Ipayipi lensimbi ye-carboniyipayipi elenziwe ngensimbi ye-carbon enekhemikhali okuthi, uma lihlaziywa ngokushisa, lingeqi umkhawulo omkhulu ongu-2.00% we-carbon kanye no-1.65% we-manganese.

Ipayipi lensimbi ye-Carbon iyinto evamile yamapayipi esetshenziswa kabanzi embonini ukuthutha uketshezi namagesi.

Izinkinobho Zokuzulazula

Ukwahlukaniswa Kwepayipi Lensimbi Yekhabhoni

I-Carbon Steel Pipe Size Range

Amazinga Okuphatha Ajwayelekile Epayipi Lensimbi Ye-Carbon

Amapharamitha angukhiye we-Carbon Steel Pipe

I-Carbon Steel Pipe Surface Coating

Izinzuzo Carbon Steel Pipe

Ukungalungi kwe-Carbon Steel Pipe

Ukusetshenziswa kwe-Carbon Steel Pipe

Ungamkhetha Kanjani Umhlinzeki Othembekile Wepayipi Lensimbi Ye-Carbon

Mayelana NATHI

Ukwahlukaniswa Kwepayipi Lensimbi Yekhabhoni

Ukuhlukaniswa Ngenhloso

Amapayipi esakhiwo: esetshenziswa kakhulu ezakhiweni zokwakha, njengezisekelo zezakhiwo, amabhuloho, nezakhiwo zezimboni.

Amapayipi okuthutha: Lawa mapayipi ensimbi asetshenziselwa ukuthutha uketshezi olufana nowoyela, igesi, namanzi.

Amashubhu Mechanical: Isetshenziswa emishinini nasezishintshayo lapho ubukhulu obunembile kanye nezakhiwo ezithile zemishini zidingeka.

Amashubhu Boiler: Ikhethekile ezindaweni ezishisa kakhulu nezinomfutho ophezulu, njengamabhoyela eziteshini zikagesi nasezimbonini ezihluza uwoyela.

Amashubhu omthombo kawoyela negesi: isetshenziswa ekukhishweni kwamafutha negesi, okumele ikwazi ukumelana nokucindezela okukhulu nokugqwala kwamakhemikhali.

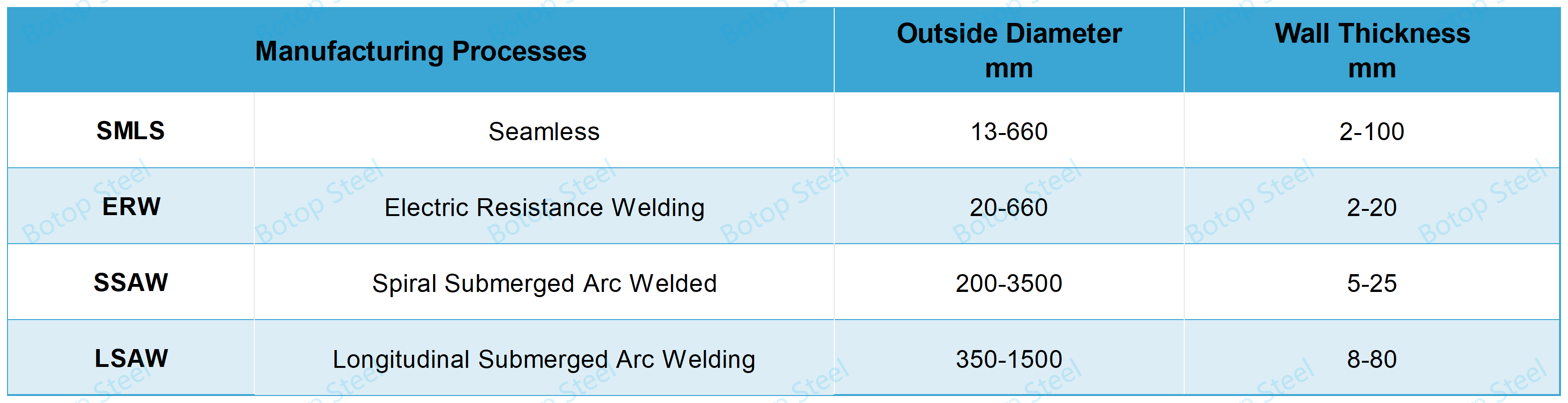

Ukuhlukaniswa Ngokwenqubo Yokukhiqiza

Ipayipi lensimbi elingenamthungo: Ipayipi lensimbi elenziwe ngokushisa okushisayo noma inqubo yokuqeda ebandayo, akukho mthungo oshiselwe, ovame ukusetshenziswa ngesikhathi sokucindezela okukhulu.

Ipayipi lensimbi elishiselwe: eyenziwe ngepuleti lensimbi noma ikhoyili ehlutshiwe ibe yithubhu, ngendlela yokushisela yokucubungula ukubumba.

Ipayipi lensimbi elishiselwe lingahlukaniswa ngokwenqubo yokushisela:

Ipayipi Lensimbi Eliqinile Lokumelana (ERW): Ipayipi elenziwe nge-roll elishiselwe ngokushisisa kwe-high-frequency resistance, ukukhiqizwa kwepayipi lensimbi ye-carbon enobubanzi obuncane kanye nesivinini sokukhiqiza esisheshayo.

Ipayipi Elishiselwe I-Arc Engaphansi (SAW): isebenzisa inqubo yokushisela ye-arc engaphansi kwamanzi ezenzakalelayo ukukhiqiza amapayipi ensimbi e-carbon anobubanzi obukhulu noma ubukhulu bodonga obukhulu.

SAWipayipi lensimbi ingabuye ihlukanisweI-LSAW(Longitudinal Submerged Arc Welding) kanyeI-SSAW(Spiral Submerged Arc Welded) ngokuya ngesiqondiso se-weld seam.

Uma ufuna ukwazi umehlukophakathi kwe-SMLS,ERW,LSAW,SSAW, ungachofoza ukuze ukuhlole.

I-Carbon Steel Pipe Size Range

Amazinga Okuphatha Ajwayelekile Epayipi Lensimbi Ye-Carbon

I-ASTM A106: Ipayipi le-carbon steel engenamthungo yesevisi yokushisa okuphezulu.

I-ASTM A53: Amashubhu ensimbi ashiselwe futhi angenamthungo wesevisi evamile kanye nengcindezi.

I-ASTM A333: Ipayipi lensimbi elingenamthungo nelishiselwe lesevisi yezinga lokushisa eliphansi.

I-API 5L: Ukucaciswa kwepayipi lensimbi kumasistimu okuthutha amapayipi asetshenziswa embonini kawoyela negesi.

I-DIN 2440: Amashubhu ensimbi ene-carbon esindayo emaphakathi ngezinjongo ezijwayelekile zesakhiwo kanye nengcindezi yokusebenza.

I-EN 10210: Amashubhu ensimbi esakhiwe ashisayo ngezinjongo zesakhiwo.

I-EN 10219: Amapayipi ensimbi akhiwe ngokubandayo ashiselwe ngezinhloso zesakhiwo.

I-JIS G3452: Amapayipi ensimbi ekhabhoni amapayipi ajwayelekile.

I-JIS G3454: I-Carbon steel amapayipi amapayipi okucindezela.

AS/NZS 1163: Amashubhu ensimbi akhiwe ngendlela ebandayo kanye nezingxenye ezingenalutho zemikhiqizo yesakhiwo kanye nezinhlelo zamapayipi esakhiwo.

Amapharamitha angukhiye we-Carbon Steel Pipe

Usayizi weThubhu

Imingcele ye-dimensional yepayipi lensimbi ye-carbon ibalulekile ukuze kuqinisekiswe ukufakwa nokusebenza okufanele kwesistimu yokukhipha amapayipi.

Ububanzi bangaphandle (OD): Ububanzi bangaphandle kwepayipi, buhlobene ngokuqondile nokuxhumeka kwepayipi kanye nesakhiwo.

Ububanzi bangaphakathi (ID): ububanzi bengaphakathi lepayipi, obuthinta izinga lokugeleza nokugeleza kwamanzi.

Ukuqina kwezindonga (WT): ubukhulu bodonga lwepayipi, okubalulekile ekubekezeleleni ukucindezela kanye nokuqina kwepayipi.

Ubude (L): Ipayipi ingaba nobude obunqunyiwe noma obungahleliwe.

Ukujikeleza nokuqondile: nquma ikhwalithi yokufaka yepayipi kanye nokuvala uxhumano.

Uhlobo lwesiphetho se-tube: Isiphetho seshubhu singaba sicaba, sibevele, noma sifakwe intambo ukuze kufakwe izinhlobo ezahlukene zokuxhuma.

Ukwakheka Kwamakhemikhali

Ukwakheka kwamakhemikhali epayipi lensimbi ye-carbon kunquma ubulukhuni bayo, amandla, ukuqina, nokumelana nokugqwala.

Ikhabhoni (C): kwandisa ubulukhuni namandla, kodwa kakhulu kunciphisa ukuqina.

I-Manganese (Mn): kwandisa amandla nokumelana nokugqoka ngenkathi kugcinwa ukuqina okuhle.

I-silicon (Si): kuthuthukisa ukunwebeka nokumelana nokushisa.

Isibabule (S)futhii-phosphorus (P): ngokuvamile zibhekwa njengokungcola futhi zidinga ukugcinwa emazingeni aphansi njengoba zinciphisa ukuqina kanye nokushisela.

Ezinye izakhi ze-alloying(isb. i-chromium, i-nickel, i-molybdenum): ingathuthukisa izici ezithile zemishini kanye nokumelana nokugqwala.

Izakhiwo Zemishini

Imingcele yempahla yemishini ithinta ngokuqondile ukuzinza kwepayipi lensimbi ye-carbon ngaphansi kwezimo zesevisi.

Amandla aqinile: ikhono lezinto ezikwaziyo ukumelana nokuqhekeka kwengcindezi.

Amandla esivuno: ingcindezi enkulu into engaphansi kwayo ngaphambi kokuthi iqale ukonakala unomphela.

Ukwelula: Inkomba yekhono lempahla ukonakala ngokwepulasitiki, izinga elinganwebeka ngalo ngaphambi kokuphuka.

Ukuqina: Amandla wento yokumelana nokuhlehlisa endaweni, ngokuvamile kukalwa ngokuhlolwa kokuqina kwe-Brinell, Rockwell, noma Vickers.

Ukuhlolwa komthelela: Ukuhlolwa komthelela okwenziwa ezingeni lokushisa elithile ukuze kuhlolwe ukuqina kwento ethile.

Lapho ukhetha amashubhu ensimbi ye-carbon, le mingcele ebalulekile kufanele ihambisane nezidingo ezithile zohlelo lokusebenza kanye namazinga ahambisanayo.

I-Carbon Steel Pipe Surface Coating

Ukuvikelwa kokumboza okungaphezulu kwepayipi lensimbi ye-carbon kuyindlela ebalulekile yokuvimbela ukugqwala nokwelula impilo yamapayipi.Izinhlobo ezahlukene zokumboza zinikeza amazinga ahlukene okuvikela futhi zifanele izindawo zokusebenza nemibandela ehlukene.

Okulandelayo ezinye izinhlobo ezivamile zokumbozwa kwendawo yepayipi lensimbi ye-carbon:

Izingubo ze-epoxy: hlinzeka ngokunamathela okuhle nokumelana namakhemikhali futhi avame ukusetshenziselwa ukuvimbela ukugqwala kanye nezicelo ezingaphansi kwamanzi.

Izembatho ze-polyurethane: Nikeza ukumelana nesimo sezulu esihle kakhulu nokuhuzuka futhi asetshenziswa ezindaweni ezivezwe ngaphandle.

Izindwangu ezicebile zinc: Iqukethe iphesenti eliphezulu le-zinc powder, inikeza ukuvikelwa kwe-cathodic futhi ifanele izindawo zasolwandle nezimboni.

I-galvanizing: Ihlinzeka ngokuvikelwa kwe-cathodic ngokucwiliswa okushisayo noma i-electroplating zinc futhi iyindlela evamile yokuvimbela ukugqwala.

I-aluminium plating: inikeza ukuvikeleka okuphakeme ekufakeni uthayela ngaphansi kwezimo ezithile, ikakhulukazi ezindaweni ezinezinga lokushisa eliphezulu.

I-polyethylene (PE).: Inikeza ukumelana okuhle kwamakhemikhali nomthelela futhi ivame ukusetshenziselwa amapayipi angaphansi komhlaba.

I-polypropylene (PP).: efana ne-PE coating kodwa inikeza ukusebenza okungcono emazingeni okushisa aphezulu.

Uhlaka lukasimende: Afanele amapayipi okuthuthwa kwendle namanzi ukuvikela ukugqwala kwangaphakathi nokungcoliswa koketshezi.

Ulwelwesi lwenjoloba: Ihlinzeka ngokuvikeleka ngokomzimba futhi inciphisa ukugqwala nokuhuzuka okubangelwa uketshezi.

Uhlobo ngalunye lokumboza lunezimo zalo eziqondile zohlelo lokusebenza, izinzuzo, kanye nokubi.Izinto ezihlukahlukene ezihlanganisa izindleko, izimo zokwakha, iminyaka yokuphila, umthelela wendawo, kanye nezidingo zokunakekelwa okufanele zicatshangelwe lapho kukhethwa ukunamathela okufanele.

Izinzuzo Carbon Steel Pipe

Ipayipi lensimbi ye-Carbon inikeza izinzuzo ezihlukahlukene ezenza kube yimpahla yokuzikhethela kwezicelo eziningi zezimboni.

1.Izinzuzo zamanani: Kushibhile kunensimbi engagqwali noma i-alloy steel, kuyisinqumo esingcono kakhulu samaphrojekthi amakhulu namapayipi amabanga amade.

2. Amandla omshini: Zinezakhiwo ezinhle zemishini, ezihlanganisa amandla aqine kakhulu kanye nokumelana nomthelela.Lokhu kusho ukuthi ingakwazi ukumelana nezingcindezi eziphezulu kanye nezindawo zokusebenza ezinzima.

3. Ukucubungula kalula: Kulula ukusika, ukushisela, nokuma ukuze kufakwe nokugcinwa kamuva.

4. Good conductivity ezishisayo: Insimbi ye-Carbon iyikhondatha enhle yokushisa futhi ifanele ukusetshenziswa njengezishintshisi zokushisa namasistimu okushisa lapho kudingeka khona ukudluliswa kokushisa okuphumelelayo.

5. Ukumelana nokushisa okuphezulu: Igcina izinto zayo ezibonakalayo emazingeni okushisa aphakeme futhi ifanele izindawo ezidinga izinga lokushisa eliphezulu lokusebenza, njengamasistimu omusi.

6. Ukusebenziseka kabusha: Iwumsebenzi osebenziseka kabusha ongabuyiselwa esithandweni ukuze usetshenziswe futhi ekupheleni kwesonto lokusetshenziswa.

7. Ukumelana nemihuzuko: Ukuqina okuhle kuvumela ukumelana okuhle kokuhuzuka lapho uhambisa izinto eziqhumayo futhi, isibonelo, kusetshenziswa kabanzi ekudlulisweni kwezinto ezimbonini zokuphatha izimayini kanye nempushana.

8. Ukuvumelana: Ihambisana nezinhlobo eziningi ezahlukene zezixhumi nokufakwa, nezinhlobonhlobo zezinsiza nokutholakala kalula.

Ukungalungi kwe-Carbon Steel Pipe

Nakuba amapayipi ensimbi e-carbon asetshenziswa kabanzi ezinhlelweni eziningi zezimboni ngenxa yezinzuzo zawo eziningana, aphinde abe nokubi noma ukulinganiselwa okuthile.

1. Kulula ukugqwala: Ikakhulukazi ezindaweni ezimanzi noma ezonakalisayo.Ukugqwala kunganciphisa ubukhulu bodonga lwepayipi lensimbi, kwandise ingozi yokuqhekeka futhi ekugcineni kuholele ekuvuzeni noma ekuhlulekeni.

2. Izindleko zokunakekela: Ukuze amelane nokugqwala futhi andise impilo yawo yesevisi, amapayipi ensimbi ye-carbon angadinga izinyathelo zokuvikela ezengeziwe ezifana nama-coatings, linings, noma amasistimu okuvikela ama-cathodic.Ukugcinwa okuvamile nokuhlolwa kuyadingeka kuyo yonke impilo yepayipi, okufaka izindleko eziphelele.

3. Ayifanelekile ukusetshenziswa namakhemikhali athile: Insimbi yekhabhoni izwela kumakhemikhali athile futhi ingagqwala ngokushesha ngaphansi kwethonya lalawa makhemikhali.Isibonelo, i-carbon steel isengozini yokuqhekeka kokugqwala kwengcindezi ezindaweni ezinokugxila okuphezulu kwe-hydrogen sulfide.

4. Izinga lokushisa elilinganiselwe: Nakuba izinsimbi zekhabhoni zingamelana nohlobo lwamazinga okushisa aphezulu, izakhiwo zensimbi ziwohloka lapho amazinga okushisa aphakeme kakhulu, okuholela ekwehleni kwamandla ezinto ezibonakalayo kanye nokukhasa (ukuguqulwa kusuka ekuchayekeni isikhathi eside emithwalweni ephezulu).

5. Ukushisa okuphansi kwe-embrittlement: Emazingeni okushisa aphansi, kokubili ukuqina nokuqina kuyancishiswa, okuholela ekuqhekekeni okuphukile ngaphansi komthelela.

6. Izinkinga zesisindo: Amapayipi ensimbi ekhabhoni asindayo kunezinye izinto, njengamapulasitiki, futhi angaholela ezidingweni ezengeziwe nezindleko zokukhwezwa kanye nezakhiwo ezisekelayo.

7. Ukunwetshwa kwe-thermal: Ukwanda kwezinga lokushisa okwenzeka ngesikhathi sokushintsha kwezinga lokushisa, ikakhulukazi kumapayipi ahamba ibanga elide.Lokhu kudinga ukucatshangelwa ekwakhiweni nasekufakweni kwamapayipi ukuze kugwenywe ukucindezeleka nokukhubazeka okubangelwa ukushintsha kwezinga lokushisa.

Ukukhetha ipayipi elifanele lezidingo zesicelo esithile kanye/noma ukuthatha izinyathelo zokuvikela ezifanele kuyisihluthulelo sokuqinisekisa impumelelo.

Ukusetshenziswa kwe-Carbon Steel Pipe

1. Imboni kawoyela negesi:Isetshenziswa kakhulu ekuthuthweni kukawoyela ongahluziwe, igesi yemvelo, neminye imikhiqizo kaphethiloli, kokubili ezinhlelweni zokuthutha zamapayipi amabanga amade kanye nakumapayipi okumba nemithombo kawoyela.

2. Izimboni zamakhemikhali nezephethiloli: Lezi zimboni zidinga amapayipi amelana namazinga okushisa aphezulu kanye nezingcindezi zokuthutha amakhemikhali noketshezi futhi ngenxa yalokho ngokuvamile zisebenzisa amapayipi ensimbi ekhabhoni aphethwe ngokukhethekile.

3. Ukukhiqiza: Ingasetshenziselwa ukwakha izingxenye zemishini nemishini, amapayipi okukhipha umoya, njll.

4. Ukwakha nokwakha: Emkhakheni wokwakha, asetshenziswa njengohlaka lwamathambo ezakhiwo ezifana nemishayo, amakholomu, nezinye izakhiwo ezisekelayo.Ibuye isetshenziswe ekwenzeni isikafula nezinye izakhiwo zesikhashana.

5. Amanzi nendle: Esetshenziswa kakhulu ezinhlelweni zamapayipi zokuthutha amanzi kanye nokuthuthwa kwendle, amapayipi ensimbi avame ukugqunywa ngaphakathi ngesendlalelo esifanelekile sokumboza, esisetshenziselwa ukuvikela amapayipi ekugqwaleni futhi andise impilo yabo yenkonzo.

6. Imboni yamandla: Ezitshalweni zikagesi, zisetshenziselwa ukuthutha izinga lokushisa eliphezulu, isitimu esinomfutho ophezulu.Zingabuye zisetshenziselwe ukwenza ama-boilers kanye nezishintshi zokushisa.

7. Amasistimu wokushisisa nokupholisa: Okokuthutha imidiya noma isitimu kumasistimu wokushisisa amaphakathi namasistimu wokupholisa umoya.

8. Imboni yasolwandle: Isetshenziswa ekwakhiweni kwemikhumbi yezakhiwo zefreyimu, izinhlelo zokudonsa amanzi, nezinye izinhlelo zokusebenza ezahlukahlukene.

9. Iziteshi zikagesi ezishisayo: Okokuthutha ngesitimu namanzi eziteshini zamandla ashisayo.

10. Izakhiwo nobunjiniyela: Ngokuvamile isetshenziselwa ukusekela izakhiwo zamabhuloho, amathaneli, amasistimu wesitimela esingaphansi komhlaba, nezindawo ezinkulu zomphakathi.

Amapayipi ensimbi ye-Carbon avame ukukhethwa ngokusekelwe kububanzi bawo, ukushuba kodonga, ubude, inqubo yokukhiqiza, nokuthi ngabe izintambo ezengeziwe noma ama-linings ayadingeka yini ukumelana nokugqwala.Lapho uzisebenzisa, kubalulekile ukucabangela izinga lokushisa, ingcindezi, nohlobo lwemidiya endaweni yokusebenza.

Ungamkhetha Kanjani Umhlinzeki Othembekile Wepayipi Lensimbi Ye-Carbon

1. Iziqu kanye nokugunyazwa:Hlola ukuthi imikhiqizo yomphakeli iyahambisana namazinga emboni yamazwe ngamazwe neyasekhaya nokuthi inesitifiketi sohlelo lokuphatha ikhwalithi (isb, ISO 9001).

2. Izinga lomkhiqizo: Ingabe umphakeli uyayinikeza imibiko yokuhlola yokwakheka kwamakhemikhali kanye nezakhiwo zemishini zezinto ezingavuthiwe nemikhiqizo eqediwe.Futhi qonda izinyathelo zokuqinisekisa ikhwalithi, okuhlanganisa ukuhlola, ukuhlola, nokulawulwa kwekhwalithi phakathi nenqubo yokukhiqiza.

3. Amandla okukhiqiza: Hlola ukuthi usayizi womphakeli namandla okukhiqiza angakwazi ukuhlangabezana nezidingo ze-oda.Hlola ukuthi amasu okukhiqiza nezinto zokusebenza ezisetshenziswa umphakeli zenziwe zamanje ukuze kuqinisekiswe ikhwalithi yomkhiqizo.

4. Idumela lemakethe: Cabangela isipiliyoni somphakeli embonini yepayipi lensimbi ye-carbon.Isipiliyoni sebhizinisi lesikhathi eside sivame ukuhlotshaniswa nokuthembeka okuphezulu.Cela impendulo namazwana kumakhasimende akhona, ikakhulukazi mayelana nekhwalithi yomkhiqizo nokwaneliseka kwesevisi.

5. Isevisi nokusekelwa:Ingabe umphakeli unikeza isevisi yamakhasimende enhle, ehlanganisa impendulo esheshayo nokuxazulula izinkinga.Ukuthi umphakeli anganikeza ukwesekwa kochwepheshe ohlelweni lokukhetha umkhiqizo, incazelo yokusebenza, kanye nokufaka.

6. Intengo nezindleko: Qhathanisa amakhotheshini avela kubahlinzeki abahlukene ukuze uqinisekise ukuthi intengo ihambisana nezinga lemakethe futhi iyonga.Qaphela izindleko ezifihliwe ezingaba khona ezivela ezintweni zokuhamba, ukupakisha, ukubambezeleka okungenzeka, njll.

7. Isikhathi sokudiliva:Ukuthi abahlinzeki bayakwazi yini ukuzibophezela futhi bahlangabezane nezinsuku eziwumnqamulajuqu zokulethwa, hlola inethiwekhi yezokuthutha yomphakeli ukuze uqinisekise ukuthi imikhiqizo ingalethwa ngokuphepha nangesikhathi.

8. Isevisi yangemuva kokuthengisa: Qonda inqubomgomo yesevisi yangemuva kokuthengisa yomphakeli, njengembuyiselo nokuhwebelana, ukuphatha ukuphikisa kwekhwalithi, njll.

9. Inhlolovo yolwazi lwenkampani: Sebenzisa izinsiza ze-inthanethi ukuze uthole ulwazi olwengeziwe.Isibonelo, amawebhusayithi ezinkampani, izinkundla zezimboni, inkundla yezokuxhumana, njll.

10. Ukuvakasha kwezindawo: Uma kungenzeka, ungavakashela imboni yokukhiqiza yomphakeli, kanye nezindawo zokukhiqiza mathupha.

11. Ukuhlolwa kwesampula: Amasampuli angacelwa ukuthi ahlolwe ukuze kuqinisekiswe ukuthi ikhwalithi yangempela yomkhiqizo ihlangabezana nezidingo.

Kuyo yonke inqubo yokukhetha, ukuhlola okuphelele nokwahlulela okuhlakaniphile kubalulekile.Qinisekisa ukuthi umphakeli omkhethayo akaphakeme nje ngokwenani, kodwa uyisinqumo esingcono kakhulu ngokwekhwalithi, ukwethembeka, kanye nenani lilonke.

Mayelana NATHI

Kusukela yasungulwa ngo-2014, i-Botop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi e-carbon eNyakatho neChina, eyaziwa ngomsebenzi wayo omuhle kakhulu, imikhiqizo esezingeni eliphezulu, nezisombululo ezibanzi.Uhlu olubanzi lwemikhiqizo yenkampani luhlanganisa amapayipi ensimbi angenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kukhwalithi, i-Botop Steel isebenzisa izilawuli eziqinile nokuhlola ukuze iqinisekise ukwethembeka kwemikhiqizo yayo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.

Tags: carbon steel pipe, abahlinzeki, abakhiqizi, izimboni, stockists, izinkampani, wholesale, thenga, inani, quotation, inqwaba, ukudayiswa, izindleko.

Isikhathi sokuthumela: May-03-2024