I-ASTM A500 ne-ASTM A501zombili zibhekana ngqo nezidingo ezihlobene nokwakhiwa kwepayipi lesakhiwo sensimbi ye-carbon.

Nakuba kunokufana ezicini ezithile, nazo zinezici zazo ezihlukile nezindlela zokusebenza.

Okulandelayo sizobheka umehluko omkhulu phakathi kwe-ASTM A500 ne-ASTM A501 nokuthi isetshenziswa kanjani ezinhlelweni ezahlukene.

Izinqubo Zokukhiqiza

Izinqubo Zokukhiqiza ze-ASTM A500

Ipayipi le-ASTM A50 lizokwenziwa ngezinqubo ezingenamthungo noma ezishiselwe.

Amashubhu ashiselwe kufanele enziwe ngensimbi egoqelwe phansi ngenqubo ye-electric-resistance-welding (ERW).

Izinqubo Zokukhiqiza ze-ASTM A501

Amapayipi azokwakhiwa ngenye yalezi zinqubo ezilandelayo: i-seamless, i-furnace butt welding (i-welding eqhubekayo);i-resistance welding noma i-arc welding engaphansi kwamanzi.

Ngemuva kwalokho izoshiswa kabusha kuso sonke isigaba esiphambanayo futhi i-thermoform ngezinqubo zokunciphisa noma zokwakheka, noma kokubili.

Ukubunjwa kokugcina komumo kuzokwenziwa ngenqubo yokubumba eshisayo.

Izinqubo Ezihlukene Zokukhiqiza

Womabili amazinga avumela ukusetshenziswa kwamasu okukhiqiza amapayipi angenamthungo;

Uma inqubo yokushisela isetshenziselwa ukukhiqiza, i-ASTM A500 isebenzisa i-electric-resistance-welded (ERW), kuyilapho i-ASTM A501 ivumela amasu ahlukahlukene wokushisela, okuhlanganisa ugesi-ukumelana ne-welded (ERW), i-arc welding engaphansi kwamanzi (SAW), njll.

Kodwa-ke, i-ASTM A501 idinga ukuthi ipayipi liphathwe ukushisa, okusiza ukuthuthukisa ukufana kanye nezakhiwo zemishini yezinto ezibonakalayo.Inhloso ye-thermoforming ukuthuthukisa izakhiwo zezinto ezibonakalayo ngokushisa ukushisa ipayipi ngaphambi kokuba ukuma kwayo kuphothulwe.

I-ASTM A500 ayinazo izidingo ezinemininingwane enjalo.

Ukuhlukaniswa kwamaBanga

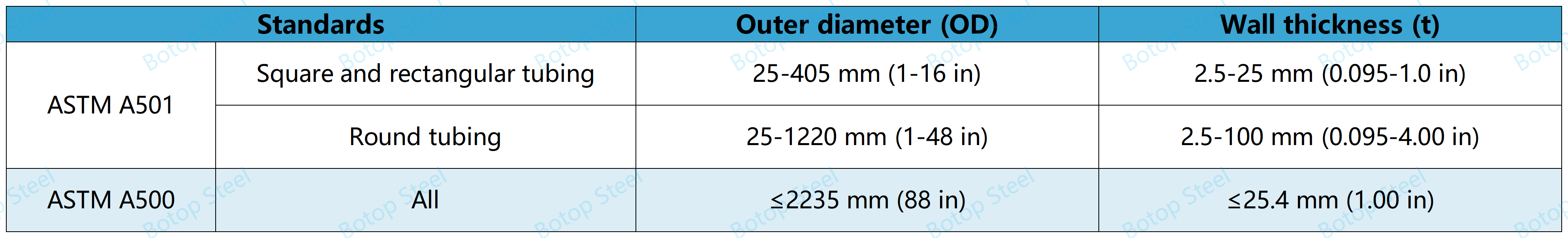

Ibanga Losayizi Osebenzayo

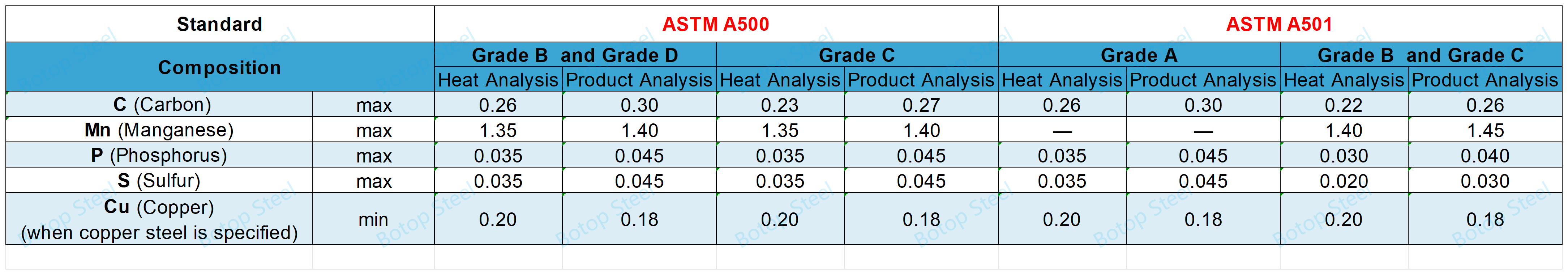

Izingxenye Zekhemikhali

Sekuhlanganiswe ndawonye, kunomehluko othile ekuqanjweni kwamakhemikhali amashubhu esakhiwo sensimbi ye-carbon ecaciswe kumazinga amabili, i-ASTM A500 ne-ASTM A501.

Ku-ASTM A500, iBanga B kanye neBanga D linezidingo ezifanayo zokwakheka kwamakhemikhali, kuyilapho iBanga C linokuqukethwe kwekhabhoni encishisiwe uma kuqhathaniswa no-B no-D. Ku-ASTM A501, ukwakheka kwamakhemikhali eBanga A kuyefana nalokhu kweBanga B, kuyilapho. IBanga C linokuqukethwe kwekhabhoni encishisiwe uma kuqhathaniswa neBanga B.

Ku-ASTM A501, ukwakheka kwamakhemikhali eBanga A kufana nalokhu kweBanga B no-D lika-A500, kodwa eBangeni B no-C okuqukethwe kwekhabhoni kuyancipha, okuqukethwe kwe-manganese kuyanda, kanti okuqukethwe kwe-phosphorus nesibabule kungaphansi ebangeni A.

Okuqukethwe kwethusi kuhlala kuyisidingo esincane esingaguquki kuwo wonke amabanga.

Izidingo ezihlukene zokwakheka kwamakhemikhali zibonisa izidingo ezithile zamazinga amabili ezinqubo ezihlukene zokukhiqiza nezinhlelo zokusebenza, okuqinisekisa ukuthi okokusebenza kuhlangabezana nemibandela yokusebenza yezinhlelo eziningi ezahlukene zobunjiniyela nesakhiwo.

Ukusebenza Komshini

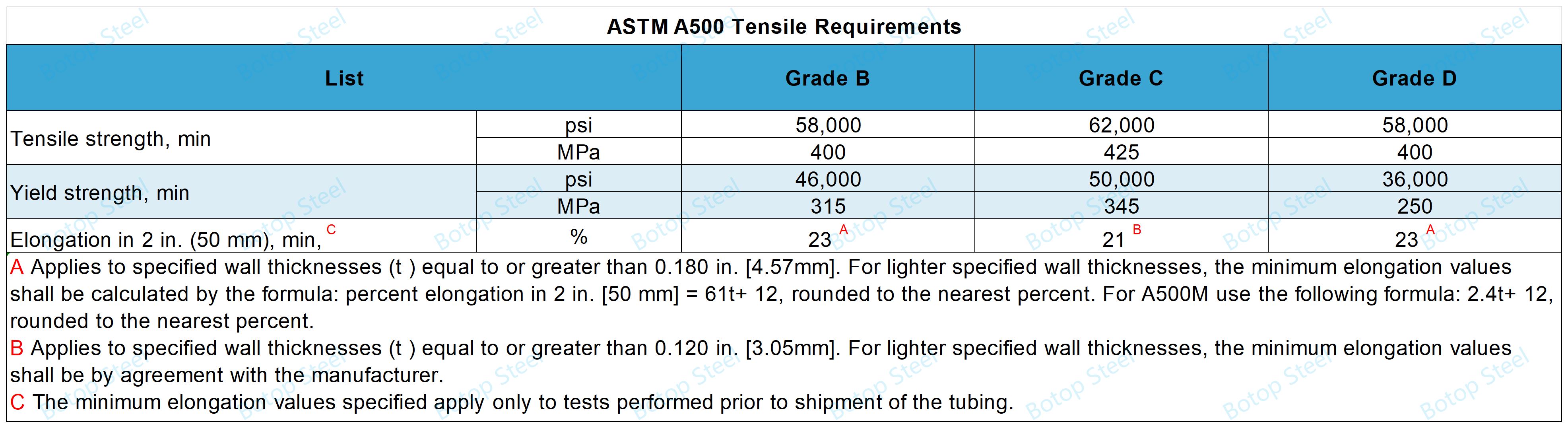

I-ASTM A500 Mechanical Performance

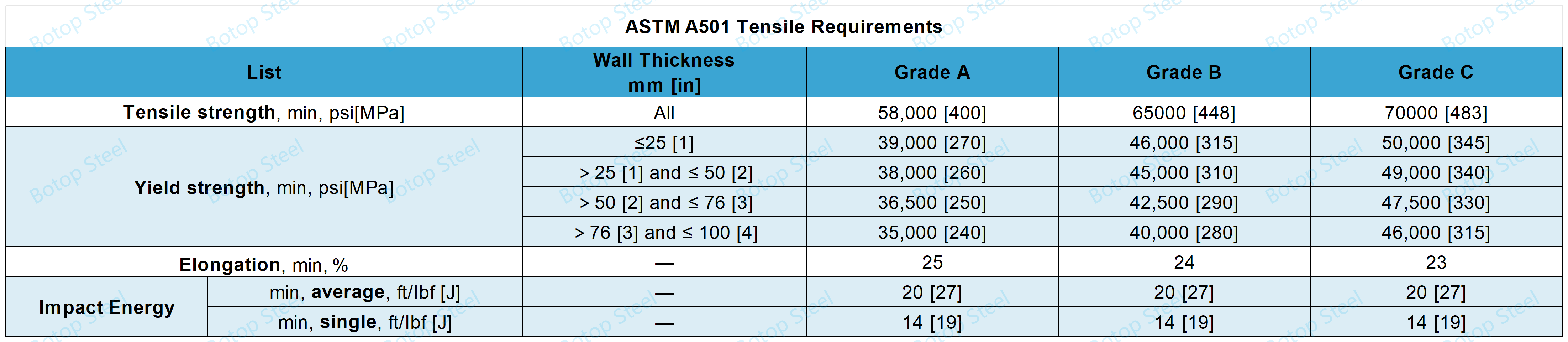

I-ASTM A501 Mechanical Performance

Izakhiwo ezihlukile zikaMechanical

Izinto eziku-A501 ngokuvamile zinikeza amazinga aphezulu wamandla ngenxa yamandla akhuphukayo ensimbi asuka kunqubo yokwakheka okushisayo.

Amaphrojekthi Okuhlola

Izidingo ezihlukene zezinto zokuhlola kumazinga amabili zibonisa izinqubo zokukhiqiza kanye nokusetshenziswa okuhlosiwe kwalawa mashubhu amabili ahlukene.

Izinga le-ASTM A500 lidinga Ukuhlaziywa Kokushisa, Ukuhlaziywa Komkhiqizo, Nezakhiwo Zemishini ngaphezu kokuhlolwa kwe-Flattening, Ukuhlolwa kokuvutha, kanye ne-Wedge Crush Tes ukuze kuqinisekiswe ukuthi inqubo yokubumba ebandayo ayiphazamisi kabi izakhiwo zezinto ezibonakalayo.

Izinga le-ASTM A501 ligcizelela inqubo ye-thermoforming, futhi njengoba imikhiqizo ye-thermoformed isivele yelashwe ngokushisa ngesikhathi senqubo yokukhiqiza, lezi zivivinyo zingase zibhekwe njengento engafuneki ngoba ukwelashwa kokushisa sekuvele kuqinisekisile ipulasitiki kanye nokuqina kwento.

Izindawo ze-Applicatio

Nakuba zombili zidlala indima yesakhiwo, ukugcizelelwa kuzohluka.

Ishubhu ye-ASTM A500 isetshenziswa kakhulu ezakhiweni zokwakha, ukukhiqizwa kwemishini, amafreyimu ezimoto, kanye nemishini yezolimo ngenxa yezakhiwo zayo ezibandayo zokugoba nokushisela.

Ishubhu ye-ASTM A501 ifaneleka kakhulu ukwakha nezinhlelo zokusebenza zesakhiwo ezidinga amandla aphakeme nokuqina, njengokwakhiwa kwebhuloho nezakhiwo ezinkulu zokusekela, ngenxa yokuqina namandla ayo amangalisayo.

Womabili la mazinga ahlinzeka ngomhlahlandlela wokwakha amashubhu ensimbi yensimbi yekhwalithi ephezulu, kodwa ukukhetha okungcono kakhulu kuncike ezidingweni kanye nemikhawulo yephrojekthi ethile.

Uma isakhiwo sidinga ukusebenza kahle endaweni enezinga lokushisa eliphansi, i-ASTM A501 ingase ikhethwe ngoba ukuqina okwenyuka okuvela ekubunjweni okushisayo kunikeza ukumelana okungcono nokuphuka okuphukayo.Ngokuphambene, uma isakhiwo sizokwakhelwa indawo yasendlini, i-ASTM A500 ingase yanele, njengoba inganikeza amandla adingekayo nokusebenza, kuyilapho ibiza kancane.

Amathegi: a500 vs a501, astm a500, astm a501, carbon steel, ipayipi lesakhiwo.

Isikhathi sokuthumela: May-06-2024