Uhlobo E ipayipi lensimbikukhiqizwa ngokuhambisanaI-ASTM A53futhi ikhiqizwa kusetshenziswa i-Electric-Resistance-Welding (ERW) inqubo.

Leli payipi lisetshenziselwa ikakhulukazi izinhlelo zokusebenza zemishini nengcindezi kodwa futhi lilungele ukusetshenziswa njengamapayipi ajwayelekile okuthutha isitimu, amanzi, igesi, nomoya.

Izinhlobo zamapayipi e-ASTM A53

Kunezinhlobo ezintathu:Uhlobo F, Uhlobo E, kanye Nohlobo S.

Phakathi kwazo, ipayipi yensimbi yohlobo E ikhiqizwa inqubo ye-ERW.

Uma ufuna ukwazi okwengeziweI-ASTM A53, ungachofoza lapha.

Ukuhlukaniswa Kwebanga

Uhlobo E lunamabanga amabili: IBanga A kanyeIbanga B.

Ububanzi besayizi

Ububanzi besayizi yeI-ASYM A53 iyi-DN 6-650.

Uhlu lokukhiqiza lweUhlobo E luyi-DN 20-650 DN.

Amadayimitha amapayipi angaphansi kwe-DN 20 mancane kakhulu ohlotsheni E. Ngenxa yezizathu zobuchwepheshe ayikho indlela yokuwakhiqiza, ngakho-ke Uhlobo S, oluwuinqubo yokukhiqiza engenamthungo, isetshenziswa kakhulu.

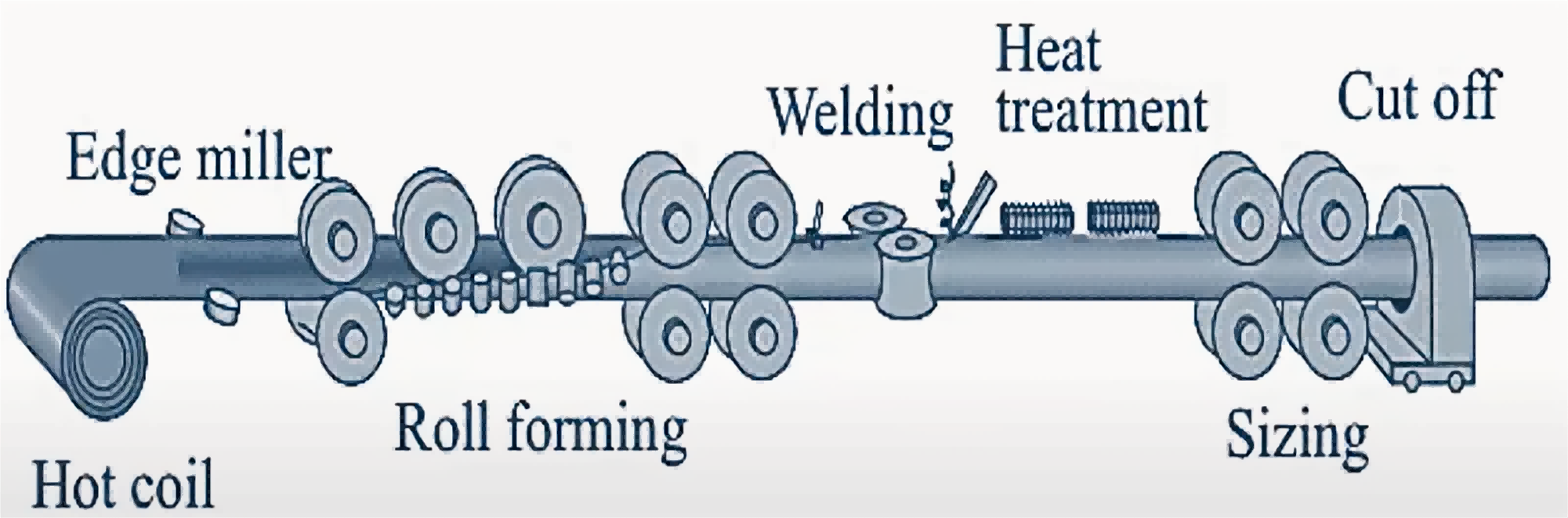

Inqubo Yokukhiqiza ye-ASTM A53 Uhlobo E

Inqubo yokukhiqiza ihlanganisa ukwenza amakhoyili ensimbi ngokusebenzisa amaroli, imiphetho yokushisela ngokushisisa ukumelana, ama-welds asusayo, nokulinganisa nokuqondisa ukwenza amashubhu.

Izici ze-ASTM A53 Type E Steel Pipe

Inamashisela amabili ama-longitudinal butt ngaphakathi nangaphandle.Imiphetho yamapuleti ensimbi ashiselwe ngaphakathi nangaphandle kwepayipi phakathi nenqubo yokukhiqiza ukuze kuqinisekiswe amandla nokuvala.

Amashisela angaphakathi nangaphandle awabonakali.Ama-welds angaphakathi nangaphandle ahlanzwa aze alingane nobude obufana nepayipi ngesikhathi sokukhiqiza, okunomthelela ekubukekeni okuphelele kanye nezakhiwo ze-hydrodynamic zepayipi.

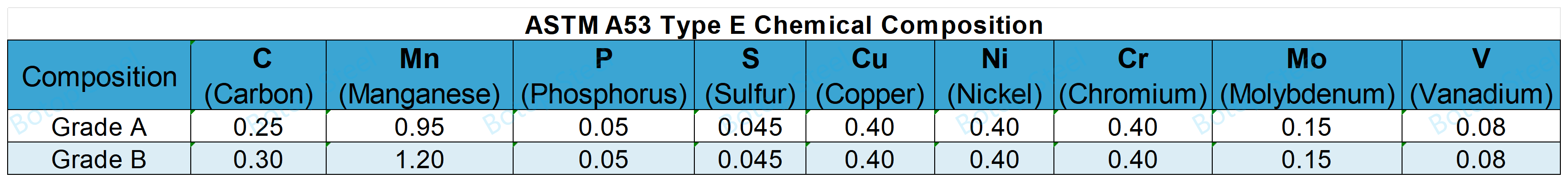

Izingxenye Zamakhemikhali ze-ASTM A53

Ekunciphiseni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu sekhabhoni esishiwo, ukwenyuka ngo-0.06 % wemanganese ngaphezu komkhawulo oshiwo kuzovunyelwa kuze kufike ku-1.65%.

I-Cu, i-Ni, i-Cr, i-Mo, ne-V, ziyizinto ezinhlanu zihlangene azidluli ku-1.00%.

I-ASTM A53 Uhlobo lwe-E Mechanical Properties

Tension Test

Amapayipi ashiselwe ukumelana ne-DN ≥ 200 azohlolwa kusetshenziswa ama-specimens amabili aguquguqukayo, eyodwa ngaphesheya kwe-weld kanti enye ibhekene ne-weld.

| Uhlu | ukuhlukaniswa | Ibanga A | Ibanga B |

| Amandla aqinile, imiz | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla okukhiqiza, imiz | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ubude ku-50 mm (2 in ) | Qaphela | A, B | A, B |

Qaphela A: Ubude obuncane kokungu-2 ku-[50 mm] buzoba yileyo enqunywa isibalo esilandelayo:

e = 625000 [1940] A0.2/U0.9

e = ubude obuncane kumaphesenti angu-2 noma angu-50 mm, okufinyezwa kumaphesenti aseduze

A = okungaphansi kuka-0.75 in2[500 mm2] kanye nendawo ephambanayo yesampula yokuhlolwa kwengcindezi, ibalwe kusetshenziswa ububanzi obushiwo bangaphandle bepayipi, noma ububanzi obuncane besampula yokuhlolwa kwengcindezi nobukhulu bodonga olushiwo lwepayipi, inani elibaliwe lifinyezwa ku-0.01 eseduze phakathi2 [1 mm2].

U=amandla e-tensile amancane acacisiwe, i-psi [MPa].

Qaphela B: Bheka Ithebula X4.1 noma Ithebula X4.2, kungakhathaliseki ukuthi ikuphi okusebenzayo, ngamavelu amancane okunweba adingekayo ezinhlanganisela ezihlukahlukene zosayizi wesifanekiso sokuhlolwa kokucindezeleka namandla ashiwo ubuncane obuncane bokunyakaza.

Bend Test

Epayipini, i-DN ≤50, ubude obanele bepayipi buzokwazi ukugotshwa ukubanda kudlule u-90° kuzungeze i-cylindrical mandrel, ububanzi bayo obuphindwe kashumi nambili kunobubanzi obushiwo bangaphandle bepayipi, ngaphandle kokwenza imifantu kunoma iyiphi ingxenye futhi ngaphandle ukuvula i-weld.

Ipayipi elinamandla aphindwe kabili ngaphezu kwe-DN 32 akudingeki ukuthi lihlolwe ukugoba.

"I-Double-extra-strong", evame ukubizwa ngokuthi i-XXSiyipayipi elinodonga oluqiniswe ngokukhethekile, elivame ukusetshenziswa ezimbonini zokusebenza ukumelana nezingcindezi eziphakeme kanye nezindawo ezinzima.Ukuqina kodonga lwaleli payipi likhulu kakhulu kunepayipi elivamile, ngakho linikeza amandla amaningi nokuqina okungcono.

Ukuhlola Ukucaba

Ukuhlolwa kokucaba kuzokwenziwa epayipini elishiselwe ngaphezulu kwe-DN 50 ngesisindo esinamandla (XS) noma esilula.

Inqubo yokuhlola elandelayo isebenza ohlotsheni E, amabanga A no-B.

Ngesikhathi sokucindezela okuphansi, i-weld kufanele ibekwe ku-0 ° noma 90 ° emgqeni wokuqondisa kwamandla, kuye ngezidingo ezithile.

Isinyathelo 1: Hlola i-ductility ye-weld.Akufanele kube nokuqhekeka noma ukuphuka endaweni yangaphakathi noma yangaphandle ye-weld kuze kube yilapho ibanga phakathi kwamapuleti ayisicaba lingaphansi kwezingxenye ezimbili kwezintathu zobubanzi obungaphandle bepayipi.

Isinyathelo sesi-2: Qhubeka nokucindezela okuthi flat futhi uhlole i-ductility endaweni engaphandle kwe-weld.Akufanele kube nokuqhekeka noma ukuqhekeka endaweni yangaphakathi noma yangaphandle yepayipi ngale kwe-weld kuze kube ibanga phakathi kwamapuleti ayisicaba lingaphansi kwengxenye eyodwa kwezintathu yobubanzi obungaphandle bepayipi, kodwa kungabi ngaphansi kokuphindwe kahlanu ubukhulu bepayipi. udonga lwamapayipi.

Isinyathelo sesi-3: Hlola ubuqotho bento ngokuqhubeka ucindezela phansi kuze kube yilapho isifanekiso sokuhlola siphuka noma izindonga zamapayipi zihlangana.Lokhu kusetshenziselwa ukuhlola okubalulekile ngezinkinga ezifana nezendlalelo eziqhekekile, ukungabi namandla, noma ukushisela okungaphelele.

Ukuhlolwa kwe-Hydrostatic

Ukuhlolwa kwe-hydrostatic kuzosetshenziswa, ngaphandle kokuvuza ngomthungo we-weld noma umzimba wepayipi.

Ipayipi elingaphethe lutho kufanele lihlolwe nge-hydrostatically kumfutho osebenzayo onikezwe kuThebula X2.2,

ipayipi eliluchungechunge nelihlanganisiwe lizohlolwa nge-hydrostatically kungcindezi esebenzayo enikezwe kuThebula X2.3.

Ngamapayipi ensimbi ane-DN ≤ 80, ukucindezela kokuhlola akufanele kudlule i-17.2MPa;

Kumapayipi ensimbi ane-DN ~80, ingcindezi yokuhlola ngeke idlule i-19.3MPa;

Ukuhlola Ugesi Okungabhubhisi

Kumapayipi oHlobo E noHlobo lwe-F Ekilasi B DN ≥ 50, ama-welds kufanele ahlolwe ugesi ongabhubhisi.

Ukuhlolwa kukagesi okungabhubhisi kuzokwenziwa ngokuya nge-Specifications E213, E273, E309 noma E570.

Uma ukuhlolwa kukagesi okungangonakali kwenziwe, ipayipi lizomakwa "NDE".

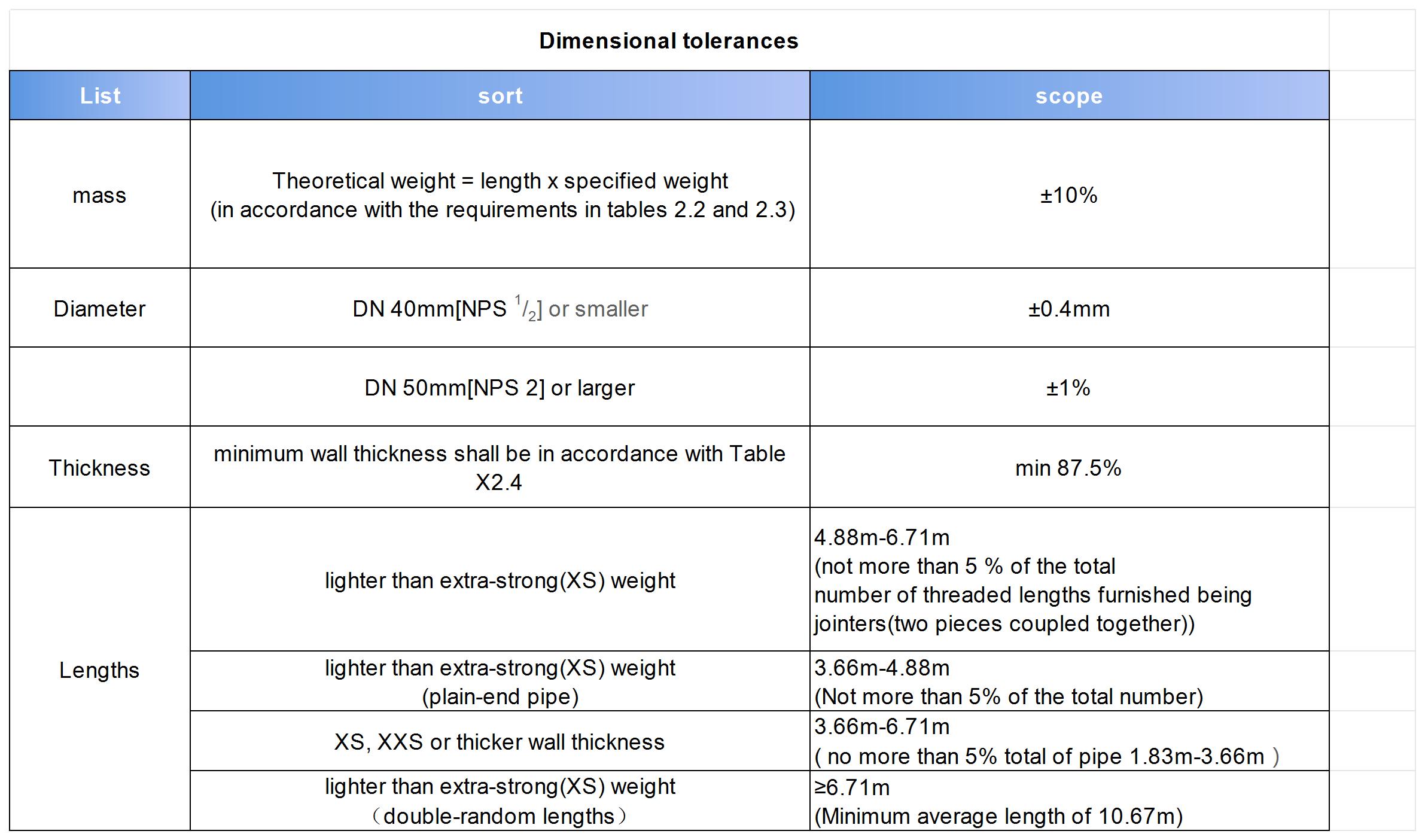

I-ASTM A53 Dimensional Tolerances

Amashadi Wesisindo Sombhobho kanye namashejuli wamapayipi

Izinzuzo ze-ASTM A53 Type E Pipe

I-Resistance welding iyindlela yokushisela enezindleko eziphansi, okwenza amashubhu ohlobo lwe-E angabizi kakhulu ukuwakhiqiza futhi alungele ukukhiqizwa ngobuningi.

Inqubo ye-resistance welding iyashesha futhi ingakhiqizwa ngokuqhubekayo, okwandisa ukukhiqiza futhi kunciphisa izikhathi zokuhola.

Ngenxa yezakhiwo zayo ezinhle zemishini nokumelana nokugqwala, lolu hlobo lwepayipi lusetshenziswa kabanzi ezinhlobonhlobo zezicelo zokuthutha uketshezi, njengamanzi, igesi, nesitimu.

Ama-welds angenziwa angabonakali ngokuphathwa kahle kwama-welds, okungathuthukisi nje ukubonakala kwepayipi kodwa futhi kungase kunciphise ukumelana nokugeleza koketshezi okubangelwa ama-welds..

Izicelo ze-ASTM A53 Type E Steel Pipe

Ukusetshenziswa kwesakhiwo: Ekwakhiweni, ipayipi lensimbi le-A53 Type E lisetshenziswa njengezingxenye zesakhiwo njengezisekelo zesakhiwo kanye nezinhlelo ze-truss.

Amapayipi amanzi: Isetshenziswa ezinhlelweni zokunikezela ngamanzi ezakhiweni, okuhlanganisa nezinhlelo zokufafaza umlilo.

Amasistimu e-Steam: Ezikhungweni zezimboni, leli payipi lensimbi livame ukusetshenziswa ezinhlelweni zokulethwa kwe-steam, ikakhulukazi kwizicelo zokucindezela okuphansi.

Ukudluliswa kwegesi: Isetshenziselwa ukuthuthwa kwamagesi emvelo noma amanye, ikakhulukazi ezinhlelweni zikamasipala nezindawo zokuhlala.

Izitshalo zamakhemikhali: yokudlulisa isitimu esinengcindezi ephansi, amanzi, namanye amakhemikhali.

Izigayo zephepha noshukela: ukudlulisa izinto ezingavuthiwe nemikhiqizo eqediwe, kanye nokulahla udoti wenqubo.

Amasistimu okushisa nawokupholisa: Isetshenziselwa kakhulu amapayipi kuzinhlelo zokufudumeza, zokungenisa umoya, nezomoya (HVAC).

Ukwelashwa kwamanzi angcolile: Okokuhambisa amanzi angcolile noma amanzi ahlanzekile.

Izinhlelo zokunisela: Amapayipi amanzi asetshenziselwa ukuchelela umhlaba wokulima.

Izimayini: Isetshenziselwa ukuthutha amanzi negesi ezimayini.

Imikhiqizo Yethu Ehlobene

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza amapayipi ensimbi ahlukahlukene kanye nemikhiqizo ehlobene,

okufaka ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Amathegi: ASTM a53, uhlobo e, grade a, grade b, erw.

Isikhathi sokuthumela: May-12-2024