Insimbi ye-ASTM A500iyishubhu yesakhiwo se-carbon steel esakhiwe ngendlela ebandayo esakhiwe ngendlela ebandayo yamabhuloho ashiselwe, acijile, noma abhawudiwe kanye nezakhiwo nezinhloso zesakhiwo esijwayelekile.

Izinkinobho Zokuzulazula

Umumo Wesigaba Esingenalutho

Ukuhlukaniswa Kwebanga

Ububanzi besayizi

Ama-Raw material

Izindlela Zokukhiqiza

I-Tube End Type

Ukwelashwa Kokushisa

Ukwakhiwa Kwekhemikhali kwe-ASTM A500

Izidingo ze-Tensile ze-ASTM A500

Ukuhlola Ukucaba

Ukuhlolwa kwe-Flaring

Ukubekezelela Dimensional kwe-ASTM A500

Ukumaka kweThubhu

Izicelo ze-ASTM A500

Ezinye izinto ze-ASTM A500

Imikhiqizo Yethu Ehlobene

Umumo Wesigaba Esingenalutho

Kungaba njaloumumo oyindilinga, oyisikwele, ongunxande, noma ezinye izakhiwo ezikhethekile.

Lesi sihloko sigxile ezidingweni ze-ASTM A500 zensimbi yesakhiwo esiyindilinga.

Ukuhlukaniswa Kwebanga

I-ASTM A500 ihlukanisa ipayipi lensimbi ngamabanga amathathu,Ibanga B, ibanga C, kanye nebanga D.

Kuyaqapheleka ukuthi izinguqulo zangaphambilini ze-ASTM A500 nazo zazineBanga A, elasuswa enguqulweni yakamuva ka-2023.

Ububanzi besayizi

Kumashubhu anobubanzi obungaphandle ≤ 2235mm [88in] nogqinsi lwezindonga ≤ 25.4mm [1in].

Ama-Raw material

Insimbi izokwenziwa ngenqubo eyodwa noma ngaphezulu yalezi ezilandelayo:i-oksijeni eyisisekelo noma isithando somlilo sikagesi.

Inqubo Ye-Oxygen Eyisisekelo: Lena indlela yesimanje esheshayo yokukhiqiza insimbi, enciphisa okuqukethwe kwekhabhoni ngokufutha umoya-mpilo ensimbi yengulube encibilikisiwe, kuyilapho ikhipha ezinye izakhi ezingafuneki njengesulfure ne-phosphorus.Ifanele ukukhiqizwa okusheshayo kwenani elikhulu lensimbi.

Inqubo yesithando somlilo sikagesi: Inqubo yesithando somlilo sikagesi isebenzisa i-arc kagesi enezinga lokushisa eliphezulu ukuze incibilikise izinsalela futhi inciphise ngokuqondile insimbi, futhi iwusizo ngokukhethekile ekukhiqizeni amamaki akhethekile nokulawula ukwakheka kwengxubevange, kanye nokukhiqizwa kwenqwaba encane.

Izindlela Zokukhiqiza

Inqubo engenamthungo noma yokushisela.

Amashubhu ashiselwe kufanele enziwe ngensimbi egoqelwe phansi ngenqubo ye-electric-resistance-welding (ERW).I-weld seam kufanele ihlanganiswe ukuze kuqinisekiswe amandla epayipi.

Amapayipi akhiqizwa inqubo yokushisela ngokuvamile awanayo i-weld yangaphakathi esusiwe.

I-Tube End Type

Uma kungadingeki ngokuqondile, amashubhu esakhiwo kufanele abeisicabafuthi uhlanzekile kuma-burrs.

Ukwelashwa Kokushisa

IBanga B kanye neBanga C

Kunganqanyulwa noma kuncishiswe ingcindezi.

Ukufakwa kwe-annealing kwenziwa ngokushisisa ishubhu ekushiseni okuphezulu bese ulipholisa kancane.I-Annealing ihlela kabusha i-microstructure yezinto ukuze kuthuthukiswe ukuqina nokufana kwayo.

Ukunciphisa ingcindezi ngokuvamile kwenziwa ngokushisisa okokusebenza ezingeni lokushisa eliphansi (imvamisa ephansi kunaleyo yokudonsa) bese uyibamba isikhathi esithile bese uyipholisa.Lokhu kusiza ukuvimbela ukuhlanekezela noma ukugqabuka kwento ngesikhathi sokusebenza okulandelayo njengokushisela noma ukusika.

Ibanga D

Ukwelashwa kokushisa kuyadingeka.

Kufanele kwenziwe ezingeni lokushisa okungenani1100°F (590°C) ihora elingu-1 ngakubugqinsi bodonga obungu-25 mm.

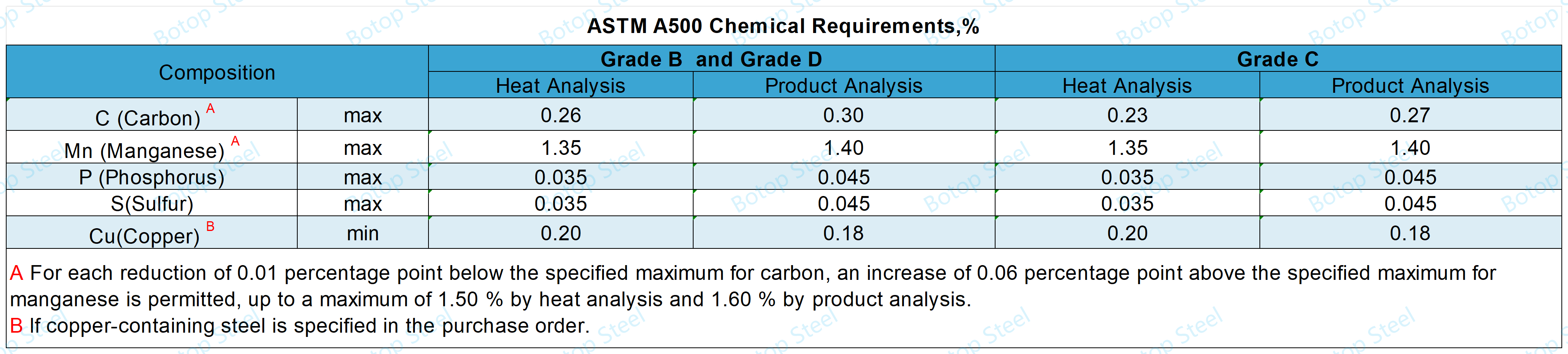

Ukwakhiwa Kwekhemikhali kwe-ASTM A500

Indlela yokuhlola: ASTM A751.

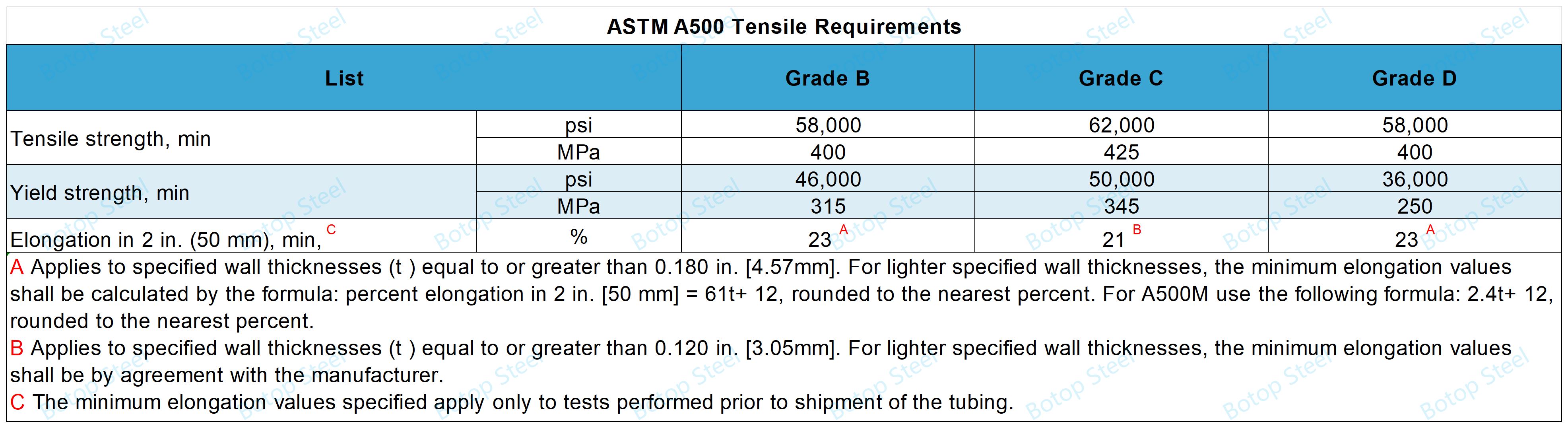

Izidingo ze-Tensile ze-ASTM A500

Izifanekiso zizohlangabezana nezidingo ezisebenzayo ze-ASTM A370, iSithasiselo A2.

Ukuhlola Ukucaba

Amashubhu Esakhiwo Esiyindilinga Ashiselwe

Welddusizotest: Usebenzisa isampula okungenani ama-intshi angu-4 (100 mm) ubude, yenza isifanekiso sibe sicaba nge-weld ku-90 ° ukuya lapho kulayishwa khona kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kuka-2/3 we-diameter yangaphandle yepayipi.isifanekiso akufanele siqhekeke noma siphuke endaweni yangaphakathi noma yangaphandle phakathi nale nqubo.

Ipayipi ductility test: qhubeka wenza isifanekiso sibe isicaba kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kwe-1/2 yobubanzi obungaphandle bepayipi.ngalesi sikhathi, ipayipi akufanele libe nemifantu noma ukuphuka endaweni yangaphakathi nangaphandle.

Ubuqothotest: Qhubeka wenze isifanekiso sibe sicaba kuze kube yilapho kuvela ukuphuka noma kuze kube yilapho izimfuneko zokuqina kodonga sezihlangatshezwana nazo.Uma ubufakazi bokucwecwa kwe-ply, impahla engazinzile, noma ukushisela okungaphelele kutholakala ngesikhathi sokuhlolwa kokucaba, isifanekiso sizothathwa njengokungagculisi.

Amashubhu Esakhiwo Esiyindilinga Angenamthungo

Ubude Besifanekiso: Ubude besampula esisetshenziselwa ukuhlola akumele bube ngaphansi kuka-2 1/2 in (65 mm).

Ukuhlolwa kwe-Ductility: Ngaphandle kokuqhekeka noma ukuphuka, isifanekiso siyenziwa isicaba phakathi kwamapuleti ahambisanayo kuze kube ibanga eliphakathi kwamapuleti lingaphansi kwenani elithi "H" elibalwa ngefomula elandelayo:

H=(1+e)t/(e+t/D)

H = ibanga phakathi kwamapuleti aphansi, ngo. [mm],

e= ukuguqulwa ngobude beyunithi ngayinye (okuqhubekayo ebangeni elithile lensimbi, u-0.07 weBanga B, no-0.06 weBanga C),

t= ukujiya kodonga olucacisiwe lweshubhu, ngaphakathi. [mm],

D = kucaciswe ububanzi obungaphandle beshubhu, ngaphakathi. [mm].

Ubuqothotest: Qhubeka wenze isifanekiso sibe sicaba kuze kube yilapho isifanekiso siphuka noma izindonga eziphambene zesampula zihlangana.

Ukwehlulekaci-riteria: Ukucwecwa kwe-laminar noma izinto ezibuthakathaka ezitholakala kulo lonke uhlolo lokucaba kuzoba yizizathu zokwenqatshwa.

Ukuhlolwa kwe-Flaring

Ukuhlolwa kokuvutha kuyatholakala kumashubhu ayindilinga ≤ 254 mm (10 in) ububanzi, kodwa akuphoqelekile.

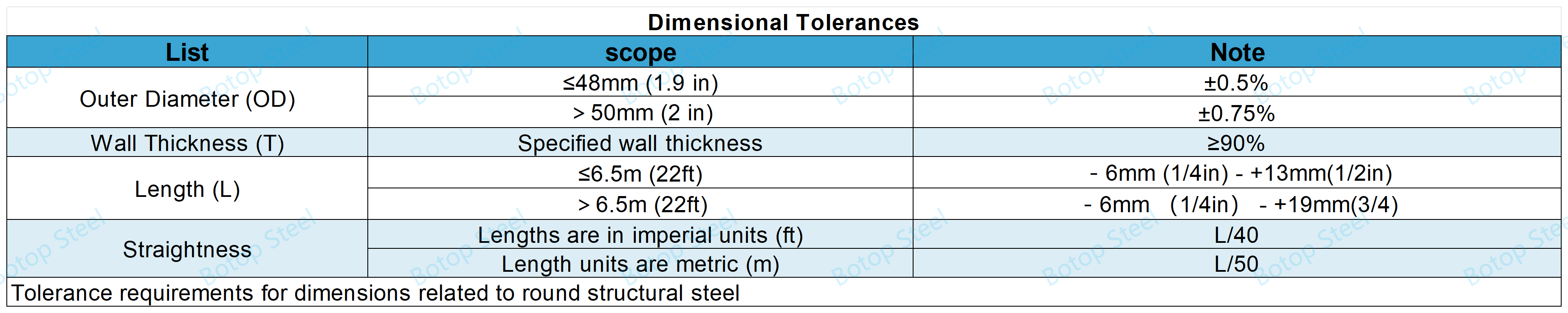

Ukubekezelela Dimensional kwe-ASTM A500

Ukumaka kweThubhu

Ulwazi olulandelayo kufanele lufakwe:

Igama lomkhiqizi: Lokhu kungaba igama eliphelele lomkhiqizi noma isifinyezo.

Ibhrendi noma uphawu lokuhweba: Igama lomkhiqizo noma uphawu lokuhweba olusetshenziswa umenzi ukuhlukanisa imikhiqizo yakhe.

Ukucaciswa komklami: I-ASTM A500, engadingi ukufaka unyaka wokushicilelwa.

Incwadi Yebanga: Ibanga B, C noma D.

Kumashubhu esakhiwo ≤ 100mm (4in) ububanzi, amalebula angasetshenziswa ukumaka ulwazi lokuhlonza ngokucacile.

Izicelo ze-ASTM A500

Ngenxa yezakhiwo zayo ezinhle kakhulu zemishini kanye nokushisela, ipayipi lensimbi le-ASTM A500 lisetshenziswa ezinhlobonhlobo zezakhiwo lapho ukuqina namandla kuyadingeka.

Ukwakha: Isetshenziselwa ukusekela izakhiwo zokwakha njengamasistimu ozimele, izakhiwo zophahla, izakhi ze-arch design, namakholomu ayindilinga.

Ukwakhiwa kwebhuloho: Okwezakhi zesakhiwo samabhuloho, njengamakholomu ayindilinga athwala umthwalo namatrusses amabhuloho.

Ingqalasizinda yezimboni: Ezakhiweni ezinkulu zezimboni ezifana nezinsiza zikawoyela negesi, izimboni zamakhemikhali, nezigayo zensimbi, amashubhu ensimbi ayindilinga asetshenziselwa ukwakha izakhiwo zokusekela kanye namapayipi okudlulisela.

Izinhlelo zokuthutha: Okwezimpawu zezimpawu zethrafikhi, izigxobo zokukhanya, nezinsimbi zokuqapha.

Ukukhiqiza imishini: Njengengxenye yemishini nemishini esindayo, njengemishini yezolimo, imishini yezimayini, nemishini yokwakha.

Izinsiza: Isetshenziswa kumapayipi amanzi, igesi, imikhiqizo ye-petroleum, njll., nanjengamapayipi ocingo namakhebula okuvikela.

Izinsiza zezemidlalo: Ekwakhiweni kwezindawo zezemidlalo, amashubhu ensimbi ayindilinga asetshenziselwa ukwenza ama-bleachers, imibhoshongo yokukhanyisa, nezinye izakhiwo zokusekela.

Ifenisha nokuhlobisa: Amashubhu ensimbi anesakhiwo esiyindilinga asetshenziselwa ukwenza ifenisha yensimbi, njengemilenze yamatafula nezihlalo, kanye nezakhi zokuhlobisa zomklamo wangaphakathi wanamuhla.

Uthango namasistimu kaloliwe: Isetshenziswa njengezigxobo zocingo kanye nezinhlelo zothango, ikakhulukazi lapho kudingeka khona amandla esakhiwo nokuqina.

Ezinye izinto ze-ASTM A500

I-ASTM A501: Lokhu indinganiso yamashubhu esakhiwo se-carbon steel esakhiwe esishisayo, esifana ne-ASTM A500, kodwa sisebenza kwinqubo yokukhiqiza eyenza ukushisa.

I-ASTM A252: Okujwayelekile kwezinqwaba zamapayipi ensimbi azosetshenziswa kusisekelo nomsebenzi wokunqwabelanisa.

I-ASTM A106: Ipayipi le-carbon steel engenamthungo, elivame ukusetshenziswa ezindaweni ezinezinga lokushisa eliphezulu.

I-ASTM A53: Olunye uhlobo lwepayipi yensimbi ye-carbon yokucindezela kanye nezicelo zemishini, ezisetshenziswa kabanzi ezinhlelweni zokudlulisa uketshezi.

I-EN 10210: E-Europe, indinganiso ye-EN 10210 icacisa izimo zokulethwa kobuchwepheshe zezingxenye ezingenalutho zesakhiwo esakhiwe ngokushisayo, ezinezindawo zokusebenza ezifanayo ne-ASTM A500.

I-CSA G40.21: Izinga lase-Canada elihlinzeka ngezinhlobo eziningi zezinsimbi zekhwalithi yesakhiwo kumabanga ahlukene wamandla angasetshenziselwa izinhlelo zokusebenza ezifanayo.

I-JIS G3466: I-Japanese Industrial Standard yamashubhu ayisikwele nawonxande ensimbi ye-carbon ukuze asetshenziswe ngokwesakhiwo okuvamile.

IBE 4923: I-Indian Standard yezingxenye ezinezimbobo zensimbi ezishicilele ezakheke ngokubanda noma ezingenamthungo.

AS/NZS 1163: Amazinga ase-Australia naseNew Zealand amashubhu ensimbi esakhiwo nezingxenye ezingenalutho.

Imikhiqizo Yethu Ehlobene

Kusukela yasungulwa ngo-2014, i-Botop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi e-carbon eNyakatho neChina, eyaziwa ngomsebenzi wayo omuhle kakhulu, imikhiqizo esezingeni eliphezulu, nezisombululo ezibanzi.Uhlu olubanzi lwemikhiqizo yenkampani luhlanganisa amapayipi ensimbi angenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kukhwalithi, i-Botop Steel isebenzisa izilawuli eziqinile nokuhlola ukuze iqinisekise ukwethembeka kwemikhiqizo yayo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.

Tags: astm a500, astm a500 grade b, astm a500 grade c, astm a500 grade d.

Isikhathi sokuthumela: May-04-2024