I-arc welding engaphansi kwamanzi ilungele amapayipi, imikhumbi yokucindezela kanye namathangi, ukwakhiwa kwezitimela kanye nezicelo ezinkulu zokwakha, nefomu le-monofilament elilula kakhulu, isakhiwo sezintambo ezimbili, isakhiwo se-tandem kabili nesakhiwo se-multi-filament.

I-arc welding engaphansi kwamanzi ingazuzisa abasebenzisi ezinhlelweni eziningi zokushisela.Ukusuka ekukhuliseni umkhiqizo, kuya ekuthuthukiseni indawo yokusebenza, kuya ekuqinisekiseni ikhwalithi engashintshi nokunye.Ama-metal processing fabricators acabangela izinguquko enqubweni yokushisela i-arc engaphansi kwamanzi kufanele acabange ukuthi angathola izinzuzo eziningi kule nqubo.

Ulwazi oluyisisekelo lwe-arc welding engaphansi kwamanzi

Inqubo yokushisela i-arc engaphansi kwamanzi iyisidingo esifanele izicelo ezisindayo zezimboni ezifana namapayipi, imikhumbi yokucindezela kanye namathangi, ukwakhiwa kwezitimela, ukwakhiwa okunzima/ukumba.Ilungele izimboni ezidinga ukukhiqiza okuphezulu, ikakhulukazi uma kuziwa ekushiseleni izinto eziwugqinsi kakhulu, kunezinzuzo eziningi ezitholakala enqubweni yokushisela ye-arc engaphansi kwamanzi.

Izinga layo eliphezulu lokubeka kanye nesivinini sokuhamba lingaba nomthelela omkhulu ekukhiqizeni kwabasebenzi, ukusebenza kahle kanye nezindleko zokukhiqiza, okungenye yezinzuzo ezibalulekile zenqubo yokushisela i-arc engaphansi kwamanzi.

Ezinye izinzuzo zifaka: ukwakheka kwamakhemikhali okuhle kakhulu kanye nezakhiwo zemishini ze-weld, ukubonakala okuncane kwe-arc kanye nentuthu yokushisela ephansi, ukunethezeka kwemvelo yokusebenza okuthuthukisiwe, nokuma okuhle kwe-weld kanye nomugqa wozwane.

I-arc welding engaphansi kwamanzi iyindlela yokudla yocingo esebenzisa i-granular flux ukuze ihlukanise i-arc emoyeni, njengoba igama libonisa, i-arc ingcwatshwa ku-flux, okusho ukuthi lapho imingcele isethiwe, i-arc ingabonakali ngokuphuma kwe-arc. ungqimba lwe-flux.Ucingo lokushisela luphakelwa ngokuqhubekayo ithoshi elihamba eduze nendawo yokushisela.

Ukushisa kwe-arc kuncibilikisa ingxenye yocingo, ingxenye ye-flux kanye nesisekelo sensimbi, kwakheka ichibi elincibilikisiwe, elijiyayo libe i-weld embozwe ungqimba lwe-slag yokushisela.Ububanzi bezinto zokushisela i-1/16 "-3/4", bungaba ngu-100% welding yokungena nge-welding eyodwa, uma ukushuba kodonga kunganqunyelwe, i-multi-pass welding ingenziwa, futhi i-weld yenziwe ngokufanele futhi kukhethiwe, futhi inhlanganisela ye-welding wire flux efanele ikhethiwe.

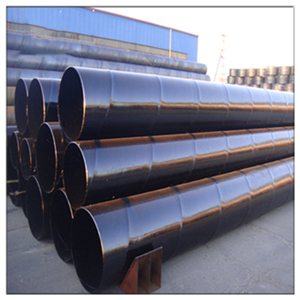

I-LSAW

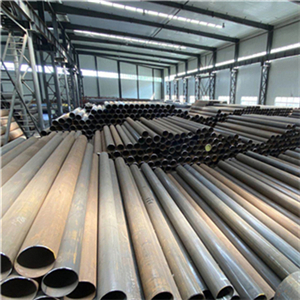

ERW

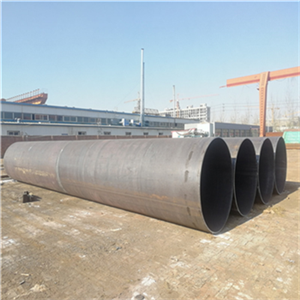

I-SSAW

Ukukhethwa kwe-flux ne-welding wire

Ukukhetha i-flux efanele kanye nocingo lwenqubo ethile yokushisela i-arc engaphansi kwamanzi kubalulekile ekuzuzeni imiphumela engcono kakhulu usebenzisa inqubo.Nakuba izinqubo zokushisela i-arc ezingaphansi kwamanzi zizodwa zisebenza kahle, ukukhiqiza nokusebenza kahle kungandiswa ngisho nangokusekelwe ocingweni lokushisela kanye ne-flux esetshenzisiwe.

I-flux ayivikeli kuphela i-weld pool, kodwa futhi ifaka isandla ekuthuthukiseni izakhiwo zemishini kanye nokukhiqiza kwe-weld.Ukwakhiwa kwama-fluxes kunomthelela omkhulu kulezi zici, okuthinta umthamo wamanje wokuthwala nokukhululwa kwe-slag.

Umthamo wamanje wokuthwala usho ukuthi kungatholakala ukusebenza kahle kwe-deposition kanye nephrofayili yekhwalithi ephezulu ye-weld.

Ukukhululwa kwe-slag kusuka ku-flux ethile kuthinta ukukhethwa kwe-flux ngoba amanye ama-flux afaneleka kakhulu kumiklamo ethile ye-solder kunabanye.

Izinketho zokukhetha i-Flux ye-arc soldering engaphansi kwamanzi ihlanganisa izinhlobo ezisebenzayo nezingathathi hlangothi zama-welds.Umehluko oyisisekelo ukuthi i-flux esebenzayo ishintsha i-chemistry ye-weld, kanti i-neutral flux ayishintshi.

Ama-fluxes asebenzayo abonakala ngokufakwa kwe-silicon ne-manganese.Lezi zakhi zisiza ukugcina amandla aqinile we-weld ekufakweni kokushisa okuphezulu, zisiza ukugcina ukushisela kubushelelezi futhi kubushelelezi ngesivinini esikhulu sohambo futhi kunikeze ukukhululwa okuhle kwe-slag.Sekukonke, ama-fluxes asebenzayo angasiza ekunciphiseni ubungozi bekhwalithi ephansi ye-solder, kanye nokuhlanza okubizayo kwangemuva kokushisela nokusebenza kabusha.Khumbula, nokho, ukuthi ama-fluxes asebenzayo ngokuvamile afaneleka kakhulu ekuthengiseni okukodwa noma okuphindwe kabili.

Ama-fluxes angathathi hlangothi angcono kuma-multipass solders ngoba asiza ukugwema ukwakheka kwama-welds aphukayo, azwela ukuqhekeka.

Kunezinhlobo eziningi zezinketho zezintambo zokushisela mayelana nokushisela i-arc engaphansi, ngayinye inezinzuzo kanye nokubi.Ezinye izintambo zenzelwe ukushiselwa ekufakweni kokushisa okuphezulu, kuyilapho ezinye ziklanyelwe ngokukhethekile ukuba zibe nama-alloys asiza ukugeleza ukwenza ukuhlanza ukushisela.

Qaphela ukuthi izakhiwo zamakhemikhali nokusebenzisana kokufakwa kokushisa kwentambo yokushisela kuthinta izakhiwo zemishini ye-weld.Ukukhiqiza kungabuye kwandiswe kakhulu ngokukhethwa kwensimbi yokugcwalisa.

Isibonelo, ukusebenzisa intambo yensimbi ewumgogodla enenqubo yokushisela i-arc engaphansi kwamanzi kungakhuphula ukusebenza kahle kwe-deposition ngo-15% kuya ku-30% uma kuqhathaniswa nokusebenzisa ucingo oluqinile, kuyilapho kuhlinzeka ngephrofayela yokungena ebanzi futhi engashoni.

Ngenxa yejubane layo eliphezulu lokuhamba, izintambo eziwumgogodla wensimbi ziphinde zehlise okokufaka ukushisa ukuze kuncishiswe ubungozi bokuwohloka kokushisela nokutubeka.

Kuzo zonke izinsimbi, izinsimbi ezingenasici ze-austenitic zinephuzu lokukhiqiza eliphansi kakhulu.Ngakho-ke, ngokwezakhiwo zemishini, i-austenitic stainless steel ayiyona into engcono kakhulu ye-valve stem, ngoba ukuqinisekisa amandla athile, ububanzi be-valve stem buzokhula.Iphuzu lokukhiqiza alikwazi ukukhushulwa ngokwelashwa okushisa, kodwa lingandiswa ngokubunjwa okubandayo.

Siyi-stockist ye-carbon kanye nepayipi lensimbi engenamthungo, siyakwamukela noma yimiphi imibuzo, sizokunikeza okokuqala!

Isikhathi sokuthumela: Jan-30-2023