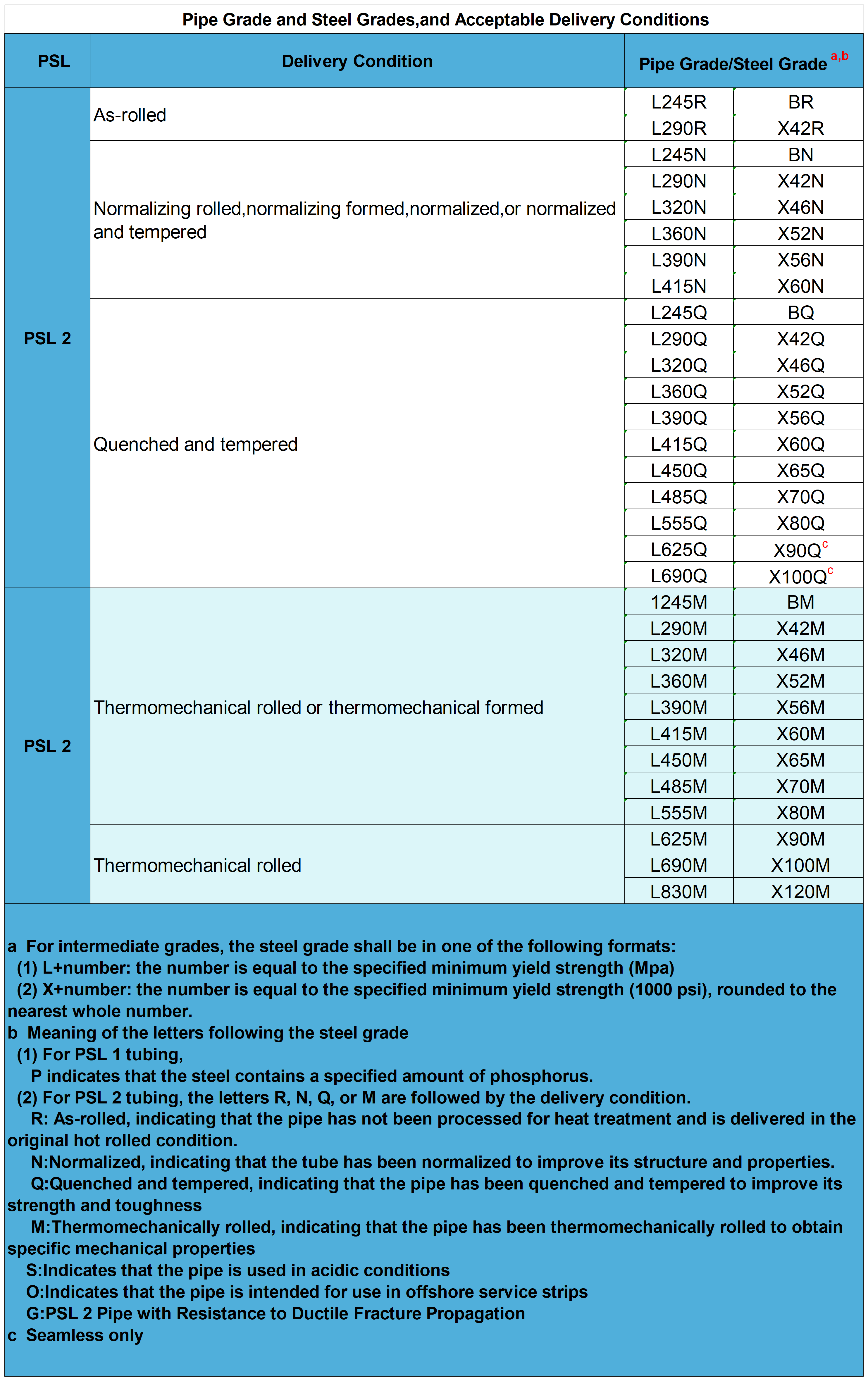

Izinhlobo zepayipi lensimbi kanye neziphetho zeshubhu ezimbozwe yi-API 5L

Ipayipi Lensimbi Elishiselwe

Ipayipi le-CW:Inqubo yokwenza umthungo ngokushisisa umucu esithandweni kanye nangokucindezela ngokomshini unqenqema olwakhiwe ndawonye, lapho amakhoyili alandelanayo omugqa aye ahlanganiswa ndawonye ukuze kuhlinzekwe ukugeleza okuqhubekayo kwesiqeshana somshini wokushisela.

I-COWHPipe:Umkhiqizo we-tubular onomthungo owodwa we-helical okhiqizwa inhlanganisela ye-arc yensimbi yegesi kanye ne-arc welding engaphansi, lapho ubuhlalu be-gas bensimbi be-arc weld bungasuswa ngokuphelele ukudlula kwe-arc welding engaphansi kwamanzi.

INKOMAZI Ipayipi:Umkhiqizo we-tubular one-seam eyodwa noma emibili ye-longitudinal ekhiqizwa inhlanganisela ye-arc yensimbi yegesi kanye ne-arc welding engaphansi, lapho i-gas metal arc weld bead ingasuswa ngokuphelele ukudlula kwe-arc welding engaphansi kwamanzi.

Ipayipi le-EW:Umkhiqizo we-Tubular one-seam eyodwa ye-longitudinal ekhiqizwa ukushisela kagesi okuphansi noma okuphezulu.

Ipayipi le-HFW:I-EWpipe ikhiqizwe' ene-welding current frequency elingana noma engaphezu kuka-70 kHz.

Ipayipi le-LFW:Ipayipi le-EW likhiqizwa ngemvamisa yamanje yokushisela engaphansi kuka-70 kHz.

Ipayipi LW:Umkhiqizo we-Tubular one-seam eyodwa ye-longitudinal ekhiqizwa nge-laser welding.

Ipayipi le-SAWH:Umkhiqizo we-Tubular one-seam eyodwa ye-helical ekhiqizwa inqubo yokushisela ye-arc engaphansi.

SAWLIpayipi:Umkhiqizo we-Tubular one-seam eyodwa noma emibili ye-longitudinal ekhiqizwa yi-arc welding engaphansi kwamanzi.

Ipayipi Lensimbi Elingenamthungo

Ipayipi le-SMLS:Ipayipi lensimbi engenamthungo elishisayo eligoqiwe kanye nepayipi lensimbi eligoqiwe elibandayo eligoqiwe, zikhona ezinye izindlela zokucubungula, njengokudweba okubandayo, ukudweba okubandayo, ukubumba, njll.

Izinhlobo zepayipi ze-API 5L PSL2 zezinhlelo zokusebenza ezikhethekile

Ukumelana Nokusakazwa Kwe-Ductile Fracture (G)

Ipayipi Lesimo Sesevisi Sour (S)

Ipayipi Lesimo Sesevisi Yasolwandle (O)

Idinga ipayipi Longitudinal Plastic Strain Umthamo

Izinhlobo Zokuphela Kwepayipi

I-Socket End, I-Flat End, I-Special Clamp Flat End, Isiphetho Esinezintambo.

Qaphela:

1. Iziphetho zesokhethi, iziphetho zamapayipi zezinsimbi ezikhethekile, neziphetho zamapayipi anentambo eze-API 5L PSL1 kuphela.

2. Ipayipi lensimbi le-L175 P/A25 P le-API 5L PSL1 lizokwenziwa ngomshini elineziphetho ezinentambo, futhi ipayipi lensimbi le-API 5L PSL1 lamanye amabanga ensimbi lizokwenziwa ngomshini elineziphetho eziyisicaba.

3. Amashubhu e-API 5L PSL 2 azolethwa aneziphetho eziyisicaba.

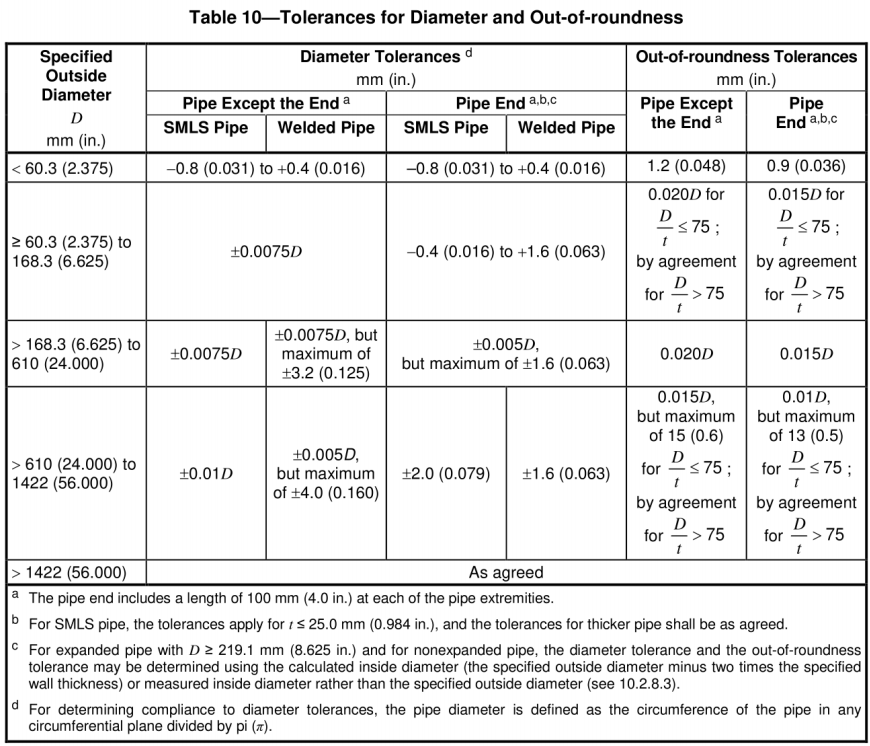

Izinqubo Ezamukelekile Zokukhiqiza ze-PSL2 Steel Tubing

| Ithebula 3—Imizila Yokukhiqiza Eyamukelekayo ye-PSL 2 Pipe | ||||

| Uhlobo Lwepayipi | Iqala i-Materia | Ukwakhiwa Kwepayipi | Ukushisa Kwepayipi Ukwelashwa | Ukulethwa Isimo |

| I-SMLS | Ingot, bloom, noma billet | Njengoba-igoqiwe | - | R |

| Ukwakheka okujwayelekile | - | N | ||

| Ukwakhiwa okushisayo | Ukujwayela | N | ||

| Ukushisa nokushisa | Q | |||

| Ukwakheka okushisayo nokubanda ukuqeda | Ukujwayela | N | ||

| Ukushisa nokushisa | Q | |||

| HFW | Ikhoyili egoqiwe ngokujwayelekile | Ukubumba okubandayo | Ukwelapha ukushisaa endaweni ye-weld kuphela | N |

| I-Thermomechanical-rolled ikhoyili | Ukubumba okubandayo | Ukwelapha ukushisaa endaweni ye-weld kuphela | M | |

| Ukwelapha ukushisaa yendawo yokushisela kanye nokunciphisa ingcindezi yepayipi lonke | M | |||

| Njengoba-igoqwe noma ikhoyili ye-thermomechanical-rolled | Ukubumba okubandayo | Ukujwayela | N | |

| Ukukhipha kanye ukuthukuthela | Q | |||

| Ukubanda kulandele ukushisa ukunciphisa ngaphansi kokulawulwa izinga lokushisa eliholela ku isimo esijwayelekile | - | N | ||

| Ukwakheka okubandayo kulandelwa ukwakhiwa kwe-thermomechanical kwepayipi | - | M | ||

| SAW noma INKOMAZI | Okujwayelekile noma okujwayelekile- ikhoyili egoqiwe noma ipuleti | Ukubumba okubandayo | - | N |

| Njengoba-igoqiwe i-thermomechanical-rolled normalizing-rolled, noma okwejwayelekile | Ukubumba okubandayo | Ukujwayela | N | |

| I-Thermomechanical-rolled ikhoyili noma ipuleti | Ukubumba okubandayo | - | M | |

| Icishiwe futhi ithukuthele ipuleti | Ukubumba okubandayo | - | Q | |

| Njengoba-igoqiwe i-thermomechanical-rolled normalizing-rolled, noma ikhoyili evamile noma ipuleti | Ukubumba okubandayo | Ukukhipha kanye ukuthukuthela | Q | |

| Njengoba-igoqiwe i-thermomechanical-rolled normalizing-rolled, noma ikhoyili evamile noma ipuleti | Ukwakheka okujwayelekile | - | N | |

| aBheka i-ISO 5L 8.8 ukuze uthole ukwelashwa okusebenzayo kokushisa | ||||

Ukuhlolwa kokubukeka kanye nokukhubazeka okuvamile kwe-API 5L

Ukubukeka

Ubuso obungaphandle bepayipi buyoba bushelelezi futhi bungabi namaphutha angase athinte amandla kanye nezakhiwo zokuvala zepayipi.

Amaphutha Amakhulu

Imiphetho ye-nibbled:Imiphetho enama-nibbled ingatholakala kangcono ngokuhlola okubonakalayo.

Ukusha kwe-arc:Ukushiswa kwe-arc kuzobhekwa njengokunesici.

Ukushiswa kwe-arc kuyinani lezindawo ezingasebenzi kahle ezakhiwe ukuncibilika kwendawo yensimbi okubangelwa i-arc phakathi kwe-electrode noma i-electrode ephansi kanye nangaphezulu kwepayipi lensimbi.

Izindawo zokuthintana ziyizindawo ezinyakazayo eduze komugqa wokushisela wepayipi le-EW, okubangelwa ukuthintana phakathi kwe-electrode ehlinzeka amandla okushisela kanye nobuso bepayipi.

I-Delamination:Noma ikuphi ukuncibilika noma ukufakwa okunwebeka ngaphezulu kwepayipi noma ubuso obunamamilimitha angu-6.4 (0.250 in) ngobude obuyindilinga ekuhlolweni okubonakalayo kuzobhekwa njengesici.

Ukuchezuka kweJomethrikhi:Ukuchezuka kwejiyomethri (isb., ibhulokhi eliyisicaba noma i-pout, njll.), ngaphandle komgodi wokudonsa, okubangelwa inqubo yokwakhiwa kweshubhu noma ukusebenza kokukhiqiza.Ibanga phakathi kwephuzu elidlulele kanye nokunwetshwa komkhonto ojwayelekile weshubhu, okungukuthi, ukujula okukhulu kuno-3.2 mm (0.125 in), kuzobhekwa njengesici.

Imigodi yokulahla izoba ≤ 0.5 D kunoma iyiphi indlela.

Ukuqina: Uma ukuhlolwa okubukwayo kuveza ubulukhuni okusolisayo, umhloli wokuqina ophathekayo uzosetshenziswa ukuze kuhlolwe ubulukhuni, futhi iphoyinti elilodwa lokuhlehlisa elinenani lokuqina elingaphezu kuka-35 HRC, 345 HV10, noma 327 HBW izobhekwa njengengenasici lapho usayizi yokuhlehlisa kukhulu kuno-50 mm (2.0 in) kunoma iyiphi indlela.

Ukuphatha Isici

Sicela ubheke izidingo ezifanele ku-API 5L Appendix C ukuze uphathwe.

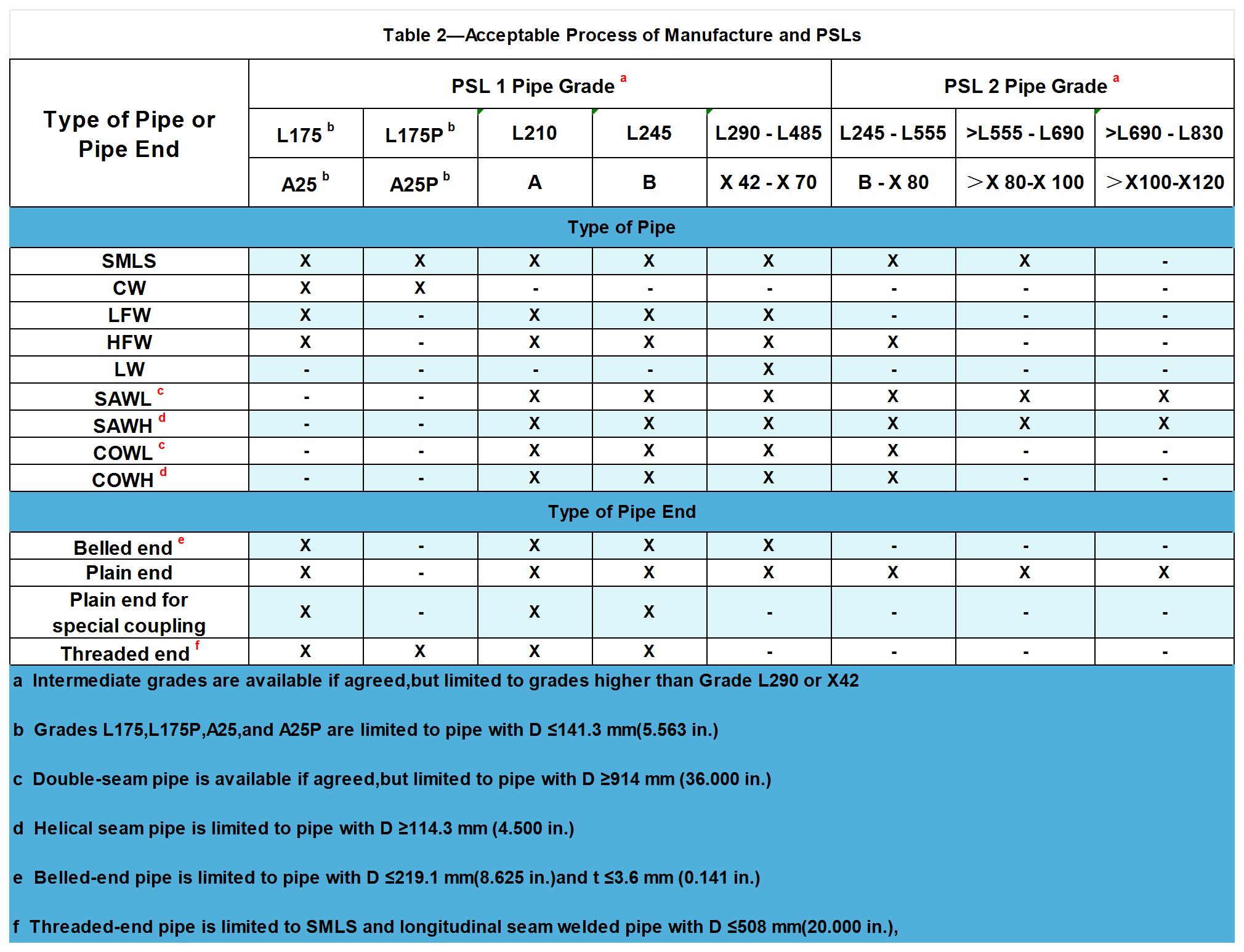

Ukuhlolwa kobukhulu (Ukuchezuka kobukhulu)

Ishadi Lesisindo Sombhobho kanye Nokwehluka Kwesisindo

Ifomula Yesisindo

M=(DT)×T×C

M yisisindo ngobude beyunithi ngayinye;

D wububanzi obushiwo bangaphandle, obuvezwa ngamamilimitha (amayintshi);

T iwugqinsi olucacisiwe lodonga, oluvezwa ngamamilimitha (amayintshi);

C ingu-0.02466 ezibalo zamayunithi e-SI kanye no-10.69 wezibalo zamayunithi e-USC.

AMASHADI Esisindo se-PIPE NAMASHEDULI

amatafula esisindo sepayipi ku-API 5L kubhekiselwa kuwoISO 4200futhiI-ASME B36.10M, ezinikeza amanani ajwayelekile epayipi elinobubanzi obushiwo bangaphandle kanye nogqinsi olucacisiwe lodonga.

Isheduli 40 kanye Isheduli 80kunamathiselwe ngezansi, uma ungathanda ukubona ishejuli yamapayipi egcwele,ngicela uchofoze lapha!

Ukuchezuka Kwesisindo

Ikhwalithi yepayipi ngayinye ehlobene ne-theoretical: isisindo: 95% ≤ isisindo sethiyori ≤ 110;

Ukuchezuka kanye namashubhu wokucaciswa okuncane kakhulu: 5% ≤ 110% wesisindo sethiyori;

I-L175, L175P, A25, ne-A25P amamaki ensimbi: 95% ≤ 110% wesisindo sethiyori.

Ububanzi Bangaphandle Nobukhulu Bodonga

| Ithebula 9—Kuvunyelwe Okucacisiwe Ububanzi Bangaphandle kanye Nokuqina Kwebonda Okucacisiwe | ||

| I-Diameter Yangaphandle Ecacisiwe D mm (ku.) | Ukuqina Kodonga Okucacisiwe t mm (ku.) | |

| Osayizi Bokukhanya Abakhethekilea | Osayizi Abavamile | |

| ≥10.3 (0.405)kuya ku-<13.7 (0.540) | - | ≥1.7 (0.068)kuya≤2.4 (0.094) |

| ≥13.7 (0.540)kuya ku-<17.1 (0.675) | - | ≥2.2 (0.088)kuya≤3.0 (0.118) |

| ≥17.1 (0.675)kuya ku-<21.3 (0.840) | - | ≥2.3 (0.091)kuya≤3.2 (0.125 |

| ≥21.3 (0.840)kuya ku-<26.7 (1.050) | - | ≥2.1 (0.083)kuya≤7.5(0.294) |

| ≥26.7(1.050)kuya ku-<33.4(1.315) | - | ≥2.1 (0.083)kuya≤7.8 (0.308) |

| ≥33.4(1311}5)kuya ku-<48.3 (1.900) | - | ≥2.1 (0.083)kuya≤10.0 (0.394) |

| ≥48.3 (1.900)kuya ku-<60.3 (2.375) | - | ≥2.1 (0.083)kuya≤12.5 (0.492) |

| ≥60.3 (2.375)kuya ku-<73.0 (2.875) | ≥2.1 (0.083)kuya≤3.6 (0.141) | >3.6 (0.141)kuya≤14.2 (0.559) |

| ≥73.0 (2.875)kuya ku-<88.9(3.500) | ≥2.1 (0.083)kuya≤3.6 (0.141) | >3.6 (0.141)kuya≤20.0 (0.787) |

| ≥88.9 (3.500)kuya ku-<101.6(4.000) | ≥2.1 (0.083)kuya≤4.0 (0.156) | >4.0 (0.156)kuya≤22.0 (0.866) |

| ≥101.6(4.000)kuya ku-<168.3 (6.625) | ≥2.1 (0.083)kuya≤4.0 (0.156) | >4.0(0.156)kuya≤25.0 (0.984) |

| ≥168.3 (6.625)kuya ku-<219.1 (8.625) | ≥2.1 (0.083)kuya≤4.0 (0.156 | >4.0 (0.156)kuya≤40.0(1.575) |

| ≥219.1 (8.625)kuya ku-<273.1 (10.750) | ≥3.2 (0.125)kuya≤4.0 (0.156 | >4.0 (0.156)kuya≤40.0 (1.575 |

| ≥273.1 (10.750)kuya ku-<323.9 (12.750) | ≥3.6 (0.141)kuya≤5.2 (0.203) | >5.2 (0.203)kuya≤45.0 (1.771) |

| ≥323.9(12.750)kuya ku-<355.6(14.000) | ≥4.0 (0.156)kuya≤5.6 (0.219) | >5.6 (0.219)kuya≤45.0(1.771 |

| ≥355.6(14.000)kuya ku-<457(18.000) | ≥4.5 (0.177)kuya≤7.1 (0.281) | >7.1 (0.281)kuya≤45.0(1.771 |

| ≥457 (18.000)kuya ku-<559 (22.000) | ≥4.8 (0.188)kuya≤7.1 (0.281) | >7.1 (0.281)kuya≤45.0(1.771) |

| ≥559 (22.000)kuya ku-<711(28.000) | ≥5.6 (0.219)kuya≤7.1 (0.281) | >7.1 (0.281)kuya≤45.0(1.771) |

| ≥711 (28.000)kuya ku-<864(34.000) | ≥5.6(0.219)kuya≤7.1 (0.281) | >7.1 (0.281)kuya≤52.0 (2.050) |

| ≥864 (34.000)kuya ku-<965(38.000) | - | ≥5.6 (0.219)kuya≤52.0 (2.050) |

| ≥965(38.000)kuya ku-<1422 (56.000) | - | ≥6.4 (0.250)kuya≤52.0 (2.050) |

| ≥1422(56.000)kuya ku-<1829 (72.000) | - | ≥9.5 (0.375)kuya≤52.0 (2.050 |

| ≥1829(72.000)kuya ku-<2134(84.000) | - | ≥10.3 (0.406)kuya≤52.0 (2.050) |

| aIpayipi elinenhlanganisela yobubanzi obushiwo bangaphandle kanye nogqinsi olucacisiwe lodonga lichazwa njengepayipi elikhethekile losayizi wokukhanya;ezinye izinhlanganisela ezinikezwe kuleli thebula zichazwa njengepayipi losayizi ojwayelekile. | ||

Ukuchezuka Kobubanzi kanye Nomjikelezo

Ukuchezuka Kokuqina Kodonga

| Ithebula 11—Ukubekezelela Ukuqina Kwezindonga | |

| Ukuqina Kwezindonga t mm (ku.) | Ukubekezelelanaa mm (ku.) |

| Ipayipi le-SMLSb | |

| ≤4.0 (0.157) | +0.6(0.024) -0.5 (0.020) |

| >4.0 (0.157)kuya ku-<25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146)noma+0.1t, noma yikuphi okukhulu -3.0 (0.120)noma-0.1t, noma yikuphi okukhulu |

| Ipayipi elishiselwecd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| >5.0 (0.197)kuya ku-<15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aUma i-oda lokuthenga licacisa ukubekezelela kokususa ukujiya kodonga okuncane kunenani elisebenzayo elinikezwe kuleli thebula, ukubekezelela okungeziwe kogqinsi lwezindonga kuzokwenyuswa ngenani elanele ukuze kugcinwe ububanzi obusebenzayo bokubekezelelana. bEpayipini eline-D2 355.6 mm (14.000 in.) kanye no-1 2 25.0 mm (0.984 in.), ukubekezelela ukushuba kodonga endaweni yangakini kungase kudlule ukubekezelela ukushuba kodonga ngo-0.05t owengeziwe, inqobo nje uma ukubekezelela okungeziwe kwesisindo (bona 9.14) aweqiwe. cUkubekezelela okungeziwe kokuqina kodonga akusebenzi endaweni yokushisela. dBheka 9.13.2 ukuze uthole imikhawulo eyengeziwe. | |

Ukuchezuka kobude

Ukubekezelela amashubhu obude obungashintshi: Ukuchezuka kobude kufanele kube ngu-500 mm (amayintshi angu-20).

Ukubekezelela amapayipi ubude okungahleliwe:

| Ithebula 12—Ukubekezelelwa Kwepayipi Lobude Okungahleliwe | |||

| Ubude obungahleliwe Ukuqokwa m(ft) | Ubude obuncane m (ft) | Ubude Obumaphakathi obuncane Ngento ye-oda ngayinye m (ft) | Ubude obukhulu m (ft) |

| Ipayipi elinentambo-futhi-ehlanganisiwe | |||

| 6(20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72(45.0 |

| Ipayipi elingenalutho | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15(50) | 5.33 (17.5) | 13.35(43.8) | 16.76(55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34(70.0) | 25.91(85.0) |

Ukuchezuka kokuqondisa

Ukuchezuka okuphelele emugqeni oqondile kubo bonke ubude bepayipi kuzoba ngu-<0.2% wobude bepayipi;

Ukuchezuka kwendawo ukusuka emugqeni oqondile kuzoba ngu-<3.2 mm (0.125 in) ngaphezu kobude obungu-1.5 m (5.0 ft) ekugcineni kwepayipi ngalinye.

I-Bevel Angle Deviation

Ishubhu eno-t > 3.2 mm (0.125 in) iziphetho eziyisicaba izokwenziwa ngomshini nge-weld bevel ene-engeli ye-bevel engu-30 ° -35 °.

Ububanzi Bendawo Yezimpande Ethuthukisiwe

1.6 mm (0.063 in) ngokuchezuka okungu-±0.8 mm (0.031 in).

Ububanzi be-Inner Cone Angle (kuphela kwepayipi lensimbi elingenamthungo)

| Ithebula 13—I-Engeli Ephezulu Ye-Taper Yangaphakathi Yepayipi le-SMLS | |

| Ukuqina Kodonga Okucacisiwe t mm (ku.) | I-Engeli ephezulu ye-Taper amadigri |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413)kuya ku-<14.0 (0.551) | 9.5 |

| 14.0 (0.551)kuya ku-<17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

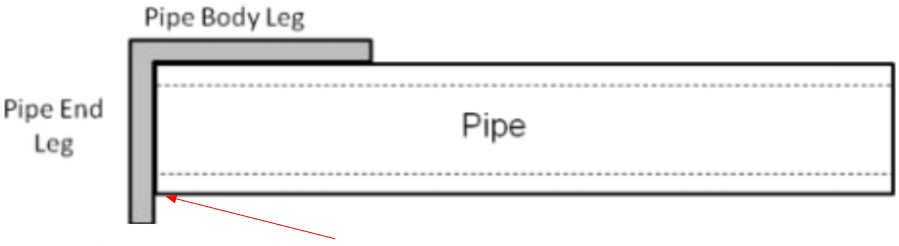

I-Pipe End Squareness (ngaphandle kwesikwele)

I-out-of-squareness ikalwa njengegebe phakathi kokuphela kwepayipi nomlenze wokuphela kwepayipi, okuzoba ngu-1.6 mm (0.063 in.).

Ukuphambuka Kwe-Welding Seam

Ukungaqondani Kahle Komdwe/Ishidi:

Epayipini eline-electro-welded (EW) kanye ne-laser-welded (LW), ukungaqondani kahle akumele kubangele ukujiya kodonga olusele endaweni yokushisela okungaphansi kobukhulu obuncane obuvunyelwe bodonga.

Ngepayipi elishiselwe i-Submerged Arc Welded (SAW) kanye neCombination Welded (COW), ukungaboni ngaso linye akufanele kudlule amanani ahambisanayo anikezwe kuThebula 14 le-API 5L.

Burrs (amashubhu e-electro-welded (EW) kanye ne-laser-welded (LW)):

Ama-burrs angaphandle azosuswa ayiswe esimweni sokuguquguquka kakhulu (ngesisekelo sempahla).

Amabhula angaphakathi akufanele anwebe ngo-1.5 mm (0.060 in) ngale komphetho weshubhu, futhi ukujiya kodonga endaweni yokukhipha amabhar akufanele kube ngaphansi kobukhulu obuncane obuvunyelwe bodonga.

Ukuphakama Kwe-Weld(I-Summerged Arc Welding (SAW) kanye ne-Combination Welding (COW) Pipe):

Susa ubude obusele be-weld yangaphakathi phakathi okungenani kuka-100 mm (4.0 in) wokuphela kwepayipi ekugcineni ngakunye kwepayipi, futhi ugaye i-weld ukuze ingakhuphuki ngaphezu kuka-0.5 mm (0.020 in) ngaphezu kwendawo wepayipi eliseduze.

Izinto Zokuhlola ze-API 5L

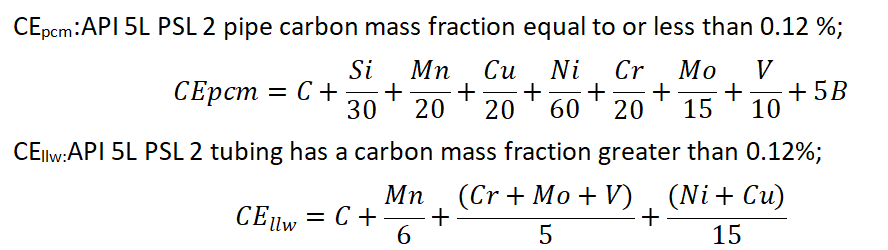

Ukwakheka Kwamakhemikhali

Indlela Yokuhlola: Bheka ku-ISO 9769 noma ku-ASTM A751.

Ukwakheka kwamakhemikhali kwe-API 5L PSL1 kanye ne-API 5L PSL2 ipayipi lensimbi t > 25.0 mm (0.984 in) kuzonqunywa ngezingxoxo ezisekelwe ekwakhiweni kwamakhemikhali kumathebula ahambisanayo.

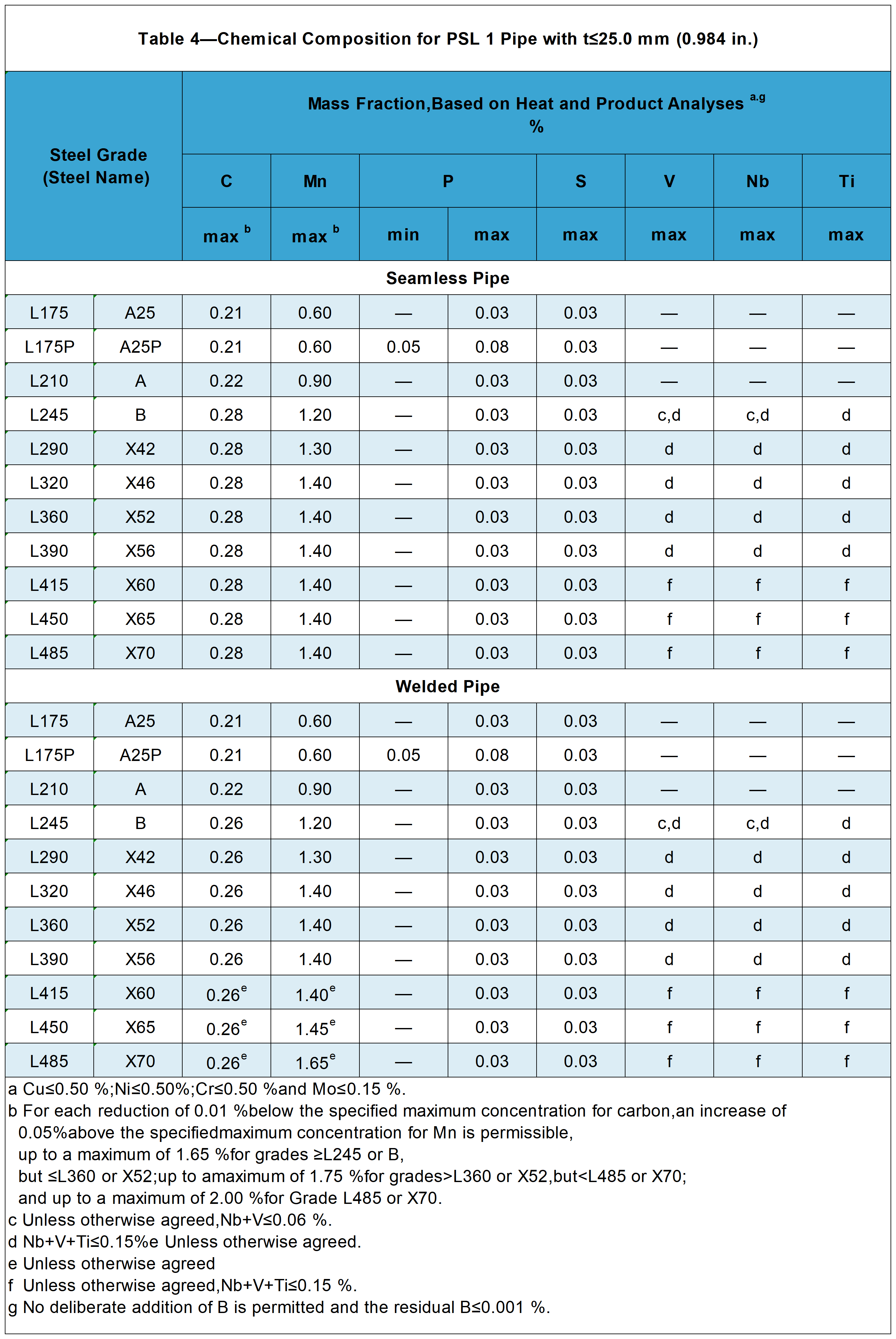

Ukwakheka Kwekhemikhali kwe-PSL 1 Ipayipi eno-t≤25.0 mm (0.984 in.)

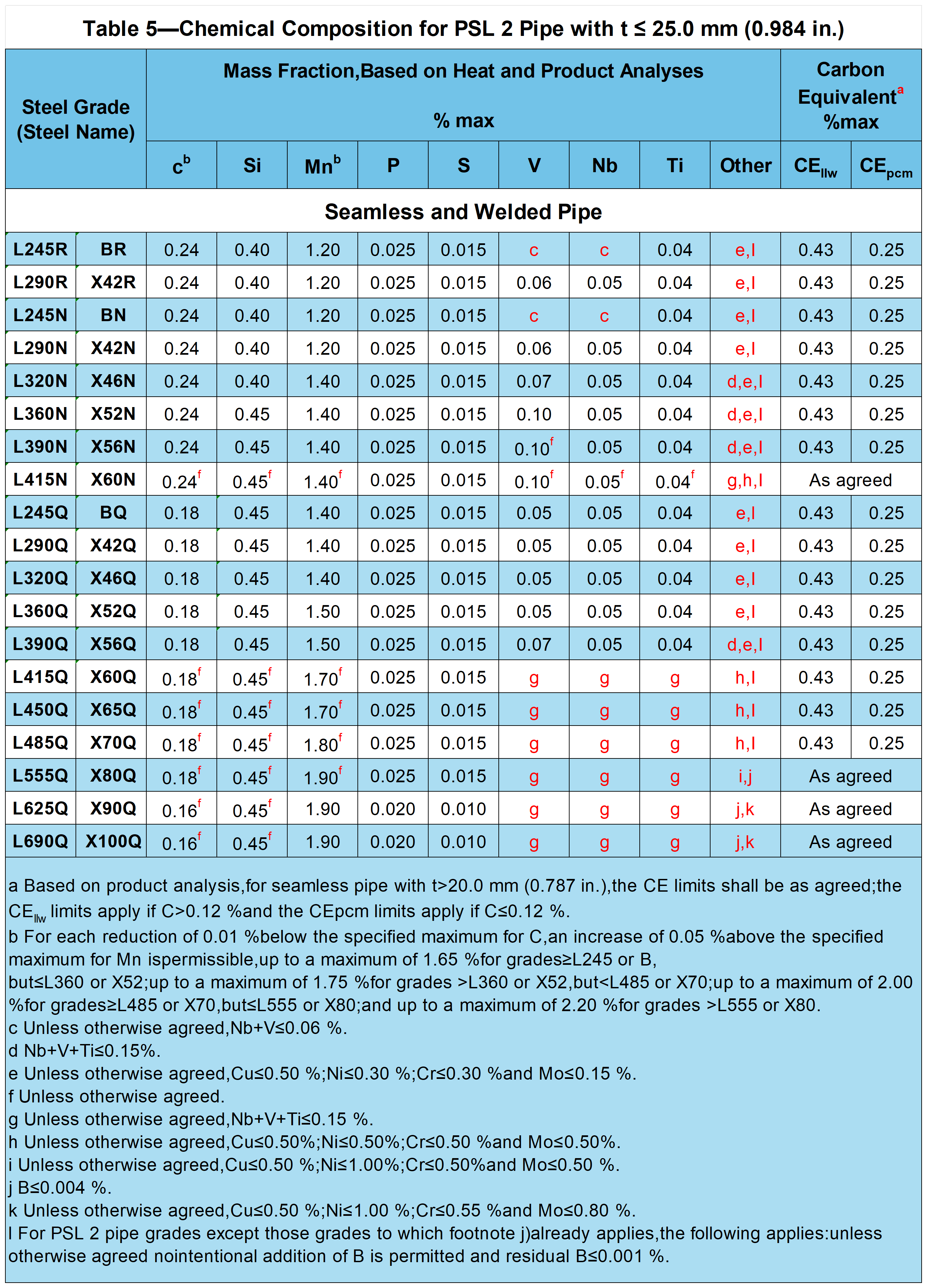

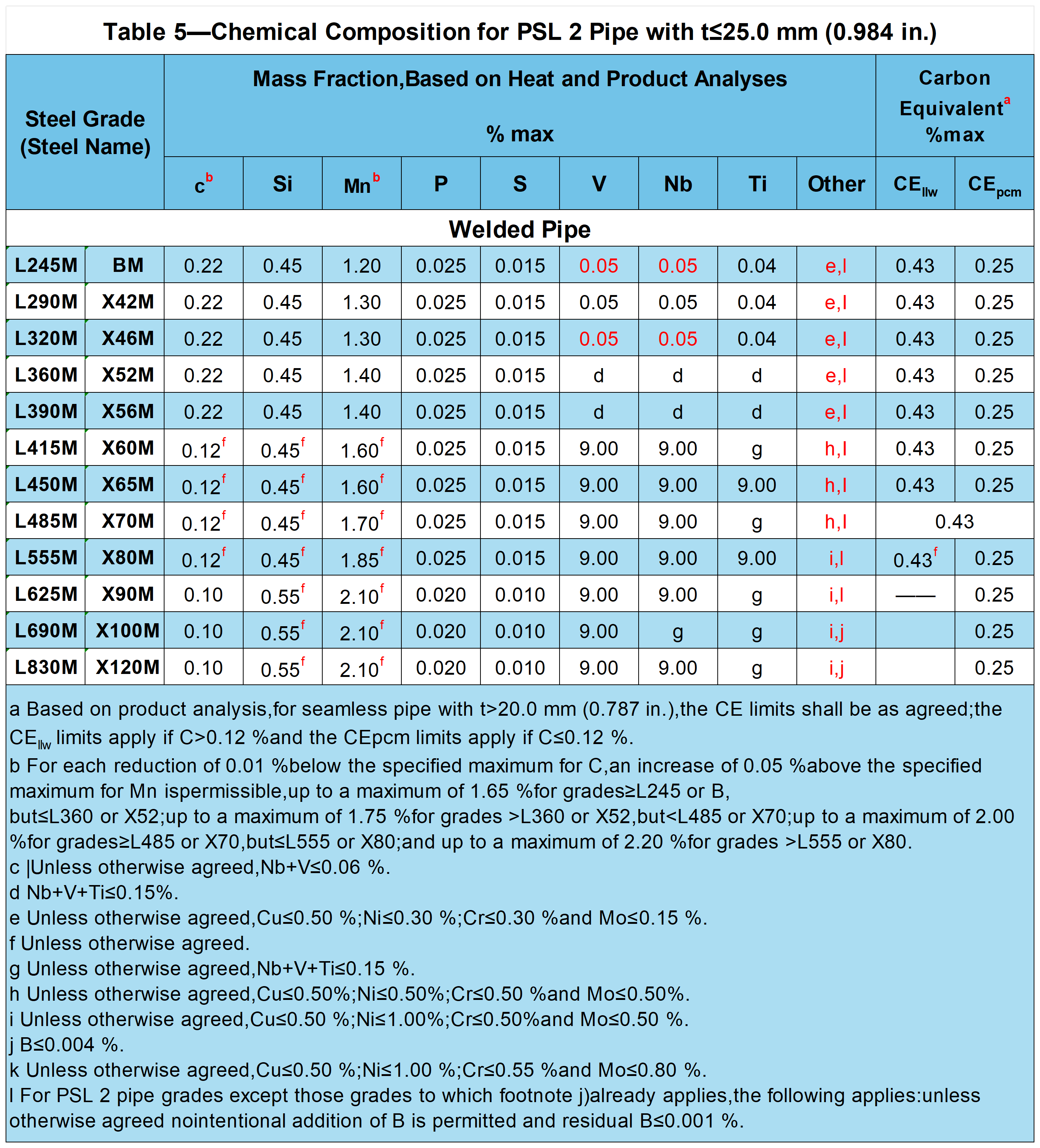

Ukwakheka Kwekhemikhali ye-PSL 2 Ipayipi eno-t≤25.0 mm (0.984 in.)

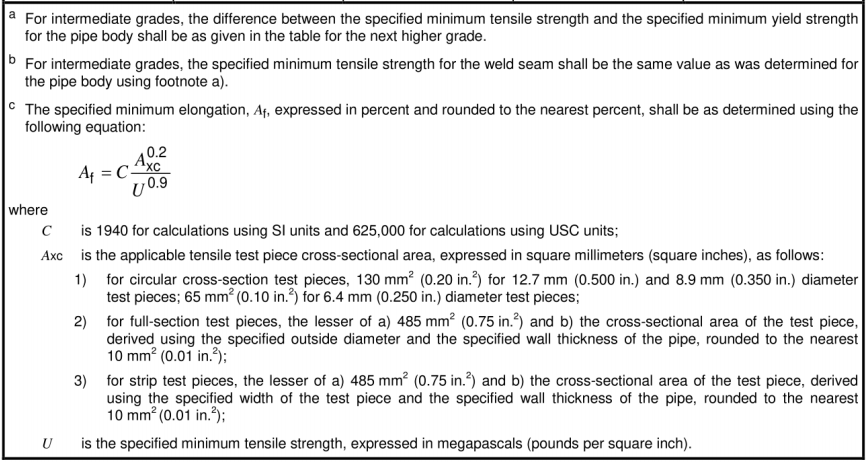

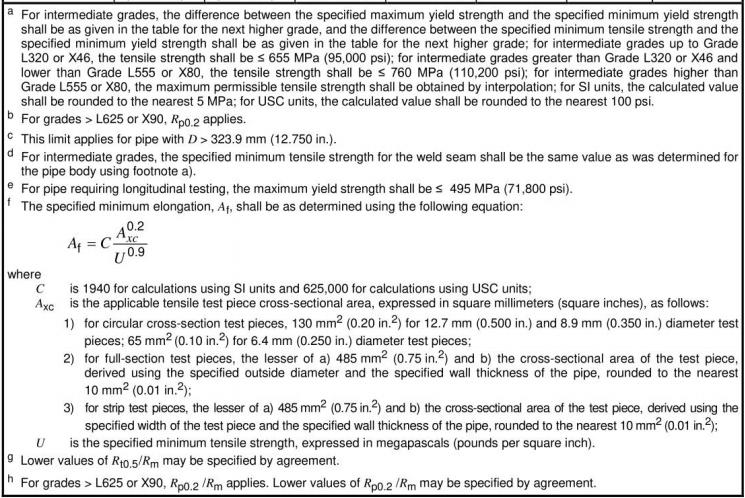

I-Tensile Properties

Izindlela Zokuhlola: Kuzokwenziwa ngokuvumelana ne-ISO 6892-1 noma i-ASTM A370.

Izidingo zemiphumela ye-Tensile Test ye-PSL 1 Pipe

| Ithebula lesi-6—Izimfuneko zemiphumela yokuhlolwa kwe-Tensile ye-PSL 1 Pipe | ||||

| Ibanga lombhobho | Ipayipi Lomzimba Wepayipi Elingenamthungo nelishiselwe | I-Weld Seam ye-EW, I-LW, i-SAW, ne-COW Pipe | ||

| Isivuno Amandlaa Rkuye.5 I-MPa(psi) | Amandla Okuqinaa Rm I-MPa(psi) | Ukwelula (ku-50 mm noma 2 in.) Af % | Amandla Okuqinab Rm I-MPa(psi) | |

| imiz | imiz | imiz | imiz | |

| I-L175 noma i-A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| I-L175P noma i-A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 noma A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 noma B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| I-L290 noma i-X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| I-L320 noma i-X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| I-L360 noma i-X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| I-L390 noma i-X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| I-L415 noma i-X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| I-L450 noma i-X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| I-L485 noma i-X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Izidingo zemiphumela ye-Tensile Test ye-PSL 2 Pipe

| Ithebula lesi-7—Izimfuneko zemiphumela yokuhlolwa kwe-Tensile ye-PSL 2 Pipe | |||||||

| Ibanga lombhobho | Ipayipi Lomzimba Wepayipi Elingenamthungo nelishiselwe | I-Weld Seam kwe HFW SAW kanye Ipayipi le-CoW | |||||

| Isivuno Amandlaa Rto.5 I-MPa(psi) | Amandla Okuqinaa Rm I-MPa (psi) | Isilinganisoac Rt0.5/Rm | Ukwelula (ku-50 mm noma 2 in.) Af % | I-tensile Amandlad Rm I-MPa (psi) | |||

| imiz | ubuningi | imiz | ubuningi | ubuningi | imiz | imiz | |

| I-L245R noma i-BR I-L245N noma i-BN I-L245Q noma i-BQ I-L245M noma i-BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| I-L290R noma i-X42R I-L290N noma i-X42N I-L290Q noma i-X42Q I-L290M noma i-X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| I-L320N noma i-X46N I-L320Q noma i-X46Q I-L320M noma i-X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| I-L360N noma i-X52N I-L360Q noma i-X52Q I-L360M noma i-X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| I-L390N noma i-X56N I-L390Q noma i-X56Q I-L390M noma i-X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| I-L390N noma i-X56N I-L390Q noma i-X56Q I-L390M noma i-X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| I-L415N noma i-X60N I-L415Q noma i-X60Q I-L415M noma i-X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| I-L450Q noma i-X65Q I-L450M noma i-X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| I-L485Q noma i-X70Q I-L485M noma i-X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| I-L555Q noma i-X80Q I-L555M noma i-X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| I-L625M noma i-X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| I-L625Q noma i-X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| I-L690M noma i-X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| I-L690Q noma i-X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| I-L830M noma i-X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Ubude bephesenti ngesikhathi sekhefu kufanele kubikwe kumasampula anegeji yobude obungu-50 mm (2 in).

Ezibonelweni ezinobude begeji obungaphansi kuka-50 mm (2 in), ubude ngesikhathi sekhefu kufanele buguqulelwe kubude obungu-50 mm (2 in) ngokuhambisana ne-ISO 2566-1 noma i-ASTM A370.

I-Hydrostatic Pressure Test

Indlela yokuhlola: API 5L 10.2.6.

Bonke osayizi bepayipi elingenamthungo (SMLS) kanye nepayipi elishiselwe eline-D ≤ 457 mm (18.000 in) bazoba nesikhathi sokuzinza esingekho ngaphansi kwamasekhondi angu-5.ipayipi elishiselwe eline-D > 457 mm (18.000 in) lizoba nesikhathi sokuzinza esingekho ngaphansi kwamasekhondi ayi-10.

Bend Test

Izindlela Zokuhlola: Ukuhlolwa kokugoba kuzohambisana nezidingo ze-ISO 8491 noma i-ASTM A370.

Ayikho ingxenye yesampula ezoqhekeka futhi i-weld ngeke iqhekeke.

Ibanga le-L175P/A25P yinsimbi ethuthukisiwe ye-phosphorus enikeza ukusebenza okungcono kokulutha kunensimbi ye-L175/A25 kodwa okunzima kakhulu ukugoba.

Ukuhlola Ukucaba

Izindlela Zokuhlola: Ukuhlolwa kokucindezelwa kuzohambisana nezidingo ze-ISO 8492 noma i-ASTM A370.

Ibanga phakathi kwamapuleti amabili liyoba ngendlela yokuthi kungabikho ukuqhekeka kwe-weld okuzokwenzeka kuze kube yilapho ibanga elibekiwe selifinyelelwe.

Ukuhlola Ukugoba Okuqondisiwe

Izindlela Zokuhlola: Ukuhlolwa kokugoba okuqondisiwe kuzohambisana nezidingo ze-ISO 5173 noma ze-ASTM A370.

Ukuhlolwa kokuqina

Indlela yokuhlola: Ukuhlolwa kokuqina ngokwe-ISO 6506, ISO 6507, ISO 6508, noma i-ASTM A370.

Lapho kutholakala izigaxa eziqinile ezisolisayo ekuhlolweni kokubukeka, umhloli wokuqina ophathekayo kufanele asetshenziselwe ukuhlola ubulukhuni.

I-CVN Impact Test ye-API 5L PSL2 Steel Pipe

Izindlela Zokuhlola: Ukuhlolwa komthelela we-charpy kuzohlangabezana nezidingo ze-ASTM A370.

I-DWT Test ye-API 5L PSL2 Welded Pipe

Indlela yokuhlola: Ukuhlolwa kwe-DWT kuzohambisana ne-API5L3.

I-Macro-Inspection kanye nokuhlolwa kwe-Metallographic

Ukuchezuka kwe-weld kwangaphakathi nangaphandle kwepayipi elishiselwe i-arc elingaphansi kwamanzi (SAW) kanye ne-combi-welded (COW) kufanele kuhlolwe ngokuhlolwa okukhulu.

Kumashubhu adinga ukwelashwa kokushiswa kwe-weld, ukuhlolwa kwe-metallurgical kuzokwenziwa ukuze kuqinisekiswe ukuthi yonke i-HAZ ilashwe ngokufanele ngokushisa odongeni oluphelele.

Kumashubhu angadingi ukwelashwa kokushiswa kwe-weld, ukuhlolwa kwe-metallographic kuzokwenziwa ukuze kuqinisekiswe ukuthi ayikho i-martensite engavunyelwe esele.

Ukuhlola Okungabhubhisi (kuphela amapayipi amathathu enhloso ekhethekile ye-API 5L PSL2)

Indlela yokuhlola: API 5L Annex E.

Ukumakwa Kwepayipi kanye Nendawo

Izinto ezivamile zokumaka zamashubhu ensimbi:

Igama lomkhiqizi wamapayipi noma ukumaka;

Imaka "API Spec 5L".(Ngokujwayelekile ifushaniswe ku-API 5L.) Imikhiqizo ehambisana nezinga elihambisanayo elingaphezu kwelilodwa ingase imakwe ngegama lezinga ngalinye.

I-Diameter Yangaphandle Ecacisiwe

Ukuqina kodonga olucacisiwe

Ibanga lepayipi (igama lensimbi)

Uhlobo lwepayipi

Ubude (ubude bepayipi ngo-m ukuya endaweni eseduze engu-0.01 m (ku-ft ukuya endaweni eseduze yeshumi yonyawo))

Indawo yezimpawu zamapayipi ensimbi

D ≤ 48.3 mm (1.900 in) ipayipi lensimbi: Amathebhu akhiwa ngokuqhubekayo ngobude bepayipi lensimbi noma angaboshelwa kunqwaba yamapayipi ensimbi.

Ipayipi eline-D > 48.3 mm (1.900 in):

Indawo engaphandle: Iqala endaweni engaphandle yepayipi phakathi kuka-450 mm no-760 mm (1.5 ft kanye no-2.5 ft) ukusuka ekugcineni kwepayipi.

Indawo engaphakathi: Qala ukumaka endaweni engaphakathi yepayipi okungenani u-150 mm (6.0 in) ukusuka ekugcineni kwepayipi.

I-Equivalence Standard

Amazinga wamapayipi aphesheya nawesifunda kanye neshubhu lapho i-API 5L ilingana noma, ezimeni ezithile, inketho ehlukile, kanye nenani lamazinga aqondene nohlelo lokusebenza:

Izindinganiso zamazwe ngamazwe nezesifunda

1. ISO 3183 - Izinga lephayiphi lomhlaba wonke lemboni kawoyela negesi elishicilelwe yi-International Organisation for Standardization futhi elihlobene eduze ne-API 5L.

2. I-EN 10208 - Izinga laseYurophu lamapayipi ensimbi okuthutha amagesi kaphethiloli noketshezi.

3. I-GB/T 9711 - Izinga lezwe laseShayina lezinhlelo zokuthutha zamapayipi embonini kawoyela negesi.

4. I-CSA Z245.1 - Ipayipi likalayini elimboza i-Canadian Standard lokuthutha uwoyela negesi.

5. I-GOST 20295 - I-Russian Standard yepayipi yensimbi yokuthutha uwoyela nemikhiqizo kawoyela.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards for line pipe yemboni kawoyela negesi.

7. I-JIS G3454, G3455, G3456 - Amazinga Ezimboni ZaseJapane zamapayipi okudlulisela amakilasi ahlukene okucindezela.

8. I-DIN EN ISO 3183 - I-German Industrial Standard esekelwe ku-ISO 3183 yamapayipi kalayini.

9. AS 2885 - I-Australian Standard yezinhlelo zamapayipi kalayini zokuthutha uwoyela negesi.

Amazinga Akhethekile Wohlelo

1. I-API 5CT - I-American Petroleum Institute standard ye-oyela well casing kanye neshubhu, okuthi, nakuba isetshenziswa ngokuyinhloko emithonjeni kawoyela, nayo ibalulekile embonini kawoyela negesi.

2. I-ASTM A106 - Indinganiso Yenhlangano YaseMelika Yokuhlola Nezinto Zokusebenza yepayipi lensimbi lensimbi engenamthungo nelishiselwe lesevisi yezinga lokushisa eliphezulu.

3. I-ASTM A53 - Isikhungo Sikazwelonke Sokuhlola Nezinto Zokusebenza indinganiso yepayipi lensimbi yensimbi engenamthungo neshiselwe, ngokuvamile elisetshenziselwa ukuthutha uketshezi ekamelweni lokushisa noma amazinga okushisa aphansi.

4. ISO 3834 - Inhlangano Yamazwe Ngamazwe Yezinga Elijwayelekile lezidingo zekhwalithi, egxile ezinhlelweni zokuqinisekisa ikhwalithi zezinsimbi ezishiselwe.

5. dnv-os-f101 - Izinga lomphakathi lokuhlukaniswa kwe-Norwegian lezinhlelo zamapayipi angaphansi kolwandle amapayipi kawoyela negesi asogwini lolwandle.

6. I-MSS SP-75 - Izinga le-Manufacturers Standards Society eligxile emandleni aphezulu, ukufakwa kwamapayipi ensimbi ashiselwe ngobubanzi obukhulu obuyindilinga.

Ukuphathwa Kwekhwalithi kanye Namazinga Okufaneleka Kwendawo

1. I-NACE MR0175/ISO 15156 - Izidingo zezinto ezisetshenziswa ekukhishweni kukawoyela negesi ezindaweni ezine-hydrocarbon enesibabule, okuthi, ngenkathi kukhulunywa ngokuyinhloko ngokukhethwa kwezinto ezibonakalayo, zibalulekile ekuqinisekiseni ukumelana nokugqwala kwezinto ezisetshenziswa embonini kawoyela negesi.

Imikhiqizo Yethu Ehlobene

I-API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Ipayipi Elishiselwe

I-API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Ipayipi Lensimbi Lekhabhoni

I-API 5L GR.B Ipayipi Yensimbi Eqinile Eqinile Yokucutshungulwa Komshini

I-API 5L Gr.X52N PSL 2 Seamless Steel Pipe ACC.Kuya ku-IPS-M-PI-190(3) & NACE MR-01-75 ngesevisi emuncu

I-API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Amafutha neGas Carbon Seamless Steel Pipe

I-API 5L GR.B Ipayipi Lomugqa Ongenamthungo wengcindezi nesakhiwo

I-API 5L/ASTM A106/ASTM A53 Gr.B Ipayipi Lensimbi Lekhabhoni Elingenamthungo

I-BotopSteel iyingcweti yaseChinaUmkhiqizi & Abahlinzeki Bempahla Yamapayipi Ensimbi EshiselweIminyaka engaphezu kwengu-16 enamathani angu-8000+ weMibhobho Yomugqa Ongenamthungo esitokweni Inyanga ngayinye.Sesilungele ukukuphendula phakathi kwamahora angu-24 ngemva nje kokuthola isicelo esisodwa futhi sithuthukise izinzuzo nenhlangano ezuzisayo enganqunyelwe.

tag: API 56 46th, Dimensional Deviations, PSL1, PSL2,abahlinzeki, abakhiqizi, izimboni, amasheya, izinkampani, iwholesale, thenga, inani, ikhotheshini, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: Mar-22-2024