Insimbi ye-ASTM A501iyishubhu yesakhiwo sensimbi emnyama futhi eshisayo ecwiliswe eshisiwe ne-carbon steel engenamthungo yamabhuloho, izakhiwo, nezinye izinjongo zesakhiwo ezijwayelekile.

Izinkinobho Zokuzulazula

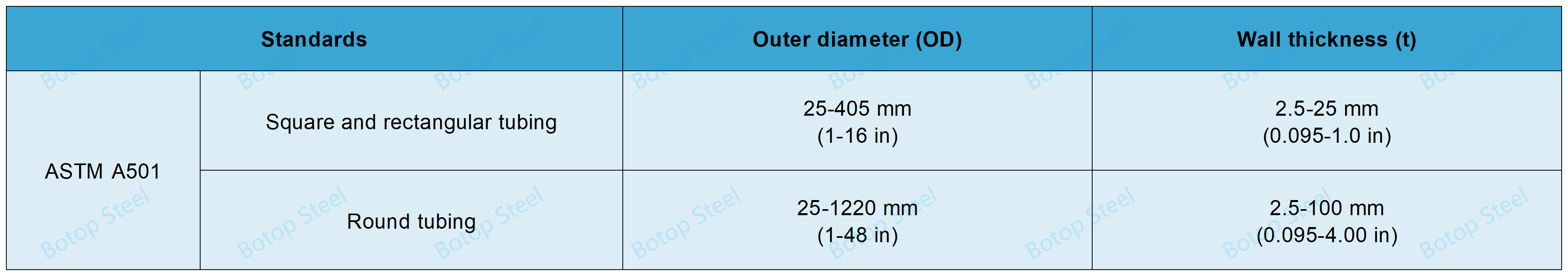

ASTM A501 Usayizi Range

Ukuhlukaniswa kwamaBanga

Izimo Zesigaba Esingenalutho

Ama-Raw material

Izinqubo Zokukhiqiza

Ukwakheka Kwekhemikhali kwe-ASTM A501

Izakhiwo Zemishini ye-ASTM A501

Ukubekezelela Dimensional kwe-ASTM A501

I-galvanizing

Ukubukeka

Ukumaka

Amazinga Abalulekile

Izinhlelo zokusebenza

Izinzuzo Zethu

ASTM A501 Usayizi Range

Ukuhlukaniswa kwamaBanga

I-ASTM A501 ihlukaniswe ngamabanga amathathu, iBanga A, iBanga B, neBanga C.

Izimo Zesigaba Esingenalutho

Umumo oyisikwele, oyindilinga, ongunxande, noma okhethekile.

Ama-Raw material

Insimbi kufanele yenziwe nge-basic-oxygen noma i-electric-arc-furnace steel-making inqubo.

Insimbi ingaphonswa ngama-ingots noma i-strand cast.

Izinqubo Zokukhiqiza

Ishubhu izokwenziwa ngenye yalezi zinqubo ezilandelayo:engenamthungo;i-welding-butt-welding (i-welding eqhubekayo);i-electric resistance welding (ERW)noma i-arc welding engaphansi kwamanzi (i-SAW) elandelwa ukushisa kabusha kuyo yonke ingxenye yesiphambano kanye nokwakhiwa okushisayo ngenqubo yokunciphisa noma yokubunjwa, noma kokubili.

Ukubunjwa kokugcina komumo kuzokwenziwa ngenqubo yokubumba eshisayo.

Kuzovunyelwa ukwengeza ukwelashwa okushisa okujwayelekile kwamashubhu anogqinsi olungaphezulu kuka-13mm [1/2 in].

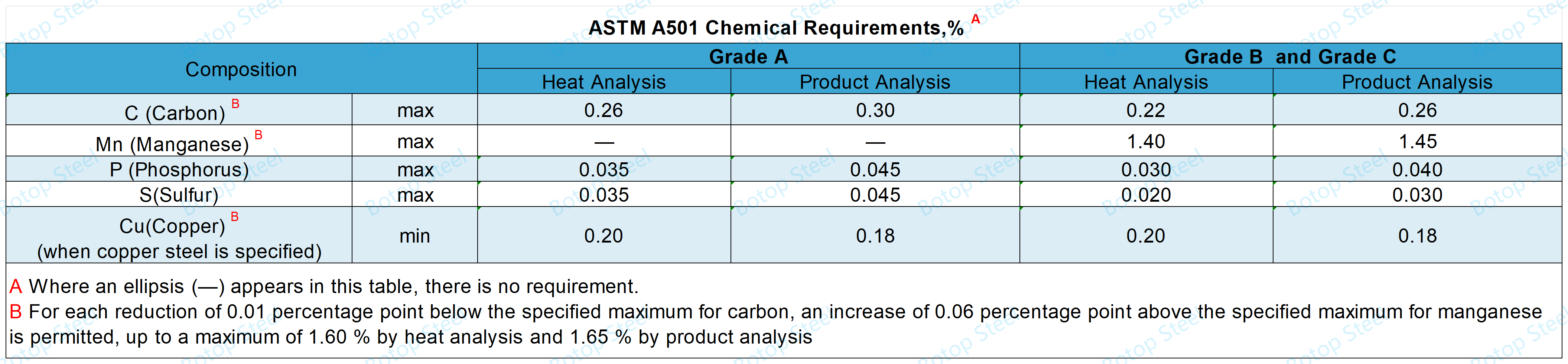

Ukwakheka Kwekhemikhali kwe-ASTM A501

Indlela yokuhlola: ASTM A751.

Ezingeni le-ASTM A501, kunezindlela ezimbili zokuhlaziya ukwakheka kwamakhemikhali ensimbi: ukuhlaziya okushisayo nokuhlaziywa komkhiqizo.

Ukuhlaziywa kokushisa kwenziwa ngesikhathi sokuncibilika kwensimbi.Inhloso yalo ukuqinisekisa ukuthi ukwakheka kwamakhemikhali ensimbi kuhlangabezana nezidingo zezinga elithile.

Ukuhlaziywa komkhiqizo, ngakolunye uhlangothi, kwenziwa ngemuva kokuba insimbi isivele yenziwe umkhiqizo.Le ndlela yokuhlaziya isetshenziselwa ukuqinisekisa ukuthi ukwakheka kwamakhemikhali omkhiqizo wokugcina kuhlangabezana nezidingo ezishiwo.

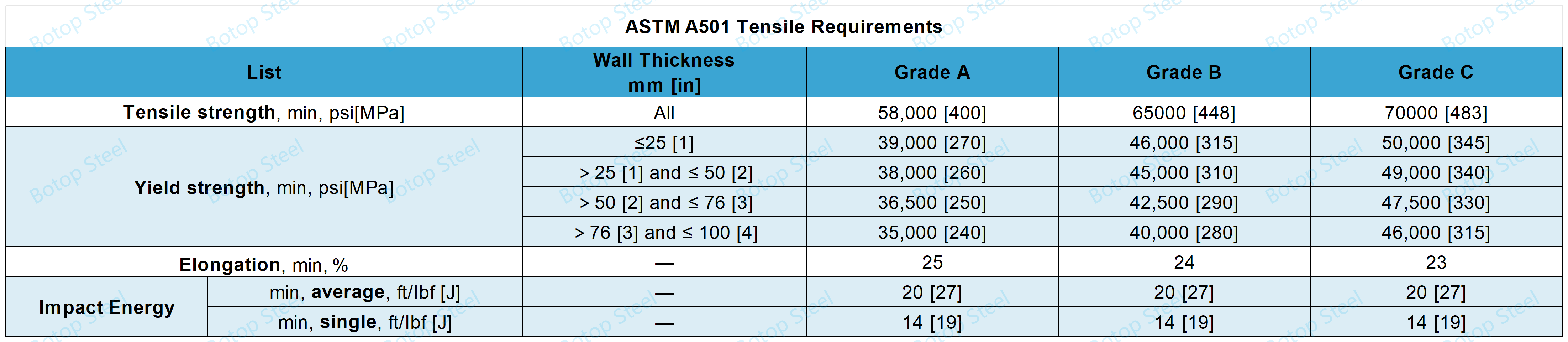

Izakhiwo Zemishini ye-ASTM A501

Izindlela zokuhlola nezincazelo zihambisana nezidingo ezifanele ze-ASTM A370.

Ukuqina kwezindonga ≤ 6.3mm [0.25in] akudingi ukuhlolwa komthelela.

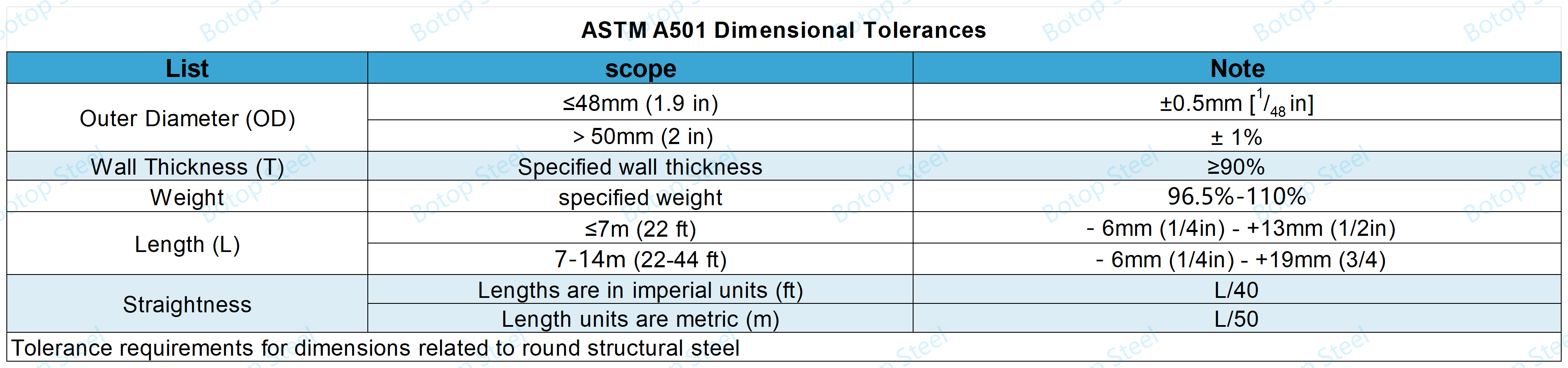

Ukubekezelela Dimensional kwe-ASTM A501

I-galvanizing

Ukuze amashubhu esakhiwo afakwe i-hot-dip galvanized, lokhu kunamathela kuzohlangabezana nezidingo ze-Specification A53/A53M.

Linganisa inani le-coating endaweni engaphandle yepayipi ukuze unqume isisindo / ubukhulu bokunamathela.

Ukubukeka

Amashubhu esakhiwo akumele angabi nasici futhi abe nendawo ebushelelezi ngesikhathi sokukhiqiza okugoqayo.

Amaphutha angaphezulu azohlukaniswa anjalo lapho ukujula kwesici sendawo kudlula u-10% wogqinsi oluvamile lodonga.

Amaphutha adinga ukulungiswa kufanele asuswe ngokuphelele ngokusika noma ukugaya ngaphambi kokushisela.

Ukumaka

Ukumaka kwe-ASTM A501 kufanele kube nolwazi olulandelayo njengobuncane:

Igama lomkhiqizi

Ibhrendi noma uphawu lokuhweba

Usayizi

Igama lezinga (unyaka wokushicilelwa awudingeki)

Ibanga

Ubude obunye beshubhu yesakhiwo kufanele buphawulwe ngendlela efanelekile, njengokugingqika, ukunyathela, ukunyathela, noma ukudweba.

Kumashubhu esakhiwo <50 mm [2 in] OD, kuvunyelwe ukumaka ulwazi lwensimbi kulebula enamathiselwe kunqwaba ngayinye.

Amazinga Abalulekile

I-ASTM A53/A53M: Ukucaciswa kwepayipi, insimbi, iMnyama ne-Hot-Dipped, i-Zinc-Coated, i-Welded, ne-Seamless.

I-ASTM A370: Izindlela Zokuhlola Nezincazelo Zokuhlolwa Komshini Kwemikhiqizo Yensimbi.

I-ASTM A700: Umhlahlandlela Wokupakisha, Ukumaka, kanye Nezindlela Zokulayisha Zemikhiqizo Yensimbi Yokuthunyelwa.

I-ASTM A751: Izindlela Zokuhlola Nezinqubo Zokuhlaziya Amakhemikhali Emikhiqizo Yensimbi.

I-ASTM A941: Amagama Ahlobene Nensimbi, Insimbi Engagqwali, Ama-alloys ahlobene, nama-Ferroalloys.

Izinhlelo zokusebenza

Isetshenziswa kakhulu kwezokwakha kanye nobunjiniyela bomphakathi.

Ukwakhiwa kwebhuloho: ngenxa yezakhiwo zayo ezinhle zemishini namandla, ifaneleka ezingxenyeni ezibalulekile zezakhiwo zebhuloho, okuhlanganisa amabhande athwala imithwalo, amadekhi amabhuloho, nezakhiwo ezisekelayo.

Ukwakhiwa kwesakhiwo: ingasetshenziswa esakhiweni sohlaka lwamathambo ezakhiwo, okuhlanganisa amakholomu, imishayo, amasistimu okwenza amafreyimu, nezisekelo zophahla nephansi.

Izicelo Zesakhiwo Esijwayelekile: Ngaphezu kwamabhuloho nezakhiwo, ifaneleka neminye imisebenzi edinga ukusekelwa kwesakhiwo, njengokwakhiwa kwezinkundla zemidlalo, izindawo zokupaka izimoto, izikole, nezinye izikhungo ezinkulu zomphakathi.

Izicelo zezimboni: Kwezinye izindawo zezimboni, njengezimboni nezindawo zokugcina izimpahla, le nsimbi ingase isetshenziselwe ukwakha izakhiwo zokusekela, amafreyimu ophahla, nezinye izakhiwo ezithwala imithwalo.

Ingqalasizinda: Le nsimbi ingase futhi isetshenziswe engqalasizinda efana nezimpawu zomgwaqo, izibani, nemibhoshongo yokuxhumana, isibonelo.

Izinzuzo Zethu

Kusukela yasungulwa ngo-2014, i-Botop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi e-carbon eNyakatho neChina, eyaziwa ngomsebenzi wayo omuhle kakhulu, imikhiqizo esezingeni eliphezulu, nezisombululo ezibanzi.Uhlu olubanzi lwemikhiqizo yenkampani luhlanganisa amapayipi ensimbi angenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kukhwalithi, i-Botop Steel isebenzisa izilawuli eziqinile nokuhlola ukuze iqinisekise ukwethembeka kwemikhiqizo yayo.Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende.

Amathegi: I-ASTM a501, ibanga a, ibanga b, ibanga c, ishubhu lensimbi, ishubhu yensimbi yesakhiwo.

Isikhathi sokuthumela: May-06-2024