I-ASTM A671 ipayipi lensimbi elenziwe ngepuleti lekhwalithi yomkhumbi ocindezelayo,I-Electric-Fusion-Welded (EFW)ezindaweni ezinomfutho ophezulu emazingeni okushisa azungezile naphansi.

Ifaneleka ngokukhethekile izinhlelo zokusebenza ezidinga ukuzinza komfutho ophezulu kanye nezakhiwo ezithile zokushisa okuphansi.

Izinkinobho Zokuzulazula

I-ASTM A671 Ubukhulu Ububanzi

Ukumakwa kwe-ASTM A671

Ukuhlukaniswa Kwebanga

Ukuhlukaniswa Kwezigaba

Ama-Raw material

Amaphuzu Abalulekile Welding

Ukwelashwa Kokushisa Kwamakilasi Ahlukene

Amaphrojekthi Wokuhlola we-ASTM A671

Ukubukeka kwe-ASTM A671

Ukuchezuka Okuvumelekile Ngosayizi

Izicelo ze-ASTM A671 Steel Tubing

Imikhiqizo Yethu Ehlobene

I-ASTM A671 Ubukhulu Ububanzi

Ibanga elinconyiwe: amapayipi ensimbi ane-DN ≥ 400 mm [16 in] kanye ne-WT ≥ 6 mm [1/4].

Ingase futhi isetshenziselwe abanye osayizi bepayipi, inqobo nje uma ihlangabezana nazo zonke ezinye izimfuneko zalokhu kucaciswa.

Ukumakwa kwe-ASTM A671

Ukuze siqonde kangcono i-ASTM A671, masiqale siqonde okuqukethwe kwayo kokumaka.Lokhu kusiza ukucacisa ububanzi bokusetshenziswa nezici zaleli zinga.

Isibonelo sokumaka isifutho:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

I-BOTOP: Igama lomkhiqizi.

EFW: Inqubo yokukhiqiza ishubhu lensimbi.

I-ASTM A671: I-Executive Standard for Steel Tubing.

CC60-22: Izifinyezo zebanga:cc60 kanye nekilasi 22.

16" x SCH80: Ububanzi kanye Nokuqina Kodonga.

UKUSHISA NO.4589716: Nokushisa.ukukhiqizwa kwamashubhu ensimbi.

Lena ifomethi evamile yokulebula kwesifutho se-ASTM A671.

Akunzima ukuthola i-ASTM A671 ebangeni kanye nezigaba zesigaba sesibili, khona-ke lezi zigaba ezimbili zimele ukuthi iyini incazelo.

Ukuhlukaniswa Kwebanga

Ihlukaniswa ngokohlobo lwepuleti elisetshenziselwa ukwakha amashubhu ensimbi.

Amamaki ahlukene amelela ukwakheka kwamakhemikhali ahlukene kanye nezakhiwo zemishini zokucindezela okuhlukile nezimo zokushisa.

Isibonelo, amanye amamaki angama-carbon steels angenalutho, kanti amanye angama-steels anezakhi ze-alloying ezengeziwe, njengezinsimbi ze-nickel.

| Ibanga lombhobho | Uhlobo Lwensimbi | Ukucaciswa kwe-ASTM | |

| Cha. | Ibanga/ikilasi/uhlobo | ||

| CA 55 | ikhabhoni engenalutho | I-A285/A285M | Gr C |

| CB60 | plain carbon, wabulawa | I-A515/A515M | Gr 60 |

| CB65 | plain carbon, wabulawa | I-A515/A515M | gr 65 |

| CB70 | plain carbon, wabulawa | I-A515/A515M | Gr 70 |

| CC 60 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516/A516M | Gr 60 |

| CC 65 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516/A516M | gr 65 |

| CC 70 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516/A516M | Gr 70 |

| iCD 70 | i-manganese-silicon, ejwayelekile | I-A537/A537M | Cl 1 |

| iCD80 | i-manganese-silicon, ivaliwe futhi ithambile | I-A537/A537M | Cl 2 |

| Idatha ye-CFA 65 | insimbi ye-nickel | I-A203/A203M | Gr A |

| CFB 70 | insimbi ye-nickel | I-A203/A203M | Gr B |

| CFD 65 | insimbi ye-nickel | I-A203/A203M | Gr D |

| Idatha ye-CFE70 | insimbi ye-nickel | I-A203/A203M | Gr E |

| CG100 | 9% i-nickel | I-A353/A353M | |

| CH 115 | 9% i-nickel | I-A553/A553M | Uhlobo 1 |

| I-CJA 115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr A |

| I-CJB 115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr B |

| I-CJE115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr E |

| CJF 115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr F |

| CJH 115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr H |

| I-CJP 115 | i-alloy steel, ivaliwe futhi ithambile | I-A517/A517M | Gr P |

| CK 75 | I-carbon-manganese-silicon | I-A299/A299M | Gr A |

| CP85 | insimbi yengxubevange, ukuqina kweminyaka, ukucima kanye nokushisa kwezulu kwelashwa | I-A736/A736M | Gr A, Ikilasi 3 |

Ukuhlukaniswa Kwezigaba

Amashubhu ahlukaniswa ngokohlobo lokwelashwa okushisa akutholayo phakathi nenqubo yokukhiqiza kanye nokuthi ahlolwa yini nge-radiographical futhi ahlolwe ingcindezi.

Izigaba ezahlukene zibonisa ukucaciswa okuhlukile kokwelashwa kwamashubhu.

Izibonelo zifaka ukujwayelekile, ukukhululeka kwengcindezi, ukucisha, nokucasuka.

| Ikilasi | Ukwelashwa kokushisa epayipini | I-Radiography, bheka inothi: | Ukuhlolwa kwengcindezi, bheka inothi: |

| 10 | akukho | akukho | akukho |

| 11 | akukho | 9 | akukho |

| 12 | akukho | 9 | 8.3 |

| 13 | akukho | akukho | 8.3 |

| 20 | ukucindezeleka kuphelile, bheka 5.3.1 | akukho | akukho |

| 21 | ukucindezeleka kuphelile, bheka 5.3.1 | 9 | akukho |

| 22 | ukucindezeleka kuphelile, bheka 5.3.1 | 9 | 8.3 |

| 23 | ukucindezeleka kuphelile, bheka 5.3.1 | akukho | 8.3 |

| 30 | okujwayelekile, bheka 5.3.2 | akukho | akukho |

| 31 | okujwayelekile, bheka 5.3.2 | 9 | akukho |

| 32 | okujwayelekile, bheka 5.3.2 | 9 | 8.3 |

| 33 | okujwayelekile, bheka 5.3.2 | akukho | 8.3 |

| 40 | ijwayelekile futhi inolaka, bheka 5.3.3 | akukho | akukho |

| 41 | ijwayelekile futhi inolaka, bheka 5.3.3 | 9 | akukho |

| 42 | ijwayelekile futhi inolaka, bheka 5.3.3 | 9 | 8.3 |

| 43 | ijwayelekile futhi inolaka, bheka 5.3.3 | akukho | 8.3 |

| 50 | ucime futhi uthukuthele, bheka 5.3.4 | akukho | akukho |

| 51 | ucime futhi uthukuthele, bheka 5.3.4 | 9 | akukho |

| 52 | ucime futhi uthukuthele, bheka 5.3.4 | 9 | 8.3 |

| 53 | ucime futhi uthukuthele, bheka 5.3.4 | akukho | 8.3 |

| 70 | okucishiwe futhi kuphathwe ukushisa kwezulu | akukho | akukho |

| 71 | okucishiwe futhi kuphathwe ukushisa kwezulu | 9 | akukho |

| 72 | okucishiwe futhi kuphathwe ukushisa kwezulu | 9 | 8.3 |

| 73 | okucishiwe futhi kuphathwe ukushisa kwezulu | akukho | 8.3 |

Ukushisa kokusetshenziswa kufanele kuqashelwe lapho ukhetha izinto.Ireferensi ingenziwa ekucacisweni kwe-ASTM A20/A20M.

Ama-Raw material

Amapuleti ekhwalithi ephezulu emikhumbi yokucindezela, imininingwane yezinhlobo, namazinga okubulala angatholakala kuthebula kuUkuhlukaniswa Kwebangangenhla.

Amaphuzu Abalulekile Welding

I-Welding: Ama-seam kufanele ashiselwe kabili, angene ngokugcwele.

Ukushisela kuzokwenziwa ngokuhambisana nezinqubo ezishiwo eSigabeni IX se-ASME Boiler kanye neKhodi Yomkhumbi Wokucindezela.

Ama-welds azokwenziwa ngesandla noma ngokuzenzakalelayo ngenqubo kagesi efaka ukufakwa kwensimbi yokugcwalisa.

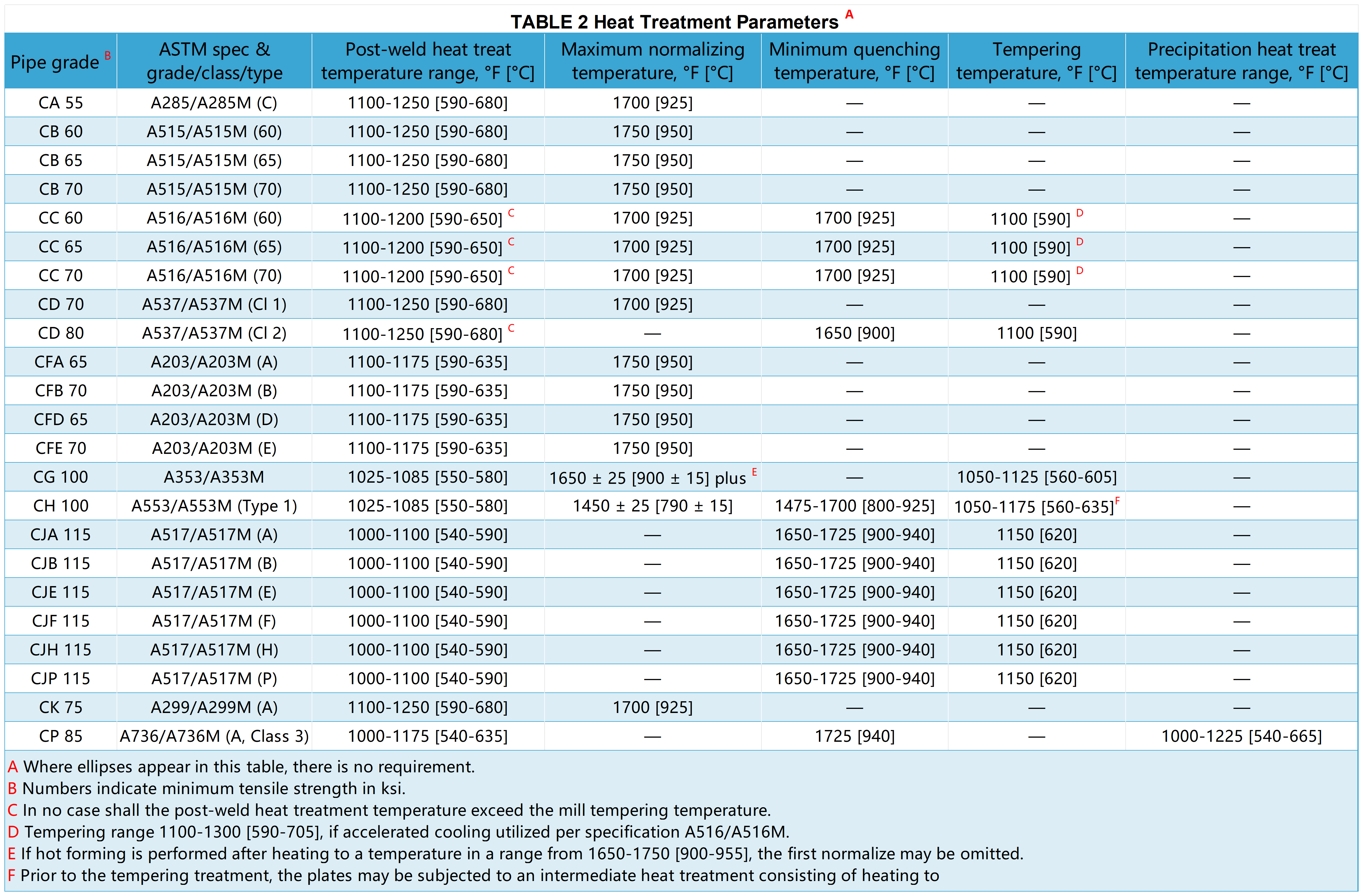

Ukwelashwa Kokushisa Kwamakilasi Ahlukene

Wonke amakilasi ngaphandle kuka-10, 11, 12, kanye no-13 azophathwa ukushisa esithandweni esilawulwa sibe ngu-±25 °F[± 15°C].

Amakilasi 20, 21, 22, kanye nama-23

Izoshiswa ngendlela efanayo phakathi kwezinga lokushisa langemva kokushisela elikhonjiswe kuThebula 2 ubuncane be-1 h/in.[0.4 h/cm] ukujiya noma ihora elingu-1, kuye ngokuthi yikuphi okukhulu.

Amakilasi 30, 31, 32, kanye nama-33

Izoshiswa ngokufanayo zibe izinga lokushisa ebangeni le-austenitizing futhi ingeqi izinga lokushisa eliphakeme lokujwayelekile elikhonjiswe kuThebula 2 futhi kamuva lipholiswe emoyeni ekamelweni lokushisa.

Amakilasi 40, 41, 42, kanye nama-43

Ipayipi kufanele lijwayele.

Ipayipi kufanele lishiselwe futhi kumazinga okushisa ashiwo kuThebula 2 njengesilinganiso esincane futhi ligcinwe ezingeni lokushisa okungenani elingu-0.5 h/in.[0.2 h/cm] ukujiya noma 0.5 h, noma yikuphi okukhulu, nomoya- ipholile.

Amakilasi 50, 51, 52, kanye 53

Ipayipi kufanele lishise ngendlela efanayo kumazinga okushisa ngaphakathi kwebanga le-austenitizing futhi lingadluli izinga lokushisa eliphezulu lokucisha eliboniswe kuThebula 2.

Okulandelayo, cisha emanzini noma emafutheni.Ngemuva kokucisha, ipayipi izoshiswa kabusha ekushiseni okuphansi okuncane okuboniswe kuThebula 2 futhi ibanjwe lapho.

izinga lokushisa okungenani libe ngu-0,5 h/intshi ukujiya noma u-0,5 h, kuye ngokuthi iyiphi enkulu, futhi lipholile emoyeni.

Amakilasi 70, 71, 72, kanye nama-73

Amapayipi kufaneleshisisa ngendlela efanayo kumazinga okushisa ebangeni le-austenitizing, engeqi izinga lokushisa eliphezulu lokucisha elikhonjiswe kuThebula 2, futhi kamuva sicinywe emanzini noma emafutheni.

Ngemva kokucisha ipayipi kufanele lishiselwe kabusha ebangeni lokwelapha ukushisa kwezulu elikhonjiswe kuThebula 2 isikhathi esizonqunywa umenzi.

Amaphrojekthi Wokuhlola we-ASTM A671

Ukwakheka Kwamakhemikhali

Ngokuvumelana nezidingo ezihambisanayo zezindinganiso zokusetshenziswa zezinto zokusetshenziswa, ukuhlaziya ukwakheka kwamakhemikhali, imiphumela yokuhlolwa ukuze kuhlangatshezwane nezidingo ezijwayelekile.

Tension Test

Wonke amapayipi ashiselwe akhiqizwe ngale mininingwane kufanele abe nokuhlolwa okuqinile kwe-cross-weld ngemva kokwelashwa kokushisa kokugcina, futhi imiphumela kufanele ihambisane nezidingo zempahla eyisisekelo ukuze kube namandla okugcina aqinile wento yepuleti elishiwo.

Ukwengeza, Amabanga e-CD XX kanye ne-CJ XXX, lapho lawa aku-Class 3x, 4x, noma 5x, kanye neBanga CP lika-6x no-7x azoba nokuhlolwa kokuqinile kwensimbi okuyisisekelo okuphambene okwenziwa kuma-specimens asikwe epayipini eliqediwe.Imiphumela yalezi zivivinyo izohlangabezana nezidingo ezincane zokuhlolwa kwemishini yokucaciswa kwepuleti.

I-Transverse Guided Weld Bend Test

Ukuhlolwa kokugoba kuzokwamukeleka uma kungekho mifantu noma okunye ukukhubazeka okweqile1/8phakathi [3 mm] kunoma iyiphi indlela akhona ensimbi yokushisela noma phakathi kwensimbi eshiselwe nesisekelo ngemva kokugoba.

Imifantu eqhamuka emaphethelweni esampula ngesikhathi sokuhlolwa, futhi engaphansi1/4phakathi. [6 mm] ikalwe kunoma iyiphi indlela ngeke inakwe.

Ukuhlolwa Kwengcindezi

Ipayipi lamakilasi X2 kanye ne-X3 azohlolwa ngokuhambisana ne-Specification A530/A530M, Izidingo Zokuhlola I-Hydrostatic.

Ukuhlolwa kwe-Radiographic

Ubude obugcwele be-weld ngayinye ye-Class X1 ne-X2 buzohlolwa nge-radiographic ngokuhambisana futhi kuhlangabezane nezimfuneko ze-ASME Boiler ne-Pressure Vessel Code, Isigaba VIII, Isigaba UW-51.

Ukuhlolwa kwe-radiographic kungenziwa ngaphambi kokwelashwa kokushisa.

Ukubukeka kwe-ASTM A671

Ipayipi eliqediwe ngeke lingabi nasici futhi lizoba nesiphetho esifana nomsebenzi.

Ukuchezuka Okuvumelekile Ngosayizi

| Ezemidlalo | Ukubekezelela Inani | Qaphela |

| Ngaphandle Ububanzi | ±0.5% | Ngokusekelwe esilinganisweni esiyindilinga |

| Ngaphandle Kwe-Roundness | 1%. | Umehluko phakathi kwamadayamitha angaphandle amakhulu namancane |

| Ukuqondanisa | 1/8 kokuthi [3 mm] | Kusetshenziswa unqenqema oluqondile olungamamitha angu-3 olubekwe ukuze iziphetho zombili zihlangane nepayipi |

| Ubukhulu | 0.01 kokuthi [0.3 mm] | Ubukhulu obuncane bodonga bungaphansi kogqinsi olushiwo |

| Ubude | 0 - +0.5in [0 - +13mm] | iziphetho ezingashintshiwe |

Izicelo ze-ASTM A671 Steel Tubing

Imboni Yamandla

Isetshenziselwa ukuthutha uketshezi lwe-cryogenic ezikhungweni zokwelapha igesi yemvelo, izindawo zokuhluza, nezindawo zokucubungula amakhemikhali.

Iziqandisi Zezimboni

Ukuze kusetshenziswe engxenyeni ye-cryogenic yesiqandisi kanye nezinhlelo zokupholisa umoya ukuze kuqinisekiswe ukuzinza nokuphepha kwesistimu.

Izinsiza

Okokugcina kanye nezindawo zokuthutha zamagesi anoketshezi.

Ukwakha Nokwakha

Kusetshenziswa kumaphrojekthi wengqalasizinda emazingeni okushisa aphansi noma izimo zemvelo ezimbi kakhulu, njengokwakhiwa kwesitoreji esibandayo.

Singomunye wabaphambili abashiselwe ipayipi lensimbi elishiselwe kanye nabakhiqizi nabahlinzeki bepayipi lensimbi engenamthungo abavela eChina, abanohlu olubanzi lwamapayipi ensimbi ekhwalithi ephezulu esitokweni, sizimisele ukukunikeza uhla olugcwele lwezixazululo zamapayipi ensimbi.Ukuze uthole imininingwane eyengeziwe yomkhiqizo, sicela ukhululeke ukuxhumana nathi, sibheke phambili ekusizeni ukuthi uthole izinketho ezingcono kakhulu zamapayipi ensimbi ngezidingo zakho!

Amathegi: ASTM a671, efw, cc 60, isigaba 22, abahlinzeki, abakhiqizi, izimboni, amasheya, izinkampani, iwholesale, thenga, inani, quotation, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: Apr-19-2024