Amashubhu ensimbi angenamthungo aminyeneidlala indima ebalulekile emishinini nasembonini esindayo ngenxa yezakhiwo zayo ezivelele zemishini, umthamo omkhulu othwala ukucindezela, nokuqina okuhle kakhulu.

Okulandelayo, sizocubungula ngokujulile izici nezinzuzo zepayipi lensimbi engenamthungo eliwugqinsi ukusuka kuma-engeli amaningi ukuze sikunikeze ulwazi oluphelele lomkhiqizo.

Izinqubo Zokukhiqiza

Kuyaziwa ukuthi inqubo yokukhiqiza ipayipi yensimbi engenamthungo inezinhlobo ezimbili zokuqeda okushisayo nokubandayo.

Kodwa-ke, kumapayipi ensimbi angenamthungo anobukhulu obunjalo bodonga, kungasetshenziswa ukuphela okushisayo kuphela.

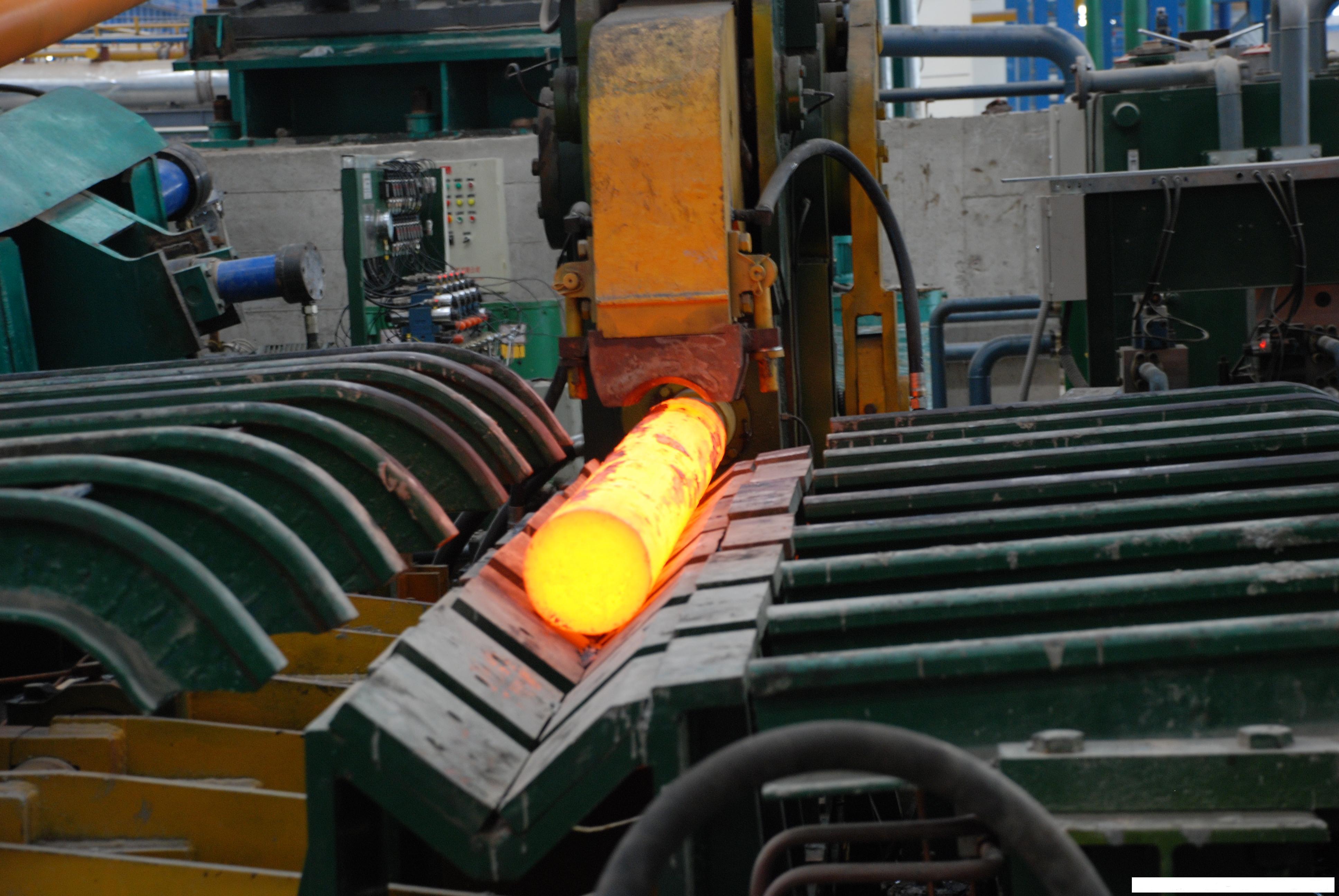

Inqubo yokukhiqiza yokuqeda okushisayo kwepayipi lensimbi engenamthungo iqukethe ikakhulukazi:

1. Ukukhethwa billets: Khetha amabhilidi osayizi ofanelekile kanye nokwakheka kwamakhemikhali ngokuya ngosayizi wokugcina kanye nezidingo.Ukukhethwa kwe-billet kunomthelela omkhulu kwikhwalithi yomkhiqizo wokugcina.

2. Ukwelashwa kwangaphambili: Susa isikhumba esine-oxidized nokunye ukungcola ebusweni be-billet.Qinisekisa ukuthi lezi zici zangaphandle asithinti ikhwalithi ye-tube ngesikhathi sokwelashwa kokushisa nokugoqa.

3. Ukushisisa i-billet: I-billet ishisiswe ekushiseni okufanele ukuze kube lula ukuguqulwa kwepulasitiki.Ukushisisa kufanele kufane ukuze kugwenywe ukukhuphuka kwezinga lokushisa ngaphakathi kwempahla, okungaholela ekulimaleni komkhiqizo.

4. Isidina kanye nesandiso se-billet: I-billet eyindilinga eshisiwe yenziwe ngomshini ibe yi-billet engenalutho.Khona-ke ukuqina kodonga kuyancishiswa futhi ubude be-billet buyanda ngokunwetshwa.

5. I-Hot Rolling: I-billet igoqwe ekushiseni okuphezulu ngokusebenzisa umshini wokugaya oshisayo ukuze kuzuzwe ububanzi obufunwayo bangaphandle nobukhulu bodonga.Ukugoqa okushisayo kuyisinyathelo esiyinhloko ekubunjweni kwethubhu, okunquma ukuma okuyisisekelo nobukhulu bethubhu.

6. Inqubo yokwelapha ukushisa: Ukuze kuthuthukiswe izakhiwo zemishini kanye ne-microstructure yamashubhu, amashubhu angaphansi kwezinqubo zokwelashwa kokushisa ezifana nokujwayelekile noma ukudonsa.Kungaqeda ukucindezeleka, okusanhlamvu okuhle futhi kuthuthukise ukuqina.

7. Ukwelashwa kwendawo kanye nokuvikela ukugqwala: Lokhu kuhlanganisa ukuhlanza nokugcoba, njengokugcoba amafutha noma ukudweba, ukuthuthukisa ukumelana nokugqwala kanye nekhwalithi yokubukeka yepayipi yensimbi.

8. Ukuhlolwa kwekhwalithi: Uchungechunge lokuhlola nokuhlola, njengokuhlola ubukhulu, ukuhlolwa okubonakalayo nokungaphezulu, ukuhlola okungalimazi (isb. ukuhlolwa kwe-ultrasonic), ukuhlolwa kwempahla eyimishini (isb. ukushuba, ukuhlolwa komthelela), kanye nokuqina nokuhlaziywa kwesakhiwo esincane ukuze kuqinisekiswe ukuthi imikhiqizo iyahambisana. ngezicaciso zobuchwepheshe kanye namazinga ekhwalithi.

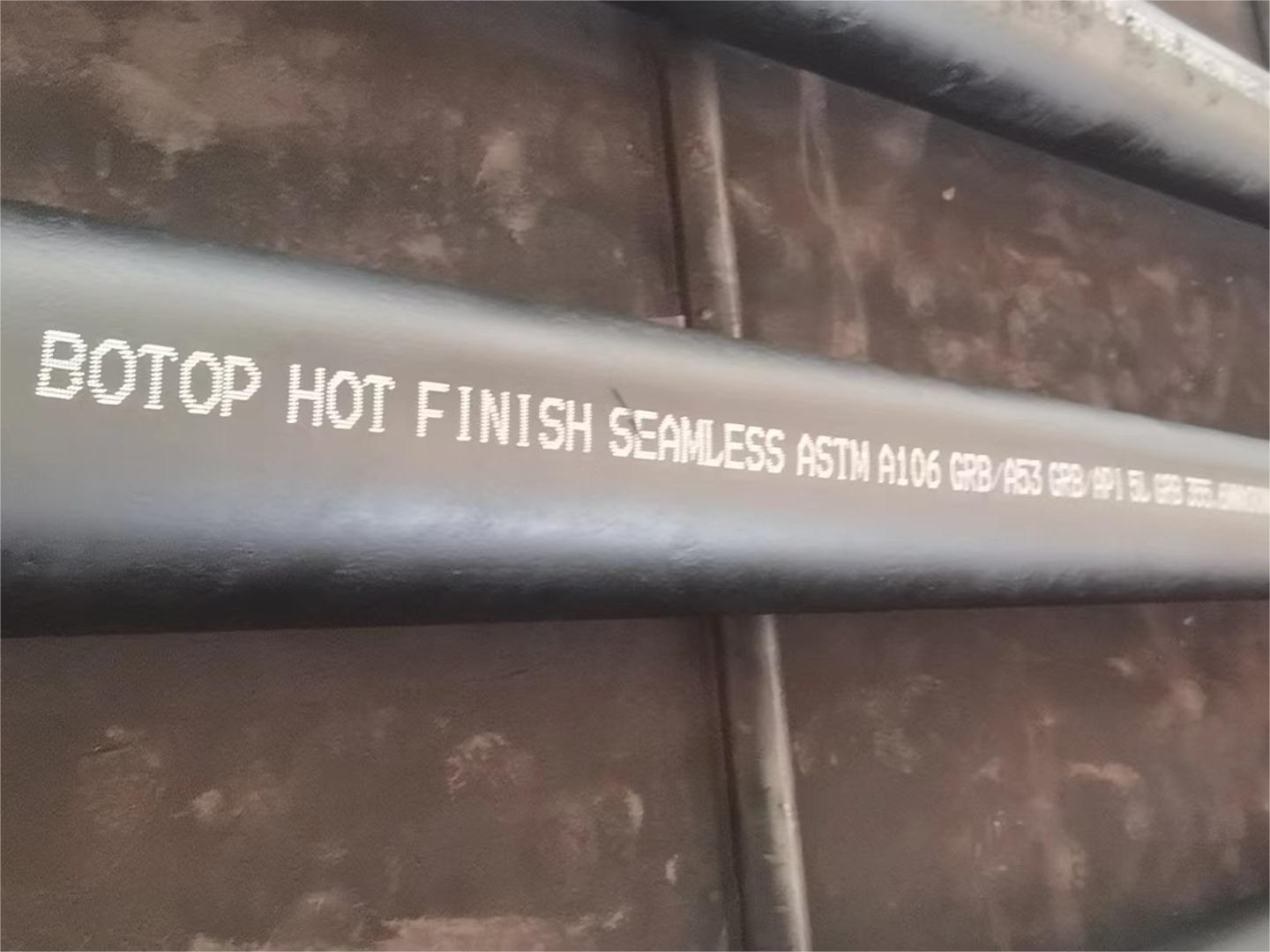

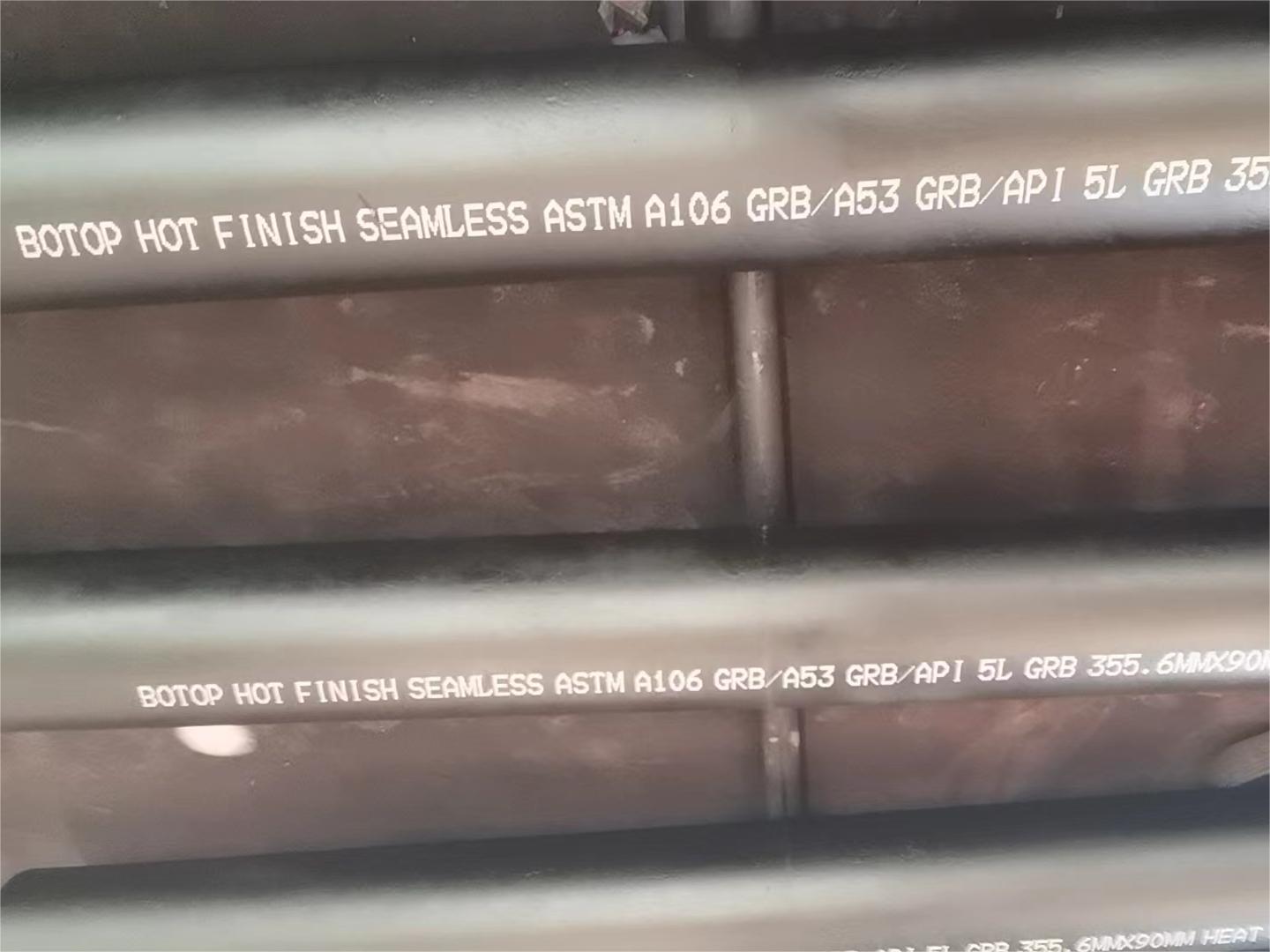

Amazinga Okuphatha Amashubhu namapayipi Ensimbi Angenazihibe

I-ASTM A106: Ipayipi lensimbi elingenamthungo lesevisi yezinga lokushisa eliphezulu.

I-ASTM A53: Ipayipi lensimbi elimnyama nelishiselwe elingenamthungo nelishiselwe ukuze kusetshenziswe ingcindezi nemishini.

I-ASTM A333: Ipayipi lensimbi elingenamthungo nelishiselwe lesevisi yezinga lokushisa eliphansi.

I-API 5L: Ipayipi lomugqa wezinhlelo zokuthutha zamapayipi.

I-API 5CT: I-Casing kanye ne-tubing yemithombo kawoyela negesi.

I-TS EN 10210: Izingxenye zensimbi ezingenamthungo nezishiselwe zezakhiwo ezine-thermoformed.

I-EN 10216: Amashubhu ensimbi angenamthungo ngezinjongo zengcindezi.

I-TS EN 10297 Amashubhu ensimbi ayindilinga angenamthungo namapayipi ngezinjongo zobunjiniyela ezijwayelekile.

I-ISO 3183: Amapayipi ensimbi wezinhlelo zokuthutha zamapayipi embonini kawoyela negesi.

I-JIS G3454: Amapayipi ensimbi ekhabhoni amapayipi okucindezela.

I-JIS G3455: Amapayipi ensimbi ye-Carbon yesevisi yokucindezela okukhulu.

I-JIS G3461: Amapayipi ensimbi ye-Carbon ama-boilers kanye nokushintshanisa ukushisa.

AS/NZS 1163: Izingxenye ezingenalutho zensimbi yesakhiwo.

AS 1074: Amapayipi ensimbi nokufakwa.

IS 1161: Ukucaciswa kwepayipi lensimbi ngezinjongo zesakhiwo.

I-API 5L, ASTM A53, kanye ne-ASTM A06zivame ukusetshenziswa kuzinga, kodwa futhi kuhlu oluthile lokunye ukusetshenziswa komunye nomunye.

namuhla inkampani yami iqedele ukuhlola futhi isilungele ukuthumela ngomkhumbi355.6 × 90ipayipi eliwugqinsi elinezindonga lensimbi engenamthungo, ekusetshenzisweni kwala mazinga.

Izinzuzo Zepayipi Lensimbi Eliqinile elinezindonga

1.Phezulusamandla kanyepqinisarukuphikisa: Ipayipi lensimbi eliwugqinsi elinezindonga elingenamthungo lingamelana nokucindezela okuphezulu ngaphandle kwamaphoyinti abuthakathaka emithungoni yokushisela yepayipi lensimbi elishiselwe, elenza lifanelekele izindawo ezinomfutho ophezulu.

2. Ukumelana nokugqwala: Ipayipi lensimbi elingenamthungo lingamelana nokugqwala ezindaweni ezinokhahlo ngokwakhiwa kwe-alloy ethile nokwelashwa kwendawo.

Njengendawo yesevisi ene-acidic, kanye nemvelo yesevisi yasolwandle.

3. Ukumelana nezinga lokushisa eliphezulu: Ipayipi lensimbi engenamthungo lingasebenza ezindaweni ezishisa kakhulu ngaphandle kokulahlekelwa amandla.

4. Izinhlobonhlobo zokujiya kodonga: Ipayipi lensimbi elingenamthungo lingakhiqizwa ngokuya ngezidingo zobukhulu obuhlukahlukene bodonga, Ububanzi bokujiya kodonga manje sebungafinyelela ku-100mm, okuyipayipi lensimbi elishiselwe elingenakufinyelelwa, ikakhulukazi ipayipi lensimbi elinobubanzi obuncane obunodonga.

5. Impilo ende yesevisi: Ngenxa yamandla ayo aphezulu kanye nokumelana nokugqwala okuhle, inokuphila kwesevisi ende futhi inciphisa ubungozi bokunakekelwa kwangemva kwesondlo.

Ububi bepayipi Lensimbi Eliqinile Elingenamthungo

1.Inani: Uma kuqhathaniswa nepayipi lensimbi elishiselwe noma okunye ukushuba odongeni okuvamile intengo izoba phezulu, lo mkhiqizo ngokuvamile udinga ukwenziwa ngezifiso.

2.Umjikelezo wokukhiqiza: Uma udinga ukwenza ngokwezifiso ukukhiqiza, umjikelezo wokukhiqiza mude uma kuqhathaniswa.

3.Kalat: Ukuqina kwezindonga eziqinile kubenza babe nzima, okungenza ukuthutha nokufaka kube nzima kakhulu.

4.Izithiyo zobukhulu: Amashubhu anogqinsi angenamthungo awanakho ukuguquguquka kwe-dimensional okufana namashubhu ashiselwe ngokuya ngamadayimitha amakhulu kakhulu noma amancane kakhulu.

Ukusetshenziswa Kwe-Thick Wall Seamless Steel Tubes

Amashubhu ensimbi aqinile anezindonga eziqinile akhethwa ezinhlelweni zezimboni ezidinga ukumelana nengcindezi ephezulu, izinga lokushisa eliphezulu, amandla aphezulu, nokuthembeka okuhle.

1. Imboni Kawoyela Negesi: Isetshenziswa ekukhishweni nasekuthuthweni kukawoyela negesi yemvelo, ikakhulukazi njengamashubhu omthombo kawoyela namapayipi angaphansi kwengcindezi ephezulu engaphansi komhlaba.

2. Imboni yamakhemikhali: Isetshenziswa ezitshalweni zamakhemikhali ukuze kudluliswe uketshezi olunomfutho ophezulu noma njengengxenye ebalulekile yezinto zokusebenza zokudlulisa ukushisa njengama-reactor noma izifudumezi.

3. Imboni yamandla: isetshenziswa njengamapayipi kabhayela, amapayipi okushintsha ukushisa, namapayipi ngesitimu emazingeni okushisa aphezulu nezingcindezi ekuhlanganiseni nasezimbonini zamandla enyukliya.

4. Oomakhenikhamukwenza: Isetshenziswa ekwenzeni izakhi zemishini ezikwazi ukumelana nezingcindezi eziphezulu, njengamasistimu asebenza ngamanzi, ama-bearings, namasilinda ekukhiqizeni izimoto.

5. Isakhiwo kanye ne-construction: ukwakhiwa komthamo ophezulu wokuthwala umthwalo wesakhiwo sesakhiwo, njengamabhuloho, amafreyimu amakhulu okusekela imishini, kanye nendawo enengcindezi ephezulu yensika.

6. Osolwandleeubunjiniyela: Isetshenziswa ekwakhiweni kwemikhumbi nasekwakhiweni kwamapulatifomu angasogwini, ikakhulukazi ezingxenyeni ezidinga ukumelana nokugqwala okuphezulu namandla.

7. Imboni yezokundiza kanye ne-aerospace: esetshenziswa ekwenziweni kwezindiza, amasathelayithi amarokhethi, nezinye izingxenye ezibalulekile zezimoto zasemkhathini, ezidinga izinto ezikwazi ukumelana nezinga lokushisa eliphezulu nezici zamandla.

8. Izinsiza zemvelo: ngezinhlelo zamapayipi ezindaweni zokuhlanza indle kanye nezindawo zokuhlanza imfucuza, kanye namapayipi okuqoqa igesi ezindaweni zokulahla imfucumfucu ephezulu.

9. Imboni ye-Geothermal: ukuze kukhishwe amandla e- geothermal, okuhlanganisa nokumbiwa kwemithombo ye- geothermal namapayipi ukuze kuthuthwe uketshezi olushisayo.

10. Ezempi Nezokuvikela: Ebunjiniyela bezempi, ekwenzeni izingxenye zemikhumbi-ngwenya, amathangi, nezinye izimoto ezihlomile, kanye nezinye izinto zezempi ezidinga amandla aphezulu nokumelana nokucindezela.

Nakuba kuphezulu ngezindleko nesisindo, amashubhu ensimbi anogqinsi anezindonga eziqinile ayadingeka ngamandla awo aphezulu, ukucindezela, nokumelana nokugqwala ezinhlelweni eziningi zezimboni.Lezi zici zizenza zibe yigugu embonini kawoyela negesi, amakhemikhali, amandla, nemishini, ikakhulukazi lapho kudingeka khona izinto ezibonakalayo ezingaguquki futhi kusetshenziswa izindawo ezinokhahlo.

Nakuba izindleko zokuthenga kusengaphambili zingase zibe phezulu, ukuqina kwesikhathi eside kanye nezindleko zokunakekelwa okuphansi ngokuvamile zenza izindleko eziphelele zobunikazi zibe ngcono.

Izinzuzo Zethu

Singomunye wabaphambili abashiselwe ipayipi lensimbi elishiselwe kanye nabakhiqizi nabahlinzeki bepayipi lensimbi engenamthungo abavela eChina, abanohlu olubanzi lwamapayipi ensimbi ekhwalithi ephezulu esitokweni, sizimisele ukukunikeza uhla olugcwele lwezixazululo zamapayipi ensimbi.

Ukuze uthole imininingwane eyengeziwe yomkhiqizo, sicela ukhululeke ukuxhumana nathi, sibheke phambili ekusizeni ukuthi uthole izinketho ezingcono kakhulu zamapayipi ensimbi ngezidingo zakho!

Amathegi: okungenamthungo, ukuphela okushisayo, ipayipi lensimbi, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, iwholesale, thenga, inani, ikhotheshini, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: May-07-2024