I-JIS G 3461 ipayipi yensimbiiyipayipi lensimbi engenamthungo (i-SMLS) noma i-electric-resistance-welded (ERW), ikakhulukazi esetshenziswa kumabhayela nezishintshisi zokushisa izinhlelo zokusebenza ezifana nokubona ukushintshana kokushisa phakathi kwangaphakathi nangaphandle kweshubhu.

Izinkinobho Zokuzulazula

Ububanzi besayizi

Ukuhlukaniswa Kwebanga

Ama-Raw material

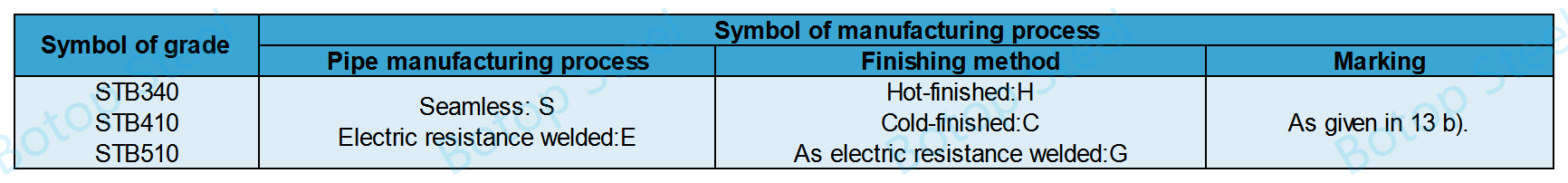

Izinqubo Zokukhiqiza ze-JIS G 3461

Uhlobo Lokuphela Kwepayipi

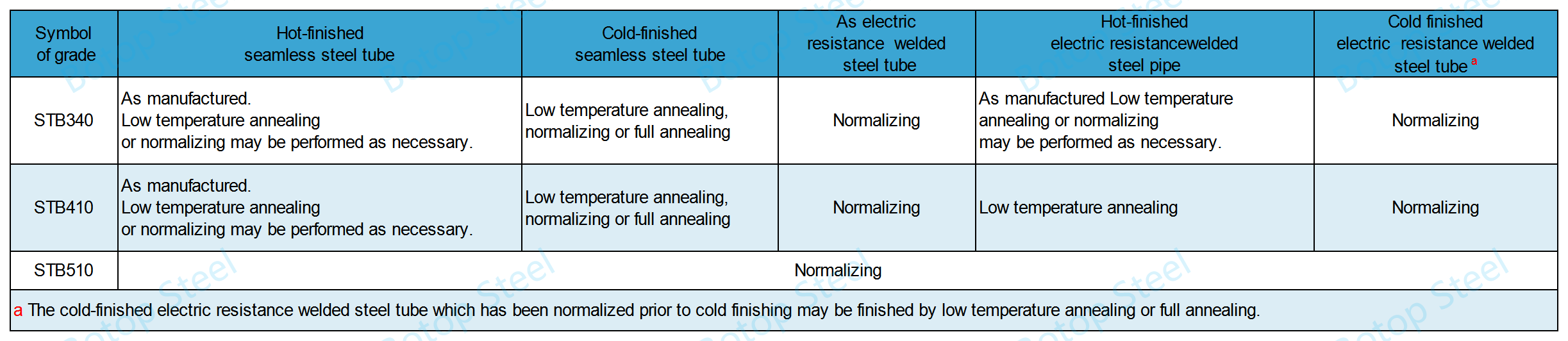

Ukwelashwa Kokushisa

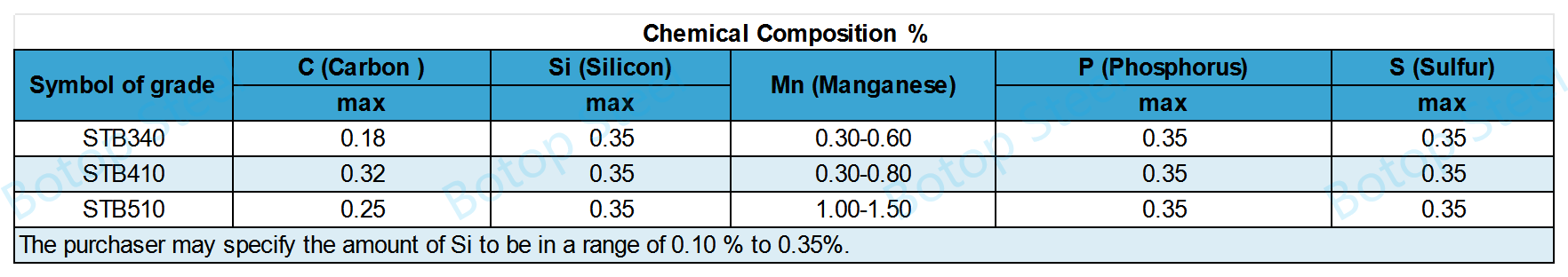

Ukwakhiwa Kwekhemikhali kwe-JIS G 3461

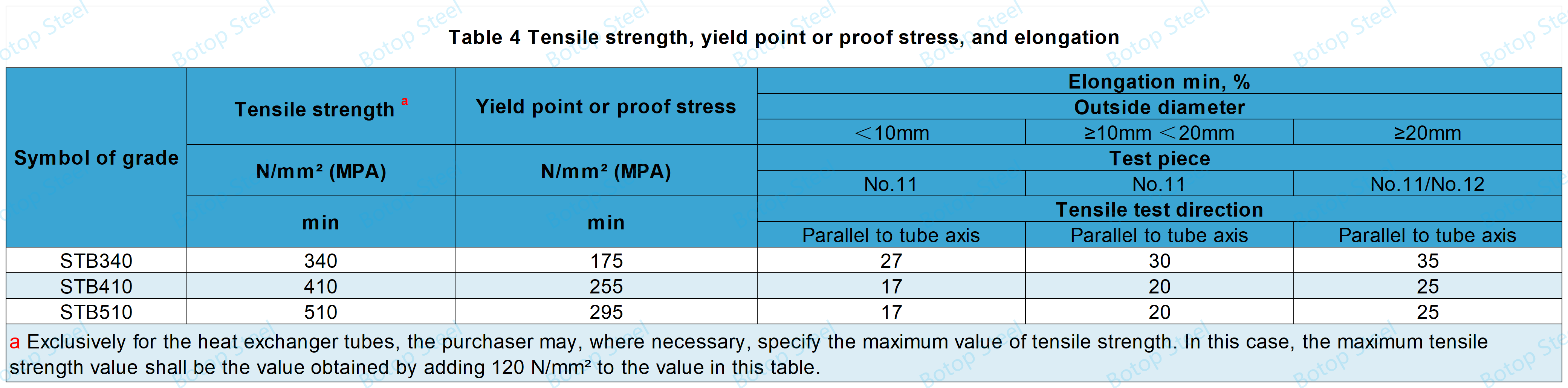

Ukusebenza Komshini kwe-JIS G 3461

Ukuhlolwa kokuqina

Ukuhlolwa Kwe-Hydraulic noma Ukuhlolwa Okungonakali

Ishadi Lesisindo Sepayipi le-JIS G 3461

I-Dimensional Tolerance ye-JIS G 3461

Ukubukeka

Ukumaka

Izicelo ze-JIS G 3461

I-JIS G 3461 Equivalent Standard

Imikhiqizo Yethu Ehlobene

Ububanzi besayizi

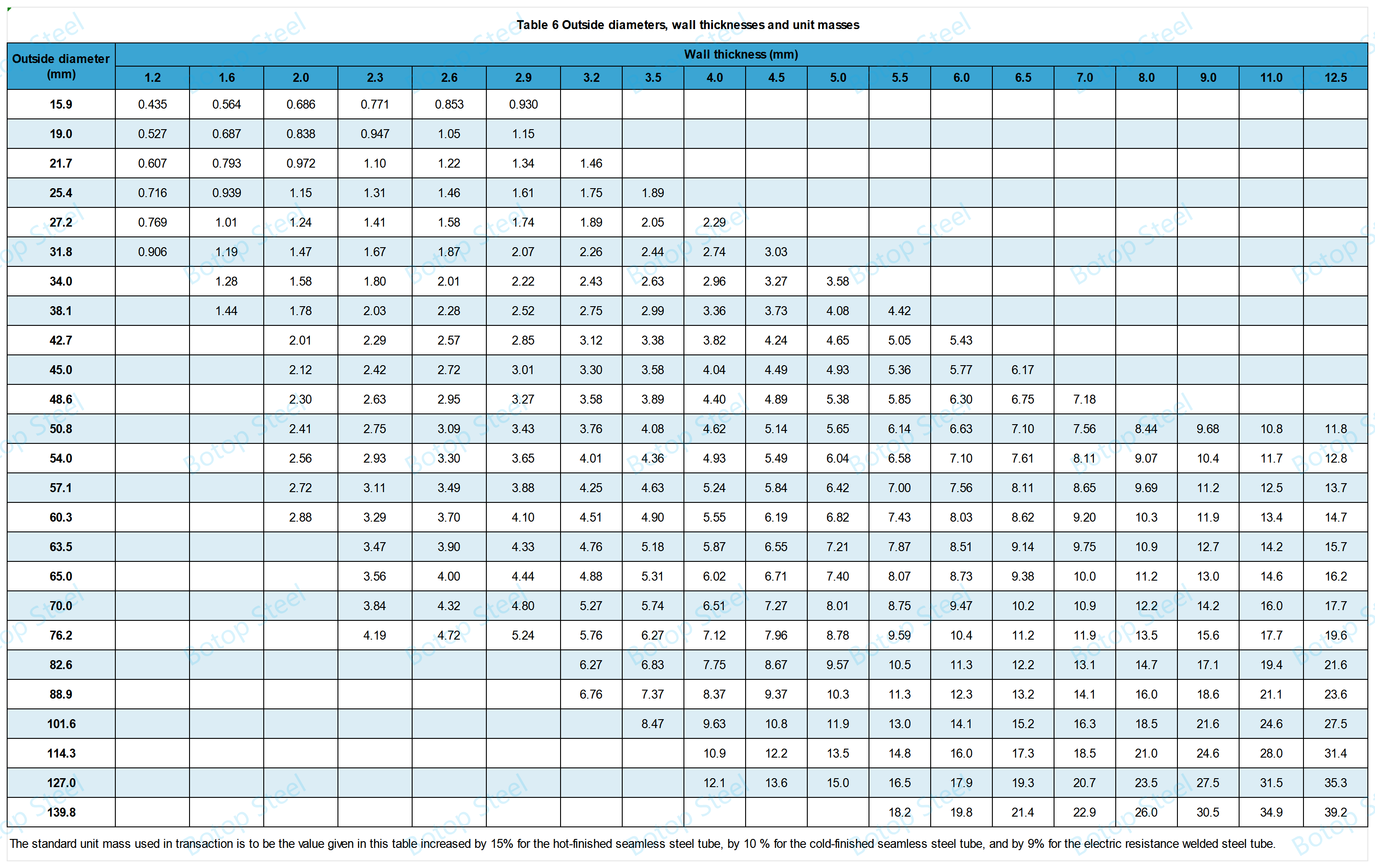

Ifanele amapayipi ensimbi ane-diameter yangaphandle ye-15.9-139.8mm.

Ama-Raw material

Amashubhu azokwenziwa kusuka ku-insimbi ebulewe.

Insimbi ebulewe wuhlobo lwensimbi lapho kukhishwa umoya-mpilo ensimbi ngokwengezwa kwe-deoxidizer efana ne-silicon, i-aluminium, noma i-manganese ngesikhathi sokuncibilika.

Lokhu kwelashwa kubangela insimbi cishe engenawo amabhamuza omoya noma ezinye izinto ezifakwa igesi, ezithuthukisa ukufana kanye nezakhiwo zensimbi zizonke.

Izinqubo Zokukhiqiza ze-JIS G 3461

Inhlanganisela yezindlela zokukhiqiza amapayipi nezindlela zokuqeda.

Ishubhu yensimbi engenamthungo eqedwe ukushisa: SH

Ishubhu yensimbi engenamthungo eqediwe ebandayo: SC

Njengoba ukumelana kagesi ashiselwe steel tube: EG

Ishubhu lensimbi elishiselwe okushisa kagesi eliqedwe ukushisa: EH

Ishubhu yensimbi eshiselwe ukuqina kagesi eqediwe ebandayo: EC

Uma ipayipi lensimbi lakhiwe ngokushisela ukumelana, ubuhlalu be-weld kufanele bukhishwe endaweni yangaphakathi nangaphandle ukuze ingaphezulu lepayipi libushelelezi eduze kwekhonta.

Ubuhlalu bokushisela endaweni engaphakathi angeke bususwe uma umthengi nomakhi bevuma.

Uhlobo Lokuphela Kwepayipi

Ipayipi lensimbi kufanele libe isicaba.

Ukwelashwa Kokushisa

Inqubo yokukhiqiza ipayipi yensimbi kanye nebanga layo lezinto ezihambisanayo kufanele kucatshangelwe lapho kukhethwa ukwelashwa okufanele kokushisa.

Izinqubo ezihlukene zokukhiqiza kanye namabanga wezinto ezibonakalayo zingadinga izindlela ezihlukene zokwelashwa kokushisa ukuze kuzuzwe izici zemishini ezifiselekayo kanye nesakhiwo esincane.

Ukwakhiwa Kwekhemikhali kwe-JIS G 3461

Izindlela zokuhlaziya ezishisayoizohambisana namazinga aku-JIS G 0320.

Izakhi ze-alloying ngaphandle kwalezo zingase zengezwe ukuze kutholwe izakhiwo ezithile.

Indlela yeukuhlaziywa komkhiqizoizohambisana namazinga aku-JIS G 0321.

Lapho umkhiqizo uhlaziywa, amanani okuchezuka okwakheka kwamakhemikhali epayipi azohlangabezana nezidingo zeThebula 3 le-JIS G 0321 lamapayipi ensimbi angenamthungo kanye neThebula 2 le-JIS G 0321 lamapayipi ensimbi anensimbi eqinile.

Ukusebenza Komshini kwe-JIS G 3461

Izidingo ezijwayelekile zokuhlolwa kwemishini zizohambisana neSigaba 7 no-9 se-JIS G 0404.

Kodwa-ke, indlela yamasampula yokuhlolwa kwemishini izohambisana nezimfuneko zemibandela Yekilasi A kuSigaba 7.6 se-JIS G 0404.

Amandla Aqinile, Iphuzu Lokuvuza noma Ingcindezi Yobufakazi, Nokwelula

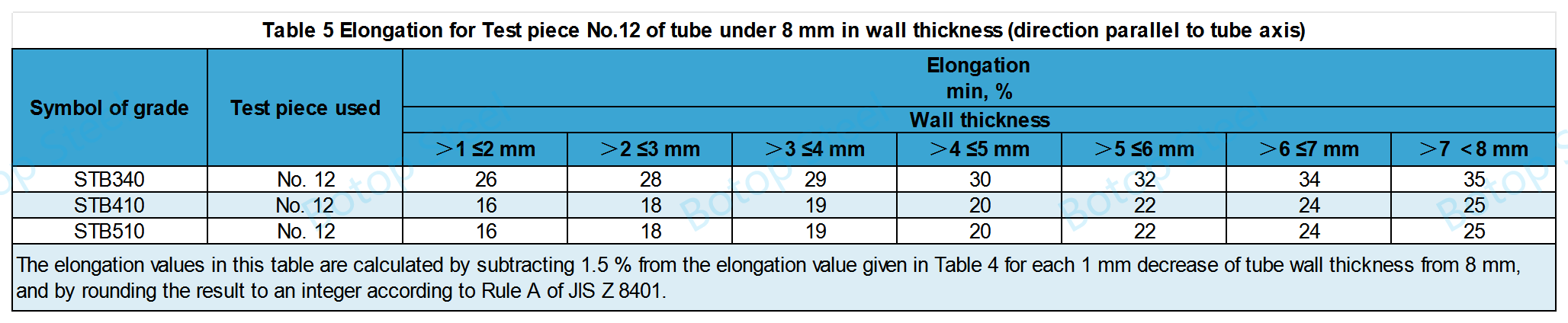

Uma ukuhlolwa okuqinile kwenziwa Engxenyeni Yokuhlola No. 12 yeshubhu elingaphansi kuka-8 mm ubukhulu bodonga, ubude kufanele buhambisane neThebula lesi-5.

Ukumelana Okuphansi

Ukuhlolwa kwe-Resistance okucaba akudingekile kumapayipi ensimbi angenamthungo.

Indlela Yokuhlola Beka isifanekiso emshinini bese usicaba kuze kube yilapho ibanga eliphakathi kwamapulatifomu amabili lifinyelela inani elishiwo.H.Bese uhlola isifanekiso ukuze uthole imifantu.

Lapho kuhlolwa ukumelana okubalulekile okushiselwe ipayipi, umugqa phakathi kwe-weld kanye nendawo yepayipi i-perpendicular isiqondiso sokucindezela.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwamapuleti (mm)

t: ukujiya kodonga lweshubhu (mm)

D: Ububanzi obungaphandle beshubhu (mm)

е: kuchazwe njalo ebangeni ngalinye leshubhu.I-STB340: 0.09;I-STB410: 0,08;I-STB510: 0.07.

Flaring Property

Ukuhlolwa kwe-Flaring Property akudingekile kumashubhu angenamthungo.

Uhlangothi olulodwa lwesifanekiso luvutha ekamelweni lokushisa (5°C kuya ku-35°C) ngethuluzi eliyindilinga nge-engeli engu-60° kuze kube yilapho ububanzi obungaphandle bukhuliswa isici esingu-1.2 futhi buhlolelwa imifantu.

Lesi sidingo sisebenza futhi kumashubhu anobubanzi obungaphandle obungaphezu kuka-101.6 mm.

Reverse Flattening Resistance

Ucezu lokuhlola lokubhekela okuphambene kanye nendlela yokuhlola izoba kanje.

Sika ucezu lokuhlola oluyi-100 mm ukusuka kolunye uhlangothi lwepayipi bese usika ucezu lokuhlola lube uhhafu wama-90° ukusuka kumugqa wokushisela ezinhlangothini zombili zesiyingi, uthathe uhhafu oqukethe i-weld njengocezu lokuhlola.

Emazingeni okushisa asekamelweni (5 °C kuya ku-35 °C) yenza isifanekiso sibe sicaba epuleti elineshisela phezulu bese uhlola isifanekiso ukuze uthole imifantu endaweni yokushisela.

Ukuhlolwa kokuqina

| Uphawu lwebanga | Ukuqina kwe-Rockwell (inani elisho inani lezikhundla ezintathu) I-HRBW |

| I-STB340 | 77 max. |

| I-STB410 | 79 max. |

| I-STB510 | 92 max. |

Ukuhlolwa Kwe-Hydraulic noma Ukuhlolwa Okungonakali

Ukuhlolwa kwe-Hydraulic noma okungacekeli phansi kuyokwenziwa epayipini ngalinye.

Ukuhlolwa kweHydraulic

Bamba ingaphakathi lepayipi okungenani ingcindezi engu-P okungenani imizuzwana emi-5, bese uhlola ukuthi ipayipi ingakwazi yini ukumelana nokucindezela ngaphandle kokuvuza.

P=2st/D

P: ingcindezi yokuhlola (MPa)

t: ukujiya kodonga lweshubhu (mm)

D: Ububanzi obungaphandle beshubhu (mm)

s: 60 % yenani elincane elishiwo lephoyinti lesivuno noma ingcindezi yobufakazi.

P max.10 MPa.

Uma Umthengi ecacisa ingcindezi, enkulu kunengcindezi yokuhlola ebaliwe engu-P noma engu-10 MPa, ukucindezela kokuhlola okusetshenzisiwe kuzovunyelwana ngayo nguMthengi nomkhiqizi.

Izocaciswa ekunyusweni okungu-0.5 MPa uma ingaphansi kuka-10 MPa futhi ekunyusweni okungu-1 kwe-MPa uma i-10 MPa noma ngaphezulu.

Ukuhlolwa Okungonakali

Ukuhlolwa okungabhubhisi kwamashubhu ensimbi kufanele kwenziwe ngokuhlolwa kwamanje kwe-ultrasonic noma eddy.

Ezicini zokuhlola ze-ultrasonic, isignali evela kusampula yereferensi equkethe izinga lereferensi lekilasi UD njengoba licaciswe ku-JIS G 0582 izobhekwa njengeleveli ye-alamu futhi izoba nesignali eyisisekelo elingana noma enkulu kuneleveli ye-alamu.

Ezicini zokuhlola zamanje ze-eddy, isignali evela kuzinga lesithenjwa esicaciswe ku-JIS G 0583 ngesigaba se-EY izobhekwa njengeleveli ye-alamu, futhi akumele kube khona isignali elingana noma enkulu kuneleveli ye-alamu.

Ishadi Lesisindo Sepayipi le-JIS G 3461

Idatha eseshadini lesisindo isekelwe kufomula engezansi.

W=0.02466t(Dt)

W: iyunithi yesisindo sepayipi (kg/m)

t: ukujiya kodonga lwepayipi (mm)

D: ububanzi obungaphandle bepayipi (mm)

0.02466: isici sokuguqulwa sokuthola i-W

Ifomula engenhla iwukuguqulwa okusekelwe ekumineni kwamashubhu ensimbi angu-7.85 g/cm³ futhi imiphumela isongwa ibe izibalo ezintathu ezibalulekile.

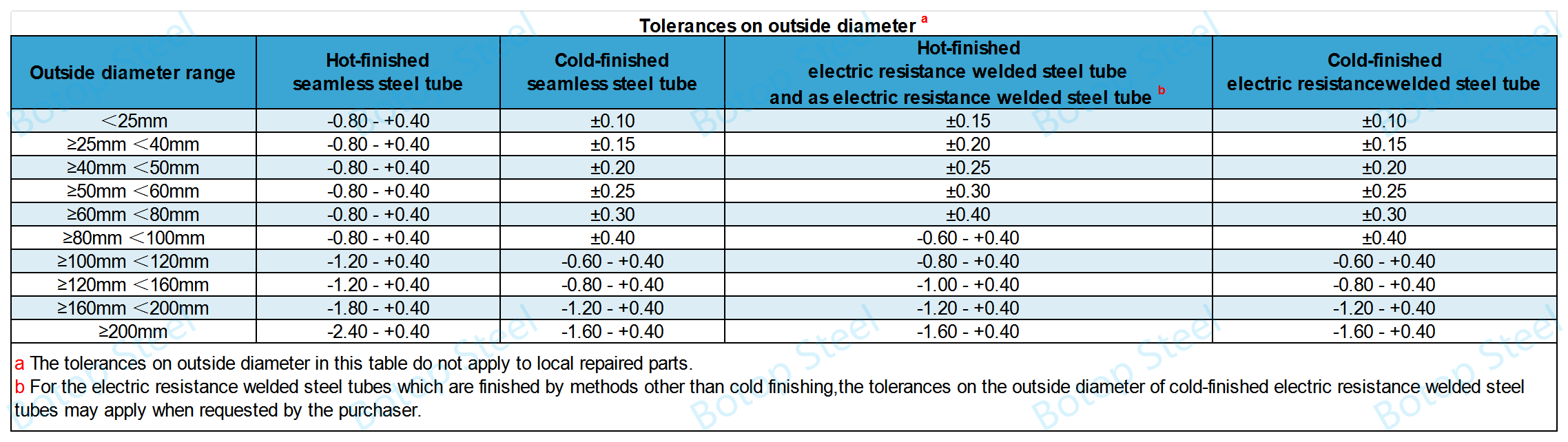

I-Dimensional Tolerance ye-JIS G 3461

Ukubekezelela ku-Diameter yangaphandle

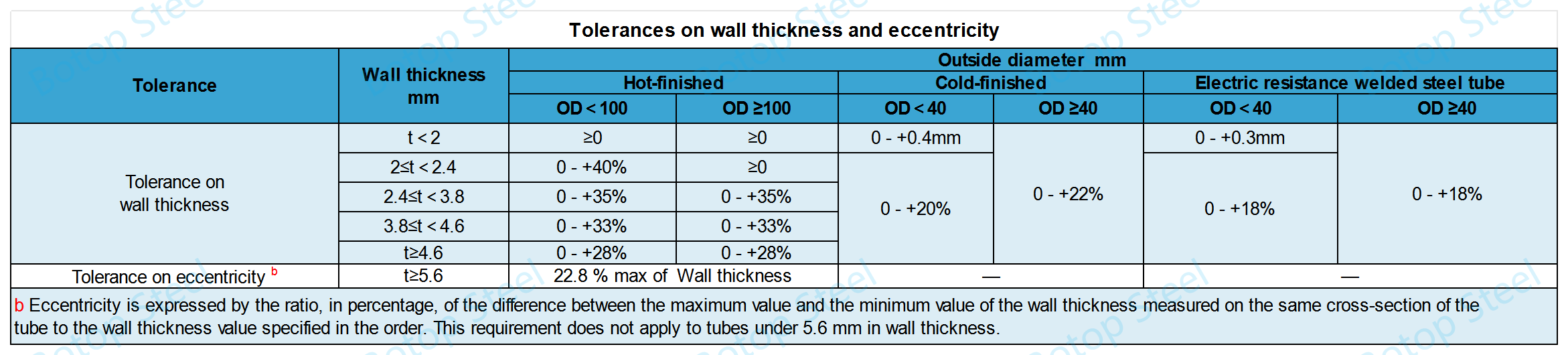

Ukubekezelela Ukuqina Kwezindonga kanye Nokuqina

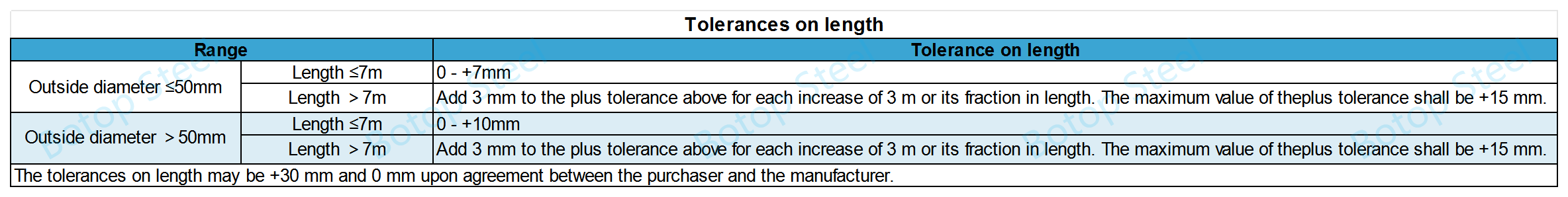

Ukubekezelela Ngobude

Ukubukeka

Indawo yangaphakathi nangaphandle yepayipi yensimbi kufanele ibe bushelelezi futhi ingabi namaphutha angalungile ukuyisebenzisa.Ukuze ukumelana Welding steel pipe, ukuphakama weld ngaphakathi ≤ 0.25mm.

Kumapayipi ensimbi ane-OD ≤ 50.8mm noma ukujiya kodonga ≤ 3.5mm, AMAKHEMPA APHAKATHI ≤ 0.15mm angadingeka.

Ingaphezulu lepayipi lensimbi lingalungiswa ngokugaya nokuqopha, ukukhanda, noma ezinye izindlela.Inqobo nje uma ukulungiswa odongeni ukushuba

ingaphakathi kokubekezelelana kokuqina kodonga olucacisiwe, futhi ubuso bengxenye elungisiwe buyoba bushelelezi.

Ukumaka

Thatha indlela efanele yokulebula ulwazi olulandelayo.

a) Uphawu lwebanga;

b) Uphawu lwendlela yokukhiqiza;

c) Ubukhulu: ububanzi obungaphandle nokuqina kodonga;

d) Igama lomkhiqizi noma uhlobo oluhlonzayo.

Izicelo ze-JIS G 3461

Ikakhulukazi esetshenziselwa amapayipi amanzi, amapayipi amanzi, amapayipi okushisa okuphezulu, namapayipi okushisa komoya kuma-boilers, lawa mashubhu ensimbi ekhabhoni asetshenziselwa ukubona ukushintshana kokushisa ngaphakathi nangaphandle kweshubhu.

Ngaphezu kwalokho, lawa mashubhu asetshenziswa kakhulu embonini yamakhemikhali kanye ne-petroleum kumashubhu okushintshanisa ukushisa, amashubhu e-condenser kanye namashubhu e-catalyst.

Kodwa-ke, awafaneleki amashubhu e-heater evuthayo namashubhu okushintshanisa ukushisa kwamazinga okushisa aphansi.

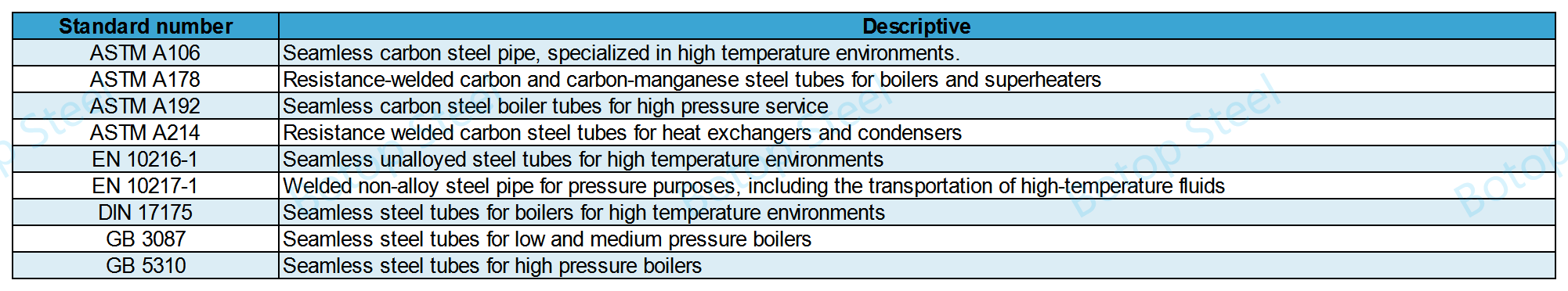

I-JIS G 3461 Equivalent Standard

Imikhiqizo Yethu Ehlobene

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Amathegi: jis g 3461, stb310, stb410, stb510, ipayipi lensimbi ye-carbon, abahlinzeki, abakhiqizi, amafekthri, amasheya, izinkampani, i-wholesale, thenga, inani, quotation, inqwaba, iyathengiswa, izindleko.

Isikhathi sokuthumela: May-11-2024