Insimbi ye-ASTM A513iyipayipi lensimbi ye-carbon ne-alloy kanye neshubhu eyenziwe ngensimbi egoqwe ngokushisayo noma ebandayo njengempahla eluhlaza ngenqubo ye-electric resistance welding (ERW), esetshenziswa kabanzi kuzo zonke izinhlobo zezakhiwo zemishini.

Izinkinobho Zokuzulazula

Izinhlobo Nezimo Ezishisayo ze-ASTM A513

Ukuhlukaniswa Kwebanga

I-ASTM A513 Ubukhulu Ububanzi

Umumo Wesigaba Esingenalutho

Ama-Raw material

Izinqubo Zokukhiqiza ze-ASTM A513

Ukwelashwa Okushisayo

Ukuphatha Seam Welding

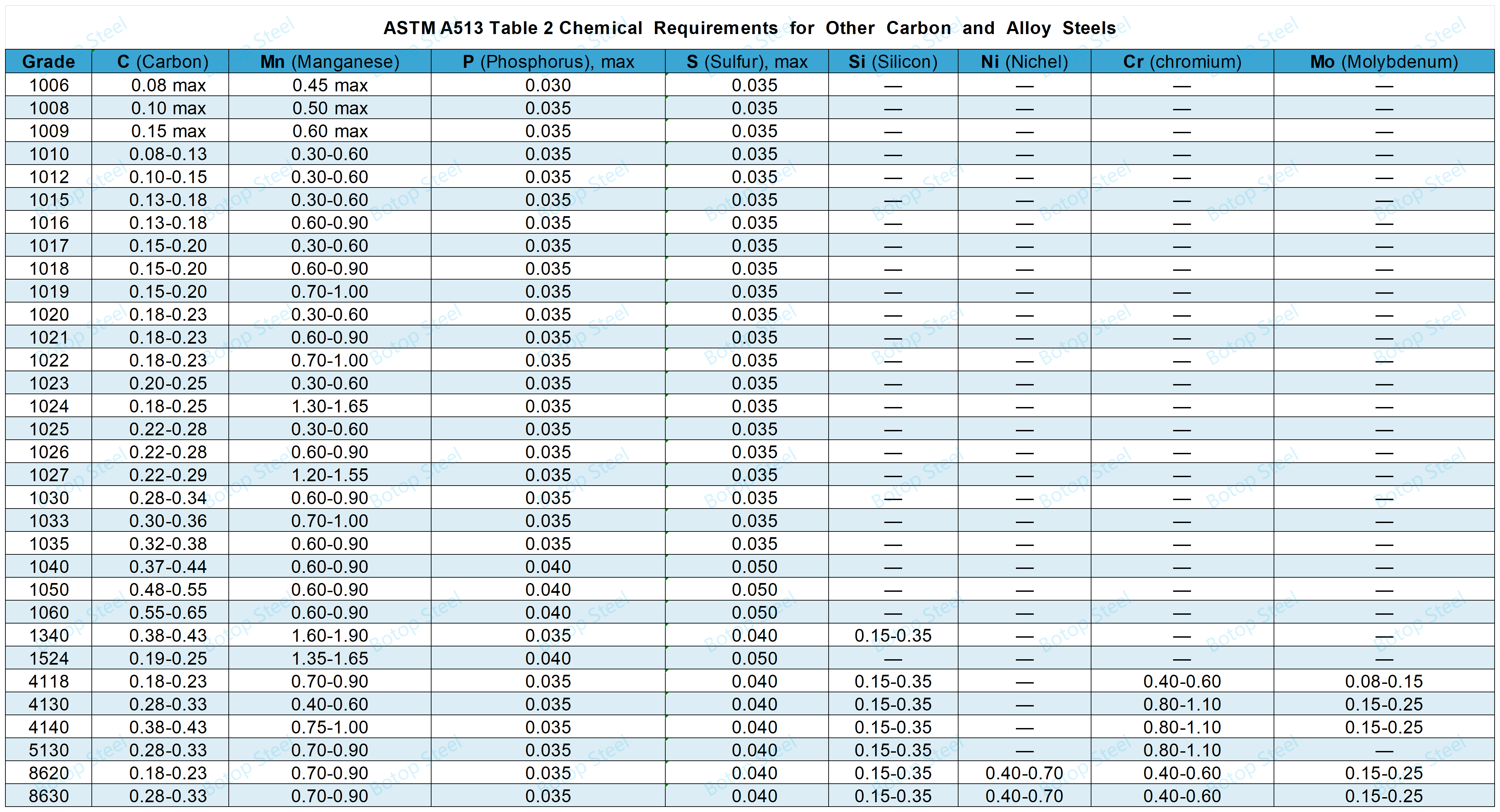

Ukwakhiwa Kwekhemikhali kwe-ASTM A513

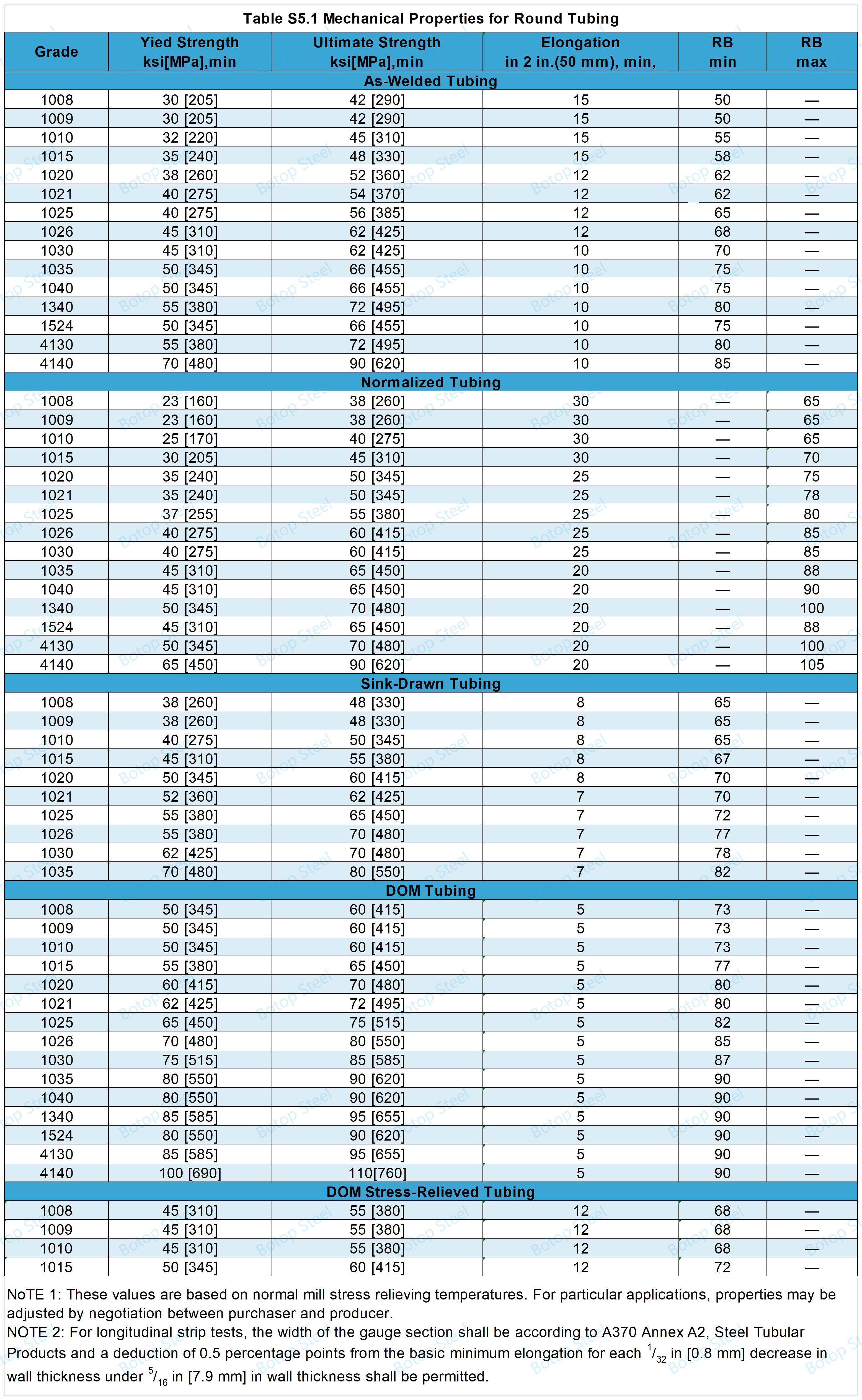

Izakhiwo Zemishini ye-ASTM A513

Ukuhlolwa kokuqina

Ukuhlola Ukucaba

Ukuhlolwa kwe-Flaring

I-Hydrostatic Test Round Tubing

Ukuhlola Ugesi Okungabhubhisi

Ukubekezelela Ubukhulu Bombhobho Oyindilinga

Ukubekezelela Ubukhulu beshubhu yesikwele kanye nonxande

Ukubukeka

Ukugqoka

Ukumaka

Izicelo ze-ASTM A513

Izinzuzo Zethu

Izinhlobo Nezimo Ezishisayo ze-ASTM A513

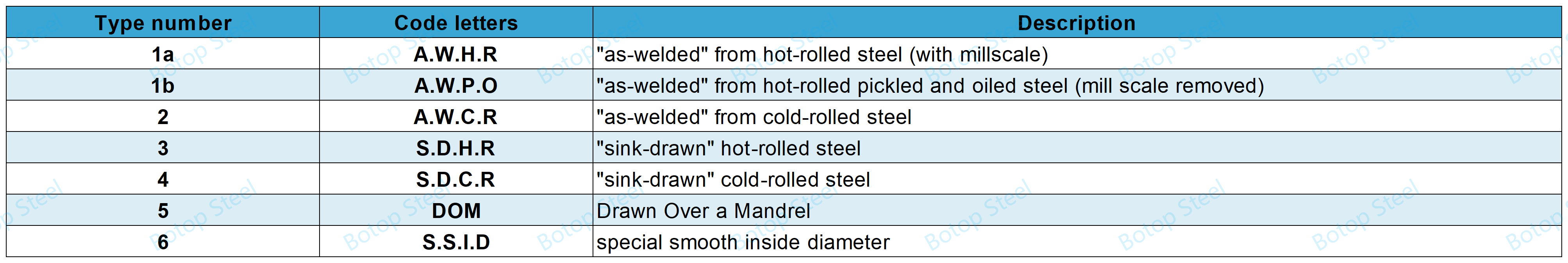

Ukuhlukaniswa kusekelwe ezimweni ezahlukene noma izinqubo zepayipi lensimbi.

Ukuhlukaniswa Kwebanga

I-ASTM A513 ingaba yinsimbi ye-carbon noma i-alloy, kuye ngohlelo lokusebenza lwangempela.

Insimbi Yekhabhoni

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 10203, 1025,1 35, 1040, 1050, 1060, 1524.

Insimbi ye-alloys

1340, 4118, 4130, 4140, 5130, 8620, 8630.

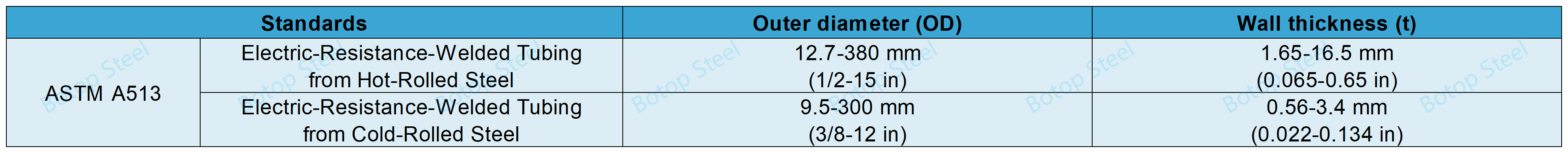

I-ASTM A513 Ubukhulu Ububanzi

Umumo Wesigaba Esingenalutho

Umjikelezo

Isikwele noma unxande

Ezinye izimo

okufana ne-streamlined, i-hexagonal, i-octagonal, eyindilinga ngaphakathi kanye ne-hexagonal noma i-octagonal ngaphandle, izimbambo ngaphakathi noma ngaphandle, unxantathu, unxande oyindilinga womumo no-D.

Ama-Raw material

Insimbi ingenziwa nganoma iyiphi inqubo.

Ukuncibilika okuyinhloko kungase kuhlanganise ukucwenga okuhlukile noma ukucwengwa futhi kungase kulandelwe ukuncibilika kwesibili, okufana ne-electro slag noma i-vacuum-arc remelting.

Insimbi ingaphonswa ngama-ingots noma i-strand cast.

Izinqubo Zokukhiqiza ze-ASTM A513

Amashubhu azokwenziwa yi-i-electric-resistance-welded (ERW)inqubo futhi izokwenziwa ngensimbi egoqelwe eshisayo noma ebandayo njengoba kucacisiwe.

Ipayipi le-ERW inqubo yokwenza i-weld ngokugoqa insimbi ibe isilinda futhi ifake ukumelana nokucindezela ngobude bayo.

Insimbi Egoqwe Okushisayo: Enkambweni yokukhiqiza, insimbi eshisayo iqala ukushisa emazingeni okushisa aphezulu, okuvumela ukuba insimbi igoqwe esimweni sepulasitiki, okwenza kube lula ukushintsha ukuma nobukhulu bensimbi.Ekupheleni kwenqubo yokugoqa okushisayo, impahla ivamise ukukalwa futhi ikhubazekile.

Insimbi Egoqwe Ngamakhaza: Insimbi egoqwe ebandayo igoqeka ngokuqhubekayo ngemva kokuba impahla ipholile ukuze kuzuzwe usayizi nokuma okufunayo.Le nqubo ngokuvamile yenziwa ekamelweni lokushisa futhi iphumela kunsimbi enekhwalithi engcono yangaphezulu kanye nobukhulu obunembe kakhudlwana.

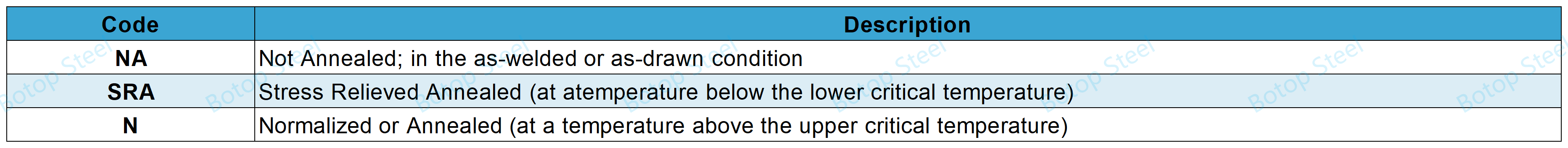

Ukwelashwa Okushisayo

Uma isimo sokushisa singacacisiwe, ithubhu ingase inikezwe esimweni se-NA.

Uma ukwelashwa kokugcina okushisayo kucacisiwe, i-oxide eqinile ijwayelekile.

Uma kucacisiwe indawo engenawo oksijini, ishubhu lingase likhishwe ngokugqamile noma lifakwe emanzini anosawoti ngokukhethwa komkhiqizi.

Ukuphatha Seam Welding

Ama-welds angaphandle kufanele ahlanzwe

Amashisela angaphakathi azoba nezidingo ezihlukene zobude kuye ngohlobo.

Izidingo ezithile zingatholakala ku-ASTM A513, isigaba 12.3.

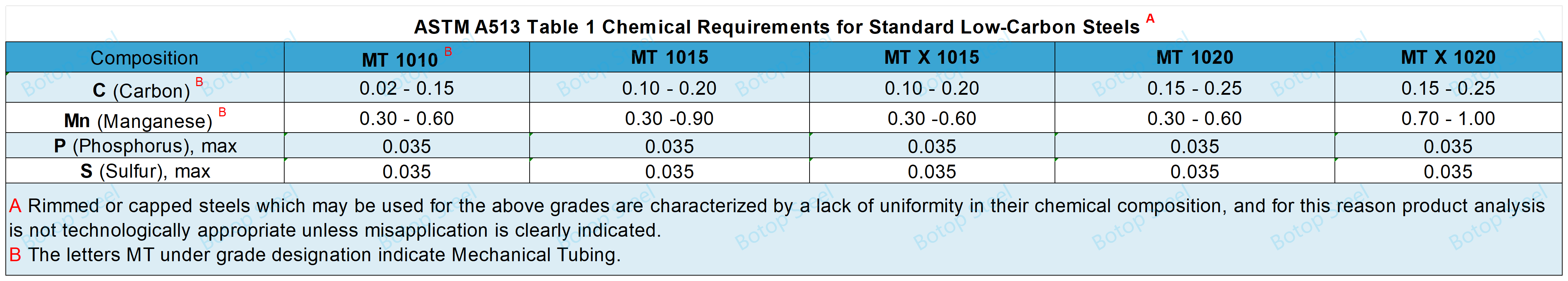

Ukwakhiwa Kwekhemikhali kwe-ASTM A513

Insimbi kufanele ihambisane nezidingo zokwakheka kwamakhemikhali ezishiwo kuThebula 1 noma Ithebula 2.

Uma amamaki ensimbi ye-carbon e-odwa kusukela ezingeni elijwayelekile, akuvumelekile ukunikeza amamaki e-alloy adinga ngokukhethekile ukwengezwa kwanoma iyiphi i-elementi ngaphandle kwalawo asohlwini lwamaThebula I no-2.

Uma lingekho ibanga elishiwo, amabanga MT 1010 kuya ku-MT 1020 ayatholakala.

Izakhiwo Zemishini ye-ASTM A513

Ukuhlolwa kwe-tensile kuzokwenziwa kanye endaweni ngayinye.

Lapho "Izakhiwo Ezidingekayo Eziqinile" zicaciswa ku-Oda Lokuthenga, amashubhu ayindilinga azohambisana nezimfuneko eziqinile hhayi nemikhawulo yokuqina eboniswe kuThebula lesi-5.

Ukuhlolwa kokuqina

I-1% yawo wonke amashubhu esakhiweni ngasinye futhi angabi ngaphansi kwamashubhu ama-5.

Ukuhlola Ukucaba

Amashubhu ayindilinga namashubhu akha ezinye izimo lapho eyindilinga ayasebenza.

Akukho kuvulwa ku-weld okuzokwenzeka kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kwezingxenye ezimbili kwezintathu zobubanzi bangaphandle bangaphandle beshubhu.

Akukho ukuqhekeka noma ukuqhekeka kwensimbi eyisisekelo okuzokwenzeka kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kwengxenye eyodwa kwezintathu yobubanzi bangaphandle bangempela beshubhu kodwa kungabi ngaphansi kokuphindwe kahlanu kogqinsi lodonga lwamashubhu.

Ubufakazi be-lamination noma izinto ezishisiwe ngeke zithuthuke ngesikhathi senqubo yokwenza isicaba, futhi i-weld ngeke ibonise amaphutha alimazayo.

Qaphela: Uma ishubhu yesilinganiso se-D-to-t ephansi ihlolwa, ngenxa yokuthi ubunzima obubekwe ngenxa yejiyomethri buphezulu ngokungafanele endaweni engaphakathi endaweni yehora lesithupha neleshumi nambili, imifantu kulezi zindawo ngeke ibe yisizathu sokwaliwa uma Isilinganiso se-D-to-t singaphansi kuka-10.

Ukuhlolwa kwe-Flaring

Amashubhu ayindilinga namashubhu akha ezinye izimo lapho eyindilinga ayasebenza.

Ingxenye yeshubhu ecishe ibe ngu-4 ku-[100 mm] ubude izoma ivutha ngethuluzi eline-engeli ehlanganisiwe engu-60 ° kuze kube yilapho ishubhu emlonyeni we-flare inwetshiwe ngamaphesenti angu-15 obubanzi bangaphakathi, ngaphandle kokuqhekeka noma ukubonisa. amaphutha.

I-Hydrostatic Test Round Tubing

Wonke amashubhu azonikezwa ukuhlolwa kwe-hydrostatic.

Gcina ingcindezi encane yokuhlolwa kwamanzi ingekho ngaphansi kwama-5s.

Ingcindezi ibalwa njenge:

P=2St/D

P= ubuncane bengcindezi yokuhlolwa kwe-hydrostatic, i-psi noma i-MPa,

S= ukucindezeleka kwe-fiber okuvumelekile kwe-14,000 psi noma i-96.5 MPa,

t= ubukhulu bodonga olucacisiwe, ngaphakathi noma mm,

D= kucaciswe ububanzi bangaphandle, in. noma mm.

Ukuhlola Ugesi Okungabhubhisi

Kuyinhloso yalokhu kuhlola ukwenqaba amashubhu aqukethe izici ezilimazayo.

Ishubhu ngalinye lizohlolwa ngokuhlolwa kukagesi okungangonakali ngokuhambisana ne-Practice E213, Practice E273, Practice E309, noma Practice E570.

Ukubekezelela Ubukhulu Bombhobho Oyindilinga

Ukuze uthole ulwazi olwengeziwe, sicela ubheke ithebula elihambisanayo elisezingeni.

Ububanzi bangaphandle

Ithebula 4Ukubekezelelwa Kobubanzi Bohlobo I (AWHR) Round Tubing

Ithebula 5Ukubekezelelwa Kobubanzi Bezinhlobo 3, 4, 5, kanye no-6 (SDHR, SDCR, DOM, kanye ne-SSID) Round Tubing

Ithebula 10Ukubekezelelwa Kobubanzi Bohlobo 2 (AWCR) Round Tubing

Ukuqina Kwezindonga

Ithebula 6Ukubekezelela Ukuqina Kwezindonga Zohlobo I (AWHR) Round Tubing (Amayunithi Eyintshi)

Ithebula 7Ukubekezelela Ukuqina Kwezindonga Zohlobo I (AWHR) Round Tubing (Amayunithi we-SI)

Ithebula 8Ukubekezelela Ukuqina Kwezindonga Kwezinhlobo 5 kanye No-6 (DOM kanye ne-SSID) I-Round Tubing (Amayunithi Amayintshi)

ITAFULA 9Ukubekezelela Ukuqina Kwezindonga Kwezinhlobo 5 no-6 (DOM kanye ne-SSID) I-Round Tubing (Amayunithi we-SI)

Ithebula 11Ukubekezelela Ukuqina Kwezindonga Zohlobo 2 (AWCR) I-Round Tubing (Amayunithi Eyintshi)

Ithebula 12Ukubekezelela Ukuqina Kodonga Kohlobo 2 (AWCR) I-Round Tubing (Amayunithi we-SI)

Ubude

Ithebula 13Ukubekezelela Ubude bokusika kwe-Lathe-Cut Round Tubing

Ithebula 14Ukubekezelela Ubude BePunch-, Saw-, noma Disc-Cut Round Tubing

Squareness

Ithebula 15Ukubekezelela (Intshi) Ye-Squareness of Cut (Noma Kuphela Ukuphela) Uma Kucaciswe I-Round Tubing

Ukubekezelela Ubukhulu beshubhu yesikwele kanye nonxande

Ukuze uthole ulwazi olwengeziwe, sicela ubheke ithebula elihambisanayo elisezingeni.

Ububanzi bangaphandle

Ithebula 16Ukubekezelela, Ubukhulu bangaphandle Isikwele kanye namashubhu angunxande

Umsakazo WamaKhona

Ithebula 17I-Radii Yamakhona E-Electric-Resistance-Welded Square kanye ne-Rectangular Tubing

Ubude

Ithebula 18Ukubekezelela Ubude-Isikwele kanye Neshubhu elingunxande

I-Twist Tolerances

Ithebula 19I-Twist Tolerances Electric-Resistance-Welded for Square and Rectangular-Mechanical Tubing

Ukubukeka

Ishubhu ngeke ingabi nasici futhi izoba nesiphetho esifana nomsebenzi.

Ukugqoka

Amashubhu kufanele ambozwe ngefilimu yamafutha ngaphambi kokuthunyelwa ukuze kuvinjwe ukugqwala.

Ivimbela ukugqwala ukuthi kwenzeke ngesikhathi esifushane.

Uma ngabe i-oda licacisa ukuthi amashubhu athunyelwe ngaphandle kowoyela ovimbela ukugqwala, ifilimu yamafutha azokwenziwa ngengozi izohlala phezulu.

Ukumaka

Ingaphezulu lensimbi limakwa kusetshenziswa indlela efanelekile futhi liqukethe imininingwane elandelayo:

Igama lomkhiqizi nomauphawu

Usayizi oshiwo

Uhlobo

inombolo ye-oda lomthengi,

Inombolo ejwayelekile, ASTM A513.

Amabhakhodi angasetshenziswa njengendlela yokuhlonza ehambisanayo.

Izicelo ze-ASTM A513

Imboni yezimoto: Isetshenziswa kumafreyimu ezihlalo zezimoto, izingxenye ezimisiwe, amakholomu esiteringi, kubakaki, nezinye izingxenye zesakhiwo semoto.

Imboni yezokwakha: njengento yokusekela izakhiwo zokwakha, njengamashubhu esikafula, ama- guardrails, ama-railing, njll.

Imishinimukwenza: Isetshenziselwa ukukhiqizwa kwezingxenye ezihlukahlukene zemishini, njengamasilinda esistimu ye-hydraulic, izingxenye ezijikelezayo, ama-bearings, njalonjalo.

Imishini yezolimo: Ekwenziweni kwemishini yezolimo, esetshenziselwa ukwenza izingxenye zesakhiwo semishini yokulima, izinhlelo zokudlulisela, njll.

Ukwenziwa Kwefenisha: Isetshenziselwa ukukhiqizwa kwefenisha yensimbi ehlukahlukene, njengamashalofu ezincwadi, amafreyimu ezihlalo, amafreyimu emibhede, njalonjalo.

Imishini yezemidlalo: ezikhungweni zemidlalo kanye nokukhiqizwa kwemishini, esetshenziswa njengezingxenye zensimbi, njengempahla yokufaneleka, amagoli ebhola lombhoxo, amagoli ebhola, njll.

Izinsiza zezimboni: isetshenziswa ekwenzeni amabhande okuthutha, amarola, amathangi, nezinye izingxenye zemishini yezimboni.

Izinzuzo Zethu

Kusukela yasungulwa ngo-2014, i-Botop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi e-carbon eNyakatho neChina, eyaziwa ngomsebenzi wayo omuhle kakhulu, imikhiqizo esezingeni eliphezulu, nezisombululo ezibanzi.Uhlu olubanzi lwemikhiqizo yenkampani luhlanganisa amapayipi ensimbi angenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kukhwalithi, i-Botop Steel isebenzisa izilawuli eziqinile nokuhlola ukuze iqinisekise ukwethembeka kwemikhiqizo yayo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.

Amathegi: ASTM A513, carbon steel, uhlobo 5, uhlobo 1, dom.

Isikhathi sokuthumela: May-07-2024