I-ASTM A106 IBanga B ipayipi lensimbi le-carbon elingenamthungo elisuselwe kuzinga le-ASTM A106 futhi elakhelwe ukumelana nezinga lokushisa eliphezulu nezindawo zokucindezela.

Isetshenziswa kakhulu ezimbonini zikawoyela, igesi, namakhemikhali ukuze kwakhiwe amapayipi namapayipi ahlobene.

Izinkinobho Zokuzulazula

Ibanga le-ASTM A106

I-ASTM A106 iwukucaciswa okujwayelekile kwepayipi lensimbi elingenamthungo lezinhlelo zokusebenza ezishisa kakhulu ezithuthukiswe yi-ASTM International.Ukucaciswa kuchaza amamaki amathathu epayipi lensimbi elingenamthungo, Ibanga A, Ibanga B, kanye neBanga C. Kulawa, iBanga B yilona elisetshenziswa kakhulu.

Ibanga "B" limele ukwakheka kwamakhemikhali athile kanye nezinga lempahla yokulungisa lempahla yokusetshenziswa kumazinga okushisa athile nezingcindezi.

Uma ufuna ukwazi okwengeziwe nge-ASTM A106 ungachofoza:Isho ukuthini i-ASTM A106?

Izici Eziyinhloko

Ukukhiqiza Okungenamthungo

Ishubhu ye-ASTM A106 yeBanga B ikhiqizwa ngenqubo yokukhiqiza engenamthungo eqinisekisa ukufana namandla okusetshenziswa ezindaweni ezingaphansi kwengcindezi ephezulu.

Ukusebenza okuphezulu kwezinga lokushisa

Leli payipi lifaneleka ngokukhethekile ukusebenza ezindaweni ezinezinga lokushisa eliphezulu, njengasezinhlelweni zamapayipi eziteshini zikagesi, ezindaweni zokuhluza, nasezimbonini zamakhemikhali.

Ukwakheka Kwamakhemikhali

Ukwakheka kwamakhemikhali eBanga B kuklanyelwe ukukunikeza ukumelana nokushisa okuhle kanye nokuqhubekela phambili.Ngokuvamile iqukethe okuqukethwe kwekhabhoni ephansi kanye namanani amaphakathi e-manganese, i-phosphorus, isulfure, ne-silicon.

Izakhiwo Zemishini

Ipayipi lensimbi le-ASTM A106 leBanga B linikeza amandla amahle kakhulu okuqina namandla esivuno esihle ezinhlelweni ezidinga izakhiwo ezinhle zemishini.

Uhla Olubanzi Lwezicelo

Ngenxa yokumelana nokushisa kwayo kanye nezakhiwo zemishini, ishubhu ye-ASTM A106 yeBanga B isetshenziswa ezinhlobonhlobo zezicelo ezifana nowoyela negesi, amakhemikhali e-petrochemicals, ama-boilers, nezishintshisi zokushisa.

Ukwakheka Kwamakhemikhali

| Ukwakheka | C (Ikhabhoni) | Mn (Manganese) | P (Phosphorus) | S (Isibabule) | Si (I-silicon) | Cr (Chromium) | Cu (Ithusi) | Mo (Molybdenum) | Ni (Nickel) | V (Vanadium) |

| ubuningi | - | ubuningi | ubuningi | imiz | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |

| ubuningi obuqukethwe | 0.30 % | 0.29 - 1.06 % | 0.035 % | 0.035 % | 0.10 % | 0.40 % | 0.40 % | 0.15 % | 0.40 % | 0.08 % |

Ngaphandle kwalapho kucaciswe ngenye indlela umthengi, ekuncishisweni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06% wemanganese ngaphezu komkhawulo oshiwo kuzovunyelwa kuze kufike ku-1.65 %.

I-Cr, i-Cu, i-Mo, i-Ni, ne-V: ingqikithi yalezi zici ezinhlanu ngeke idlule u-1%.

Izakhiwo Zemishini

| Uhlu | Amandla aqinile, imiz | Amandla okukhiqiza, imiz | ||

| ukuhlukaniswa | psi | I-MPa | psi | I-MPa |

| I-ASTM A106 Ibanga b | 60,000 | 415 | 35,000 | 240 |

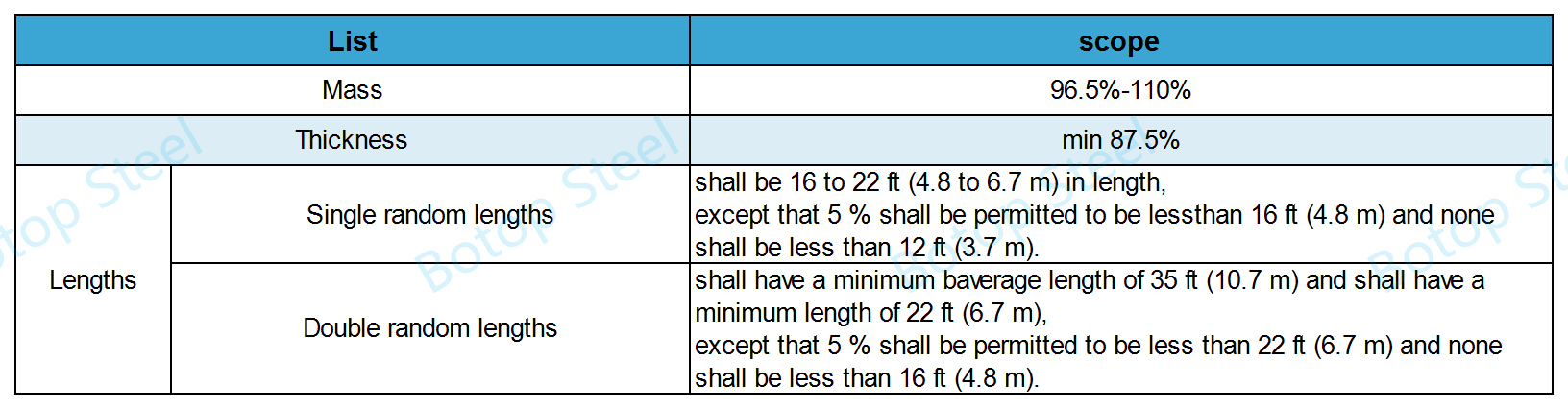

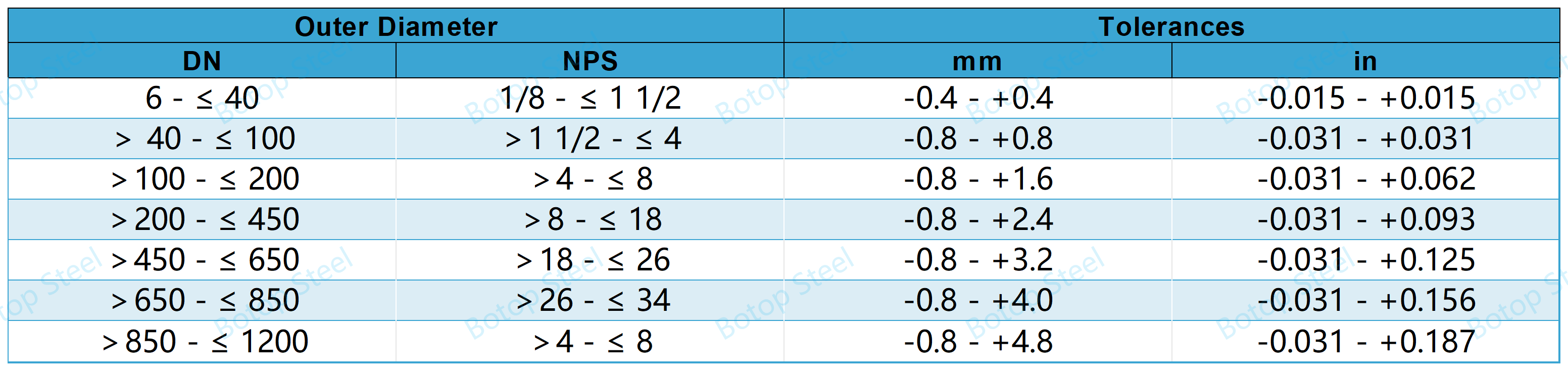

I-Dimensional Tolerances

Ubukhulu, Ubukhulu, Nobude

Ububanzi bangaphandle

Ukuhlola kanye Nezitifiketi

Ukuhlaziywa Kokwakheka Kwamakhemikhali

Nquma ukwakheka kwamakhemikhali kwepayipi, okuhlanganisa ikhabhoni, i-manganese, i-phosphorus, isulfure, ne-silicon ukuze uqinisekise ukuthi okokusebenza kuhlangabezana nezidingo zokwakheka kwamakhemikhali ezicaciswe ezingeni.

Ukuhlolwa kwe-Tensile

Linganisa amandla aqinile, amandla okukhiqiza, nobude bepayipi lensimbi.Lezi zivivinyo zisiza ukuhlola ukusebenza kokuqukethwe kanye nokuqina ngaphansi kwengcindezi eqinile.

Ukugoba Test

Ukuhlolwa kokugoba kwenziwa epayipini elishiselwe futhi elingenamthungo ukuze kuhlolwe umthamo walo wokuguga wepulasitiki kanye nobuqotho bamalunga ashiselwe.

Ukuhlola Ukucaba

Ukuhlolwa kwe-flattening kwenziwa kumashubhu ukuze kuhlolwe ukuguquguquka kwawo kanye nezici zokuphuka ngaphansi kwengcindezi.

Ukuhlola Ukuqina

Ukuqina kwempahla kuhlolwa ngokuhlolwa kokuqina kwe-Brinell noma i-Rockwell.Lokhu kuhlola kubalulekile ekunqumeni ukucutshungulwa kanye nezici zokusetshenziswa kwezinto ezibonakalayo.

I-Hydrotesting

Ipayipi ngalinye kufanele lihlolwe nge-hydrostatic ukuze kuqinisekiswe ukuthi alivuzi ngengcindezi eshiwo ukuze kuqinisekiswe ukucinana nokuphepha kwesistimu yamapayipi.

Ukuhlola Okungonakali

Kubandakanya Ukuhlolwa kwe-Ultrasonic (UT), Ukuhlola I-Magnetic Particle (MT) kanye/noma Ukuhlola I-Radiographic (RT) ukuze kutholwe ukukhubazeka kwangaphakathi nangaphezulu njengokuqhekeka, okufakiwe kanye ne-porosity.

Ukuhlolwa Komthelela (ngesicelo)

Kwezinye izimo, ukuhlolwa komthelela (isb, ukuhlolwa kwe-Charpy V-notch) kungase kudingeke ukuze kuhlolwe ukuqina kokuphuka kwento emazingeni okushisa aphansi.

Izicelo Eziyinhloko ze-ASTM A106 Ibanga B

Ukuthutha uwoyela negesi: ezindaweni ezinomfutho ophezulu kanye nezinga lokushisa eliphezulu.

Ukucubungula amakhemikhali: kumasistimu amapayipi amelana nokugqwala kanye nezinga lokushisa eliphezulu.

Iziteshi zikagesi: imigqa yesitimu kanye nezitolo zokubhayela.

Ukukhiqiza Kwezimboni: amapayipi okucindezela kanye nemishini yokucindezela okuphezulu.

Ukwakhiwa nokwakhiwa kwemikhumbi: wokwakha amasistimu okushisa nawokupholisa kanye namasistimu wokubilisa nesitimu emikhumbi.

Imboni yezimoto: ukwakhiwa kwezingxenye zezimoto ezimelana namazinga okushisa aphezulu nezingcindezi.

Enye indlela ye-ASTM A106 GR.B

Lapho kukhethwa ezinye izinto zokwakha, kufanele kucatshangelwe izakhiwo zemishini, ukumelana nezinga lokushisa, ukumelana nokucindezela, nokumelana nokugqwala kwezinto ukuze kuqinisekiswe ukuhambisana nezidingo ezithile zohlelo lokusebenza kanye nemithetho nezindinganiso ezifanele.

| Igama Elijwayelekile | Ububanzi besicelo |

| I-ASTM A53 Ibanga B | Ingcindezi Ephansi kanye Nezicelo Zesakhiwo Semishini |

| I-API 5L Ibanga B | Amapayipi kawoyela negesi |

| I-ASTM A333 Ibanga lesi-6 | Ngesevisi yezinga lokushisa eliphansi |

| I-ASTM A335 P11 或 P22 | Ngamazinga okushisa aphezulu njengama-boilers eziteshini zikagesi |

| I-ASTM A312 TP304 或 TP316 | Izinhlelo zokusebenza ezidinga ukumelana nokugqwala okuphezulu |

| I-ASME SA106 | Izimo ezishisayo nezinomfutho ophezulu wokushisa |

| AS/NZS 1163 C350L0 | Izinhloso zesakhiwo kanye nemishini |

| GB 3087 | Amashubhu ensimbi angenamthungo wamabhayela anengcindezi ephansi naphakathi |

| I-GB 5310 | Amashubhu ensimbi angenamthungo wamabhayela anengcindezi ephezulu |

| GB 9948 | Amashubhu ensimbi angenamthungo wokuqhekeka kwamafutha |

I-Protective Coating ye-ASTM A106 GR.B

Kufakwe amagalani

I-galvanizing iyindlela yokuhlinzeka ngokuvikelwa kokugqwala ngokusebenzisa i-zinc coating ebusweni bensimbi.

Indlela evame kakhulu yokufaka uthayela iwukwenza idiphu elishisayo lifake ulaka, lapho ipayipi lensimbi licwiliswa ku-zinc encibilikisiwe ukuze lenze ungqimba oluminyene lwezinc ebusweni balo.

Lolu ngqimba lwe-zinc alugcini nje ngokuvala i-substrate yensimbi emoyeni nasemanzini, luvimbele i-oxidation, kodwa futhi lunciphisa izinga lokugqwala kwensimbi ngokuvikelwa komhlatshelo kwe-anodic (i-zinc isebenza kakhulu kune-iron).

Ipayipi lensimbi elifakwe emanzini ashisayo lifanele ukusetshenziswa ngaphandle noma ezindaweni ezimanzi, njengezindawo zokuhlanza amanzi kanye nezakhiwo zezakhiwo zangaphandle.

Ukugqoka

Ukumboza kuyindlela yokuvimbela ukugqwala ngokusebenzisa isendlalelo esisodwa noma eziningi ze-anti-corrosion coating ethile ebusweni bepayipi lensimbi.

Lezi zembatho zingaba i-epoxy, i-polyurethane, i-polyethylene, noma ezinye izinto zokwenziwa.

Izembatho ze-epoxy zisetshenziswa kakhulu kumapayipi ezimboni ngenxa yokuqina kwawo okuhle kakhulu kwamakhemikhali nokunamathela kwawo.

Umsebenzi oyinhloko we-coating ukuvimbela umswakama kanye namakhemikhali abolayo, ukuvimbela ukuthi bangathintani ngqo nensimbi.Ukwelashwa kokumboza kufanelekile ezindaweni eziningi ezifana nezitshalo zamakhemikhali, izindawo zasolwandle kanye namanethiwekhi amapayipi asemadolobheni.

I-Lining Coating

Ukwelashwa kolayini ukusebenzisa ungqimba lwento evimbela ukubola, njenge-epoxy resin, i-ceramics, noma irabha, ngaphakathi kwepayipi lensimbi ukuvimbela ukugqwala kwendawo yokudlulisa odongeni lwangaphakathi lwepayipi lensimbi.

Le ndlela ifaneleka kakhulu ukudlulisa uketshezi olubolayo (isb. ama-asidi, ama-alkali, izixazululo zikasawoti, njll.).

I-epoxy resin lining ihlinzeka ngongqimba oluqinile lokulwa nokugqwala olungamelana nezinga elithile lokuhlaselwa kwamakhemikhali kanye nokuhuzuka komzimba.

Ulwelwesi alugcini nje ngokunweba ukuphila kwepayipi kodwa futhi lugcina ukuhlanzeka koketshezi futhi luvimbela ukungcola.

Imikhiqizo Yethu Ehlobene

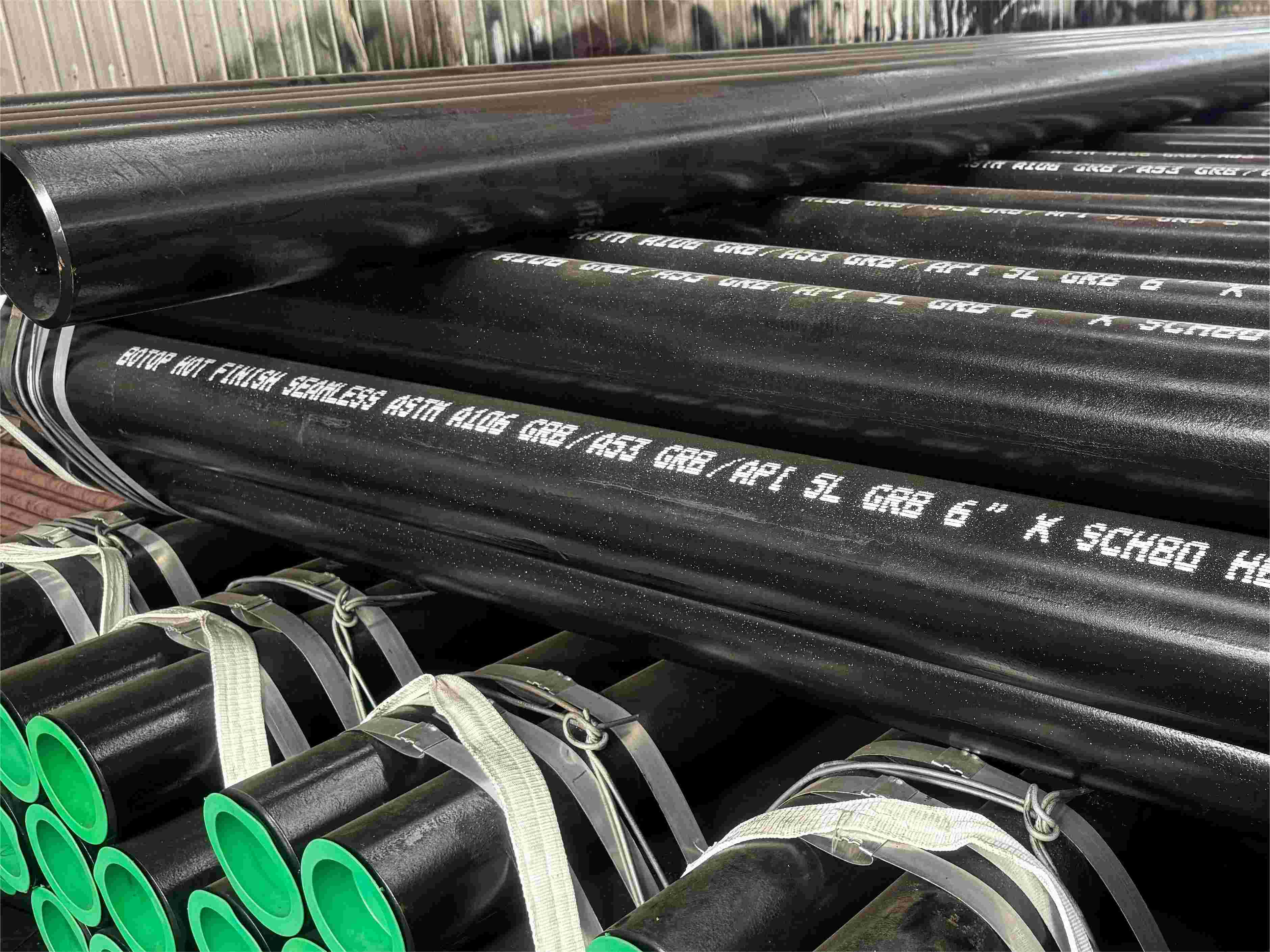

Singomunye wabaphambili abashiselwe ipayipi lensimbi elishiselwe kanye nabakhiqizi nabahlinzeki bepayipi lensimbi engenamthungo abavela eChina, abanohlu olubanzi lwamapayipi ensimbi ekhwalithi ephezulu esitokweni, sizimisele ukukunikeza uhla olugcwele lwezixazululo zamapayipi ensimbi.Ukuze uthole imininingwane eyengeziwe yomkhiqizo, sicela ukhululeke ukuxhumana nathi, sibheke phambili ekusizeni ukuthi uthole izinketho ezingcono kakhulu zamapayipi ensimbi ngezidingo zakho!

tags:a106 grade b, a106, engenamthungo, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, iwholesale, thenga, intengo, ikhotheshini, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: Mar-01-2024