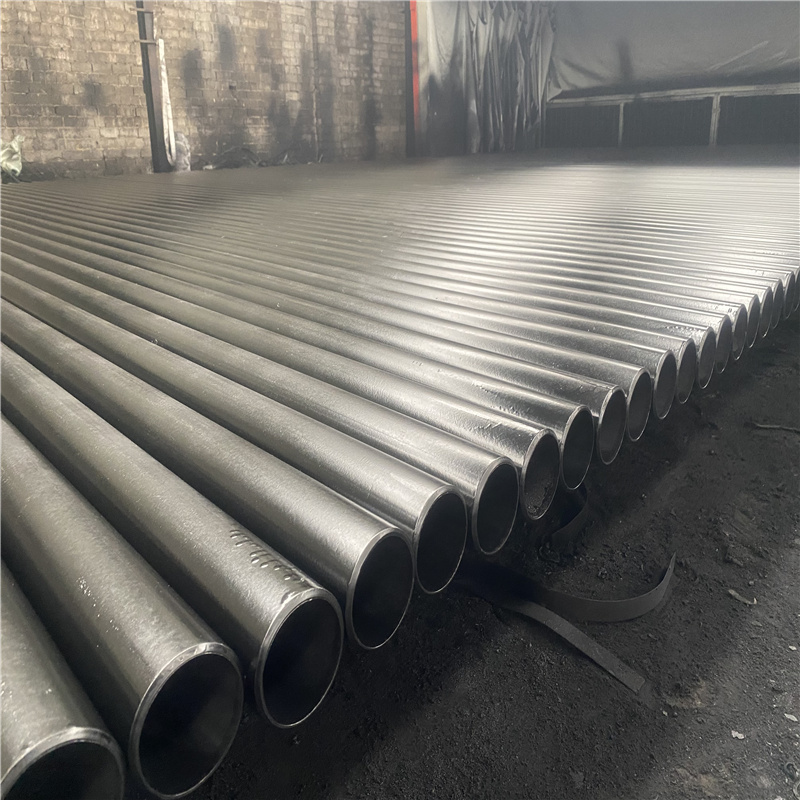

I-ASTM A192:Ukucaciswa Okujwayelekile Kwamashubhu Abilayo Ensimbi Yensimbi Yekhabhoni Yesevisi Yokucindezela Okuphezulu.

Lokhu kucaciswa kuhlanganisa ubuncane bokujiya kodonga, ibhoyela yensimbi engenamthungo, namashubhu okushisa aphezulu esevisi enengcindezi ephezulu.

Izinkinobho Zokuzulazula

I-ASTM A192 Ubukhulu Ububanzi

Ngaphandle Ububanzi: 12.7-177.8mm [1/2-7 phakathi.]

Ubukhulu obuncane bodonga:2.2-25.4mm [0.085 -1in.]

Amashubhu anobunye ubukhulu angase anikezwe, inqobo nje uma lawo mashubhu ethobela zonke ezinye izimfuneko zalokhu kucaciswa.

Ukukhiqiza

Amashubhu ngeke abe nekhono futhi ashise noma abandayo asetshenziswe njengokucutshungulwa okucacisiwe.

I-ASTM A192 izindlela ezimbili eziyinhloko zokukhiqiza zamapayipi ensimbi angenamthungo: abandayo adonswayo futhi ashiswe agingqelwe.

Ukwelashwa Kokushisa

Ukushisa kwelashwa ku-1200℉ [650℃] noma ngaphezulu ngemva kokumuncwa okubandayo kokugcina.

I-Dimensional Tolerances

Izinto ezinikeziwe zizohlangabezana nezidingo ezisebenzayo ze-ASTM A450.

| Ukubekezelelana kwe-Dimensional | ||

| Uhlu | hlunga | ububanzi |

| IMisa | DN≤38.1mm[NPS 11/2] | +12% |

| DN>38.1mm[NPS 11/2] | +13% | |

| Ububanzi | DN≤38.1mm[NPS 11/2] | +20% |

| DN>38.1mm[NPS 11/2] | +22% | |

| Ubude | DN<50.8mm[NPS 2] | +5mm[NPS 3/16] |

| DN≥50.8mm[NPS 2] | +3mm[NPS 1/8] | |

| Ukuqondile futhi Qeda | Amashubhu aqediwe kufanele aqonde ngokufanelekile futhi abe neziphetho ezibushelelezi ezingenazo ama-burrs. | |

| Ukuphatha Isici | Noma yikuphi ukungaqhubeki noma okungajwayelekile okutholakala kushubhu kungase kususwe ngokugaya, inqobo nje uma kugcinwa indawo ebushelelezi egobile, futhi ukujiya kodonga akwehliswa kube ngaphansi kwalokho okuvunyelwe yilokhu noma ukucaciswa komkhiqizo. | |

I-ASTM A192 Pipe Weight Calculator

Ifomula yesisindo ithi:

M=(DT)×T×C

Mubukhulu beyunithi ngayinye;

Diwububanzi obushiwo bangaphandle, obuvezwa ngamamilimitha (amayintshi);

T ubukhulu bodonga olucacisiwe, obuvezwa ngamamilimitha (amasentimitha);

Cingu-0.0246615 yezibalo zamayunithi e-SI kanye no-10.69 wezibalo zamayunithi e-USC.

Uma ufuna ukwazi okwengeziwe ngensimbiishadi lesisindo sepayipifuthiisimiso sepayipi, Chofoza lapha!

Ukuhlolwa kwe-ASTM A192

Amazinga okusebenza okuhlola

| Hlola | Okujwayelekile |

| Izingxenye Zekhemikhali | Ingxenye ye-ASTM A450 |

| Ukuhlolwa Kwemishini | I-ASTM A450 Ingxenye 7 |

| Ukuhlolwa kokucaba | I-ASTM A450 Ingxenye 19 |

| Ukuhlolwa kokuvutha | I-ASTM A450 Ingxenye 21 |

| Ukuhlolwa kokuqina | I-ASTM A450 Ingxenye 23 |

| Ukuhlolwa kwengcindezi ye-Hydraulic | I-ASTM A450 Ingxenye 24 |

| Ukuhlolwa Okungonakali | I-ASTM A450, Ingxenye 26 |

Leli zinga linezidingo ezithile zokwakheka kwamakhemikhali kanye nezakhiwo zemishini: ezinye izivivinyo zibhekisa ku-ASTM A450.

Izingxenye Zekhemikhali

| Izingxenye Zekhemikhali | |

| C(Ikhabhoni) | 0.06-0.18 |

| Mn(Manganese) | 0.27-0.63 |

| P(Phosphorus) | ≤0.035 |

| S(Isibabule) | ≤0.035 |

| Si(I-silicon) | ≤0.25 |

| Akuvumelekile ukunikeza amamaki e-alloy abiza ngokusobala ukuthi kwengezwe noma iyiphi i-elementi ngaphandle kwalezi ezibalwe ngenhla. | |

I-Tensile Properties

| Izidingo ze-Tensile | |||

| Uhlu | ukuhlukaniswa | inani | |

| Amandla aqinile, imiz | ksi | 47 | |

| I-MPa | 325 | ||

| Amandla esivuno, imiz | ksi | 26 | |

| I-MPa | 180 | ||

| Ukwelula ku-50mm (2 in), imiz | % | 35 | |

Izinto Ezibalulekile Zokumaka

Izomakwa ngokucacile:

igama lomkhiqizi noma umkhiqizo

inombolo yokucaciswa,ibanga

igama nenombolo ye-oda yomthengi

kushisa noma kubanda.

Qaphela: Ukumaka akufanele kufake idethi yonyaka yalokhu kucaciswa.

Okwamashubhu angaphansi kuka-11/4ngaphakathi. [31.8 mm] ububanzi namashubhu angaphansi kwamamitha amathathu ubude, ulwazi oludingekayo lungase luphawulwe umaka onamathiselwe ngokuvikelekile kunqwaba noma ebhokisini okuthunyelwa kulo amashubhu.

Ukucutshungulwa Okungeziwe

Lapho uthenga futhi usebenzisa ipayipi le-ASTM A192, indawo yokusetshenziswa kokugcina kanye nezidingo ezithile zomsebenzisi zingadinga ukucutshungulwa okwengeziwe:

Upende noma I-Coating

Upende ongagqwali noma ezinye izinto zokuzivikela zingasetshenziswa phezulu.Lezi zembatho zinikeza ukuvikeleka okuthile ekugqwaleni, ikakhulukazi uma ishubhu lebhayela lichayeka kumswakama.

Imithi elwa nokugqwala

Ngaphezu kokudweba, ezinye izindlela zokwelapha zokunqanda ukugqwala okufana nokufaka i-galvanizing, i-aluminizing, noma ukumbozwa ngezinye izinto ezilwa nokugqwala kungase kusetshenziswe ukusiza ukwandisa ukuqina kweshubhu ezindaweni ezinokhahlo.

Ukwelashwa Kokushisa

Nakuba i-ASTM A192 icacisa izidingo zokwenziwa nokuhlolwa kwepayipi, kwezinye izinhlelo zokusebenza zokwelapha ukushisa okwengeziwe (isb., ukujwayela, ukuhlanganisa) kungase kudingeke ukuze kuzuzwe izici ezithile zemishini noma ukuthuthukisa isakhiwo esincane sepayipi.

I-Surface Yangaphakathi Nangaphandle Iyaphela

Indawo yangaphakathi nengaphandle yamashubhu obhayela kungase kudingeke ukuthi igaywe, iphuculwe, noma ihlanzwe ukuze kuthuthukiswe izici zokugeleza koketshezi noma ukuhlanzeka.

Qeda ukwenza imishini

Ngokuya ngezidingo zokufakwa nokuxhumeka, iziphetho zamashubhu obhayela zingadinga ukucutshungulwa, kushaywe, noma kwenziwe ngomshini ukuze kube lula ukufakwa.

Ukuhlola Okwengeziwe

Ukuqinisekisa ukuthi amashubhu ahlangabezana ne-ASTM A192 kanye nezidingo eziqondene nekhasimende, ukuhlolwa okwengeziwe kungenziwa.Isibonelo, ukuhlolwa kwe-ultrasonic, ukuhlolwa kwe-X-ray, njll.

Isicelo Esiqondile

Isebenza ngokukhethekile kubhayela wensimbi engenamthungo kanye namashubhu okushisa aphezulu.Lawa mashubhu asetshenziselwa ikakhulukazi izinsizakalo zokucindezela okuphezulu njengama-boilers anengcindezi ephezulu, ama-boilers we-ultra-high-pressure, nemishini esebenza ezindaweni ezishisa kakhulu nezinomfutho ophezulu.

Okulandelayo ukusetshenziswa kwepayipi lensimbi le-ASTM A192 ekusebenzeni:

Ama-boilers anengcindezi ephezulu

Amashubhu angenamthungo e-ASTM A192 afaneleka ngokukhethekile ukukhiqiza amashubhu okushisa aphezulu, amashubhu abhayela amanzi ashisayo, amapayipi omusi, amashubhu amakhulu, njll., kuma-boiler amashubhu amanzi anomfutho ophezulu nangaphezulu.Okuvame ukusetshenziswa eziteshini zamandla, izitshalo zezimboni kanye nezimayini kanye nemishini yamakhemikhali, esetshenziselwa ukukhiqiza izinga lokushisa eliphezulu kanye nomusi womfutho ophezulu.

Ama-boilers we-Ultra-high-pressure

Amashubhu e-ASTM A192 asetshenziswa kakhulu ku-ultra-high-pressure (imvamisa ebizwa ngokuthi ama-boilers anengcindezi yokusebenza engaphezu kuka-9.8 MPa) izinhlelo zokusebenza.Lawa ma-boilers ngokuvamile asetshenziswa eziteshini ezinkulu zikagesi.

Ama-Superheaters nama-reheaters

Lezi yizici ezibalulekile ze-boiler futhi zisetshenziselwa ukwandisa izinga lokushisa le-steam, okubuye kwandise ukusebenza kahle kokushisa kwalo lonke uhlelo.

Izishintshi zokushisa

Nakuba i-ASTM A192 ngokuyinhloko isetshenziselwa amashubhu okubhayela, ingasetshenziswa futhi ekushintshaniseni ukushisa lapho izakhiwo ezinhle zokudlulisa ukushisa zidingeka, ikakhulukazi endaweni yokushisa ephezulu, enengcindezi ephezulu.

Ama-Boiler Amafutha Ashisayo

Kulolu hlobo lwe-boiler, amandla ashisayo adluliswa ngokushisa uwoyela oshisayo, ovame ukusetshenziswa ezimbonini zamakhemikhali, zokucubungula ukudla nezindwangu.Ishubhu ye-astm a192 ifanele izinga lokushisa eliphezulu, izimo zengcindezi ephezulu ezitholakala kulezi zinhlelo zokusebenza.

Amazinga Abalulekile

I-ASTM A192: Kumashubhu kabhayela wensimbi engenamthungo wamabhayela anengcindezi ephezulu.

I-ASTM A179: Isishintshi sokushisa sensimbi esithambile esidonswa ngokubanda esingenamthungo kanye namashubhu e-condenser ezimweni zezinga lokushisa eliphansi.

I-ASTM A210: I-boiler yensimbi ye-Seamless medium kanye namashubhu we-superheater.

I-ASTM A213: I-ferritic ne-austenitic alloy steel boilers engenamthungo, i-superheater, namashubhu okushintsha ukushisa.

I-ASTM A106: Amashubhu ensimbi angenamthungo esevisi yezinga lokushisa eliphezulu.

I-ASTM A335: Amashubhu ensimbi angenamthungo kanye ne-austenitic alloy steel kanye namapayipi esevisi yezinga lokushisa eliphezulu, isb iziteshi zikagesi.

I-ASTM A516: Insimbi ye-Carbon steel plate ifanele imikhumbi yengcindezi ephakathi nendawo nephansi.

I-ASTM A285: I-Carbon steel plate ifanele imikhumbi yokucindezela okuphansi kuya komaphakathi.

I-ASTM A387: I-alloy steel plate esetshenziswa ekwenzeni ama-boilers ashiselwe kanye nezitsha zokucindezela, ikakhulukazi lapho kudingeka ukumelana nokushisa okuhle kakhulu.

I-ASTM A53: Amashubhu ensimbi amnyama nashiselwe angenamthungo futhi ashiselwe ezinhlakeni ezijwayelekile neziwumshini.

Ngokuhlangene, lawa mazinga amboza izakhiwo zezinto ezibonakalayo, ukubekezelelana kobukhulu, izakhiwo zemishini, nokwakheka kwamakhemikhali okudingekayo ukuze kusetshenziswe kumabhayela, imikhumbi yokucindezela, izishintshisi zokushisa, njll., emazingeni okushisa ahlukahlukene, izingcindezi, nezimo zesevisi.

Imikhiqizo Yethu Ehlobene

I-Botop Steel iyi-China Professional Welded Carbon Steel Pipes Umkhiqizi & Abahlinzeki Beminyaka engaphezu kwe-16 enama-8000+ Tons Seamless Linepipe esitokweni Inyanga ngayinye.Uma ufuna ukwazi okwengeziwe ngemikhiqizo yethu yamapayipi ensimbi, ungaxhumana nathi ukuze sikunikeze imikhiqizo namasevisi asezingeni eliphezulu!

tags:astm a192, carbon steel pipe, Boiler Tubes, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, iwholesale, thenga, intengo, ikhotheshini, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: Apr-01-2024