I-ASTM A106 ne-ASTM A53 zisetshenziswa kabanzi njengezindinganiso ezivamile zokwenziwa kwepayipi lensimbi ye-carbon.

Nakuba amashubhu ensimbi e-ASTM A53 kanye ne-ASTM A106 eshintshana kwezinye izinhlelo zokusebenza zezimboni, izakhiwo zawo ezihlukene zenza ukukhetha okufanele kwamashubhu amisiwe kubaluleke kakhulu ezindaweni ezithile nezimo ezithile.

Izinkinobho Zokuzulazula

Uhlobo Lwepayipi

Ipayipi lensimbi le-ASTM A53 libandakanya ipayipi lensimbi elishiselwe futhi elingenamthungo.

I-ASTM A106 ihlanganisa kuphela ipayipi lensimbi elingenamthungo.

| Okujwayelekile | Ububanzi | Izinhlobo | Ibanga | |

| I-ASTM A106: Ipayipi Lensimbi Lekhabhoni Elingenamthungo Yesevisi Yezinga Lokushisa Eliphezulu | I-NPS 1/8 - 48 in (DN 6 -1200mm) | Ipayipi Lensimbi Le-Carbon Elingenamthungo | A, B, kanye no-C | |

| I-ASTM A53: Imnyama futhi Iyashisa, Ifakwe Zinc, Ishiselwe futhi Ayinamthungo | I-NPS 1/8 - 26 in (DN 6 -650mm) | uhlobo S: Ayinamthungo | U-A kanye no-B | |

| uhlobo F: Isithando somlilo-izinqe-ezishiselwe, ezishiselwe ngokuqhubekayo | U-A kanye no-B | |||

| uhlobo E: Ukumelana nogesi-okushiselwe | U-A kanye no-B | |||

| Qaphela: Womabili amazinga avumela ukuhlinzekwa kwepayipi elinobunye ubukhulu inqobo nje uma lihlangabezana nazo zonke ezinye izidingo zekhodi. | ||||

Izidingo Zokwelashwa Kokushisa

I-ASTM A106

Kumelwe iphathwe ngokushisa, ngokuvamile ngokujwayela (inqubo yokushisisa ngaphezu kwezinga lokushisa elibalulekile bese ipholisa izinga lokushisa elimaphakathi).

Ipayipi eligoqiwe elishisayo: alidingi ukwelashwa kokushisa.Uma ipayipi eligoqiwe elishisayo liphathwa ngokushisa, lizophathwa ngokushisa ku-1200 °F [650 °C] noma ngaphezulu.

Ipayipi elidonswa ngokubanda: lizophathwa ngokushisisa ku-1200 °F [650 °C] noma ngaphezulu ngemva kwenqubo yokugcina yokudweba okubandayo.

I-ASTM A53

Uhlobo E, Ibanga B, Nohlobo F, IBanga B: luzophathwa ngokushisa ngemva kokushiselwa okungenani lube ngu-1000 °F [540°C] ukuze kungabikho i-martensite engavunyelwe ekhona, noma iphathwe ngenye indlela ukuze kungabi khona i-martensite engapheli.

Uhlobo S: Ukwelashwa kokushisa akudingekile kumapayipi angenamthungo.

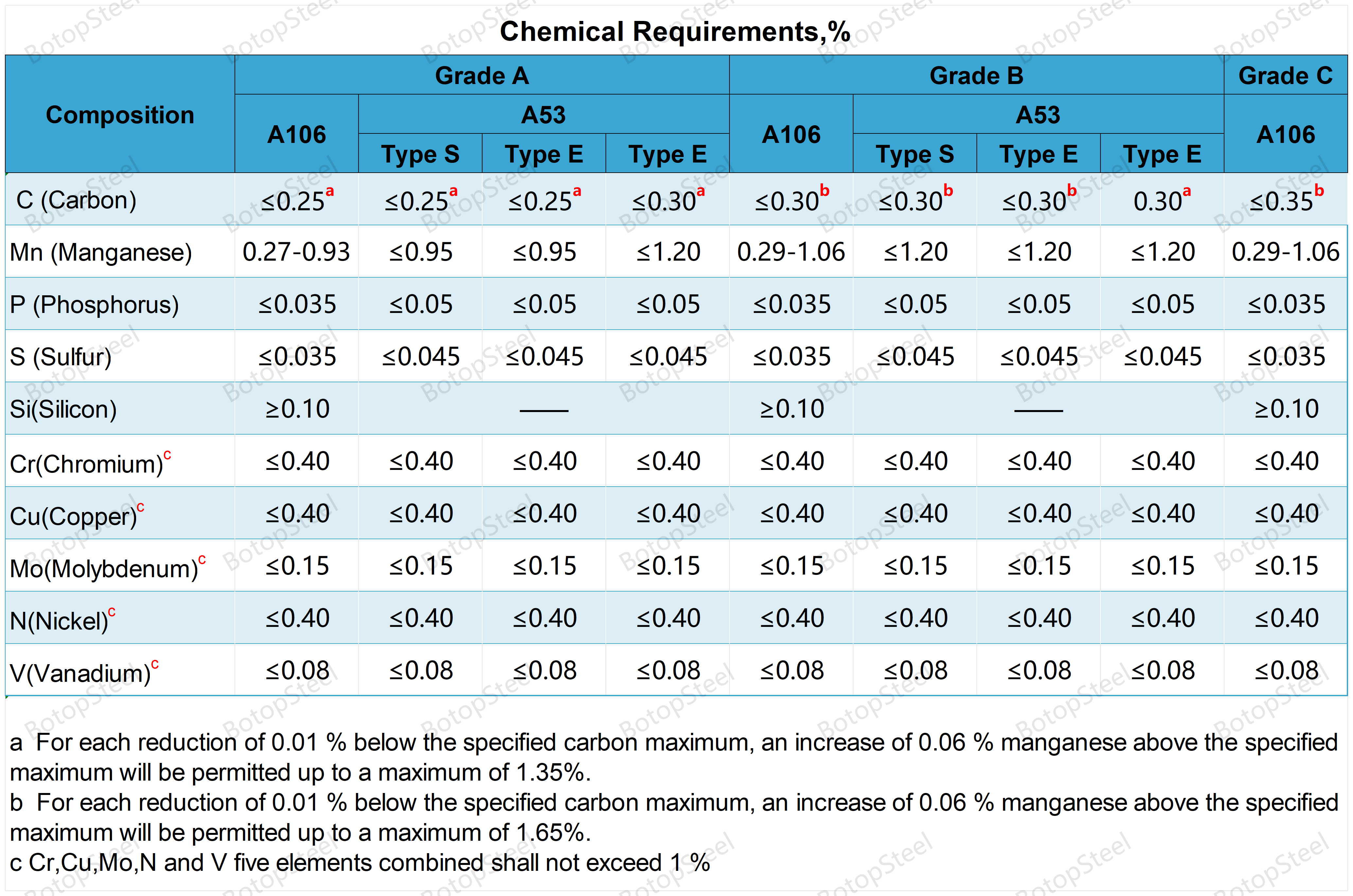

Izingxenye Zekhemikhali

Lapho kuhlaziywa ukwakheka kwamakhemikhali kwe-ASTM A53 kanye neshubhu ye-ASTM A106, umehluko omkhulu obalulekile ungaqashelwa.I-ASTM A106 icacisa okuqukethwe kwe-silicon (Si) okungengaphansi kuka-0.10%, okunomthelela ekusebenzeni kwayo emazingeni okushisa aphakeme, okuyenza ifaneleke ikakhulukazi ukusetshenziswa ezindaweni ezinezinga lokushisa eliphezulu njengalezo ezisembonini ye-petrochemical kanye nezinhlelo zokuhambisa isitimu.

Kokuqukethwe kwekhabhoni (C), izinga le-ASTM A53 licacisa umkhawulo ongaphezulu ophansi, ikakhulukazi kumabanga A no-B oHlobo S noHlobo E. Lokhu kwenza amashubhu oHlobo lwe-A53 afaneleke kakhulu ekushiseleni nasekusebenzeni okubandayo ngakho-ke avame ukusetshenziswa ekwakheni nasemanzini. izinhlelo zokuhamba, njengamapayipi amanzi negesi.

Mayelana nokuqukethwe kwe-manganese (Mn), i-ASTM A106 ihlinzeka ngebanga elibanzi leBanga B kanye no-C, elivumela ukuguquguquka okuthuthukisiwe enqubweni yokukhiqiza ngenkathi kuthuthukiswa amandla.Ngakolunye uhlangothi, ipayipi le-A53 lilinganiselwe emkhawulweni ongaphezulu oqinile wokuqukethwe kwe-manganese, okwenza kube lula ukuzinza ngesikhathi sokushisela.

Izakhiwo Zemishini

| Ukwakheka | Ukwahlukanisa | Ibanga A | Ibanga B | Ibanga C | ||

| A106 | A53 | A106 | A53 | A106 | ||

| Amandla aqinile imiz | psi | 48,000 | 48,000 | 60,000 | 60,000 | 70,000 |

| I-MPa | 330 | 330 | 415 | 415 | 485 | |

| Amandla esivuno imiz | psi | 30,000 | 30,000 | 35,000 | 35,000 | 40,000 |

| I-MPa | 205 | 205 | 240 | 240 | 275 | |

I-ASTM A106 IBanga A kanye neBanga B banezidingo ezifanayo neze-ASTM A53 IBanga A kanye neBanga B ngokwamandla esivuno namandla okuqina.

Kodwa-ke, i-ASTM A106 Grade C iyisetha ibha phezulu, okusho ukuthi inikeza ukusebenza okungcono ngaphansi kwezimo zokusebenza ezidlulele kakhulu, njengezingcindezi eziphezulu noma amazinga okushisa.

Lezi zakhiwo ezengeziwe zemishini zenza iBanga C lifaneleke kakhulu izinhlelo zokusebenza zezimboni ezikhethekile ezidinga izinto ezinekhono elingcono lokuthwala umthwalo kanye nokuqina.

I-Dimensional Tolerances

I-ASTM A106 Izidingo Eziqondile Zokubekezelelana Kobukhulu

| Uhlu | Ububanzi | Qaphela | |

| IMisa | 96.5%-110% | Ngaphandle uma kuvunyelwene ngenye indlela phakathi komkhiqizi nomthengi, ipayipi eliku-NPS 4 [DN 100] nangaphansi lingakalwa ngenkatho efanelekile;ipayipi elikhulu kune-NPS 4 (DN 100] lizokalwa ngokuhlukana. | |

| Ububanzi (ububanzi obukhulu kuno-10in (DN250)) | ±1% | I-Diameter-Ngaphandle kokuthi ihlinzekwe ngepayipi elinodonga oluncane isigaba 12.2 se-Specification A530/A530M, ukubekezelelana i-diameter kufanele ihambisane nalokhu okulandelayo: | |

| Ububanzi Bangaphakathi (I-diameter yangaphakathi inkulu kuno-10in(DN250)) | ±1% | ||

| Ubukhulu | iminithi 87.5% | —- | |

| Ubude | Ubude obubodwa obungahleliwe | izoba ngu-16 kuya ku-22 ft (4.8 kuya ku-6.7 m) ubude, ngaphandle kokuthi u-5 % uzovunyelwa ukuba ube ngaphansi kuka-16 ft (4.8 m) futhi akekho oyoba ngaphansi kuka-12 ft (3.7 m) | —- |

| Ubude obuphindwe kabili obungahleliwe | izoba nobuncane isilinganiso sobude obungu-35 ft (10.7 m) futhi buzoba nobuncane bobude obungu-22 ft (6.7 m), ngaphandle kokuthi u-5 % uzovunyelwa ukuthi ube ngaphansi kuka-22 ft (6.7 m) futhi akukho okuzoba ngaphansi kuka-16 ft ( 4.8 m) | —- | |

Izidingo Eziqondile ze-ASTM A53 Zokubekezelelana Kobukhulu

| Uhlu | hlunga | ububanzi |

| IMisa | Isisindo sethiyori = ubude x isisindo esishiwo (ngokuhambisana nezidingo ezikumathebula 2.2 kanye no-2.3) | ±10% |

| Ububanzi | I-DN 40mm[NPS 1/2] noma encane | ±0.4mm |

| I-DN 50mm[NPS 2] noma ngaphezulu | ±1% | |

| Ubukhulu | ubuncane bodonga obukhulu kufanele buhambisane neThebula X2.4 | iminithi 87.5% |

| Ubude | ilula kunesisindo esinamandla kakhulu(XS). | 4.88m-6.71m (hhayi ngaphezu kuka-5% wesamba inombolo yobude obucutshiwe obunikezwe ngokuba amajoyinti (izingcezu ezimbili ezihlanganiswe ndawonye)) |

| ilula kunesisindo esinamandla kakhulu(XS). (ipayipi elingenalutho) | 3.66m-4.88m (Ayidluli ku-5% yenani eliphelele) | |

| I-XS, XXS, noma ukujiya kodonga | 3.66m-6.71m (akukho ngaphezu kuka-5% isiyonke ipayipi 1.83m-3.66m) | |

| ilula kunesisindo esinamandla kakhulu(XS). (ubude obuphindwe kabili okungahleliwe) | ≥6.71m (Isilinganiso esimaphakathi sobude obungu-10.67m) |

Izinhlelo zokusebenza

Izidingo zokuklama nokukhiqiza ze-ASTM A53 kanye nepayipi lensimbi le-ASTM A106 zibonakalisa izimo ezihlukile zohlelo lokusebenza zazo.

Ipayipi lensimbi le-ASTM A53ivamise ukusetshenziswa ekwakhiweni nasezakhiweni zemishini nasezindaweni ezinengcindezi encane yokuthutha uketshezi noma amagesi, njengamanzi kamasipala kanye negesi yemvelo.

Amashubhu ensimbi e-ASTM A106asetshenziswa kakhulu ezinhlelweni ezingaphansi kwezindawo ezishisa kakhulu, njengakumabhayela ezitshalweni ze-petrochemical kanye neziteshi zikagesi ukuthutha isitimu esinezinga lokushisa eliphezulu noma uwoyela oshisayo.Amandla aphezulu okudonsa kanye nesivuno abawanikezayo aqinisekisa ukusebenza nokuqina ngaphansi kwezimo ezinzima, ikakhulukazi kumashubhu ensimbi e-A106 Grade C, anikeza isici sokuphepha esiphezulu endaweni yokushisa ephezulu kanye nengcindezi ephezulu.

Uma ungathanda ukwazi okwengeziwe nge-ASTM A106 ne-ASTM A53, sicela uchofoze lapha.

Mayelana NATHI

I-Botop Steel ibingumkhiqizi kanye nomnikezeli wepayipi le-Welded Carbon Steel Pipe iminyaka eyi-16, enamathani angaphezu kuka-8000 epayipi Lensimbi Elingenasici esitokweni inyanga ngayinye.Sikunikeza isevisi yobuchwepheshe nekhwalithi ephezulu.

tag:astm a106,astm a53,a53 gr.b, abahlinzeki, abakhiqizi, izimboni, amasheya, izinkampani, iwholesale, thenga, inani, ikhotheshini, inqwaba, okuthengiswayo, izindleko.

Isikhathi sokuthumela: Mar-16-2024