ASTM A106 steel pipe is a seamless carbon steel pipe suitable for use in high temperature and high pressure environments. It is widely used in many fields such as oil and gas industry, power plants and chemical plants.

In particular, ASTM A106 Grade B tubing is especially popular for many applications because of its ability to meet the mechanical performance requirements of most construction machinery and its affordability.

ASME SA106 = ASTM A106.

ASME SA106 and ASTM A106 are equivalent in terms of materials and properties, and have the same standard requirements, but belong to different standards publishing organizations and are used to satisfy different certification systems.

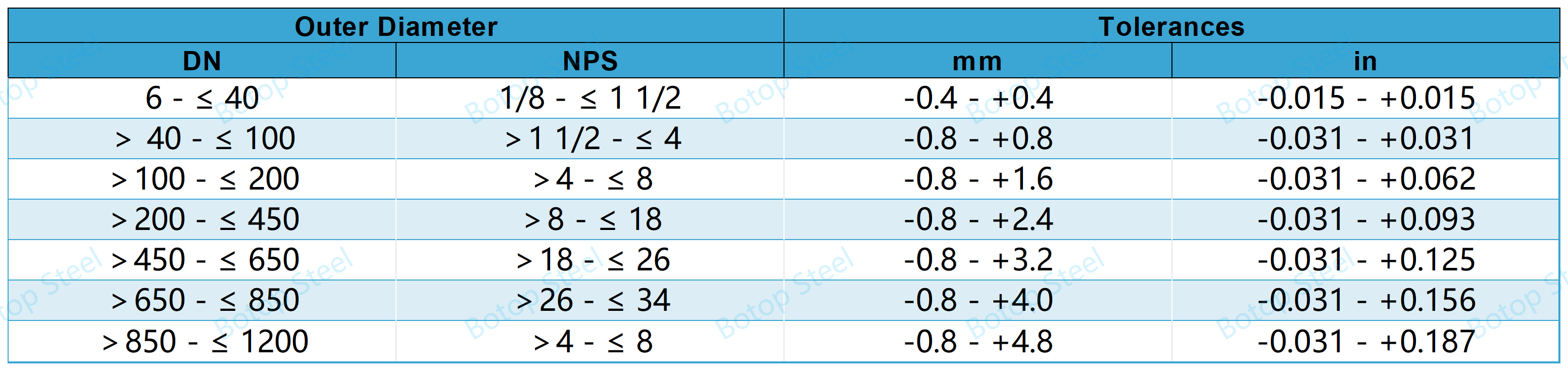

Nominal Diameter: DN 6 - DN 1200 [NPS 1/8 - NPS 48];

Outer Diameter: 10.3 - 1219 mm [0.405 - 48 in.];

Wall thicknesses are as shown in ASME B 36.10.

Common wall thickness classes are Schedule 40 and Schedule 80.

Pipe sizes other than standard may be used, provided it meet all other requirements of this code.

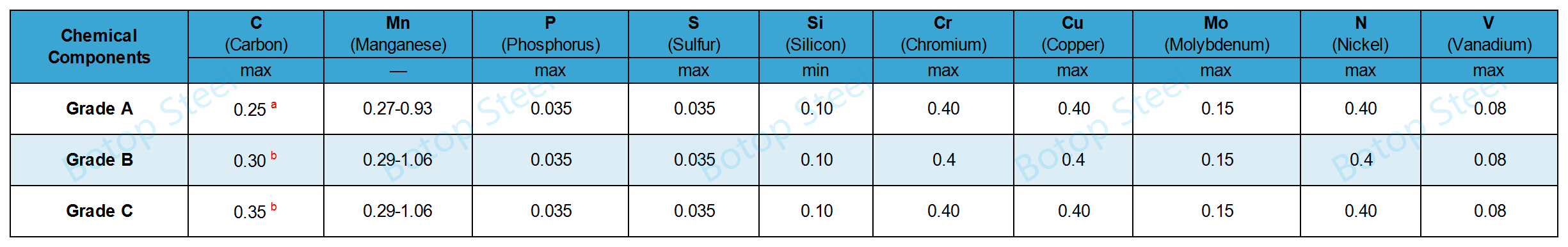

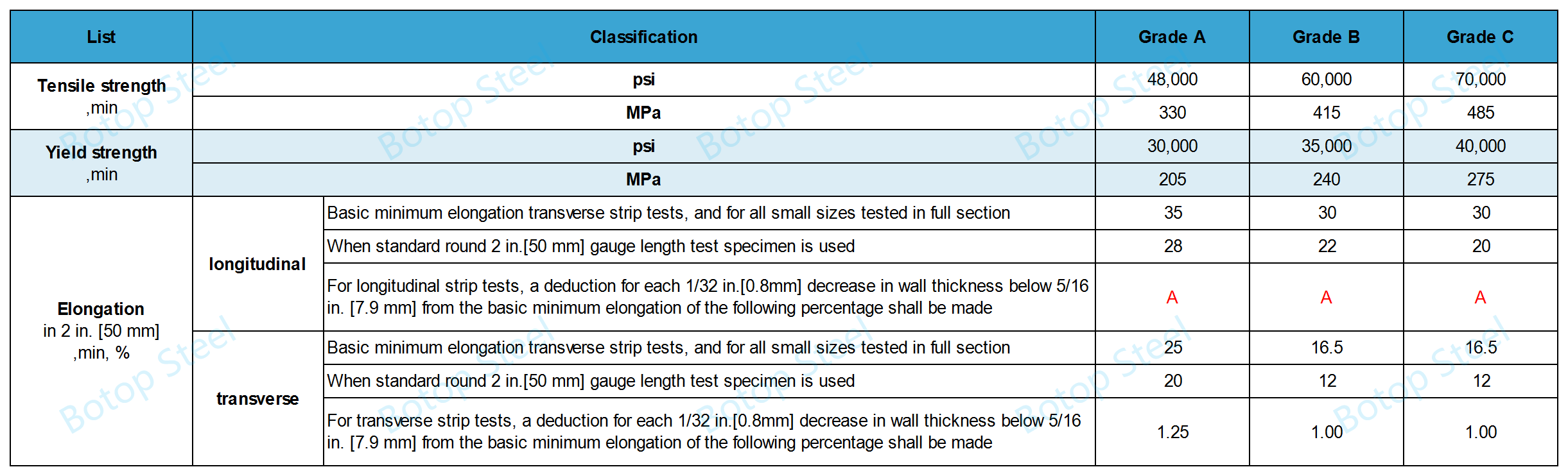

The ASTM A106 standard has three different grades, Grade A, Grade B, and Grade C.

The yield strength and tensile strength increase with the grade, which is used to cope with different usage environments.

The steel shall be killed steel.

ASTM A106 steel pipe shall be manufactured using a seamless production process.

Depending on the size of the pipe and the specific application, they can be further categorized into hot-finished and cold-drawn types.

DN ≤ 40 [NPS ≤ 1 1/2], can make hot finished or cold drawn, mostly cold drawn.

DN ≥ 50 [NPS ≥ 2] shall be hot finished. Cold-drawn seamless steel tubes are also available upon request.

Below is a schematic diagram of the production process of hot-finished seamless steel pipe.

Cold-drawn production flow chart schematics can be viewed by clicking on ASTM A556 Cold Drawn Seamless Carbon Steel Tubes.

Hot-finished and cold-drawn seamless steel tubes have mechanical properties, surface quality, and dimensional accuracy in addition to dimensional differences.

Hot-finished tubes are manufactured at high temperatures and have better toughness but rougher surfaces and lower dimensional accuracy; whereas cold-drawn tubes are manufactured by plastic deformation at room temperature and have higher strength, smoother surfaces, and more precise dimensional control, making them suitable for applications that require higher precision and performance.

Cold-drawn tubing should be heat-treated at 1200°F [650 °C] or higher after final cold-drawing.

Hot-finished steel tubes usually do not require further heat treatment.

If heat treatment is required for hot finished steel pipe, the heat treatment temperature shall be above 1500°F [650°C].

Heat treatment improves the microstructure of the tube, improves mechanical properties, enhances corrosion resistance, improves machinability, ensures dimensional stability, as well as meets the requirements of specific standards, thus significantly enhancing the overall performance and suitability of the tube.

a For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.35%.

b Unless otherwise specified by the purchaser, for each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

c Cr, Cu, Mo, Ni, and V must not exceed 1% of the total content of these five elements.

Grades A, B and C differ in their chemical composition, mainly in terms of carbon and manganese content.

These differences affect the mechanical properties and application scenarios of the tubes. The higher the carbon content, the stronger the pipe will be, but the toughness may be reduced. An increase in manganese content contributes to the strength and hardness of the steel.

Tensile Property

A: The minimum elongation in 2 in. [50 mm] shall be determined by the following equation:

inch-pound units: e = 625,000A0.2/UO.9

Sl units: e = 1940A0.2/U0.9

e: minimum elongation in 2 in. [50 mm], %, rounded to the nearest 0.5%,

A: cross-sectional area of the tension test specimen, in.2 [mm2], based upon specified outside diameter or nominal specimen width and specified wall thickness, rounded to the nearest 0.01 in2 [1 mm2].

(If the area thus calculated is equal to or greater than 0.75 in2 [500 mm2], then the value 0.75 in2 [500 mm2] shall be used.),

U: specified tensile strength, psi [MPa].

Bending Test

For pipes DN 50 [NPS 2] and smaller, there shall be a sufficient length of pipe to allow cold bending of the pipe through 90° without cracking around a cylindrical mandrel with a diameter 12 times the outside diameter of the pipe.

For OD > 25in. [635mm], if OD/T ≤ 7, a bending test is required to bend 180° without cracking at room temperature. The inside diameter of the bent part is 1in.

Flattening Test

ASTM A106 seamless steel pipe does not need to be flattened test, but the performance of the pipe must meet the corresponding requirements.

Unless specifically required, every pipe must be hydro tested or non-destructively electrically tested, and sometimes both.

If neither hydrostatic nor non-destructive testing has been carried out, the pipe shall be marked with “NH”.

Hydrostatic Test

The value of water pressure shall not be less than 60% of the specified minimum yield strength.

It can be calculated by the following formula:

P = 2St/D

P = hydrostatic test pressure in psi or MPa,

S = pipe wall stress in psi or MPa,

t = specified nominal wall thickness, nominal wall thickness corresponding to specified ANSI schedule number, or 1.143 times the specified minimal wall thickness, in. [mm],

D = specified outside diameter, outside diameter corresponding to specified ANSI pipe size, or outside diameter calculated by adding 2t (as defined above) to the specified inside diameter, in. [mm].

If a water pressure test is performed, the steel pipe shall be marked with the test pressure.

Nondestructive Electric Test

It may be used as an alternative to hydrostatic testing.

The entire body of each pipe shall be subjected to a non-destructive electrical test in accordance with E213, E309, or E570 specifications.

If nondestructive testing has been performed, “NDE” shall be indicated on the surface of the pipe.

Mass

The actual mass of the pipe should be in the range of 97.5% - 110% of the specified mass.

Outer Diameter

Thickness

Minimum wall thickness = 87.5% of the specified wall thickness.

Lengths

It can be categorized into specified length, single random length, and double random length.

Specified length: as required by the order.

Single random length: 4.8-6.7 m [16-22ft].

5% of the length is allowed to be less than 4.8 m [16 ft], but not shorter than 3.7 m [12 ft].

Double random lengths: The minimum average length is 10.7 m [35 ft] and the minimum length is 6.7 m [22 ft].

Five percent of the length is allowed to be less than 6.7 m [22 ft], but not shorter than 4.8 m [16 ft].

ASTM A106 steel pipe is widely used in many industrial applications due to its superior resistance to high temperatures and pressures.

1. Oils and gas industry: ASTM A106 steel pipe is widely used in long-distance oil and gas pipelines, drilling equipment, and refineries, where its high-temperature and high-pressure resistance ensures safety and reliability in harsh environments.

2. Power plants: Used in high-temperature, high-pressure boiler piping, heat exchangers, and high-pressure steam delivery systems to provide stable performance and service life under extreme conditions.

3. Chemical plants: ASTM A106 steel tubing is used in chemical plants for piping systems for high-pressure reactors, pressure vessels, distillation towers, and condensers, where it can withstand high temperatures and corrosive chemicals to ensure process safety and efficiency.

4. Buildings and infrastructure: Used in heating, ventilation, and air conditioning (HVAC) systems as well as high-pressure fire protection systems to ensure the efficient operation and safety of systems in buildings.

ASTM A53 Grade B and API 5L Grade B are the common alternatives to ASTM A106 Grade B.

On the marking of seamless steel pipe, we often see steel pipe that meets these three standards at the same time, which indicates that they have a high degree of consistency in terms of chemical composition, mechanical properties, and so on.

In addition to the standard materials mentioned above, there are a number of other standards that are similar to ASTM A106 in terms of chemical composition and mechanical properties.

GB/T 5310: Apply to seamless steel pipe for high-pressure boiler.

JIS G3454: For carbon steel pipe for pressure piping.

JIS G3455: Suitable for carbon steel pipe for high-pressure pipelines.

JIS G3456: Carbon steel pipes for high-temperature pipelines.

EN 10216-2: Seamless steel tubes for high-temperature applications.

EN 10217-2: Welded steel pipes for high-temperature applications.

GOST 8732: Seamless hot-rolled steel tubes for high-pressure and high-temperature applications.

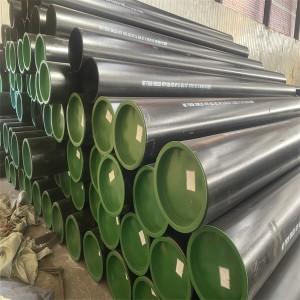

Every batch of ASTM A106 seamless steel pipe has been carefully self-inspected or third-party professional inspection before leaving the factory, which is our insistence on quality and our unchanging commitment to customers.

Outside Diameter Inspection

Wall Thickness Inspection

Straightness Inspection

UT Inspection

End Inspection

Appearance Inspection

While ensuring the quality of our products, we also offer diverse packaging options to meet different transportation and storage needs. From traditional strapping to customized protective packaging, we are committed to providing the best possible protection for each shipment of steel tubes to ensure they reach you safely and without damage.

Black Painting

Plastic Caps

3LPE

Wrapper

Galvanized

Bundling and Sling

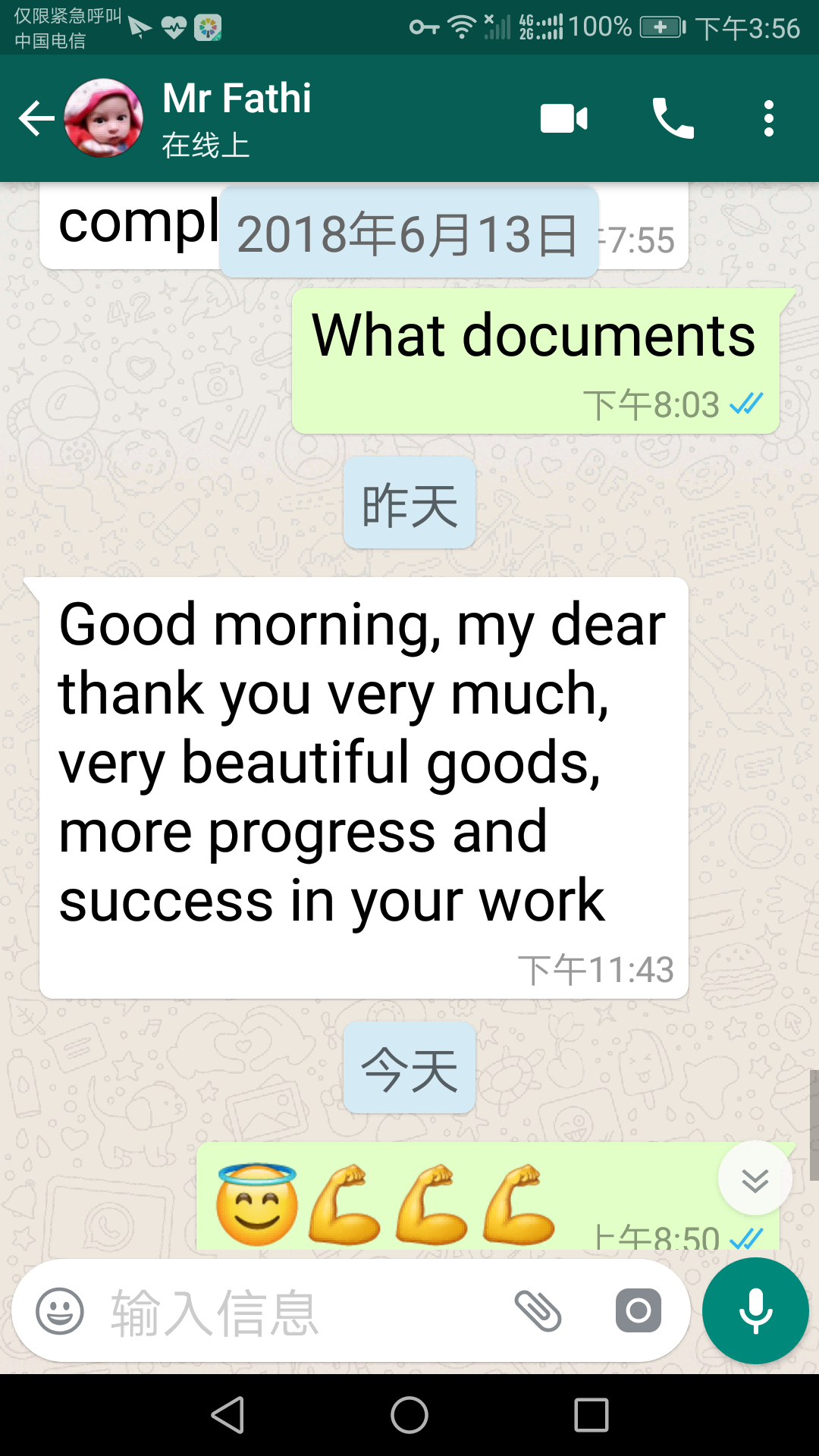

These reviews not only recognize the quality of our products but also our service commitment. We are looking forward to cooperating with you to provide the most suitable ASTM A106 GR.B steel pipe solutions for your projects with professional and efficient service.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

ASTM A53 Gr.A &Gr. B Carbon Seamless Steel Pipe For Oil And Gas Pipeline

ASTM A556 Cold Drawn Seamless Carbon Steel Feedwater Heater Tubes

ASTM A334 Grade 1 Carbon Seamless Steel Pipe

ASTM A519 Carbon And Alloy Seamless Steel Mechanical Pipe

JIS G3455 STS370 Seamless Steel Pipe For High Pressure Service

ASTM A192 Boiler Carbon Steel Tubes For High Pressure

JIS G 3461 STB340 Seamless Carbon Steel Boiler Pipe

AS 1074 Seamless Steel Tubes For Ordinary Service

API 5L GR.B Heavy Wall Thickness Seamless Steel Pipe For Mechanical Processing

ASTM A53 Gr.A &Gr. B Carbon Seamless Steel Pipe For Oil And Gas Pipeline