I-JIS G 3454 amashubhu ensimbiamashubhu ensimbi ekhabhoni afaneleka ngokuyinhloko ukuthi asetshenziswe ezindaweni ezingenaso ingcindezi ephezulu enobubanzi bangaphandle obusuka ku-10.5 mm ukuya ku-660.4 mm namazinga okushisa okusebenza afika ku-350 ℃.

Izinkinobho Zokuzulazula

Ukuhlukaniswa Kwebanga

Izinqubo Zokukhiqiza

I-Hot Dip Galvanizing -Ipayipi Elimhlophe

Ukwakhiwa kwamakhemikhali kwe-JIS G 3454

Izakhiwo Zemishini ye-JIS G 3454

Ukuhlola Ukucaba

Ukugoba Test

Ukuhlolwa Kwe-Hydraulic noma Ukuhlolwa Okungonakali

I-Dimensional Tolerances

Ithebula lesisindo sepayipi namashejuli wamapayipi we-JIS G3454

Ukubukeka

I-Surface Coating ye-JIS G 3454

Ukumaka

Izicelo ze-JIS G 3454 Steel Pipe

Imikhiqizo Yethu Ehlobene

Ukuhlukaniswa Kwebanga

I-JIS G 3454 inamabanga amabili ngokusho kwamandla amancane okukhiqiza wepayipi lensimbi eliqediwe.

STPG370, STPG410

Izinqubo Zokukhiqiza

Kwenziwe kusetshenziswa inhlanganisela efanele yezinqubo zokukhiqiza amashubhu nezindlela zokuqeda.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | ||

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | Ukuhlukaniswa kwe-zinc-coating | |

| I-STPG370 I-STPG410 | Ingenamthungo:S Ukumelana nogesi okushiselwe:E | Okushisayo kuqedile:H Kuqedwe okubandayo:C Njengoba ukumelana kukagesi kushiselwe:G | Amapayipi amnyama: amapayipi awanikezwanga i-zinc-coating Amapayipi amhlophe: amapayipi anikezwe i-zinc-coating |

Ipayipi lensimbi esetshenzwe ngokubanda lizodonswa ngemva kokwakhiwa. Uma kunesidingo, umthengi angacacisa ukwelashwa kokushisa kwama-welds we-STPG 410 ukumelana nepayipi lensimbi elishiselwe.

Uma kusetshenziswa i-resistance welding, ama-welds endaweni yangaphakathi nangaphandle yepayipi kufanele asuswe ukuze kutholakale i-weld ebushelelezi eduze kwe-contour yepayipi. Kodwa-ke, uma kunzima ukususa i-weld endaweni engaphakathi, isimo esihlanganisiwe singagcinwa.

I-Hot Dip Galvanizing -Ipayipi Elimhlophe

Ngobamhlopheipayipi(amapayipi anikezwe i-zinc-coating), ingaphezulu elihloliweipayipi elimnyama(amapayipi anganikezwanga i-zinc-coating) azohlanzwa ngokuqhunyiswa kwesanti, ukucotshwa, noma okunye ukwelashwa ngaphambi kokufakwa kwe-hot-dip galvanizing. I-Zinc yokwenziwa kwediphu eshisayo izoba i-JIS H 2107 Ibanga loku-1 ingot ye-zinc ehlutshiwe noma i-zinc yekhwalithi elinganayo noma engcono.

Ezinye izimfuneko ezijwayelekile zokufaka uthayela zihambisana ne-JIS H 8641.

Ukwakhiwa kwamakhemikhali kwe-JIS G 3454

Izinto ezijwayelekile zokuhlolwa kohlaziyo nezindlela zokuthatha amasampula nokuhlaziya zizohambisana ne-JIS G 0404 into 8 (Ukwakheka kwekhemikhali).

Indlela yokuhlaziya izohambisana ne-JIS G 0320.

| Uphawu lwebanga | C (Ikhabhoni) | I-Si (Silicon) | Mn (Manganese) | I-P (Phosphorus) | S (Sulfur) |

| ubuningi | ubuningi | ubuningi | ubuningi | ||

| I-STPG370 | 0.25% | 0.35% | 0.30-0.90% | 0.04% | 0.04% |

| I-STPG410 | 0.30% | 0.35% | 0.30-1.00% | 0.04% | 0.04% |

Izakhiwo Zemishini ye-JIS G 3454

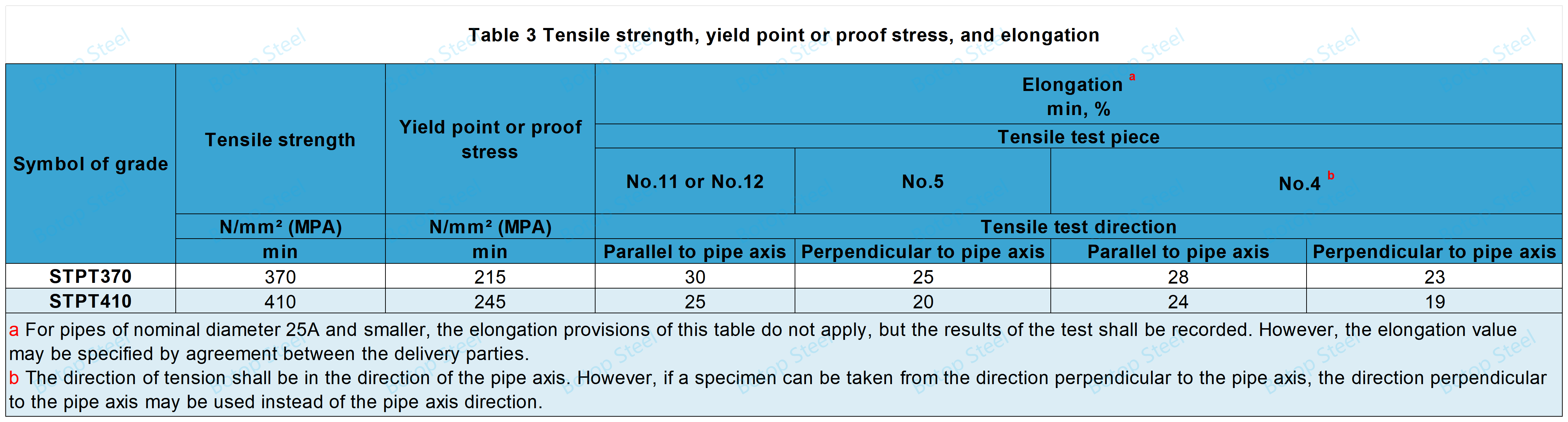

Izidingo ezijwayelekile zokuhlolwa kwemishini zihambisana ne-JIS G 0404 Isigaba somthetho 7 (Izimfuneko Ezivamile) kanye Nomthetho 9 (Izakhiwo zikaMechanical).

Nokho, indlela yokuqoqwa kwesifanekiso sokuhlolwa kwemishini izohambisana ne-JIS G 0404 Isigaba somthetho 7.6 (Izimo zokuqoqwa kwesifanekiso nezifanekiso), Uhlobo A.

Abahloli bamapayipi bazokwenza izivivinyo ngokuhambisana ne-JIS Z 2241 futhi amandla aqinile, amandla okukhiqiza, nobude kuzohambisana neThebula 3.

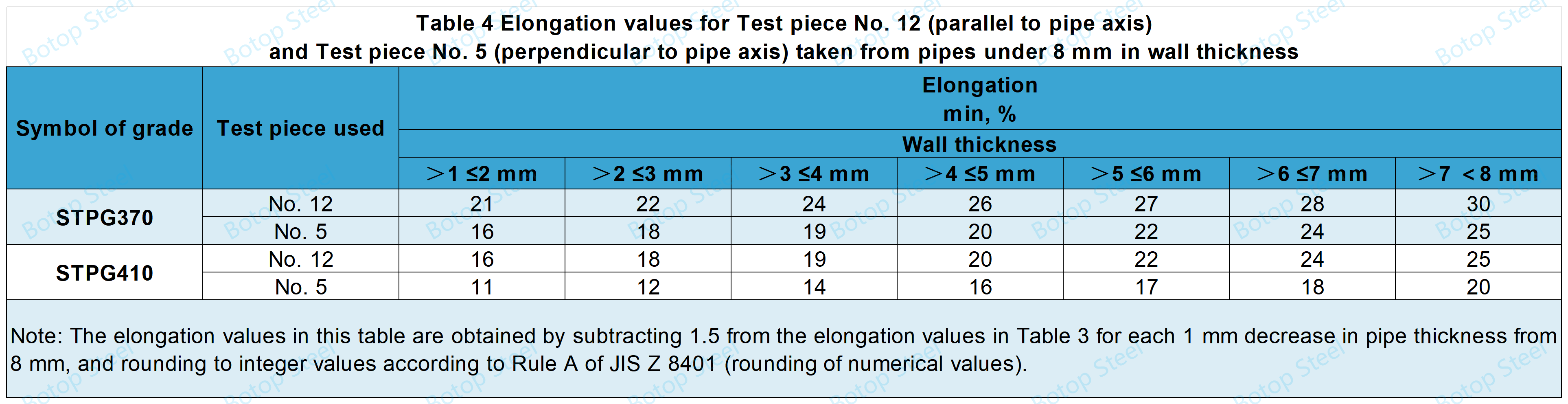

Kodwa-ke, kumashubhu angaphansi kuka-8 mm ubukhulu, ubude kufanele buhambisane neThebula lesi-4 lokuhlola ukuqina kusetshenziswa izibonelo ze-No. 12 noma No. 5.

Ukuhlola Ukucaba

Izinga lokushisa lokuhlola kufanele libe izinga lokushisa legumbi (5~35℃), isifanekiso sibekwe phakathi kwamapuleti amabili ayisicaba futhi sicindezelwe kuze kube yilapho ibanga H phakathi kwamapuleti lingaphansi kwenani elishiwo, lapho isifanekiso sicaba, bheka ukuthi kukhona yini ukuqhekeka ebusweni bebhulokhi yesampula yepayipi lensimbi.

Lapho H=2/3D, hlola i-weld ukuthi ayinamifantu.

Lapho H=1/3D, hlola ukuqhekeka kwezinye izingxenye ngaphandle kwe-weld seam.

Ipayipi yensimbi engenamthungo ingase ikhululwe ekuhlolweni kokunciphisa, kodwa ukusebenza kwepayipi kufanele kuhambisane nezinhlinzeko.

Ukugoba Test

Isebenza kumapayipi anobubanzi obungaphandle ≤ 40A (48.6mm).

Isifanekiso akufanele siqhekeke lapho sigotshwa ku-90° ngeradiyasi yangaphakathi ephindwe ka-6 ubukhulu bangaphandle.

Umthengi angase acacise i-engeli egobayo engu-180 kanye/noma irediyasi engaphakathi ephindwe izikhathi ezingu-4 ububanzi bangaphandle bepayipi.

Ngokumelana namapayipi ashiselwe, i-weld seam izotholakala cishe ngama-90 ° ukusuka engxenyeni engaphandle yokugoba.

Ukuhlolwa Kwe-Hydraulic noma Ukuhlolwa Okungonakali

Wonke amapayipi kumele ahlolwe nge-hydraulically noma angonakalisi.

Kodwa-ke, kumapayipi amhlophe, lokhu kuvame ukwenziwa ngaphambi kokufaka ama-galvanizing.

Ukuhlola i-Hydrotesting noma okungacekeli phansi kuyindlela ebalulekile yokulawula ikhwalithi yamapayipi ukuze kuqinisekiswe ukuphepha nokwethembeka kwamapayipi ngesikhathi sokufakwa nokusetshenziswa.

Ukuhlolwa kwe-Hydrostatic

Faka ingcindezi yokuhlola uketshezi oluningilizayo ephakeme kunaleyo eshiwo epayipini bese uyibamba okungenani imizuzwana emi-5 ukuze ubone ukuthi ipayipi lingakwazi yini ukumelana nokucindezela futhi uma ukuvuza kwenzeka.

| Ithebula 5 Ingcindezi encane yokuhlolwa kwe-hydraulic | ||||||

| Ukujiya kodonga okuzisholo | Inombolo yeshejuli: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Ukuhlola Okungonakali

Indlela yokuhlola ye-ultrasonic (UT) izohambisana ne-JIS G 0582. Nokho, kungase kusetshenziswe ukuhlolwa okuqinile kunokwehlukaniswa kwe-UD kweziphambeko zokwenziwa.

Indlela yamanje yokuhlola (ET) ka-Eddy izohambisana ne-JIS G 0583. Kodwa-ke, ingase futhi indawo yayo ithathelwe indawo ukuhlolwa okuqinile kunohlelo lwe-EY Artificial Defects.

Impela, ezinye izindlela zokuhlola ezingalimazi ezihlangabezana nemibandela zingakhethwa esikhundleni salokho.

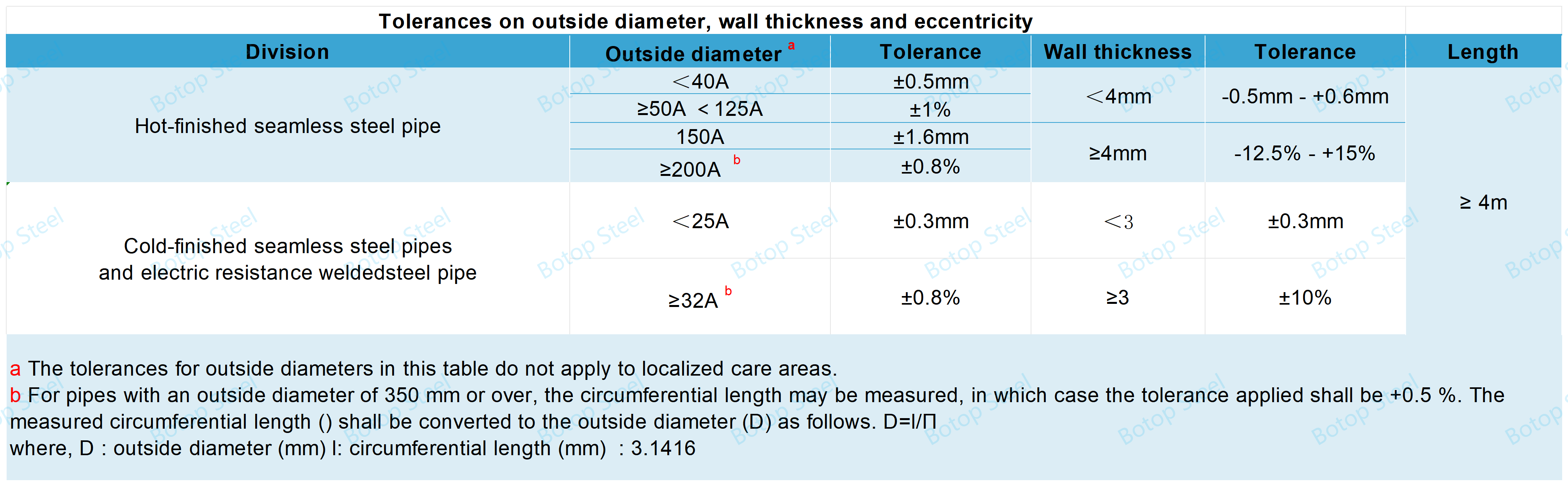

I-Dimensional Tolerances

Ukubekezelelana okungalungile kubukhulu bamapayipi ensimbi ahlanganisiwe asebenza kuphela kuma-welds wepayipi ensimbi ehlanganisiwe; ukubekezelelana okuhle akusebenzi.

Ithebula lesisindo sepayipi namashejuli wamapayipi we-JIS G3454

Steel Pipe Weight Calculation Formula

W=0.02466t(Dt)

W: iyunithi yesisindo sepayipi (kg/m)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

0.02466: isici sokuguqulwa sokuthola i-W

Ifomula engenhla iwukuguqulwa okusekelwe ekumineni kwamashubhu ensimbi angu-7.85 g/cm³ futhi imiphumela isongwa ibe izibalo ezintathu ezibalulekile.

Steel Pipe Weight Table

Amashadi anesisindo samapayipi adlala indima ebaluleke kakhulu ohlelweni lokuklanywa kwamapayipi, ubunjiniyela, ukuthengwa kwempahla, nokwakhiwa, futhi ayinkomba ebalulekile nebalulekile kubunjiniyela bamapayipi.

Ipayipi Amashejuli

Isheduli yepayipi itafula elisetshenziselwa ukulinganisa ubukhulu bepayipi, ngokuvamile ukucacisa ukushuba kodonga kanye nobubanzi obuncane bepayipi.

Ishejuli 10, 20, 30, 40, 60 kanye no-80 ku-JIS G 3454.

Funda kabanzi mayelanaizisindo zamapayipi namashejuli wamapayipingaphakathi kokujwayelekile.

Ukubukeka

Ipayipi kufanele iqonde ngokuyisisekelo futhi iziphetho zayo kufanele zibe yi-perpendicular ku-axis yepayipi.

Indawo yangaphakathi nengaphandle yepayipi kufanele ibe nesiphetho esihle futhi ingabi namaphutha angalungile ukuyisebenzisa.

Ukwelashwa okungaphezulu kungenziwa ngokugaya, umshini, nezinye izindlela zokubhekana neziphambeko ezingaphezulu, kodwa ukushuba ngemva kokwelashwa abukho ngaphansi kobukhulu obuncane, futhi ukuma kwepayipi kuhlala kuhambisana.

I-Surface Coating ye-JIS G 3454

Izindawo zangaphakathi nezingaphandle zamapayipi ensimbi zingagcotshwa ngezingubo zokunqanda ukubola, njengezingubo ezinothe nge-zinc, ama-epoxy coatings, ama-primer coatings, i-3PE, ne-FBE.

Ukumaka

Amashubhu ensimbi adlula ekuhlolweni azophawulwa ngolwazi olulandelayo ngeshubhu ngeshubhu. Kodwa-ke, uma ububanzi obuncane bangaphandle bamashubhu benza kube nzima ukumaka ishubhu ngalinye ngalinye, amashubhu angase ahlanganiswe futhi inyanda ngayinye imakwe ngendlela efanele.

Uhlelo lokumaka alucacisiwe. Ngaphezu kwalokho, izinto ezithile zingase zishiywe ngesivumelwano phakathi kwezinhlangothi ekulethweni, inqobo nje uma umkhiqizo ungakhonjwa.

a) Uphawu lwebanga

b) Uphawu lwenqubo yokukhiqiza

Uphawu lwenqubo yokukhiqiza luzoba kanje. Amadeshi angase ashintshwe kufakwe izikhala.

Ipayipi lensimbi elingenamthungo eliqedwe ukushisa:-SH

Ipayipi lensimbi elingenamthungo eliqedwe ngokubanda:-SC

Njengoba ukumelana kukagesi ashiselwe steel pipe:-EG

Ipayipi lensimbi elishiselwe ukumelana nogesi eliqedwe ukushisa:-EH

Ipayipi lensimbi elishiselwe ukumelana nogesi elipholile:-EC

c) Ubukhulu, obuvezwa ngobubanzi obuncane × ubukhulu bodonga lokuzisholo, noma ububanzi bangaphandle × ukujiya kodonga.

d) Igama lomkhiqizi noma uhlobo oluhlonzayo

Isibonelo: BOTOP JIS G 3454-SH STPG 370 50A×SHC40 HEAT NO.00001

Izicelo ze-JIS G 3454 Steel Pipe

Amapayipi ensimbi ajwayelekile e-JIS G 3454 anezinhlobonhlobo zezicelo emikhakheni eyahlukene yezimboni neyokwakha, ikakhulukazi esetshenziselwa ukudlulisa imidiya ehlukahlukene ewuketshezi.

Amasistimu wokuphakelwa kwamanzi:Amapayipi ensimbi ajwayelekile e-JIS G 3454 angasetshenziswa ezinhlelweni zikamasipala zokuphakelwa kwamanzi, izinhlelo zokuphakelwa kwamanzi ezimbonini, njll. ukuthutha amanzi kampompi ahlanzekile noma amanzi ahlanzekile.

Amasistimu e-HVAC:Lawa mapayipi ensimbi ajwayele ukusetshenziswa ezinhlelweni ze-HVAC ukudlulisa amanzi okupholisa noma amanzi ashisayo.

Imikhumbi yokucindezela:Amapayipi ensimbi e-JIS G 3454 nawo asetshenziswa kwezinye izitsha zokucindezela kanye nama-boilers

Izitshalo zamakhemikhali:Lezi zingasetshenziselwa ukudlulisa imidiya ehlukahlukene yamakhemikhali.

Imboni kawoyela negesi:nakuba i-JIS G 3454 ifaneleka kakhulu ezokuthutha ezinengcindezi ephansi, ingase futhi isetshenziswe kwezinye izinhlelo zokusebenza zemboni zikawoyela negesi ezingadingeki kangako.

Imikhiqizo Yethu Ehlobene

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Amathegi: I-JIS G 3454, STPG, SCH, ipayipi lekhabhoni, ipayipi elimhlophe, ishubhu elimnyama, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, iwholesale, thenga, inani, quotation, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: May-01-2024