I-BS EN 10219 insimbiiyinsimbi yesakhiwo engenalutho eyakhiwe ngendlela ebandayo eyenziwe ngezinsimbi ezingezona i-alloy nezicolisekile ukuze zisetshenziswe ngokwesakhiwo ngaphandle kokwelashwa kokushisa okulandelayo.

I-EN 10219 ne-BS EN 10219 ngamazinga afanayo kodwa anezinhlangano ezahlukene.

Izinkinobho Zokuzulazula

I-BS EN 10219 Ukuhlukaniswa

I-BS EN 10219 Ububanzi Bosayizi

Izinto Ezisetshenziswayo kanye Nezimo Zokulethwa

I-BS EN 10219 Igama Lensimbi

Ukubunjwa Kwekhemikhali kwe-BS EN 10219

Izakhiwo Zemishini ye-BS EN 10219

Izivivinyo Zomthelela

Ukuhlola Okungonakali

Ukubukeka Nokulungiswa Kwesici

I-Dimensional Tolerances

Kufakwe amagalani

I-BS EN 10219 Ukumaka

Izinhlelo zokusebenza

Imikhiqizo Yethu Ehlobene

I-BS EN 10219 Ukuhlukaniswa

Ngohlobo Lwensimbi

Izinsimbi ezikhethekile ezingaluliwe nezihlanganisiwe.

Izinsimbi ezingaluliwe:

I-S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H,I-S275NH, S275NLH, S355NH, S355NLH.

Izinsimbi ezikhethekile ezihlanganisiwe:

I-S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

Indlela elula yokuveza umehluko: izinhlobo zensimbi eziqukethe i-M noma 4 ziyi-alloys, futhi izakhiwo ze-alloying zensimbi zingabonakala ngokushesha.

Ngenqubo Yokukhiqiza

Izinqubo zokukhiqiza ezisetshenziswa ikakhulukazi ukukhiqiza amapayipi ensimbi ngokuya nge-BS EN 10219 zifaka phakathi.I-Electric Resistance Welding (ERW) kanye ne-Submerged Arc Welding (SAW).

I-SAW ingaphinde ihlukaniswe ibe yi-Longitudinal Submerged Arc Welding (LSAW) kanye ne-Spiral Submerged Arc Welding (SSAW) ngokusekelwe kuhlobo lwe-weld seam.

Nge-Cross-section Shape

I-CFCHS: Izingxenye eziyizigodi eziyiziyingi ezibandayo ezakhiwe;

I-CFRHS: Izingxenye eziyisikwele ezibandayo ezakhiwe noma eziwunxande;

I-CFEHS: Izingxenye ezinezimbobo ezibandayo ezakhiwe;

Leli phepha ligxile ku-CFCHS (Isigaba Esiyizingqimba Esibandayo Esakhiwe Ngesiyingi).

I-BS EN 10219 Ububanzi Bosayizi

Ukujiya kodonga: T ≤ 40mm

Ububanzi bangaphandle (D):

Umjikelezo (CHS): D ≤ 2500 mm;

Isikwele (RHS): D ≤ 500 mm × 500 mm;

Unxande (RHS): D ≤ 500 mm × 300 mm;

Okusaqanda(EHS): D ≤ 480 mm × 240 mm.

Izinto Ezisetshenziswayo kanye Nezimo Zokulethwa

Izinsimbi ezingezona i-alloy

ngokweSithasiselo A, Esigoqiwe noma Esimisiwe/Esiyingiwe Esijwayelekile (N) saJR, J0, J2, kanye ne-K2izinsimbi;

Izinsimbi zokusanhlamvu ezinhle

NgokweSithasiselo B, Ukugingqa Okumisiwe/Okujwayelekile (N) kokuthiN kanye ne-NLizinsimbi;

NgokweSithasiselo B.M kanye ne-ML, izinsimbi zazigoqelwa nge-thermomechanically (M).

Izingxenye ezingenalutho zizolethwa zakhiwe ngendlela ebandayo ngaphandle kokwelashwa kokushisa okulandelayo ngaphandle kokuthi umthungo wokushisela ungase ube sesimweni esishiselwe njenge-welded noma esiphathwe ngokushisa.

Ezingxenyeni ezingenalutho ze-SAW ezingaphezu kuka-508 mm ngaphandle kobubanzi, kungase kudingeke ukuba kwenziwe umsebenzi wokubumba ofudumele, ongathinti izakhiwo zemishini, ukuze kuhlangatshezwane nezidingo zokubekezelela ngaphandle kokujikeleza.

I-BS EN 10219 Igama Lensimbi

Ingqungquthela yokuqamba amagama ye-BS EN 10219 iyafanaI-BS EN 10210, esebenzisa indinganiso ye-EN10027-1.

Ezingxenyeni ezingenalutho zensimbi engeyona i-alloy, igama lensimbi liqukethe

Isibonelo: Insimbi yesakhiwo (S) enamandla ashiwo ubuncane besivuno sogqinsi olungekho ngaphezu kuka-16 mm ka-275 MPa, enenani eliphansi lomthelela lamandla elingu-27 J ku-0 ℃(J), ingxenye engenalutho (H).

I-BS EN 10219-S275J0H

Iqukethe izingxenye ezine:S, 275, J0, kanye no-H.

1. S: kukhombisa ukuthi insimbi yesakhiwo.

2. Inani lenombolo (275): ukujiya ≤ 16mm ngobuncane bamandla esivuno ashiwo, ku-MPa.

3. JR: ikhombisa ukuthi kumazinga okushisa asekamelweni anezici ezithile zomthelela;

J0: ikhombisa ukuthi ku-0 ℃ enezici ezithile zomthelela;

J2 or K2: kukhonjiswe ku -20 ℃ ngezici ezithile zomthelela;

4. H: ikhombisa izigaba ezingenalutho.

Ezingxenyeni ezingenalutho zensimbi yokusanhlamvu, igama lensimbi liqukethe

Isibonelo: Insimbi yesakhiwo (S) enamandla ashiwo ubuncane besivuno sogqinsi olungekho ngaphezu kuka-16 mm wama-355 MPa.I-normalized fine grain steel feedstock (N), enenani eliphansi lomthelela lamandla elingu-27 J ku -50 ℃(L), ingxenye engenalutho (H).

I-EN 10219-S355NLH

Iqukethe izingxenye ezinhlanu:S, 355, N, L, kanye no-H.

1. S: ikhombisa insimbi yesakhiwo.

2. Inani lenombolo(355): ukujiya ≤ 16mm ubuncane obubekiwe bamandla esivuno, iyunithi i-MPa.

3. N: ukuginqika okujwayelekile noma okujwayelekile.

4. L: izici ezithile zomthelela ku -50 °C.

5. H: ichaza isigaba esingenalutho.

Ukubunjwa Kwekhemikhali kwe-BS EN 10219

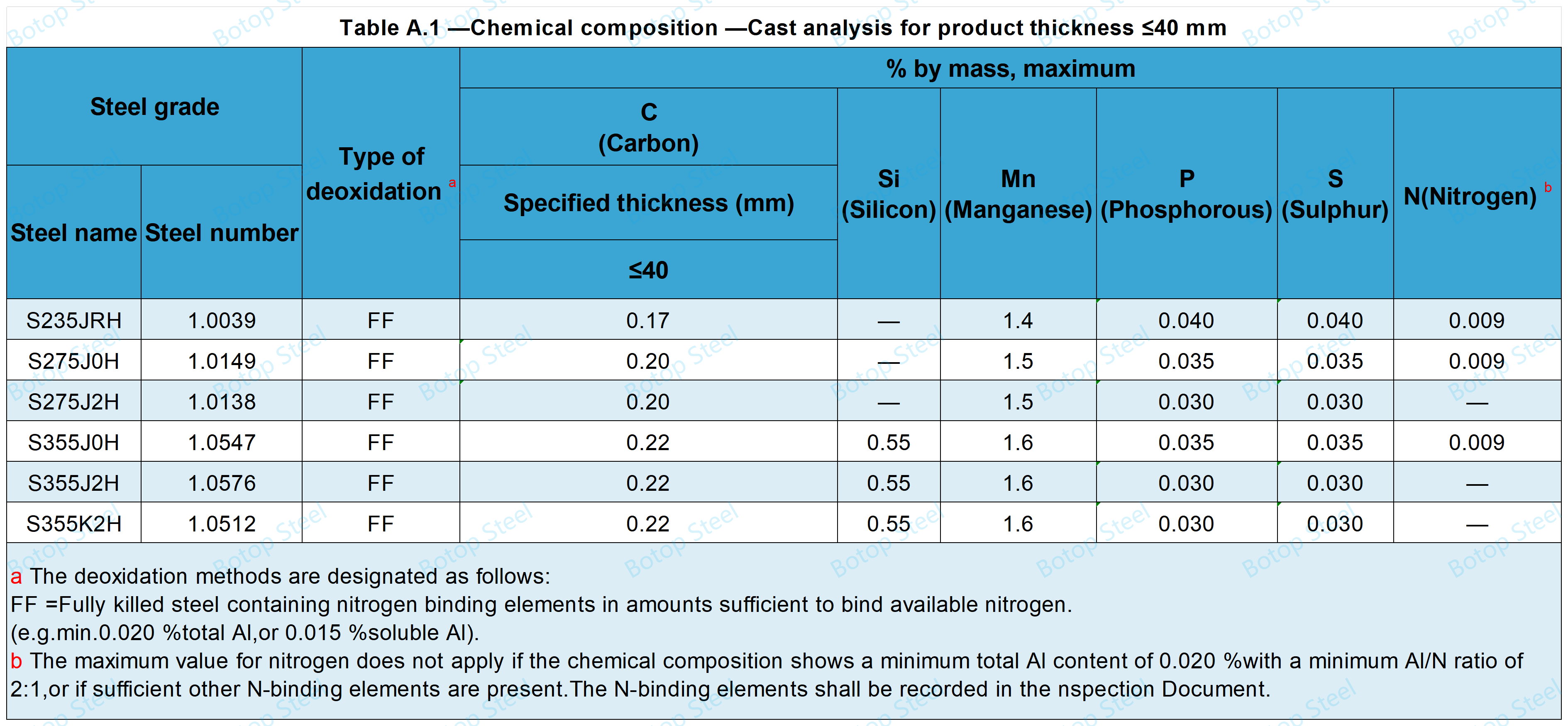

Izinsimbi ezingezona i-alloy - Ukwakheka Kwamakhemikhali

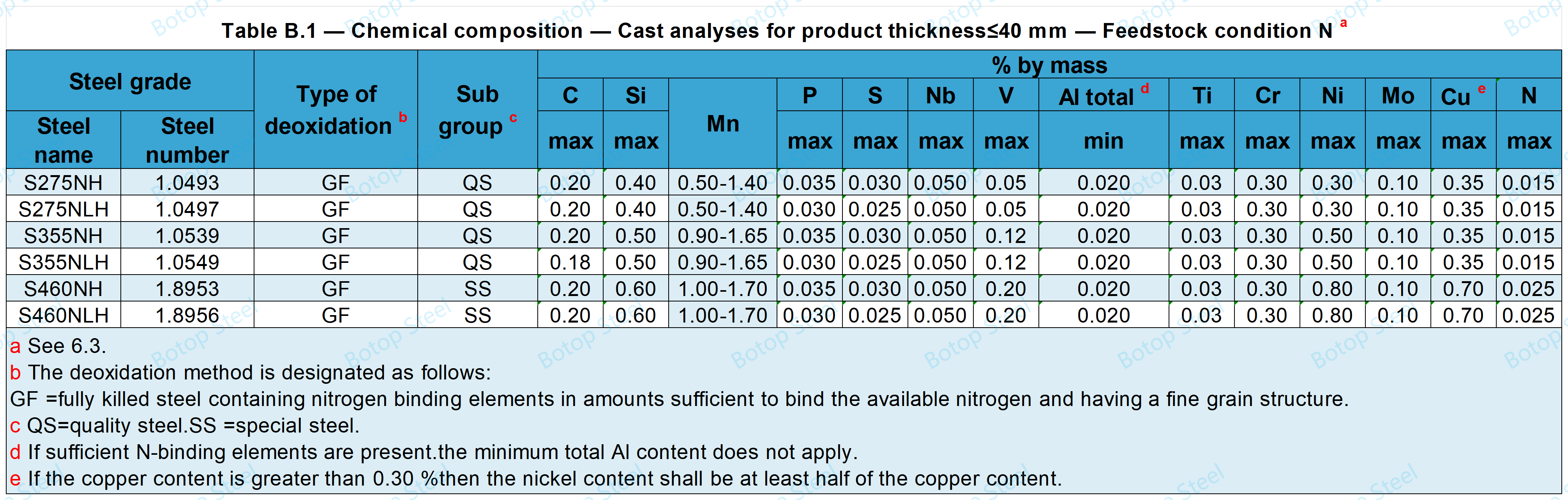

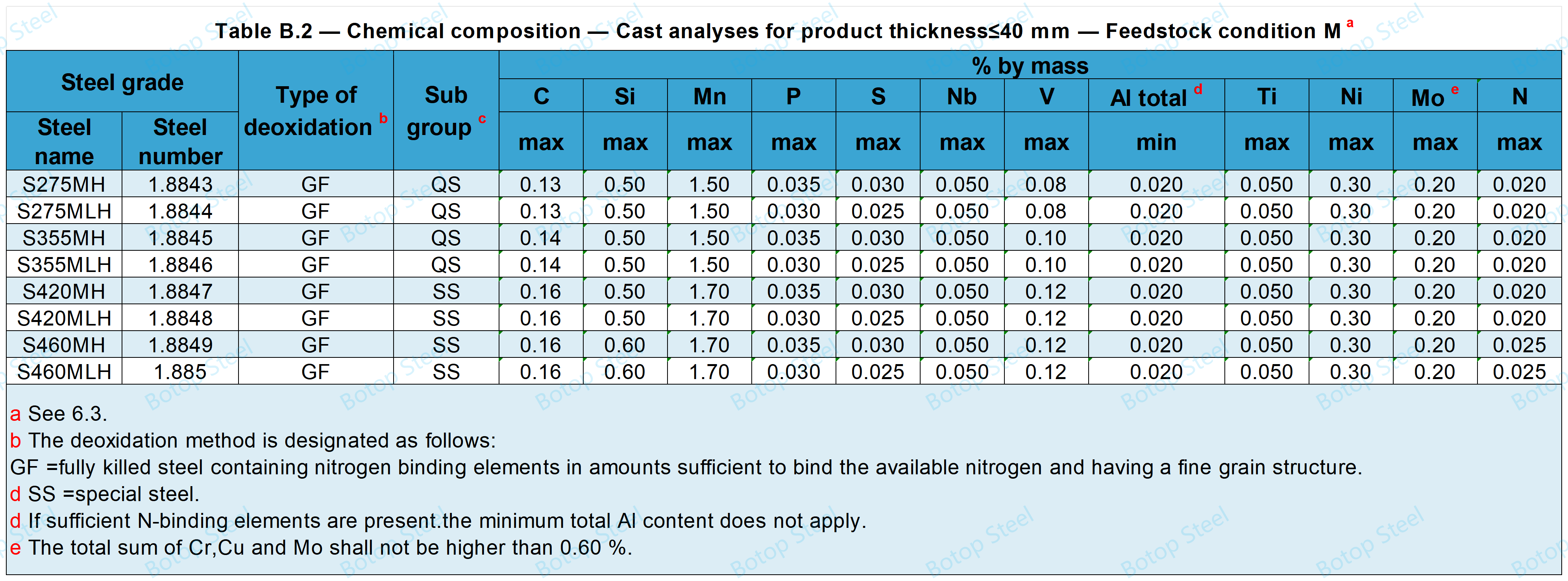

Fine Grain Steels - Ukwakheka kwamakhemikhali

Uma insimbi ecolekile isetshenziswa njengempahla eluhlaza, ingahlukaniswa ibe ngu-M no-N ngokuya ngezimo zokulethwa, futhi izidingo zokwakheka kwamakhemikhali zalezi zinhlobo ezimbili zingase zehluke.

Lapho kunqunywa i-CEV kuzosetshenziswa ifomula elandelayo: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Isimo se-Feedstock N

Isimo se-Feedstock M

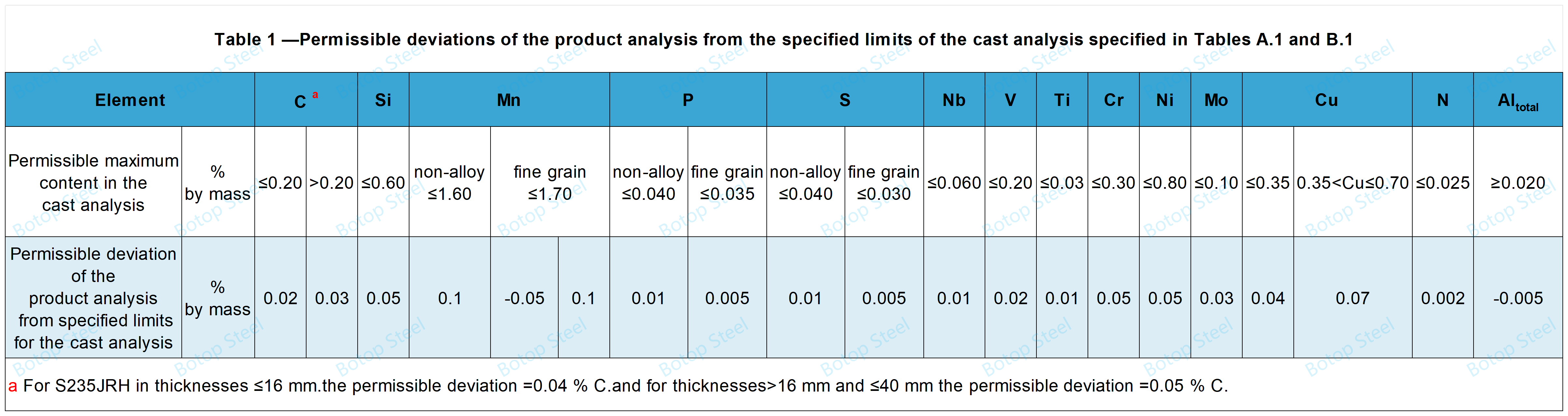

Ukuchezuka Ekubunjweni Kwamakhemikhali

Izakhiwo Zemishini ye-BS EN 10219

Kufanele kwenziwe ngokuhambisana ne-EN 1000-2-1.Ukuhlolwa kufanele kwenziwe ebangeni lokushisa kusuka ku-10°C kuya ku-35°C.

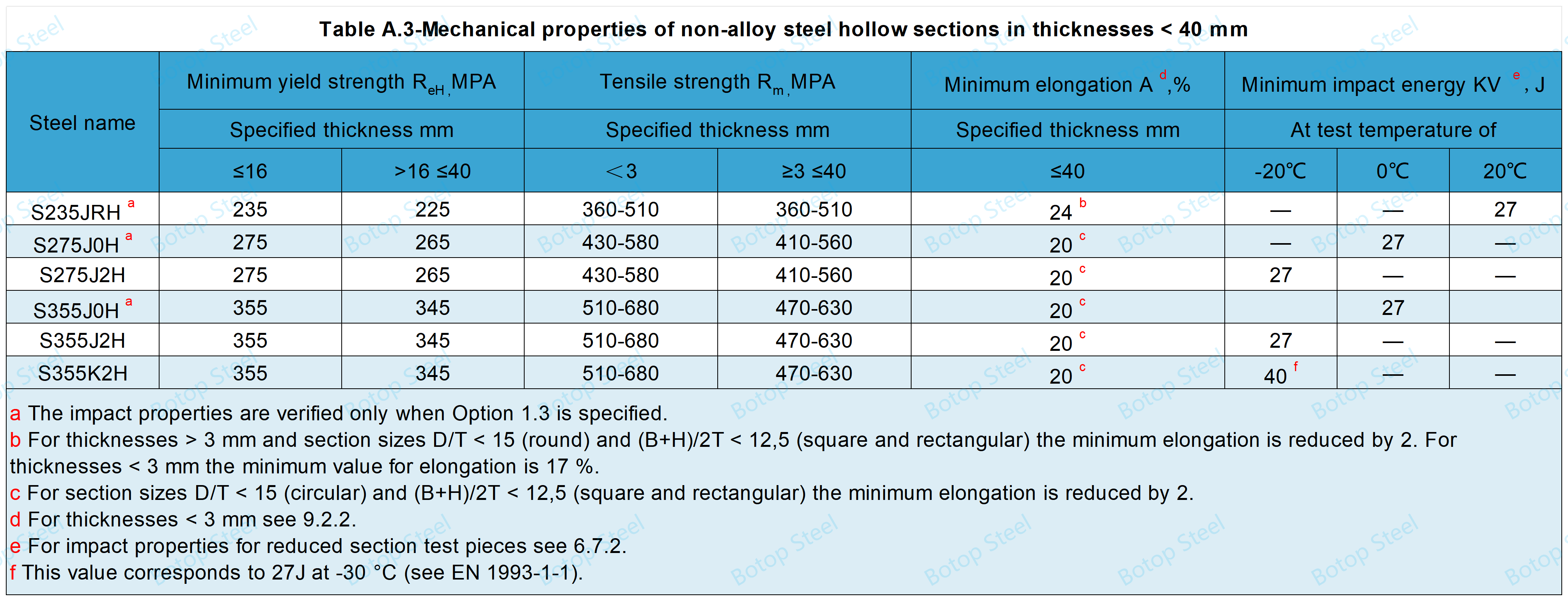

Izinsimbi ezingezona i-alloy - Izakhiwo Zemishini

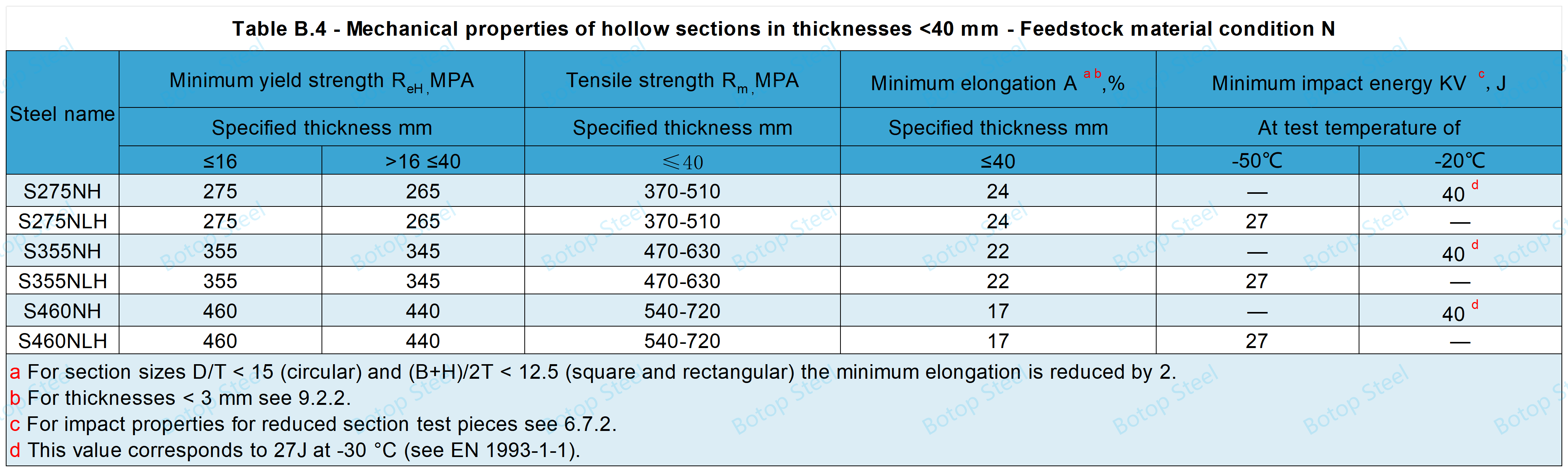

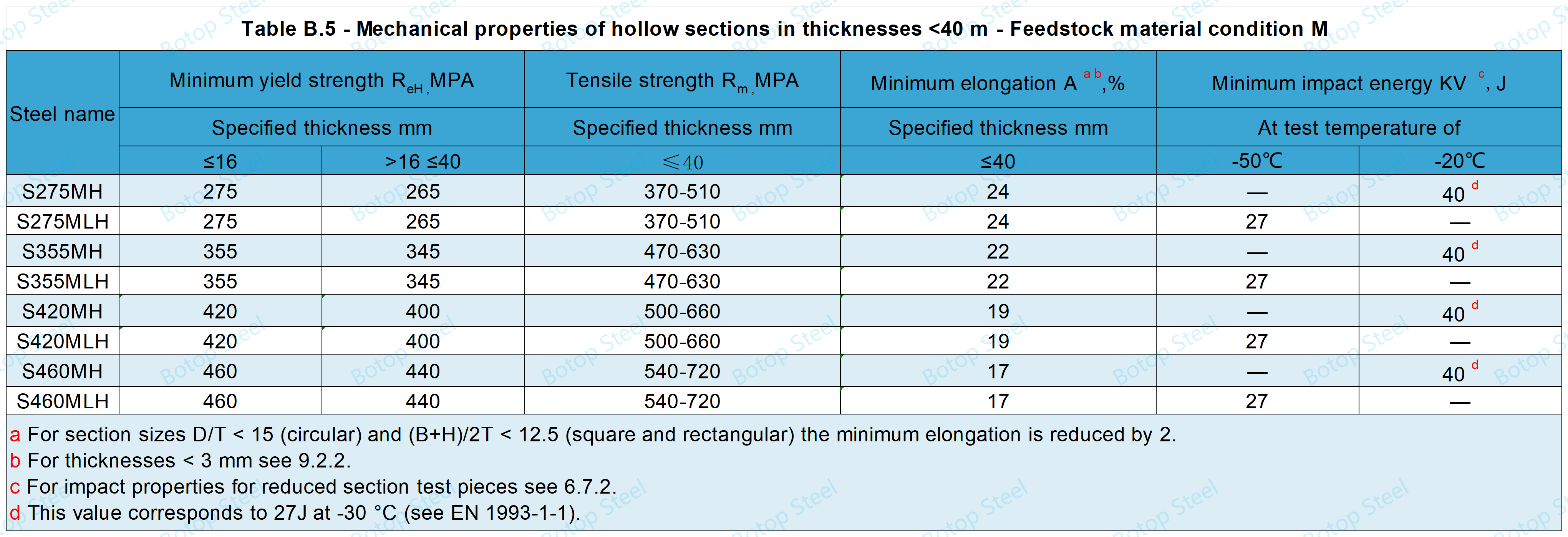

Fine Grain Steels - Mechanical Properties

Uma insimbi enohlamvu oluhle isetshenziswa njengempahla eluhlaza, ingahlukaniswa ibe ngu-M no-N ngokwezimo zokulethwa, futhi izici zemishini zalezi zinhlobo ezimbili zingahluka.

Isimo se-Feedstock N

Isimo sempahla ye-Feedstock M

Izivivinyo Zomthelela

Ukuhlolwa komthelela kuzokwenziwa ngokuhambisana ne-EN 10045-1.

Inani elimaphakathi lesethi yezifanekiso ezintathu lizolingana noma libe likhulu kunevelu eshiwo.

Inani ngalinye lingase libe ngaphansi kwenani elishiwo, kodwa alikho ngaphansi kuka-70% walelo nani.

Ukuhlola Okungonakali

Lapho kwenziwa i-NDT kumashisela asezigabeni zesakhiwo esingenalutho, lezi zidingo ezilandelayo kufanele kuhlangatshezwane nazo.

Izigaba ezishiselwe ngogesi

Hlangana nenye yalezi zidingo ezilandelayo:

a) I-EN 10246-3 kuya kuzinga lokwamukela u-E4, ngaphandle kokuthi ishubhu elizungezayo/indlela yekhoyili ye-pancake ngeke ivunyelwe;

b) I-EN 10246-5 kuya ezingeni lokwamukelwa F5;

c) I-EN 10246-8 kuya ezingeni lokwamukela u-U5.

Izigaba Ezishiselwe I-Arc Engaphansi

Umthungo we-weld wezingxenye ezingenalutho ze-arc ezishiselwe ngaphansi kwamanzi uzohlolwa ngokuya nge-EN 10246-9 kuya ezingeni lokwamukela u-U4 noma nge-radiography ngokuhambisana ne-EN 10246-10 ngesigaba sekhwalithi yesithombe esingu-R2.

Ukubukeka Nokulungiswa Kwesici

Ukubukeka Kobuso

Izingxenye ezingenalutho zizoba nendawo ebushelelezi ehambisana nendlela yokukhiqiza esetshenzisiwe;amaqhuqhuva, ama-grooves noma ama-longitudinal grooves angashoni ngenxa yenqubo yokukhiqiza avunyelwe uma ukushuba okusele kungabekezelelwa.

Iziphetho zengxenye engenalutho zizosikwa ngokwezikwele ku-eksisi yomkhiqizo.

Ukulungiswa Kwesici

Amaphutha angaphezulu angasuswa ngokugaya inqobo nje uma ukujiya angekho ngaphansi kogqinsi oluncane oluvumelekile olushiwo ku-BS EN 10219-2 ngemva kokulungiswa.

Ezingxenyeni ezingenalutho zokusanhlamvu, ukulungiswa komzimba ngokushisela ngeke kuvunyelwe ngaphandle uma kuvunyelwene ngenye indlela.

Izinqubo zokulungisa i-weld zizohambisana nezidingo ze-EN ISO 15607, EN ISO 15609-1, kanye ne-EN ISO 15614-1.

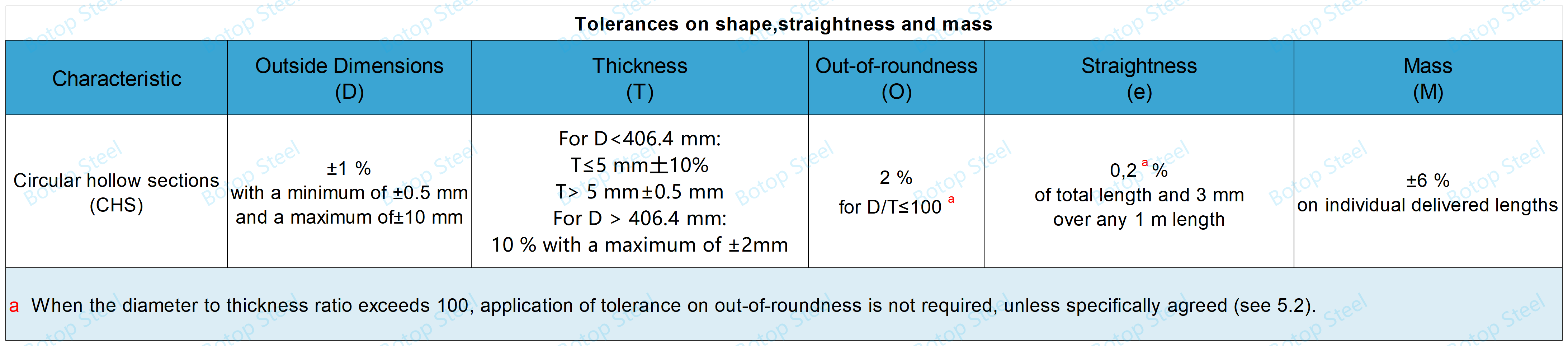

I-Dimensional Tolerances

Ukubekezelelana kobukhulu kufanele kuhambisane nezidingo ezihambisanayo ze-EN 10219-2 futhi kuzonakwa ukwakheka kwesigaba esiphambanayo.

Ukubekezelela Isimo, UkuQopha kanye NeMisa

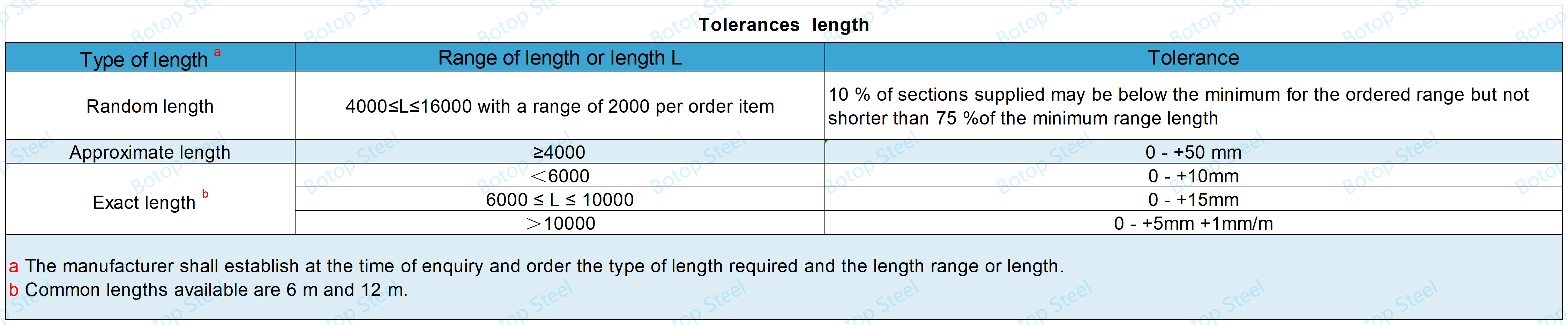

Ukubekezelela Ubude

Ukuphakama Kwe-Seam ye-SAW Weld

Ukubekezelela ukuphakama kwe-weld seam yangaphakathi nangaphandle yezingxenye ezingenalutho ze-arc ezishiselwe.

| Ubukhulu, T | Ubukhulu bobude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Kufakwe amagalani

I-BS EN 10219 Amashubhu angenalutho angafakwa uthayela oshisayo ukuze aphile impilo yesevisi.

Amashubhu angenalutho afakwa kubhavu oqukethe okungenani u-98% we-zinc ukuze akhe ungqimba olunothayela.

I-BS EN 10219 Ukumaka

Okuqukethwe kokumaka ipayipi lensimbi kufanele kuqukathe:

Igama lensimbi, isb EN 10219-S275J0H.

Igama noma uphawu lokuhweba lomkhiqizi.

Ikhodi kamazisi, isb inombolo ye-oda.

I-BS EN 10219 amashubhu ensimbi angamakwa ngezindlela ezahlukahlukene zokuqinisekisa ukukhonjwa kalula nokulandeleka, kungaba ngokudweba, ukugxiviza, amalebula okunamathela, noma amalebula engeziwe, angasetshenziswa ngawodwana noma ahlanganiswe.

Izinhlelo zokusebenza

Ukusetshenziswa kwezinga le-BS EN 0219 lihlanganisa zonke izindawo zezidingo zensimbi yesakhiwo.

Ukwakha:I-BS EN 10219 amapayipi ensimbi asetshenziswa kabanzi kumaphrojekthi wokwakha, njengokwakha amabhuloho, ukusekelwa kwesakhiwo sezakhiwo, njll.

Ukwakhiwa kwengqalasizinda: asetshenziswa ezinhlelweni zokonga amanzi, ukwakhiwa kwemigwaqo, izinhlelo zamapayipi, kanye neminye imiklamo yokwakha ingqalasizinda, njengamapayipi okukhipha amanzi, amapayipi amanzi, njalonjalo.

Ukukhiqiza: Lawa mapayipi ensimbi aphinde asetshenziswe ekwenzeni imishini, amasistimu okuthutha, nezinye izinhlelo zokusebenza zezimboni.

Ubunjiniyela bakamasipala: Ebunjiniyela bakamasipala basemadolobheni, i-BS EN 10219 amapayipi ensimbi ajwayelekile angasetshenziswa ukwenza ama- guardrails, ama-railing, imigoqo yomgwaqo, nokunye.

Umhlobiso wezakhiwo: Idizayini yobuhle namandla amashubhu ensimbi awenza abe yinto evamile esetshenziswa ekuhlobiseni kwezakhiwo, njengezitebhisi, ama-balustrade, amabakaki okuhlobisa, njll.

Kusukela yasungulwa ngo-2014, i-Botop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi e-carbon eNyakatho neChina, eyaziwa ngomsebenzi wayo omuhle kakhulu, imikhiqizo esezingeni eliphezulu, nezisombululo ezibanzi.Uhlu olubanzi lwemikhiqizo yenkampani luhlanganisaamapayipi ensimbi angenamthungo, ERW, LSAW, kanye ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kukhwalithi, i-Botop Steel isebenzisa izilawuli eziqinile nokuhlola ukuze iqinisekise ukwethembeka kwemikhiqizo yayo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.

Amathegi: bs zu 10219, zu 10219, chs, cfchs, s355j0h, s275j0h.

Isikhathi sokuthumela: Apr-26-2024