I-JIS G 3456 amapayipi ensimbiamashubhu ensimbi ekhabhoni afaneleka ngokuyinhloko ukusetshenziswa ezindaweni zesevisi ezinobubanzi bangaphandle obuphakathi kuka-10.5 mm no-660.4 mm emazingeni okushisa angaphezu kuka-350℃.

Izinkinobho Zokuzulazula

I-JIS G 3456 Ukuhlelwa Kwebanga

Ama-Raw material

I-JIS G 3456 Izinqubo Zokukhiqiza

Ipayipi End

Ukwelashwa Okushisayo

Izingxenye Zekhemikhali ze-JIS G 3456

I-Tensile Test ye-JIS G 3456

Isilingo Sokucaba

I-Bendability Test

Ukuhlolwa kweHydraulic noma Ukuhlolwa Okungabhubhisi (NDT)

Ishadi Lesisindo Sepayipi kanye Nezinhlelo Zepayipi ze-JIS G 3456

I-Dimensional Tolerances

Ukubukeka

I-JIS G 3456 Ukumaka

I-JIS G 3456 Izicelo Zepayipi Lensimbi

Amazinga Ahlobene ne-JIS G 3456

Imikhiqizo Yethu Ehlobene

I-JIS G 3456 Ukuhlelwa Kwebanga

Izinga le-JIS G 3456 linamabanga amathathu ngokuya ngamandla aqinile wepayipi.

I-STPT370,STPT410 kanye ne-STPT480

Amele amashubhu anamandla amancane okudonsa angu-370, 410, kanye no-480 N/mm² (MPa) ngokulandelanayo.

Ama-Raw material

Amapayipi azokwenziwa ngensimbi ebulewe.

Insimbi ebulewe iwuhlobo olukhethekile lwensimbi olubonakala ngokwengezwa kwezakhi ezithile, njenge-aluminium ne-silicon, ngesikhathi senqubo yokuncibilika ukuze imunce futhi ibophe umoya-mpilo kanye nokunye ukungcola okuyingozi ensimbi.

Le nqubo isusa ngokuphumelelayo amagesi nokungcola, ngaleyo ndlela ithuthukise ukuhlanzeka nokufana kwensimbi.

I-JIS G 3456 Izinqubo Zokukhiqiza

Ikhiqizwe kusetshenziswa inhlanganisela efanele yezinqubo zokukhiqiza ishubhu nezindlela zokuqeda.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | ||

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | Ukumaka | |

| I-STPT370 I-STPT410 I-STPT480 | Ingenamthungo:S | Okushisayo kuqedile:H Kuqedwe okubandayo:C | Njengoba kunikeziwe ku-13 b). |

| Ukumelana nogesi okushiselwe:E I-Butt ishiselwe:B | Okushisayo kuqedile:H Kuqedwe okubandayo:C Njengoba ukumelana kukagesi kushiselwe:G | ||

NgobaIsinyathelo 480ipayipi lezinga, ipayipi lensimbi elingenamthungo kuphela elizosetshenziswa.

Uma i-resistance welding isetshenziswa, ama-welds ezindaweni zangaphakathi nangaphandle zepayipi zizosuswa ukuze kutholakale i-weld ebushelelezi.

Ipayipi End

Ipayipi kufanele ibeekupheleni flat.

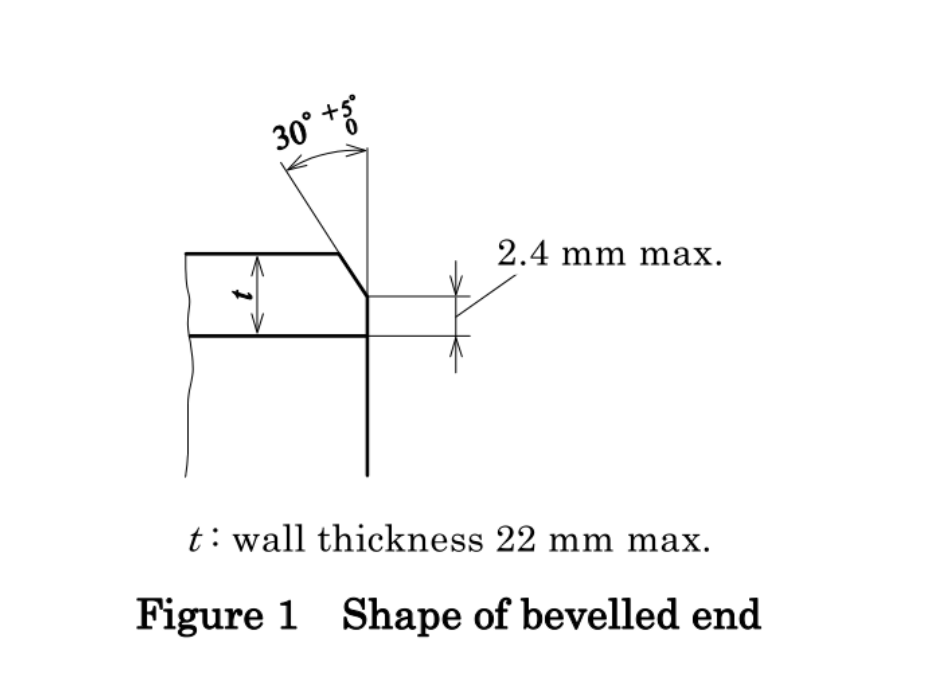

Uma ipayipi idingeka ukuthi icutshungulwe ekugcineni okugobile, ngokuqina kodonga ≤ ipayipi lensimbi engu-22mm, i-engeli ye-bevel ingu-30-35 °, ububanzi be-bevel bonqenqema lwepayipi lensimbi: i-max 2.4mm.

Ubukhulu bodonga obukhulu kuno-22mm wepayipi lensimbi elishelelayo ekugcineni, elivame ukucutshungulwa njenge-bevel eyinhlanganisela, ukuqaliswa kwamazinga kungabhekisela ezidingweni ezifanele ze-ASME B36.19.

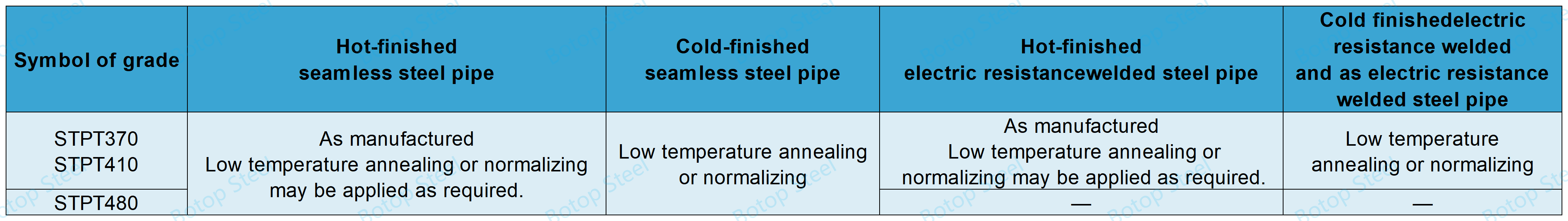

Ukwelashwa Okushisayo

Khetha inqubo efanele yokwelapha ukushisa ngokuya ngebanga kanye nenqubo yokukhiqiza.

Izingxenye Zekhemikhali ze-JIS G 3456

Ukuhlolwa Kokwakheka Kwamakhemikhali

Indlela yokuhlaziya ukushisa izohambisana ne-JIS G 0320.

Indlela yokuhlaziya umkhiqizo izohambisana ne-JIS G 0321.

| Uphawu lwebanga | C(Ikhabhoni) | Si(I-silicon) | Mn(Manganese) | P(Phosphorus) | S(Isibabule) |

| ubuningi | ubuningi | ubuningi | |||

| I-STPT370 | 0.25% | 0.10-0.35% | 0.30-0.90% | 0.035% | 0.035% |

| I-STPT410 | 0.30% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

| I-STPT480 | 0.33% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

Ukubekezelela Ukwakheka Kwamakhemikhali

Amapayipi ensimbi angenamthungo azobhekana nokubekezelelwa kuThebula 3 le-JIS G 0321.

Amapayipi ensimbi anensimbi eqinile azobhekana nokubekezelelana kuThebula 2 le-JIS G 0321.

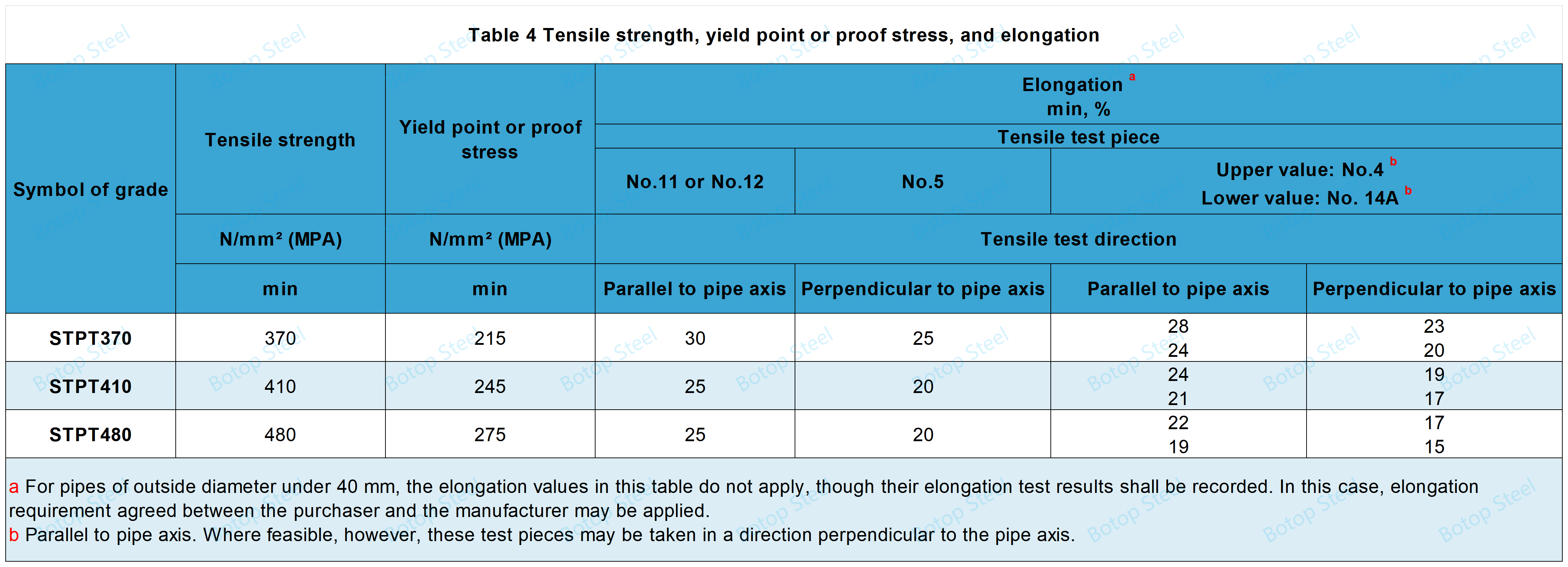

I-Tensile Test ye-JIS G 3456

Izindlela Zokuhlola: Izindlela zokuhlola zizohambisana namazinga aku-JIS Z.2241.

Ipayipi kufanele lihlangabezane nezidingo ezinikezwe kuThebula lesi-4 zamandla aqinile, amandla okukhiqiza, nokwelula.

Ucezu lokuhlola olusetshenziswayo luyoba lukaNombolo 11, No. 12 (No. 12A, No. 12B, noma No. 12C), No. 14A, No. 4 noma No. 5 olucaciswe ku-JIS Z 2241.

Ububanzi besiqephu sokuhlola No. 4 sizoba ngu-14 mm (ubude begeji 50 mm).

Izingcezu zokuhlola No. 11 kanye noNo. 12 zizothathwa ngokuhambisana ne-axis yepayipi,

Izingcezu zokuhlola No. 14A kanye no-4, ngokuhambisana noma nge-perpendicular ku-axis yepayipi,

kanye nesiqephu sokuhlola esingunombolo 5, ku-perpendicular eksisi yepayipi.

Ucezu lokuhlola No. 12 noma No. 5 oluthathwe ku-electric resistance welded steel pipe ngeke luqukathe i-weld.

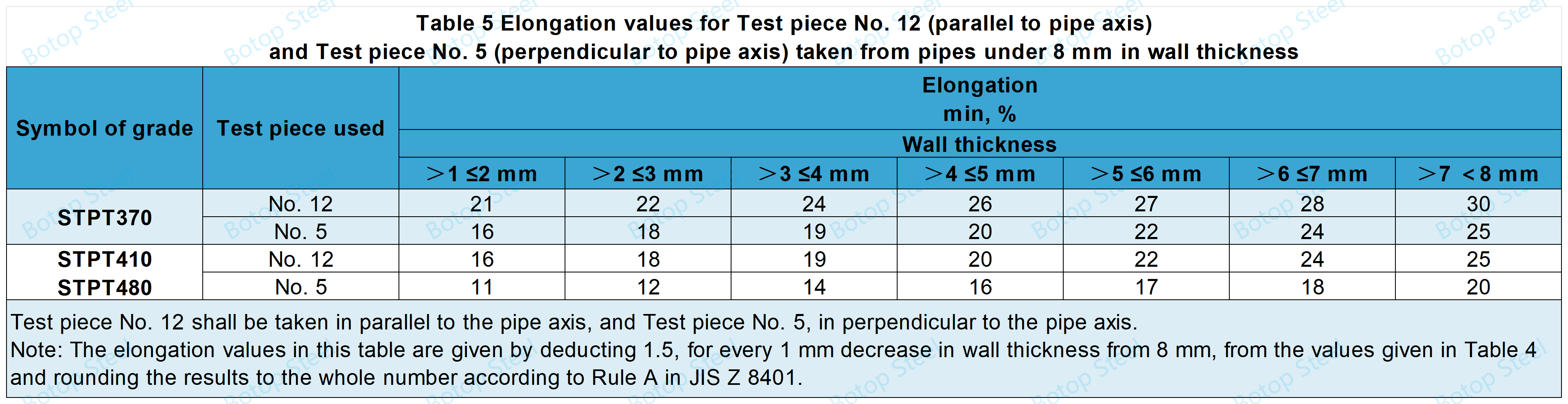

Ukuze kuhlolwe ukushuba kwamapayipi angaphansi kuka-8 mm ubukhulu okwenziwa kusetshenziswa ucezu Lokuhlola No. 12 noma ucezu Lokuhlola No. 5, imfuneko yokwelulwa enikezwe kuThebula lesi-5 izosebenza.

Isilingo Sokucaba

Emazingeni okushisa asekamelweni (5°C - 35°C), caba isifanekiso phakathi kwamapulatifomu amabili size sifikeibanga (H) phakathi kwawo lifinyelela inani elishiwo bese uhlola ukuqhekeka.

H=(1+e)t/(e+t/D)

н: ibanga phakathi kwamapuleti (mm)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

е: kuchazwe njalo ebangeni ngalinye lepayipi:

0.08 ye-STPT370,

0.07 ye-STPT410 kanye ne-STPT480

I-Bendability Test

I-Bendability isebenza kumapayipi anobubanzi obungaphandle obungu-60.5 mm noma ngaphansi.

Indlela yokuhlola Emazingeni okushisa asekamelweni (5°C kuya ku-35°C), goba ucezu lokuhlola uzungeze i-mandrel kuze kube yilapho indawo engaphakathi iphindwe izikhathi ezingu-6 ububanzi bangaphandle bepayipi futhi uhlole ukuqhekeka. Kulesi sivivinyo, i-weld kufanele ibekwe cishe ku-90 ° kusukela engxenyeni engaphandle yokugoba.

Ukuhlolwa kwe-Bendability nakho kungenziwa ngokuhambisana nemfuneko yokuthi i-radius yangaphakathi iphindwe kane ububanzi bangaphandle bepayipi kanye ne-engeli yokugoba i-180 °.

Ukuhlolwa kweHydraulic noma Ukuhlolwa Okungabhubhisi (NDT)

Ukuhlolwa kwe-hydraulic noma ukuhlolwa okungabhubhisi kuyokwenziwa epayipini ngalinye.

Ukuhlolwa kweHydraulic

Bamba ipayipi okungenani ekucindezelweni okuncane kokuhlolwa kwe-hydraulic okucaciswe okungenani imizuzwana emi-5 futhi uqaphele ukuthi ipayipi liyakwazi ukumelana nokucindezela ngaphandle kokuvuza.

Isikhathi se-Hydraulic sicacisiwe ngokusho kweSheduli yepayipi yensimbi.

| Ithebula 6 Ingcindezi encane yokuhlolwa kwe-hydraulic | ||||||||||

| Ukujiya kodonga okuzisholo | Inombolo yeshejuli: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Ukuhlolwa Okungonakali

Uma kusetshenziswa ukuhlolwa kwe-ultrasonic, amasiginali asuka kumasampula ereferensi aqukethe izilinganiso zereferensi zohlobo lwe-UD, njengoba kucaciswe ku-JIS G 0582, azosetshenziswa njengamaleveli e-alamu; noma iyiphi isignali evela epayipini elingana noma enkulu kuneleveli ye-alamu izonqatshwa. Ukwengeza, ubuncane bokujula kwezindawo eziyisikwele zokuhlola amapayipi, ngaphandle kokuphothula okubandayo, kuzoba ngu-0.3 mm.

Uma kusetshenziswa ukuhlolwa kwamanje kwe-eddy, amasiginali asuka kuzinga lereferensi lohlobo lwe-EY njengoba acaciswe ku-JIS G 0583 azosetshenziswa njengeleveli ye-alamu; noma iyiphi isignali evela epayipini elingana noma enkulu kuneleveli ye-alamu kuyoba isizathu sokwaliwa.

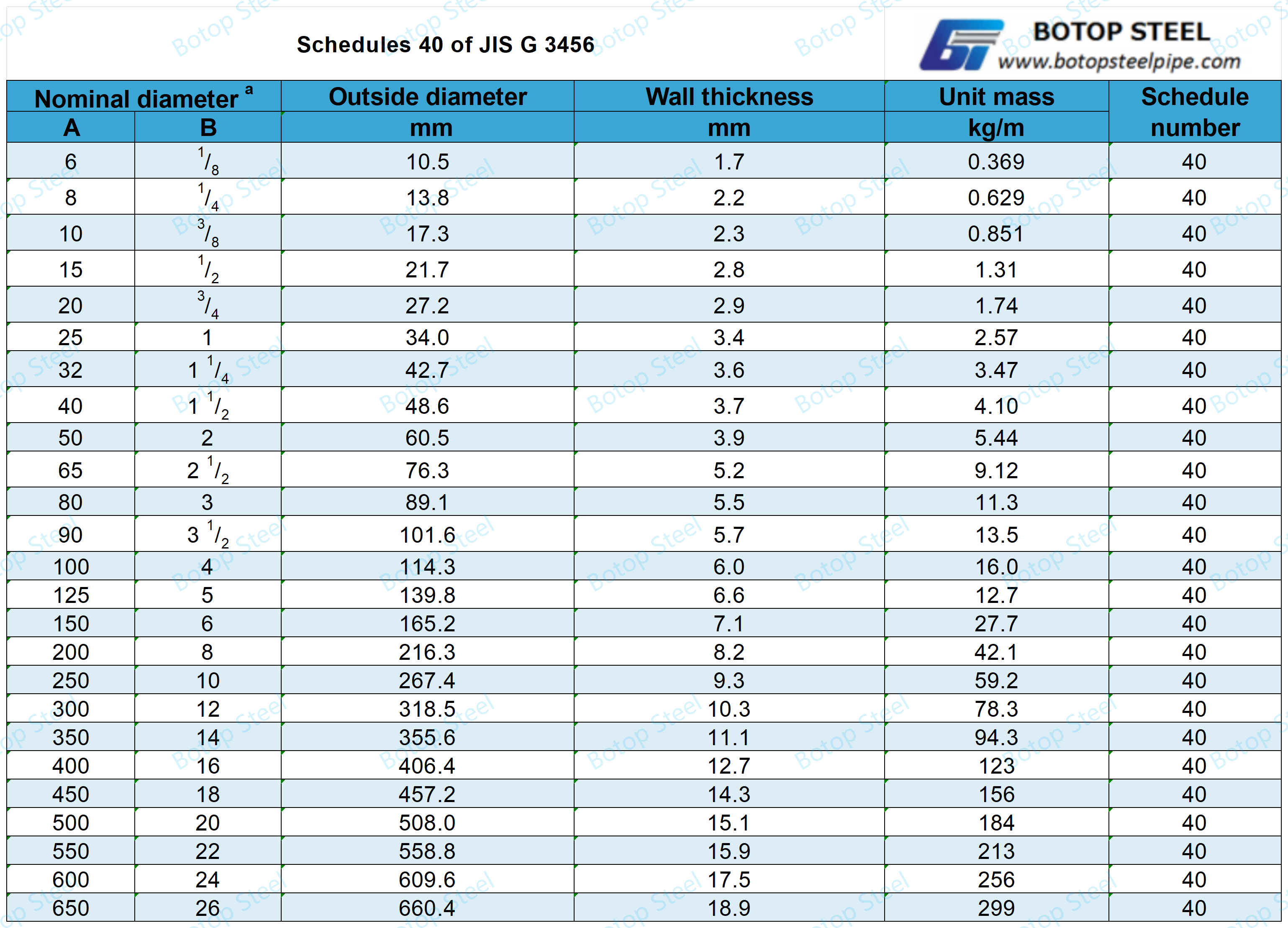

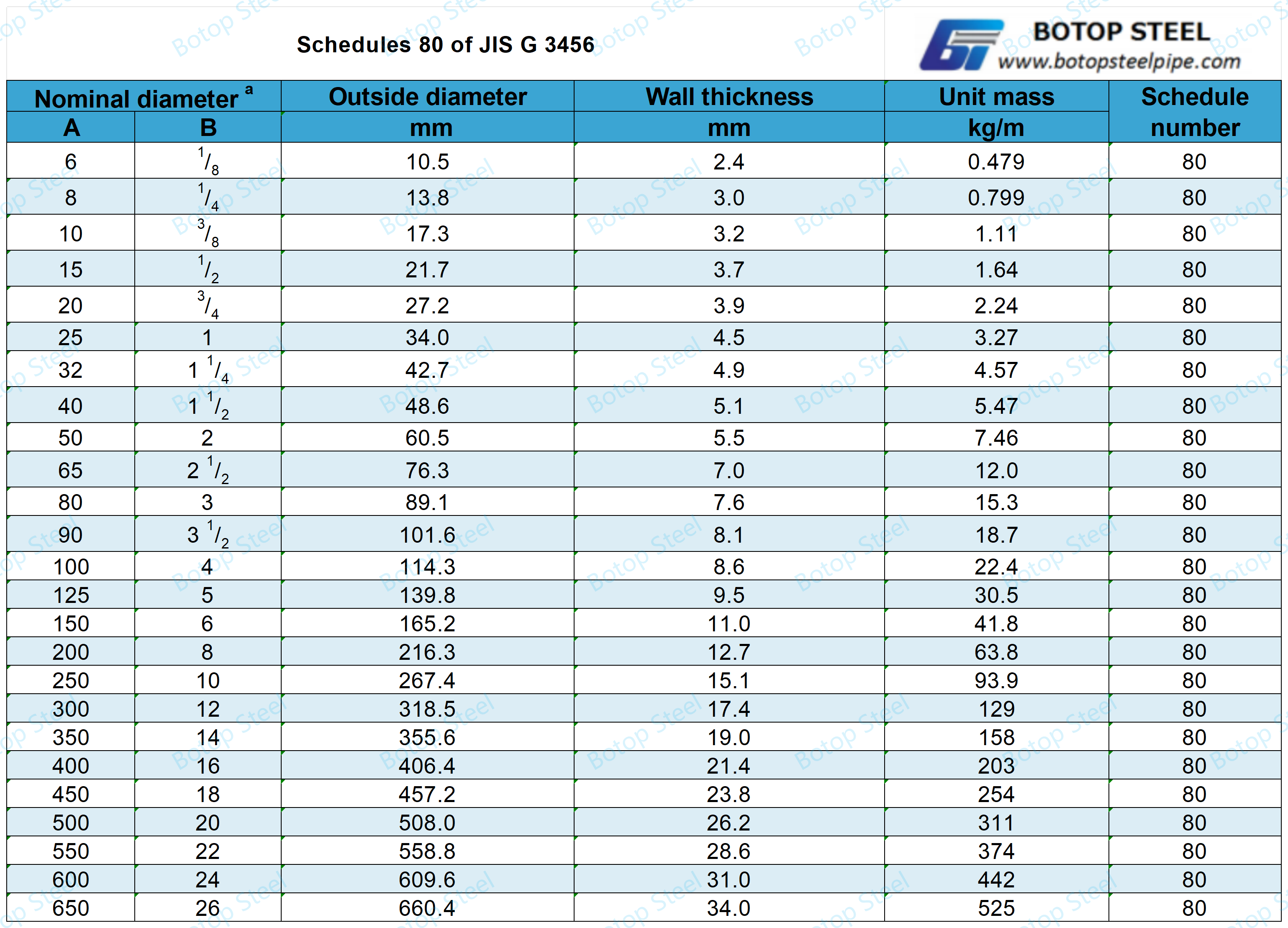

Ishadi Lesisindo Sepayipi kanye Nezinhlelo Zepayipi ze-JIS G 3456

Steel Pipe Weight Calculation Formula

Thatha ukuminyana okungu-7.85 g/cm³ ngeshubhu lensimbi bese uzungezisa umphumela ube izibalo ezintathu ezibalulekile.

W=0.02466t(Dt)

W: iyunithi yesisindo sepayipi (kg/m)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

0.02466: isici sokuguqulwa sokuthola i-W

Ishadi Lesisindo Sombhobho

Amathebula esisindo samapayipi namashejuli ayizinkomba ezibalulekile ezivame ukusetshenziswa kubunjiniyela bamapayipi.

Ipayipi Amashejuli

Isheduli inhlanganisela emisiwe yokuqina kodonga kanye nobubanzi bepayipi.

Isheduli 40 kanye neSheduli 80 amashubhu ensimbi asetshenziswa kabanzi embonini nasekwakheni. Zingamasayizi amapayipi avamile anobukhulu obuhlukene bodonga namandla ezimo ezihlukene zohlelo lokusebenza.

Uma ufuna ukwazi okwengeziwe mayelanaipayipi isisindo ithebula kanye nesimiso ipayipingokwezinga, ungachofoza ukuze ukuhlole!

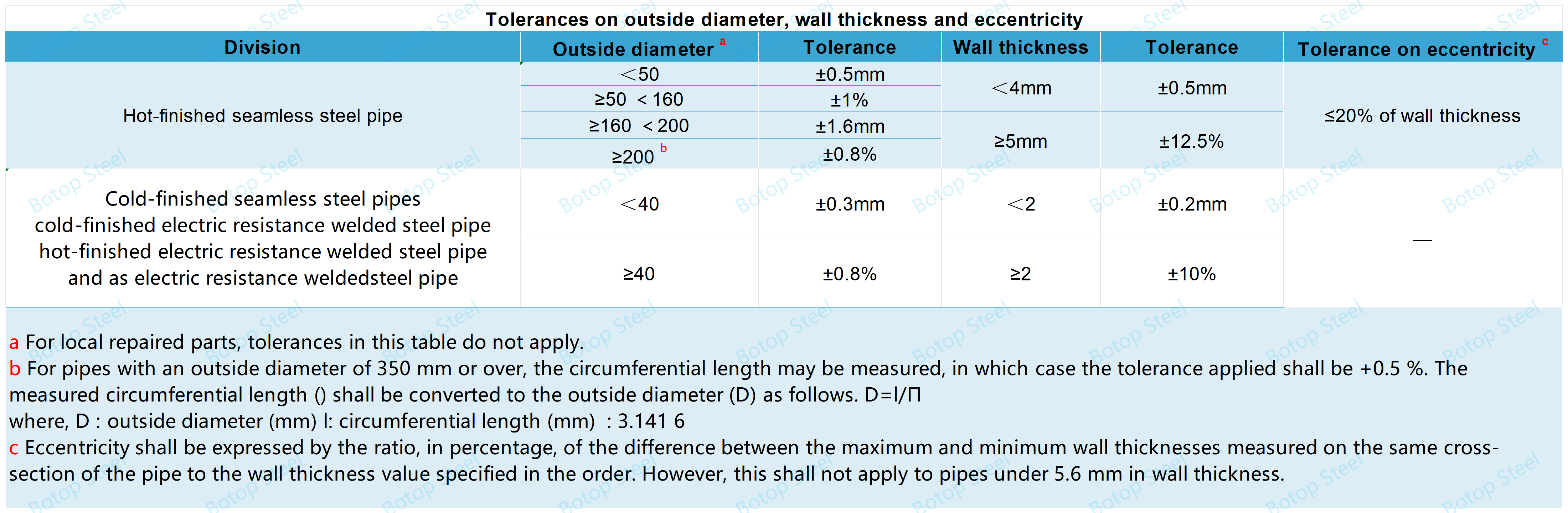

I-Dimensional Tolerances

Ukubukeka

Indawo yangaphakathi nengaphandle yepayipi izoba bushelelezi futhi ingabi namaphutha angalungile ukuyisebenzisa.

Ipayipi kufanele iqonde, iziphetho zibe ngama-engeli angakwesokudla ku-axis yepayipi.

Amapayipi angase alungiswe ngokugaya, ngomshini noma ezinye izindlela, kodwa ukujiya kodonga olulungisiwe kuzohlala ngaphakathi kokubekezelelana okucacisiwe futhi indawo elungisiwe izoba bushelelezi kuphrofayela.

Ukuqina kodonga lwepayipi elilungisiwe kufanele kugcinwe ngaphakathi kokubekezelelana okucacisiwe futhi ubuso bepayipi elilungisiwe buyoba bushelelezi kuphrofayela.

I-JIS G 3456 Ukumaka

Ipayipi ngalinye elidlula ukuhlolwa kufanele lilebulwe ngolwazi olulandelayo. Amalebula angasetshenziswa ezinyandeni zamapayipi anobubanzi obuncane.

a) Uphawu lwebanga

b) Uphawu lwenqubo yokukhiqiza

Uphawu lwenqubo yokukhiqiza luzoba kanje. Amadeshi angase ashintshwe kufakwe izikhala.

Ipayipi lensimbi elingenamthungo eliqedwe ukushisa:-SH

Ipayipi lensimbi elingenamthungo eliqedwe ngokubanda:-SC

Njengokumelana kukagesi ipayipi lensimbi elishiselwe: -EG

Ipayipi lensimbi elishisiwe elishisiwe elishisiwe: -EH

Ipayipi lensimbi elishiselwe ukumelana nogesi elipholile:-EC

c) Ubukhulu, uvezwa ngobubanzi obuncane × ubukhulu bodonga lokuzisholo, noma ububanzi bangaphandle × ukujiya kodonga.

d) Igama lomkhiqizi noma uhlobo oluhlonzayo

Isibonelo:BOTOP JIS G 3456 SH STPT370 50A×SHC40 HEAT NO.00001

I-JIS G 3456 Izicelo Zepayipi Lensimbi

Ipayipi lensimbi le-JIS G 3456 livamise ukusetshenziselwa izinto zokusebenza kanye nezinhlelo zamapayipi ezindaweni ezishisa kakhulu nezinomfutho ophezulu, njengakumabhayela, izinto ezishintsha ukushisa, amapayipi omusi anengcindezi ephezulu, izitshalo zamandla ashisayo, izitshalo zamakhemikhali, nezigayo zephepha.

Amazinga Ahlobene ne-JIS G 3456

Amazinga alandelayo wonke ayasebenza ekufakeni amapayipi ezindaweni ezishisa kakhulu nezinomfutho ophezulu futhi angasetshenziswa njengenye indlela ye-JIS G 3456.

I-ASTM A335/A335M: isebenza kumapayipi ensimbi ye-alloy

I-DIN 17175: yamapayipi ensimbi angenamthungo

I-TS EN 10216-2: Amapayipi ensimbi angenamthungo

I-GB 5310: isebenza kumapayipi ensimbi angenamthungo

I-ASTM A106/A106M: Amashubhu e-carbon steel angenamthungo

I-ASTM A213/A213M: Amashubhu angenamthungo namapayipi ensimbi yengxubevange nensimbi engagqwali

I-TS EN 10217-2: Ifanele amashubhu ashiselwe namapayipi

I-ISO 9329-2: Amashubhu namapayipi ensimbi ekhabhoni engenamthungo nealloy

I-NFA 49-211: yamashubhu ensimbi angenamthungo namapayipi

I-BS 3602-2: yamapayipi ensimbi ensimbi engenamthungo nokufakwa

Imikhiqizo Yethu Ehlobene

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi! Uma ufuna ukwazi ulwazi olwengeziwe mayelana nemikhiqizo yamapayipi ensimbi, ungaxhumana nathi.

Amathegi: JIS G 3456, SPTP370, STPT410, STPT480, STPT, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, i-wholesale, thenga, inani, ikhotheshini, inqwaba, ukuthengisa, izindleko.

Isikhathi sokuthumela: Apr-29-2024