I-JIS G 3455 ipayipi yensimbiikhiqizwa nguipayipi lensimbi engenamthungoinqubo yokukhiqiza, ikakhulukazi esetshenziselwa carbon steel pipe ngeizinga lokushisa elisebenzayo elingaphansi kuka-350 ℃ imvelo, ikakhulukazi esetshenziselwa izingxenye zemishini.

Izinkinobho Zokuzulazula

Ububanzi besayizi

Ukuhlukaniswa Kwebanga

Izinqubo Zokukhiqiza

Ukwelashwa Kokushisa

Uhlobo Lokuphela Kwepayipi

Izingxenye Zekhemikhali ze-JIS G 3455

Impahla Yemishini ye-JIS G 3455

Ukuhlolwa kwe-Hydrostatic noma Ukuhlolwa Okungabhubhisi

Ishadi lesisindo sepayipi le-JIS G 3455 kanye namashejuli wamapayipi

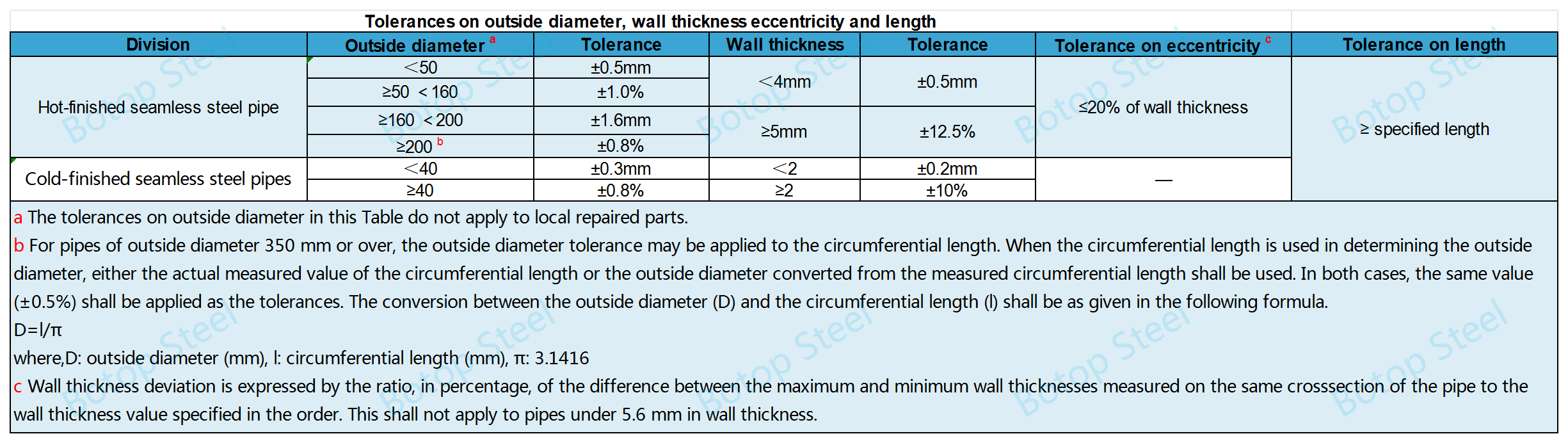

I-JIS G 3455 Ukubekezelelana Kwe-Dimensional

Ukubukeka

Ukumaka

Izicelo ze-JIS G 3455 Steel Pipe

I-JIS G 3455 Amazinga Alinganayo

Imikhiqizo Yethu Ehlobene

Ububanzi besayizi

Ipayipi elingaphandle ububanzi: 10.5-660.4mm (6-650A) (1/8-26B)

A=DN;B=NPS.

Ukuhlukaniswa Kwebanga

I-JIS G 3455 inamabanga amathathu ngokokuqina okuncane kwepayipi, okungukuthiSTS370, I-STS410, futhiSTS480.

Izinqubo Zokukhiqiza

Amapayipi azokhiqizwa ngaphandle komthungo ngensimbi ebulewe.

Ukubunjwa kokugcina kuhlukaniswe izinhlobo ezimbili, ezishisayo-eziphelile futhi ezibandayo, kuye ngokuthi ububanzi obungaphandle nobukhulu bodonga.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | |

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | |

| STS370 I-STS410 STS480 | I-Seamless: S | Ukuqedwa okushisayo: H Ukuqedwa okubandayo: C |

Ukwelashwa Kokushisa

| Uphawu lwebanga | Kuqedwe okushisayo ipayipi lensimbi engenamthungo | Kubanda-kuqedile ipayipi lensimbi engenamthungo |

| STS370 I-STS410 | Njengoba kukhiqizwa. Kodwa-ke, i-annealing yezinga lokushisa eliphansi noma ukujwayela kungase kusetshenziswe njengoba kudingeka. | Izinga lokushisa eliphansi liyancishiswa noma lijwayelekile |

| STS480 | Izinga lokushisa eliphansi liyancishiswa noma lijwayelekile | |

Ukwelashwa kokushisa ngaphandle kwalezo ezinikezwe etafuleni kungenziwa ngesivumelwano phakathi komthengi nomkhiqizi.

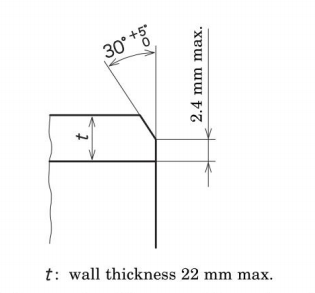

Uhlobo Lokuphela Kwepayipi

Amapayipi azoqedwa ngeziphetho eziyisicaba.

Uma isiphetho esine-beveled sicacisiwe, umumo wokuphela ocijile wamapayipi anogqinsi lodonga ≤ 22 mm kufanele uhambisane no-30-35 °, futhi ububanzi be-bevel bonqenqema lwepayipi lensimbi bungaphezu kuka-2.4mm.

Izingxenye Zekhemikhali ze-JIS G 3455

Ukuhlaziywa kokushisa kuzohambisana ne-JIS G 0320. Ukuhlaziywa komkhiqizo kuzohambisana ne-JIS G 0321.

Amanani okuhlaziya okushisayo azohambisana nalezi zidingo ezilandelayo:

| Uphawu lwebanga | C (Ikhabhoni) | I-Si (Silicon) | Mn (Manganese) | I-P (Phosphorus) | S (Sulfur) |

| ubuningi | ubuningi | ubuningi | |||

| STS370 | 0.25% | 0.10-0.35% | 0.30-1.10% | 0.35% | 0.35% |

| I-STS410 | 0.30% | 0.10-0.35% | 0.30-1.40% | 0.35% | 0.35% |

| STS480 | 0.33% | 0.10-0.35% | 0.30-1.50% | 0.35% | 0.35% |

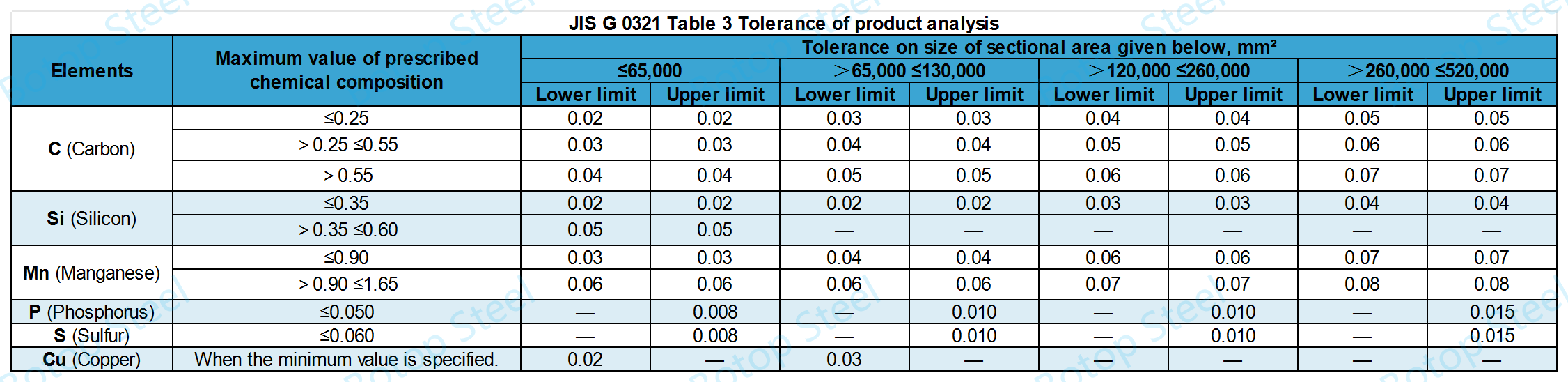

Amanani ahlaziyiwe omkhiqizo akufanele ahlangabezane namanani kuthebula kuphela, kodwa ububanzi bokubekezelela bento ngayinye kufanele buhambisane nezimfuneko zeThebula 3 le-JIS G 3021.

Impahla Yemishini ye-JIS G 3455

Izidingo ezijwayelekile zokuhlolwa kwemishini zizohambisana nesigaba somthetho 7 no-9 se-JIS G 0404. Izindlela zesampula zokuhlolwa kwemishini kufanele zihambisane Nekilasi A le-JIS G 0404, Isigaba somthetho 7.6.

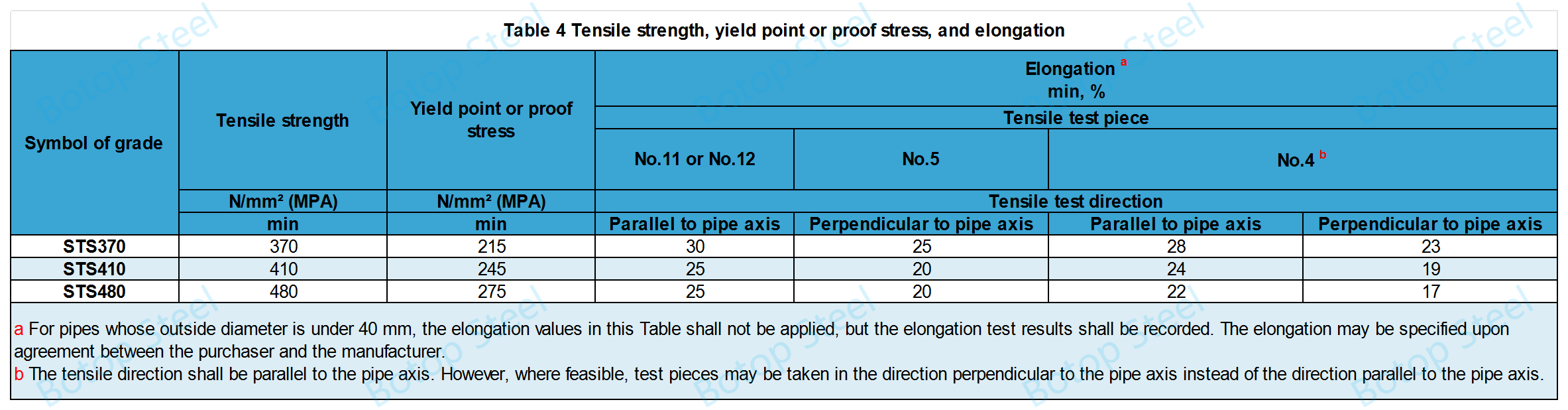

Amandla Aqinile, Iphuzu Lokuvuza noma Ingcindezi Yobufakazi, Nokwelula

Indlela yokuhlola izohambisana namazinga aku-JIS Z 2241.

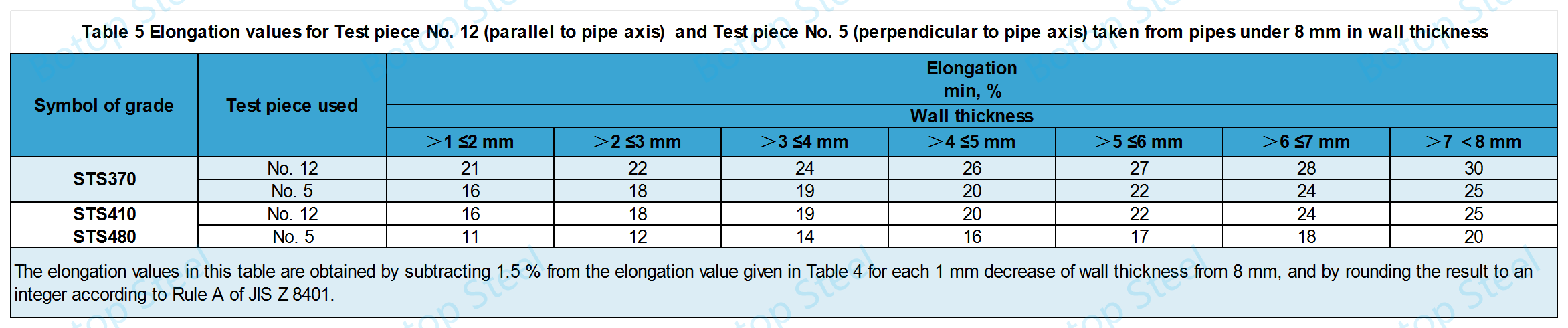

Kumapayipi angaphansi kokuhlolwa kokuqina kusetshenziswa isifanekiso No. 12 noma No. 5, ubude kufanele buhlangabezane nezimfuneko zeThebula lesi-5.

Ukumelana Okuphansi

Ukuhlola kungase kukhishwe ngokubona komkhiqizi inqobo nje uma amapayipi enelisa ukumelana okuyisicaba okucacisiwe.

Isifanekiso sibekwa phakathi kwamaplathifomu amabili futhi sincishiswe kuze kube yilapho ibanga H phakathi kwamapulatifomu lifinyelela inani elishiwo.Isifanekiso sibe sesihlolelwa ukuqhekeka.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwamapuleti (mm)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

е: kuchazwe njalo ebangeni ngalinye lepayipi: 0.08 ye-STS370, 0.07 ye-STS410 kanye ne-STS480.

I-Bendability Test

Isebenza kumapayipi anobubanzi obungaphandle ≤50 mm njengoba kucaciswe umthengi.

Isifanekiso ngeke sibe nemifantu uma sigotshwa nge-engeli engu-90° enobubanzi bangaphakathi obuphindwe ka-6 kunobubanzi obungaphandle bepayipi.I-engeli yokugoba izolinganiswa ekuqaleni kokugoba.

Ukuhlolwa kwe-Hydrostatic noma Ukuhlolwa Okungabhubhisi

Ukuhlolwa kwe-hydrostatic noma okungabhubhisi kuzokwenziwa epayipini ngalinye.

Ukuhlolwa kwe-Hydrostatic

Bamba ipayipi ngaphansi kokucindezela okuncane okucacisiwe kwe-hydrostatic test okungenani imizuzwana emi-5 futhi uhlole ukuthi ipayipi ingakwazi ukumelana nokucindezela ngaphandle kokuvuza.

Lapho Umthengi engacacisi ingcindezi yokuhlola, futhi lapho ipayipi lingaphansi kwengcindezi encane yokuhlola ye-hydrostatic enikeziwe, ipayipi lizokwazi ukumelana nalo ngaphandle kokuvuza.

| Ukujiya kodonga okuzisholo | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Ingcindezi encane yokuhlolwa kwe-hydraulic, i-Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Lapho ubukhulu bodonga be-diameter yangaphandle yepayipi yensimbi akuyona inani elijwayelekile etafuleni lesisindo sepayipi yensimbi, kuyadingeka ukusebenzisa ifomula ukubala inani lokucindezela.

P=2st/D

P: ingcindezi yokuhlola (MPa)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

s: 60 % yenani elincane lephoyinti lesivuno noma ingcindezi yobufakazi enikeziwe.

Lapho ingcindezi encane yokuhlolwa kwe-hydrostatic yenombolo yohlelo olukhethiwe idlula ingcindezi yokuhlola engu-P etholwe ifomula, ingcindezi engu-P izosetshenziswa njengengcindezi yokuhlola ye-hydrostatic encane esikhundleni sokukhetha ukucindezela okuncane kwe-hydrostatic test kuthebula elingenhla.

Ukuhlolwa Okungonakali

Ipayipi lizohlolwa ngokutholwa kwe-ultrasonic noma ukutholwa kwamanje kwe-eddy.

Ezicini zokutholwa kwe-ultrasonic, amasiginali wamasampuli ayireferensi aqukethe amazinga ereferensi ekilasi le-UD acaciswe ku-JIS G 0582 azobhekwa njengeleveli ye-alamu, futhi akukho siginali elingana noma enkulu kuneleveli ye-alamu ezoba khona.

Ezicini zokutholwa zamanje ze-eddy, isignali yesampula yereferensi equkethe izinga lereferensi lesigaba EY njengoba licaciswe ku-JIS G 0583 izobhekwa njengeleveli ye-alamu, futhi akukho siginali elingana noma enkulu kuneleveli ye-alamu ezoba khona.

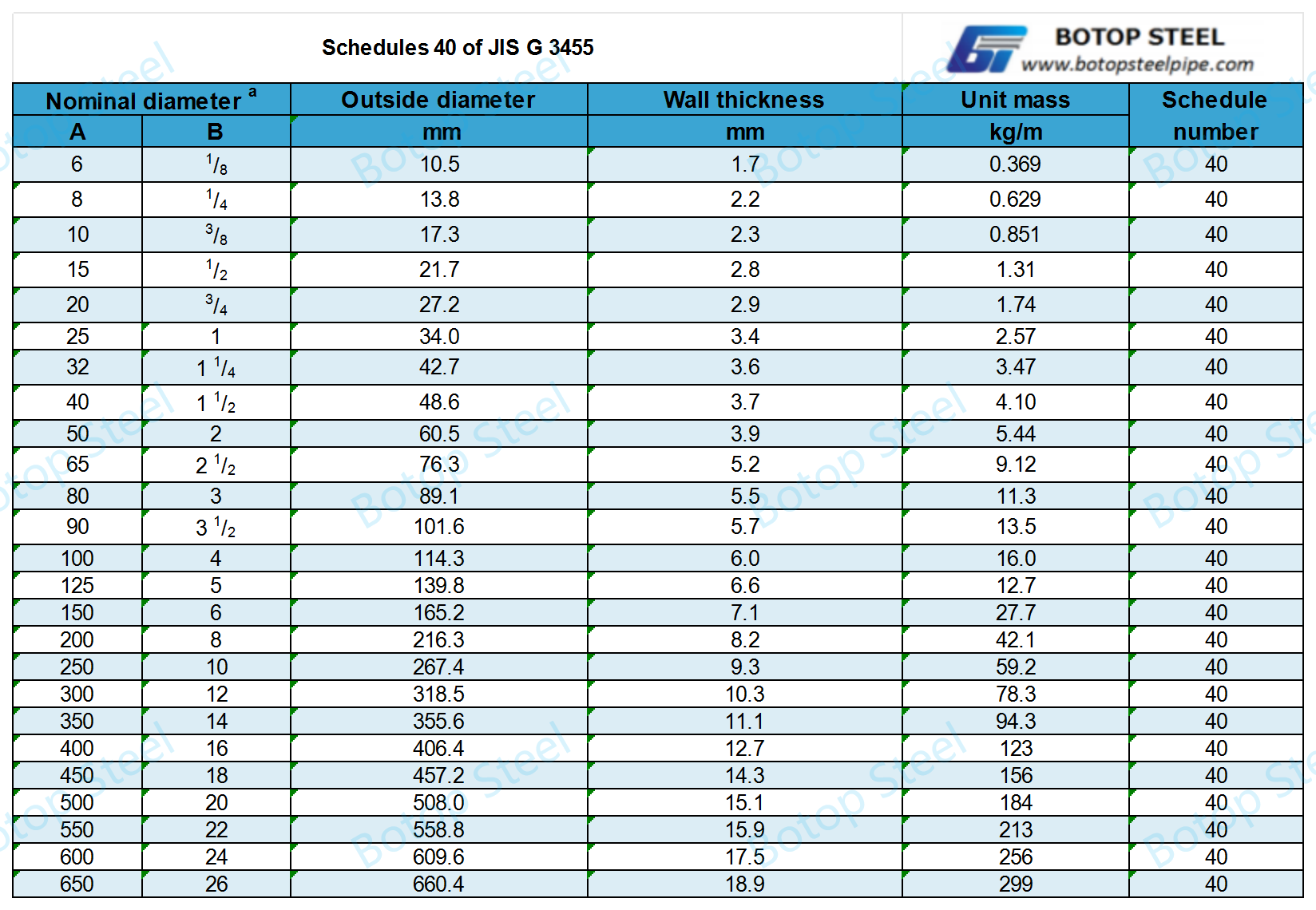

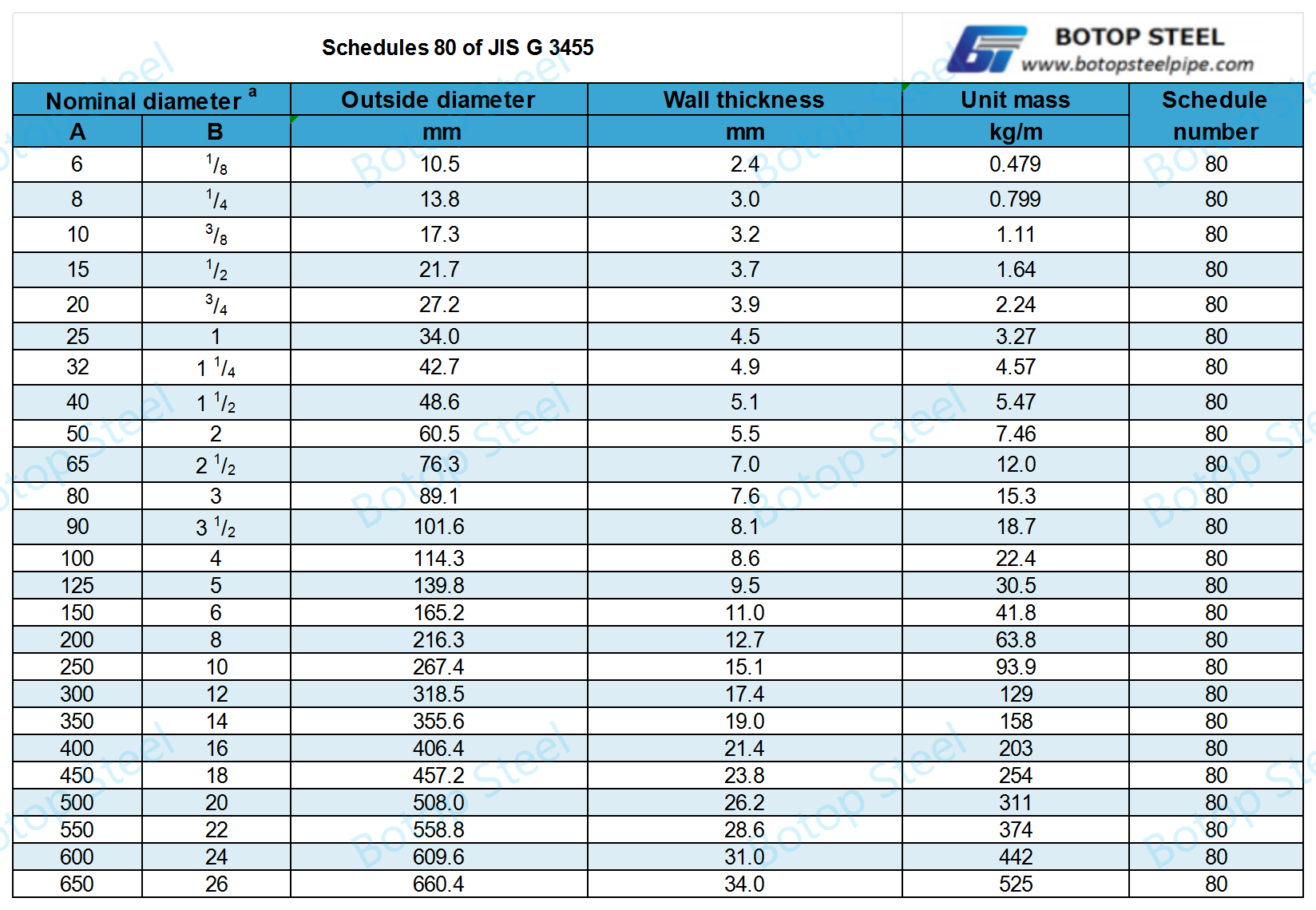

Ishadi lesisindo sepayipi le-JIS G 3455 kanye namashejuli wamapayipi

Ishadi Lesisindo Sepayipi Lensimbi

Endabeni yobukhulu obungacacisiwe kumathebula wesisindo sepayipi, ifomula ingasetshenziswa ukubala.

W=0.02466t(Dt)

W: iyunithi yesisindo sepayipi (kg/m)

t: ukujiya kodonga lwepayipi (mm)

D: ngaphandle kobubanzi bepayipi (mm)

0.02466: isici sokuguqulwa sokuthola i-W

Thatha ukuminyana okungu-7.85 g/cm³ ngeshubhu lensimbi bese uzungezisa umphumela ube izibalo ezintathu ezibalulekile.

Ipayipi Amashejuli

Izinga licacisa izilinganiso ezinhlanu zeShejuli 40, 60, 80, 100, 120, kanye no-160.

Ukuze kube lula kuwe, nansi ishejuli esetshenziswa kakhulu 40 kanye neshejuli yama-80.

I-JIS G 3455 Ukubekezelelana Kwe-Dimensional

Ukubukeka

Indawo yangaphakathi nengaphandle yepayipi izoba bushelelezi futhi ingabi namaphutha angalungile ukuyisebenzisa.

Iziphetho zepayipi lensimbi zizoba ngama-engeli angakwesokudla ku-axis yepayipi.

Ukumaka

Ishubhu ngalinye lizofakwa ilebula ngolwazi olulandelayo.

a) Uphawu lwebanga;

b) Uphawu lwendlela yokukhiqiza;

Ipayipi lensimbi elingenamthungo eliqedwe ukushisa: -SH

Ipayipi lensimbi elingenamthungo eliqedwe ngokubanda: -SC

c) UbukhuluIsibonelo 50AxSch80 noma 60.5x5.5;

d) Igama lomkhiqizi noma uhlobo oluhlonzayo.

Lapho ububanzi bangaphandle beshubhu ngalinye buncane futhi kunzima ukumaka ishubhu ngalinye, noma lapho umthengi efuna ukuthi inyanda ngayinye yamashubhu imakwe, inyanda ngayinye ingase imakwe ngendlela efanele.

Izicelo ze-JIS G 3455 Steel Pipe

Ukukhiqiza ngomshini: Ngenxa yamandla ayo aphezulu kanye nokumelana nezinga lokushisa eliphezulu, isetshenziselwa ukwenziwa kwezingxenye zemishini ehlukahlukene, njengezingxenye zesistimu ye-hydraulic kanye nezinhlelo zokujova uphethiloli ocindezela kakhulu.

Izinhlelo zamapayipi ezimboni: Isetshenziswa kakhulu ezinhlelweni zezimboni ezidinga umthamo wokuthwala ingcindezi ephezulu, njengamapayipi ezitshalweni zamakhemikhali, izindawo zokuhluza, nezinye izimboni zokucubungula.Bayakwazi ukuthutha ngokuphepha isitimu esinomfutho ophezulu, amanzi, uwoyela, namanye amakhemikhali.

Izitshalo zamandla: Isetshenziswa ezingxenyeni ezibucayi ezifana nama-boilers nama-superheaters angaphansi kwezinga lokushisa eliphezulu nezimo zokusebenza ezinomfutho ophezulu.

Ukwakha nokwakha: Angasetshenziselwa ukusekela izakhiwo noma njengamapayipi okucindezela, ikakhulukazi lapho kudingeka khona amandla engeziwe nokuqina.

I-JIS G 3455 Amazinga Alinganayo

I-ASTM A106 / ASME SA106: Asezingeni elichaza amashubhu ensimbi yensimbi engenamthungo yesevisi yezinga lokushisa eliphezulu, ngokuvamile asetshenziswa ezindaweni zokucwenga, amabhayela, nezishintshisi zokushisa.

Idatha ye-DIN 17175: Imboza amashubhu ensimbi engenamthungo namapayipi ukuze asetshenziswe ezimeni ezisezingeni eliphezulu futhi iyasebenza ezinhlelweni ezimelana nezinga lokushisa eliphezulu ezifana nemboni yokubhayela.

I-EN 10216-2: Imboza amashubhu angenamthungo namapayipi ensimbi engafakwanga nealloyed ukuze isetshenziswe ezimeni ezisezingeni eliphezulu.

I-GB 5310: Izinga lamashubhu ensimbi angenamthungo namapayipi amabhoyela anengcindezi ephezulu, anezidingo zobuchwepheshe ezifana nalezo ze-JIS G 3455, futhi ezisebenza ezindaweni ezishisa kakhulu nezinomfutho ophezulu.

I-API 5L: Isetshenziselwa ikakhulukazi izintambo zokuhambisa uwoyela negesi, izidingo zayo zezinto ezibonakalayo, kanye nokusetshenziswa kwepayipi elingenamthungo ngaphansi kwezimo ezithile ezifanayo.

Imikhiqizo Yethu Ehlobene

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Tags: JIS G 3455, carbon steel pipe, STS, nekhono.

Isikhathi sokuthumela: May-14-2024