I-JIS G 3444 ipayipi yensimbiiyipayipi lensimbi yensimbi elenziwe ngenqubo engenamthungo noma eshiselwe, esetshenziswa ikakhulukazi kubunjiniyela bomphakathi kanye nokwakhiwa.

Izinkinobho Zokuzulazula

Ububanzi besayizi

Ukuhlukaniswa Kwebanga

I-JIS G 3444 Izinqubo Zokukhiqiza

I-Tube End Type

Ukubunjwa Kwekhemikhali kwe-JIS G 3444

Impahla Yemishini ye-JIS G 3444

Ukumelana Okuphansi

Bend Test

Okunye Ukuhlolwa

Ithebula Lesisindo Sepayipi le-JIS G 3444

I-Dimensional Tolerance ye-JIS G 3444

Ukubukeka

Ukumaka

JIS G 3444 Isicelo

Amazinga Ahlobene

Izinzuzo Zethu

Ububanzi besayizi

Inhloso evamile Ububanzi bangaphandle: 21.7-1016.0mm;

Izinqwaba zesisekelo nezinqwaba zokucindezelwa kokudilika komhlaba OD: ngaphansi kuka-318.5mm.

Ukuhlukaniswa Kwebanga

Amashubhu ahlukaniswe ngamabanga ama-5.

I-STK 290,I-STK 400, STK 490, STK 500, STK 540.

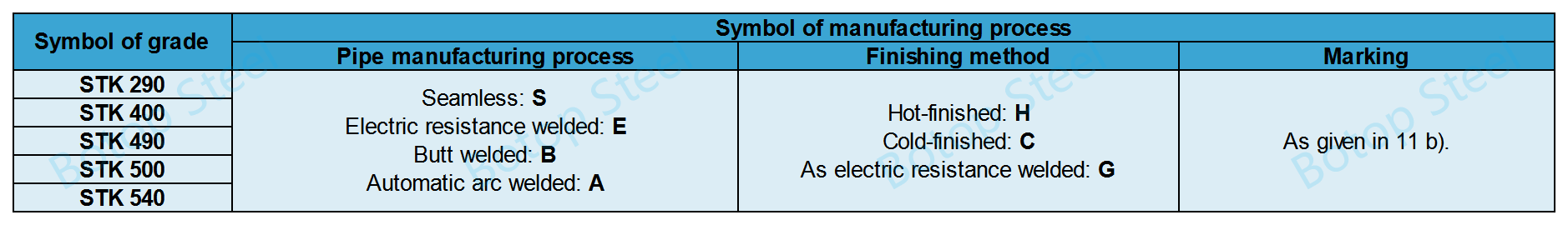

I-JIS G 3444 Izinqubo Zokukhiqiza

Amashubhu azokwenziwa ngenhlanganisela yendlela yokukhiqiza ishubhu kanye nendlela yokuqeda ekhonjisiwe.

Amashubhu angaphathwa kahle ngokushisa uma efunwa.

Uma kudingwa uMthengi, ipayipi lingase lenziwe ngeshidi lensimbi eliboshiwe noma ibha yensimbi eboshwe.Kulokhu, uhlobo lwe-coating kanye nekhwalithi ye-coating izohambisana nezimfuneko ze-JIS G 3444, Isithasiselo A.

Izinhlobo ze-coating ezingase zifakwe i-hot-dip zinc coating, i-electrolytic zinc coating, hot-dip aluminium coating, hot-dip zinc-5% aluminium alloy coating, hot-dip 55% aluminium-zinc alloy coating, noma ukushisa- cwilisa i-zinc-aluminium-magnesium alloy coating.

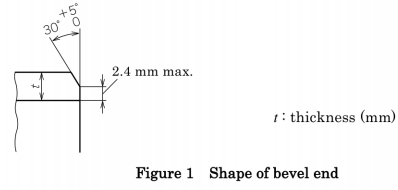

I-Tube End Type

Iziphetho zamapayipi ensimbi kufanele zibe flat.

Uma ipayipi idingeka ukuthi icutshungulwe ekugcineni kwe-beveled, i-engeli ye-bevel ingu-30-35 °, ububanzi be-bevel bonqenqema lwepayipi yensimbi: i-max 2.4mm.

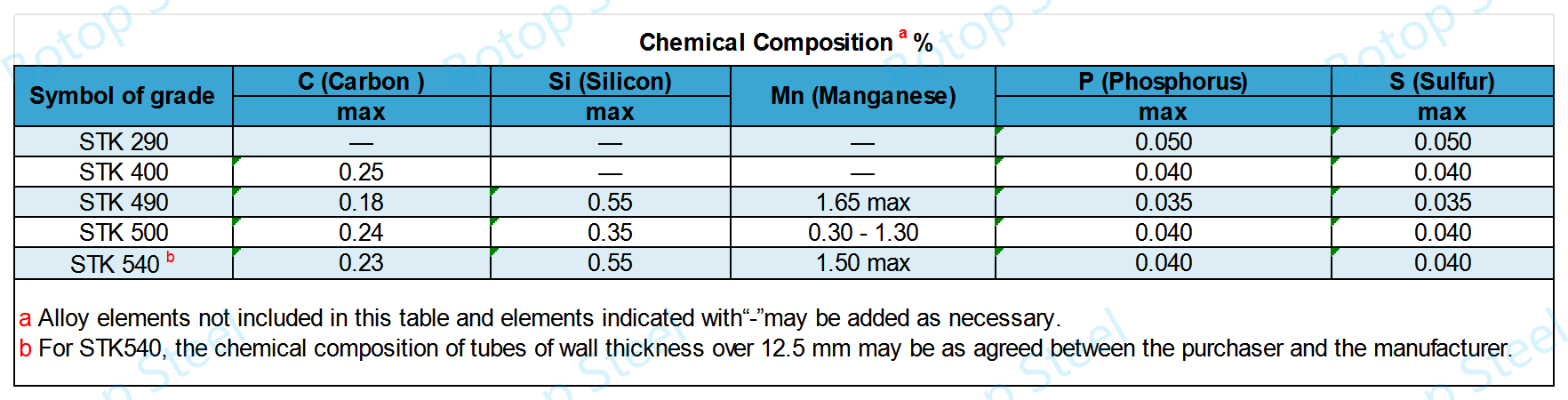

Ukubunjwa Kwekhemikhali kwe-JIS G 3444

Izindlela zokuhlaziya ukushisa kufanele zihambisane nezidingo ku-JIS G 0320.

Indlela yokuhlaziya umkhiqizo izohambisana nezidingo ku-JIS G 0321.

Impahla Yemishini ye-JIS G 3444

Izidingo ezijwayelekile zokuhlolwa kwemishini zizohambisana neSigaba 7 no-9 se-JIS G 0404.

Kodwa-ke, indlela yamasampula yokuhlolwa kwemishini izohambisana nezimfuneko zemibandela Yekilasi A kuSigaba 7.6 se-JIS G 0404.

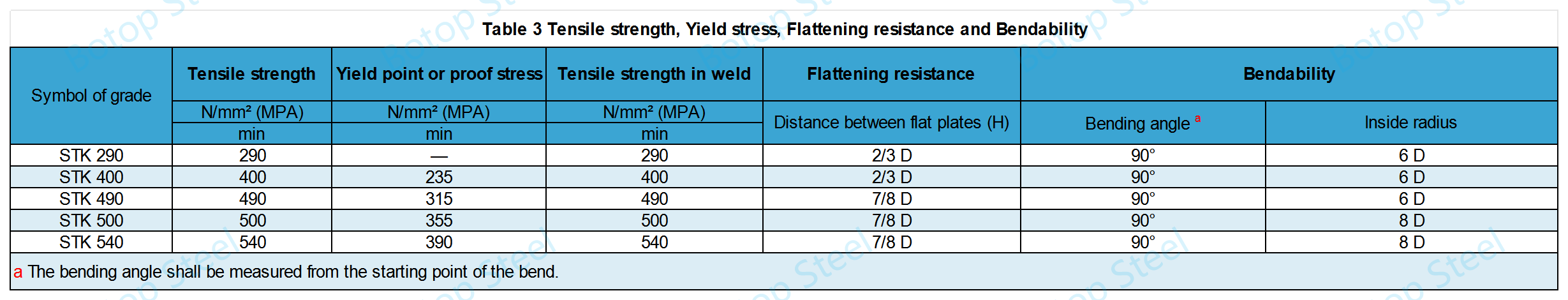

Amandla Okuqina kanye Nephuzu Lokukhipha noma Ingcindezi Yobufakazi

Amandla aqinile nephuzu lokukhiqiza noma ingcindezi yobufakazi kanye namandla okuqina ku-weld kuzokwanelisa amanani ashiwo kuThebula lesi-3.

Amandla aqinile we-weld asebenza kumashubhu ashiselwe nge-arc othomathikhi.

Amandla we-weld afana nalawo adingekayo emzimbeni wepayipi.Ingxenye eshiselwe ngokuvamile iyisixhumanisi esibuthakathaka esakhiweni, ngakho ukuba namandla afanayo okuqina kuqinisekisa ukuthembeka kwesakhiwo esihlanganisiwe.

Ithebula lesi-3 liqukethe nezidingo zebanga zokumelana ne-Flattening kanye nezidingo ze-engeli yokugoba kanye nerediyasi yokugoba ekugcineni kokugobeka.

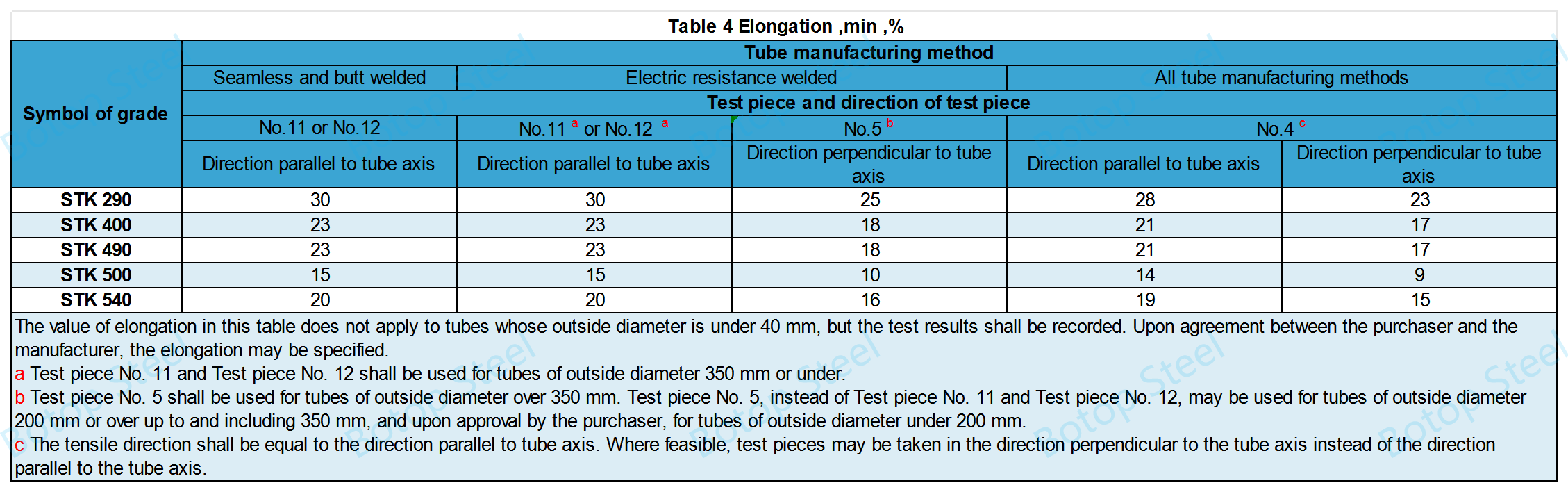

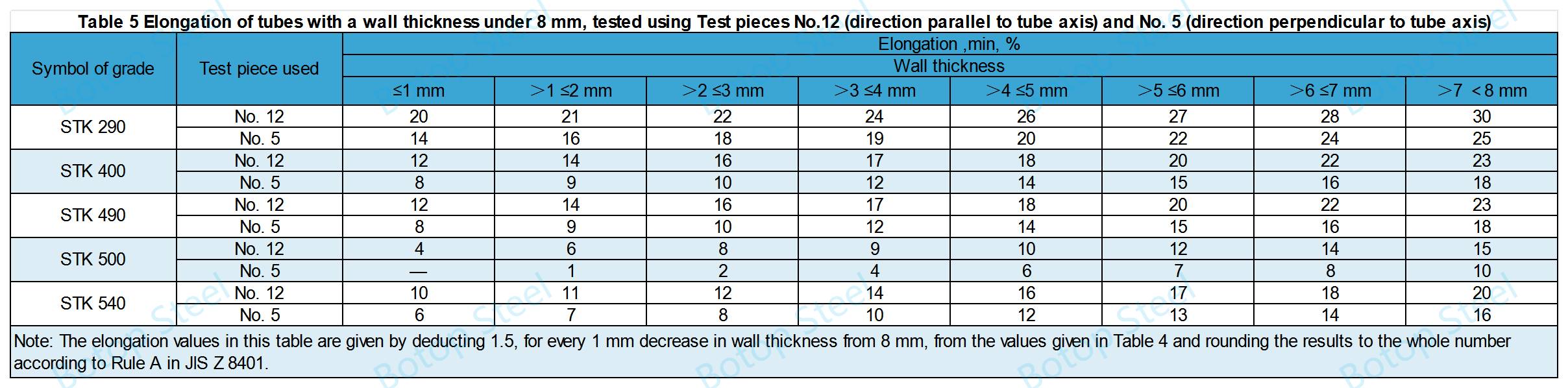

Ukwelula

Ukwelulwa okuhambisana nendlela yokukhiqiza ishubhu kukhonjiswe kuThebula lesi-4.

Kodwa-ke, uma ukuhlolwa kwe-tensile kwenziwa ku-Test Piece No. 12 noma ku-Test Piece No.5 ethathwe eshubhuni elingaphansi kuka-8 mm ubukhulu bodonga, ubude kufanele buhambisane neThebula lesi-5.

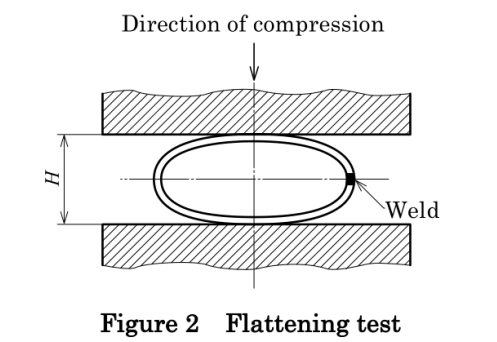

Ukumelana Okuphansi

Beka ucezu lokuhlola ezingeni lokushisa elivamile (5 °C kuya ku-35 °C) phakathi kwamapuleti amabili ayisicaba bese ucindezela ukuze ufane kuze kube yilapho ibanga phakathi kwamapuleti H lilingana noma libe lincane kunenani elishiwo kuThebula 3, bese uhlola ukuqhekeka ucezu lokuhlola.

Beka ama-welds wokumelana ashiselwe ipayipi lensimbi kanye nepayipi lensimbi elihlanganisiwe ukuze umugqa ophakathi kwesikhungo sepayipi kanye ne-weld uhambisane nesiqondiso sokucindezela.

Bend Test

Gobisa ucezu lokuhlola luzungeze isilinda ezingeni lokushisa elivamile (5 °C kuya ku-35 °C) nge-engeli egobayo engengaphansi kwe-engeli yokugoba eshiwo kuThebula 3, futhi ngeradiyasi yangaphakathi engeqile kunomkhawulo omkhulu ongaba yirediyasi eshiwo kuThebula. 3, bese uhlola ucezu lokuhlola ukuqhekeka.

Ukuze uhlole ishubhu lensimbi elishiselwe ukumelana nogesi kanye neshubhu lensimbi elinezinqe, beka ucezu lokuhlola ngendlela yokuthi ukushisela kube ngu-90 °C ukusuka endaweni engaphandle yokugoba.

Okunye Ukuhlolwa

Ukuhlolwa kwe-Hydrostatic, ukuhlolwa okungangonakali kwamashisela, noma okunye ukuhlolwa kuzovunyelwana kusengaphambili ngezidingo ezifanele.

Ithebula Lesisindo Sepayipi le-JIS G 3444

Ifomula yokubala isisindo sepayipi lensimbi

W=0.02466 t (Dt)

W: iyunithi yesisindo seshubhu (kg/m)

t: ukujiya kodonga lweshubhu (mm)

D: Ububanzi obungaphandle beshubhu (mm)

0.02466: isici sokuguqulwa kweyunithi sokuthola i-W

Ifomula isuselwe eqinisweni lokuthi ukuminyana kwensimbi kungu-7.85 g/cm³.

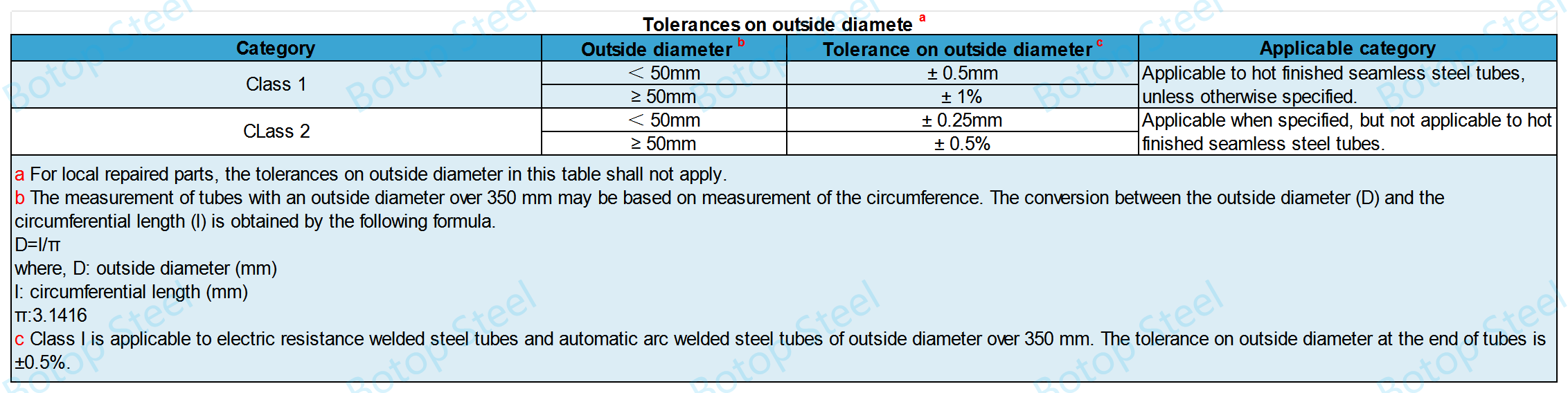

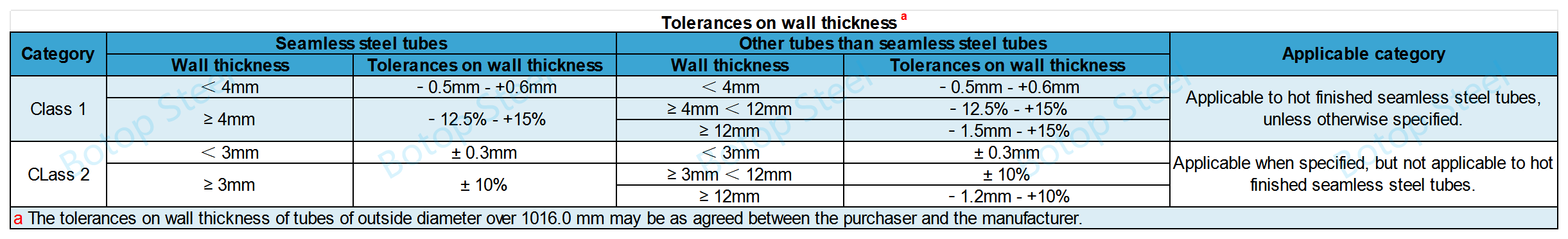

I-Dimensional Tolerance ye-JIS G 3444

Ukubekezelelana Kwangaphandle Kobubanzi

Ukubekezelela Ukuqina Kwezindonga

Ukubekezelela Ubude

Ukubekezelelana kobude bepayipi yensimbi, ukubekezelelana okungalungile kungu-zero, ukubekezelelana okuhle akudingekile ngokucacile, umthengi nomkhiqizi banqume ngokuvumelana ngokuvumelana.

Ukubukeka

Indawo yangaphakathi nangaphandle yepayipi yensimbi izoba bushelelezi futhi ingabi namaphutha angalungile ukuyisebenzisa.

Izingubo zokunqanda ukugqwala ezifana ne-zinc-rich coatings, i-epoxy coatings, i-peint coatings, njll. ingasetshenziswa ezindaweni zangaphandle noma zangaphakathi.

Ukumaka

Ipayipi ngalinye lensimbi lizofakwa ilebula ngolwazi olulandelayo.

a)Uphawu lwebanga.

b) Uphawu lwendlela yokukhiqiza.Uphawu lwendlela yokukhiqiza luzoba kanje.Udeshi ungase ushintshwe kufakwe okungenalutho.

1) Ishubhu yensimbi engenamthungo ephelile ngokushisa: -SH

2) Ishubhu yensimbi engenamthungo epholile eqediwe: -SC

3) Njengoba ukumelana kagesi ashiselwe steel tube: -EG

I-4) I-Hot-finished kagesi ukumelana ne-welded steel tube: -EH

5) Ukumelana kukagesi okuqediwe okuphothuliwe okushiselwe ishubhu lensimbi: -EC

6) Amashubhu ensimbi anezinqe -B

7) Automatic arc welded steel amashubhu -A

c) Ubukhulu.Ububanzi bangaphandle nokuqina kodonga kuzomakwa.

d) Igama lomkhiqizi noma isifinyezo.

Uma ukumaka eshubhuni kunzima ngenxa yokuthi ububanzi balo bangaphandle buncane noma uma umthengi ecelwe kanjalo, ukumaka kungase kunikezwe kunqwaba yamashubhu ngendlela efanelekile.

Izindlela ezifana nokusetshenziswa kwamalebula, njll.

JIS G 3444 Isicelo

Zisetshenziselwa ubunjiniyela bomphakathi kanye nezakhiwo ezifana nemibhoshongo yensimbi, ama-scaffoldings, inqwaba yezinyawo, inqwaba yesisekelo, kanye nenqwaba yokucindezelwa kokudilika komhlaba.

Amazinga Ahlobene

I-JIS G 3452: Icacisa amapayipi ensimbi ye-carbon ngezinjongo ezijwayelekile (ehlukile ezinjongweni zesakhiwo futhi egxile kakhulu ekuthuthweni koketshezi noma amagesi).

I-JIS G 3454: Icacisa izindinganiso zamapayipi ensimbi ye-carbon amapayipi okucindezela.

I-ASTM A500: imboza amashubhu esakhiwo sensimbi esakhiwe ngendlela ebandayo futhi ifana ne-JIS G 3444 kwezinye izimfuneko zayo.

I-EN 10219: Imboza izingxenye ezingenalutho ezakhiwe ngendlela ebandayo ezishiselwe ngezinhloso zesakhiwo, okuhlanganisa amaphrofayili ayindingilizi, ayisikwele, nawonxande.

Izinzuzo Zethu

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Tags: jis g 3444, carbon steel pipe, stk, steel tube, structure pipe.

Isikhathi sokuthumela: May-10-2024